Food waste composting method and rural waste classification method using same

A technology of food waste and composting method, which is applied to the treatment of biological organic parts, invertebrate treatment, combined biological treatment, etc., can solve the problems of large area, long time, complicated methods, etc., to solve the problem of disposal, Solve the effect of long time and short composting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

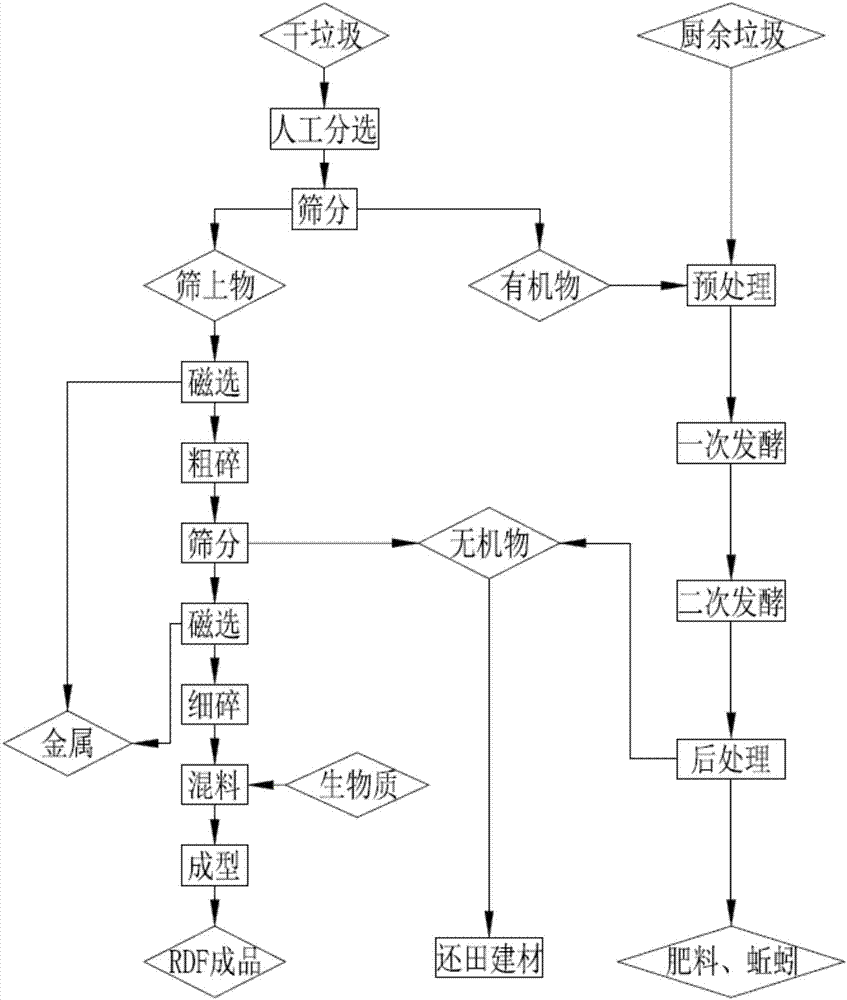

Method used

Image

Examples

Embodiment 1

[0063] a. Garbage pretreatment: crush the collected kitchen waste, mix it with the crushed straw at a dry weight ratio of 1:1, adjust the moisture content to 50%, and adjust the carbon-nitrogen ratio to 25:1;

[0064] b. Primary fermentation: first lay a layer of unbroken straw on the bottom of the fermentation tank, spread the adjusted food waste on the straw, and finally cover the crushed food waste with a layer of semi-decomposed waste; after 3 days of fermentation, Let the temperature reach 50°C-60°C, then maintain it for 5 days, and complete the first fermentation;

