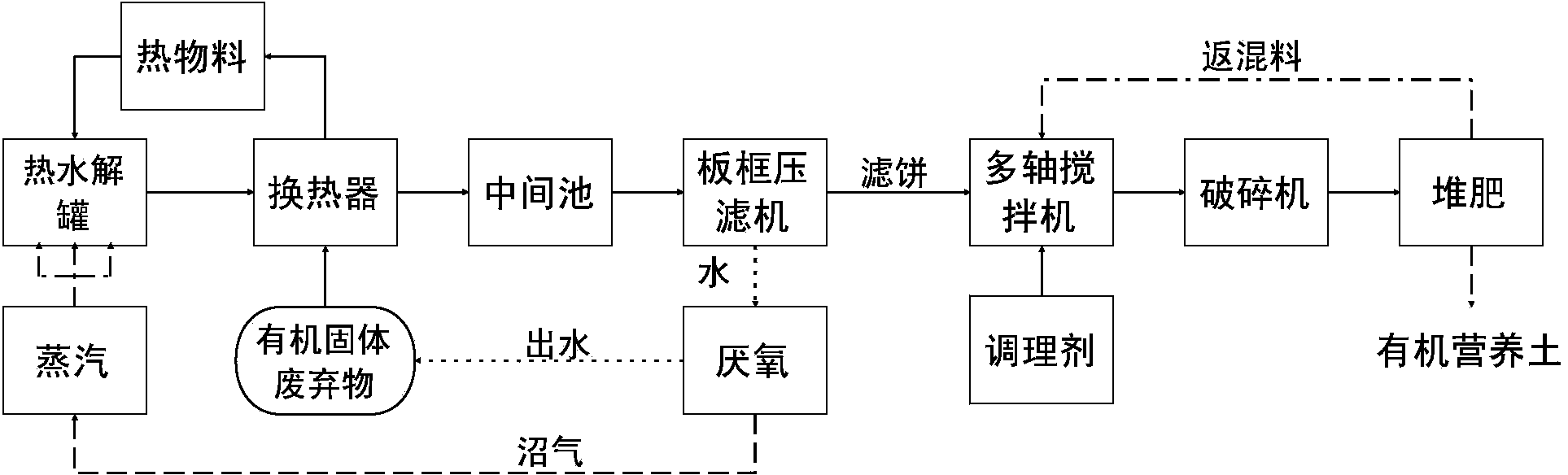

Thermal hydrolysis and high-temperature aerobic composting treatment process of organic solid wastes

An organic solid, aerobic composting technology, which is applied in the treatment of biological organic parts, the preparation of organic fertilizers and organic fertilizers, etc., to achieve the effects of reducing operating costs, improving dehydration performance, and improving processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The dewatered sludge with a water content of 80% in urban sewage treatment plants is diluted to a water content of 90% (solid content is 10%), and the diluted sludge is sent to the heat exchanger, and the hot sludge from thermal hydrolysis Carry out heat exchange for preheating treatment. After the sludge is preheated, the temperature is 95°C; then it is intermittently and quantitatively transported to the thermal hydrolysis tank. Thermal hydrolysis treatment with 1.0Mpa steam for 15 minutes; the solid content of the sludge after thermal hydrolysis treatment is 8%, and the heat exchange treatment with the original sludge is carried out through a heat exchanger to reduce the temperature of the sludge to 85°C Temporarily stored in the intermediate pool, and then intermittently and quantitatively sent to the plate and frame filter press for dehydration treatment. After dehydration, the moisture content of the filter cake is 50%. The biogas boiler produces steam, and the ef...

Embodiment 2

[0030] The organic waste has a moisture content of 80% and is diluted to a water content of 88% (that is, a solid content of 12%), and the diluted organic waste is transported to a heat exchanger for heat exchange with the hot organic waste from thermal hydrolysis for pretreatment. Heating treatment, the temperature of the organic waste is 88°C after preheating; then it is intermittently and quantitatively transported to the thermal hydrolysis tank, and the organic waste in the thermal hydrolysis tank is fed with steam at a temperature of 170°C and a pressure of 0.7Mpa at multiple points Thermal hydrolysis treatment was carried out for 52 minutes; the solid content of organic waste after thermal hydrolysis treatment was 11%, and the heat exchange treatment with the original organic waste was carried out through a heat exchanger, so that the temperature of the organic waste dropped to 77°C and then temporarily stored in the intermediate pool , and then intermittently and quantit...

Embodiment 3

[0032] The poultry manure with a water content of 80% in the farm is diluted to a water content of 85% (solid content is 15%), and the diluted poultry manure is transported to the heat exchanger, and the hot poultry manure from thermal hydrolysis Carry out heat exchange for preheating treatment. After preheating, the temperature of poultry manure is 80°C; then it is intermittently and quantitatively transported to the thermal hydrolysis tank, and the multi-point feeding temperature of the poultry manure in the thermal hydrolysis tank is 150°C , steam with a pressure of 0.4Mpa for 90 minutes of thermal hydrolysis treatment; the solid content of poultry manure after thermal hydrolysis treatment is 13%, and the heat exchange treatment is carried out with the diluted poultry manure through a heat exchanger, and the poultry manure temperature After dropping to 70°C, it is temporarily stored in the intermediate pool, and then intermittently and quantitatively sent to the plate and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com