Method for rapid recycling of sludge

A technology of recycling and sludge, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. The effect of reducing dosage, low cost and easy solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

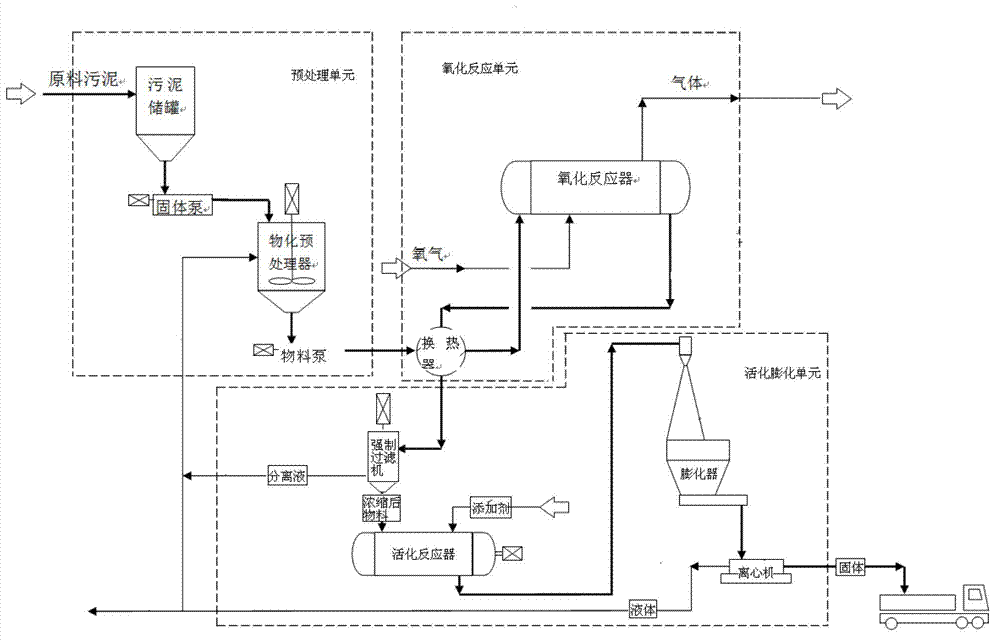

[0026] (1) Preprocessing unit

[0027] The raw sludge is sent to the sludge storage tank through the conveyor. The sludge in the sludge storage tank is exported from the bottom of the tank and transported to the physical and chemical preprocessor by a solid pump. In the physical and chemical preprocessor, the preparation of materials is completed. The prepared material is transported to the oxidation reactor through the material pump. In the physical and chemical preprocessor, the preheating of the material uses the separated liquid obtained through the forced filter and the liquid obtained by the centrifuge to exchange heat, and the temperature of the material rises to 60°C.

[0028] (2) Oxidation reaction unit

[0029] The low-temperature material from the physical and chemical preprocessor and the high-temperature material after the reaction from the oxidation reactor exchange heat through the heat exchanger, and the temperature of the material entering the oxidation rea...

Embodiment 2

[0034] (1) Preprocessing unit

[0035] The raw sludge is sent to the sludge storage tank through the conveyor. The sludge in the sludge storage tank is exported from the bottom of the tank and transported to the physical and chemical preprocessor by a solid pump. In the physical and chemical preprocessor, the preparation of materials is completed. The prepared material is transported to the oxidation reactor through the material pump. In the physical and chemical preprocessor, the preheating of the material uses the separated liquid obtained through the forced filter and the liquid obtained by the centrifuge to exchange heat, and the temperature of the material rises to 80°C.

[0036] (2) Oxidation reaction unit

[0037] The low-temperature material from the physical and chemical preprocessor and the high-temperature material from the oxidation reactor are exchanged through the heat exchanger, and the temperature of the material entering the oxidation reactor after heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com