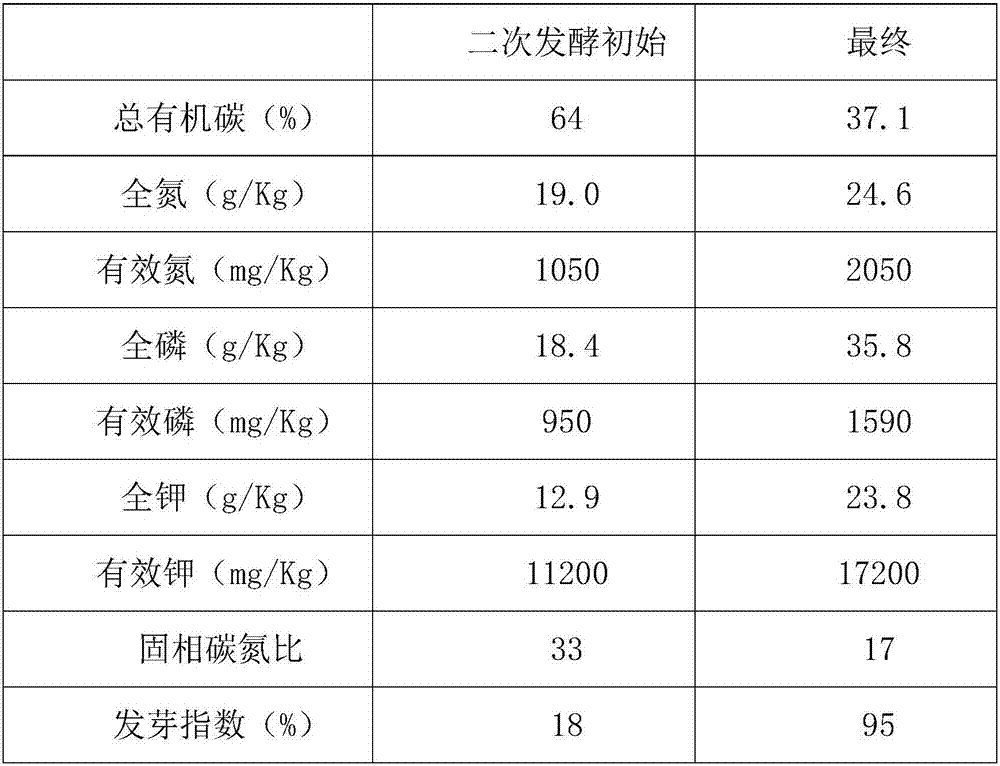

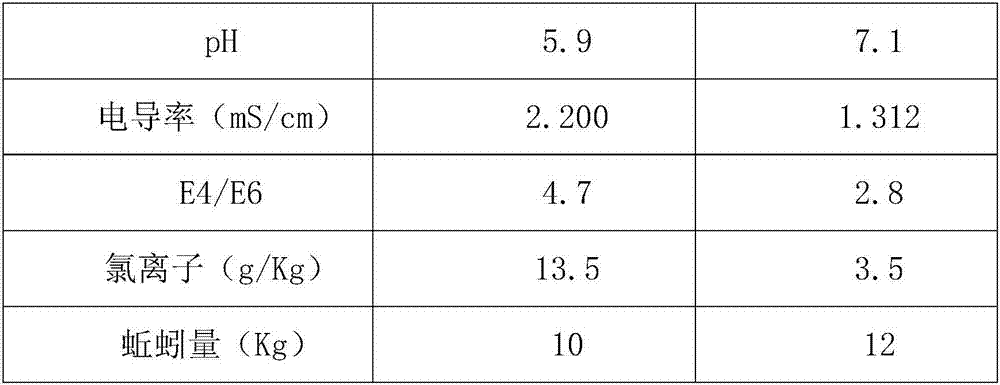

[0065] c. Secondary fermentation: adjust the pH value of the primary fermentation product to 7, adjust the moisture to 65%, adjust the carbon-to-nitrogen ratio to 30, add soil and fresh kitchen waste, the quality of the primary fermentation product, soil and fresh kitchen waste The ratio is 80:10:10; finally, Eisenia foetida is evenly implanted in the mixture;

[0066] After 7 days of earthworm treatment, th...

Embodiment 2

[0074] a. Garbage pretreatment: crush the collected kitchen waste, mix it with the crushed straw at a dry weight ratio of 1:1, adjust the moisture content to 60%, and adjust the carbon-nitrogen ratio to 27:1

[0075] b. Primary fermentation: first lay a layer of unbroken straw on the bottom of the fermentation tank, spread the adjusted food waste on the straw, and finally cover the crushed food waste with a layer of semi-decomposed waste; make the temperature reach 50 ℃-60℃, then maintain for 4 days, and the first fermentation is completed;

[0076] c. Secondary fermentation: adjust the pH value of the primary fermentation product to 7.5, adjust the water content to 61%, adjust the carbon-to-nitrogen ratio to 32, add soil and fresh kitchen waste, the mass ratio of the primary fermentation product, soil and fresh kitchen waste The ratio is 70:10:20; finally, Eisenia foetida is evenly implanted in the mixture;

[0077] After 10 days of earthworm treatment, the weight of earthwo...

Embodiment 3

[0079] a. Garbage pretreatment: crush the collected kitchen waste, mix it with the crushed straw at a dry weight ratio of 2:1, adjust the moisture content to 55%, and adjust the carbon-nitrogen ratio to 30:1

[0080] b. Primary fermentation: first lay a layer of unbroken straw on the bottom of the fermentation tank, spread the adjusted food waste on the straw, and finally cover the crushed food waste with a layer of semi-decomposed waste; make the temperature reach 50 ℃-60℃, then maintain for 4 days, and the first fermentation is completed;

[0081] c. Secondary fermentation: adjust the pH value of the primary fermentation product to 6.5, adjust the water content to 63%, adjust the carbon-to-nitrogen ratio to 35, add soil and fresh kitchen waste, the mass ratio of the primary fermentation product, soil and fresh kitchen waste The ratio is 75:5:20; finally, evenly implant Eisenia foetida in the mixture;

[0082] After 10 days of earthworm treatment, the weight of earthworms in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com