Efficient aerobic composting oil removing preparation for kitchen waste and method for preparing efficient aerobic composting oil removing preparation

A technology of food waste and aerobic composting, which is applied in applications, organic fertilizers, fertilization devices, etc., can solve problems such as high production costs, hindering effective separation, and difficulty in giving production guidance routes, achieving obvious effects and improving composting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example is the preparation example of degreasing preparation.

[0034] Grease-degrading bacteria agent, nutrient activator and surfactant were prepared respectively.

[0035] The oil-degrading bacteria agent is composed of three dried bacteria of Bacillus subtilis, Bacillus coagulans and Bacillus licheniformis in a weight ratio of 1:1:1, and the concentration of viable bacteria of Bacillus subtilis is (5~9)×10 8 CFU / g, the viable concentration of Bacillus coagulans is (5~9)×10 8 CFU / g, the live bacterial concentration of Bacillus licheniformis is (1~4)×10 8 CFU / g.

[0036] The nutritional activator is composed of 95% brown sugar, 5% malt infusion powder.

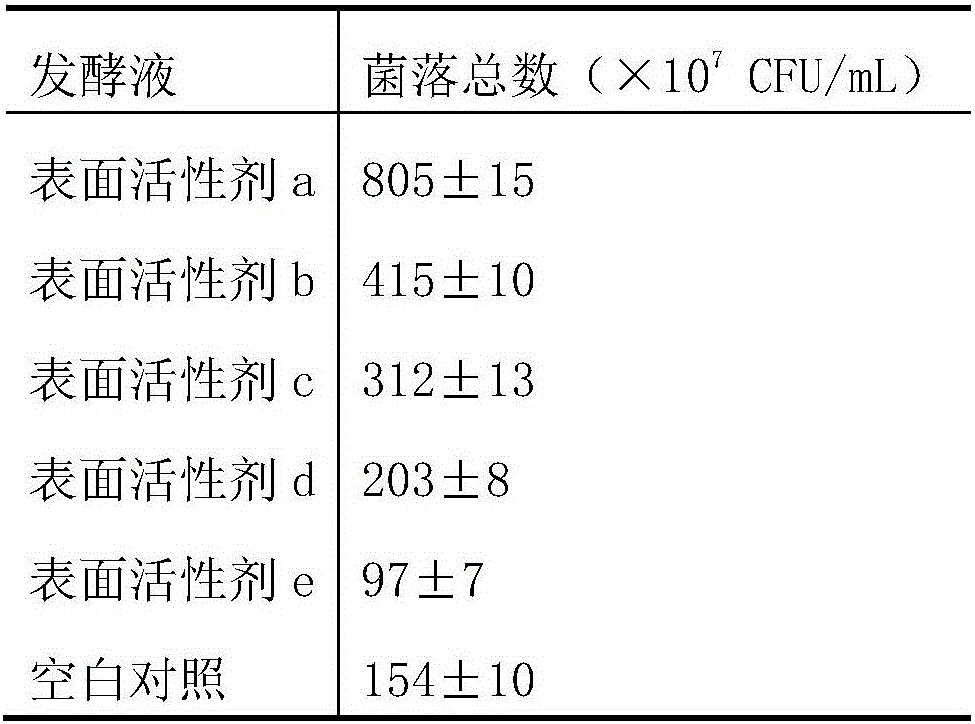

[0037] The surfactant is mixed by the following raw materials in parts by weight: 9 parts of sodium dodecylbenzene sulfonate, 24 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 14 parts of fatty alcohol polyoxyethylene ether, coconut oil fatty acid 3 parts of diethanolamide, 3 parts of urea, 47 p...

Embodiment 2

[0040] This example is the preparation example of degreasing preparation.

[0041] Grease-degrading bacteria agent, nutrient activator and surfactant were prepared respectively.

[0042] The oil-degrading bacteria agent is composed of the dried bacteria of Bacillus subtilis and Bacillus coagulans in a weight ratio of 2:1, and the concentration of viable bacteria of Bacillus subtilis is (5-9)×10 8 CFU / g, the viable concentration of Bacillus coagulans is (5~9)×10 8 CFU / g.

[0043] Nutrient Activator consists of brown sugar.

[0044] The surfactant is mixed by the following raw materials in parts by weight: 24 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 15 parts of fatty alcohol polyoxyethylene ether, 12 parts of sodium dodecylbenzenesulfonate, alkanolamide 3 parts, 46 parts of water.

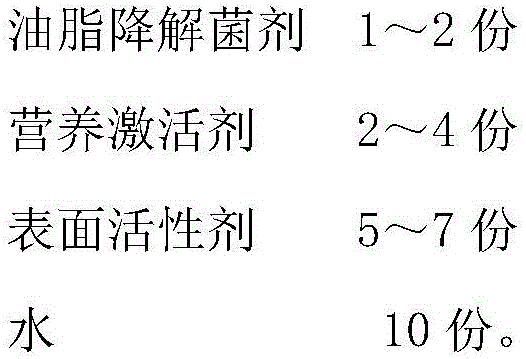

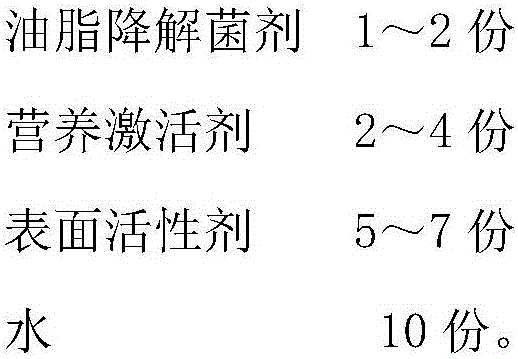

[0045] The degreasing preparation is prepared according to the following method, and the parts are all parts by weight: (1) After stirring and mixing 1 part of the oil-degradi...

Embodiment 3

[0047] This example is the degradation test of the oil removal preparation prepared in Example 1 on kitchen waste grease.

[0048] Initially add 250kg of composting microbial inoculum to the aerobic composting kitchen waste disposer with a volume of 600L, and the composting microbial inoculum is prepared according to the preparation method described in the patent application number CN201410468958.3. 100kg of food waste is put into the kitchen waste every day. Among the food waste, animal offal, skin and other meat food wastes account for 50%, vegetables, potatoes and other plant food wastes account for 50%, and the oil content of food waste is 8% to 10%. %. The food waste disposer is kept ventilated and stirred and kept at a temperature above 35°C for aerobic composting. After 10 days of continuous feeding of food waste, it can be observed that the waste residue is very greasy, black muddy, and accompanied by a sour smell. Now record the grease content in the rubbish residue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com