Method for carrying out sludge aerobic composting by using cane sugar and straws as carbon source conditioning agents

A carbon source regulator and aerobic composting technology, which is applied in the preparation and application of organic fertilizers, organic fertilizers, etc., can solve the problems of large nitrogen loss, increase nitrogen content, reduce ammonia volatilization, and increase humus content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

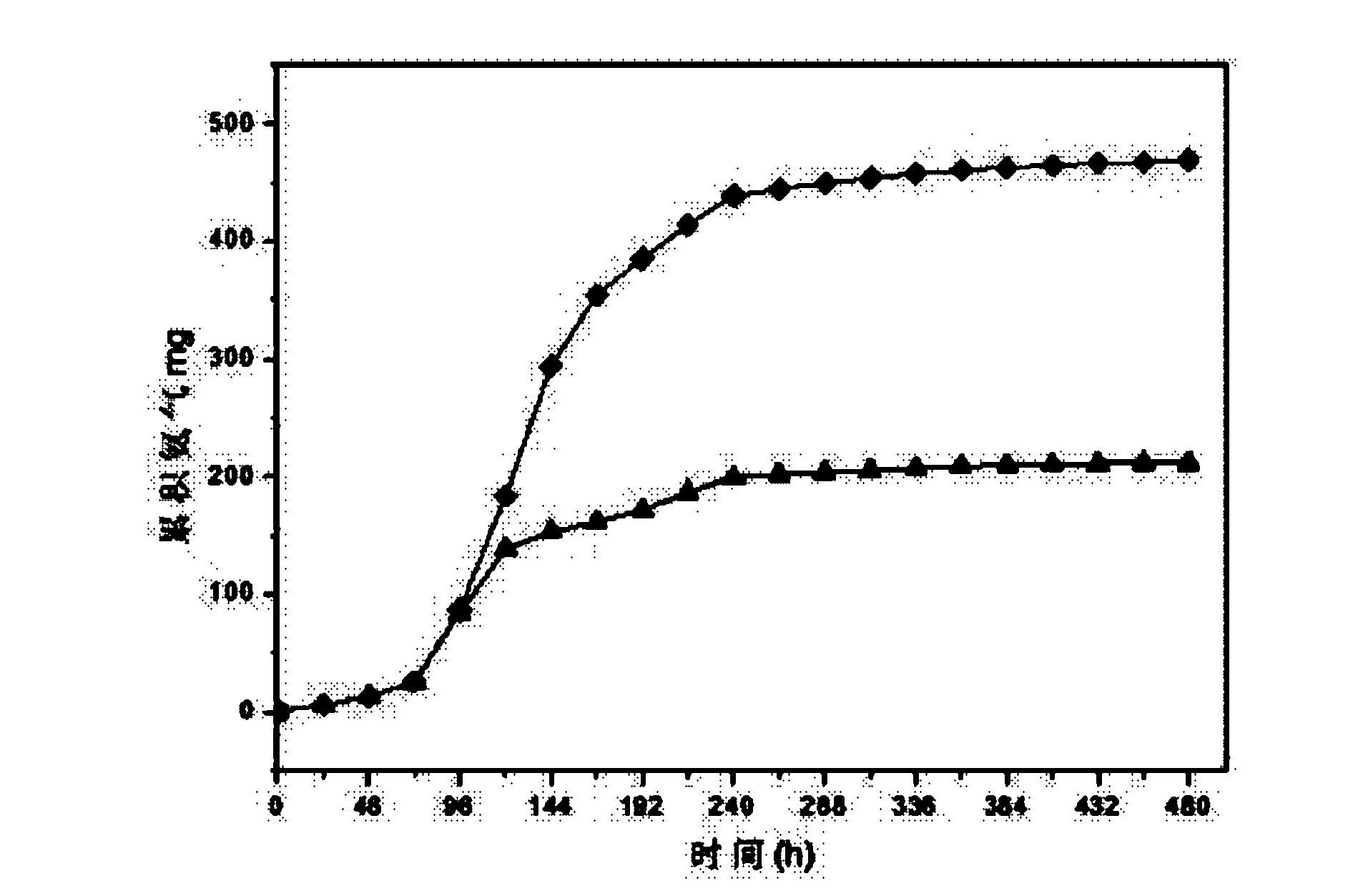

[0014] Specific Embodiment 1: In this embodiment, the method of using sucrose and straw powder as a carbon source regulator to carry out sludge aerobic composting is carried out in the following steps: 1. Mix sucrose and straw powder evenly in a mass ratio of 6 to 8:3, Wherein straw powder and sucrose moisture content are below 5%, as carbon source regulator; 2, conditioner and dewatered sludge are mixed uniformly by mass ratio 1: 1, obtain mixture; 3, conditioner and dehydration in step 2 The mixture of sludge is composted at high temperature, and the ventilation rate is 0.05-2m 3 / min, monitor the temperature of the compost during the composting process, add the carbon source regulator in step 1 after reaching the high temperature period for 18-24 hours, mix and stack until the temperature of the compost reaches the ambient temperature, stop ventilation, and complete high-temperature composting; step 3 The mass ratio of the medium carbon source regulator to the mixture is 1:...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, sucrose and straw powder are mixed evenly at a mass ratio of 7:3. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the conditioning agent in step 2 is sawdust, straw or straw. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com