Oxidation treatment system for waste gas produced during innocent treatment of animal manure

A harmless treatment and oxidation treatment technology, which is applied in animal husbandry wastewater treatment, gas treatment, sludge treatment, etc., can solve the problems of bulky equipment, large air resistance, slow degradation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Embodiment 1: Exhaust gas oxidation treatment system of the present invention

[0110] The implementation mode of this embodiment is as follows:

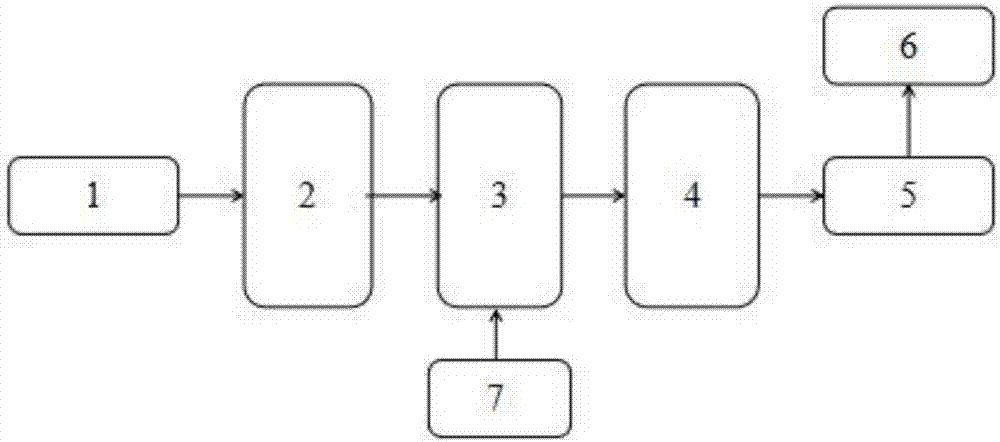

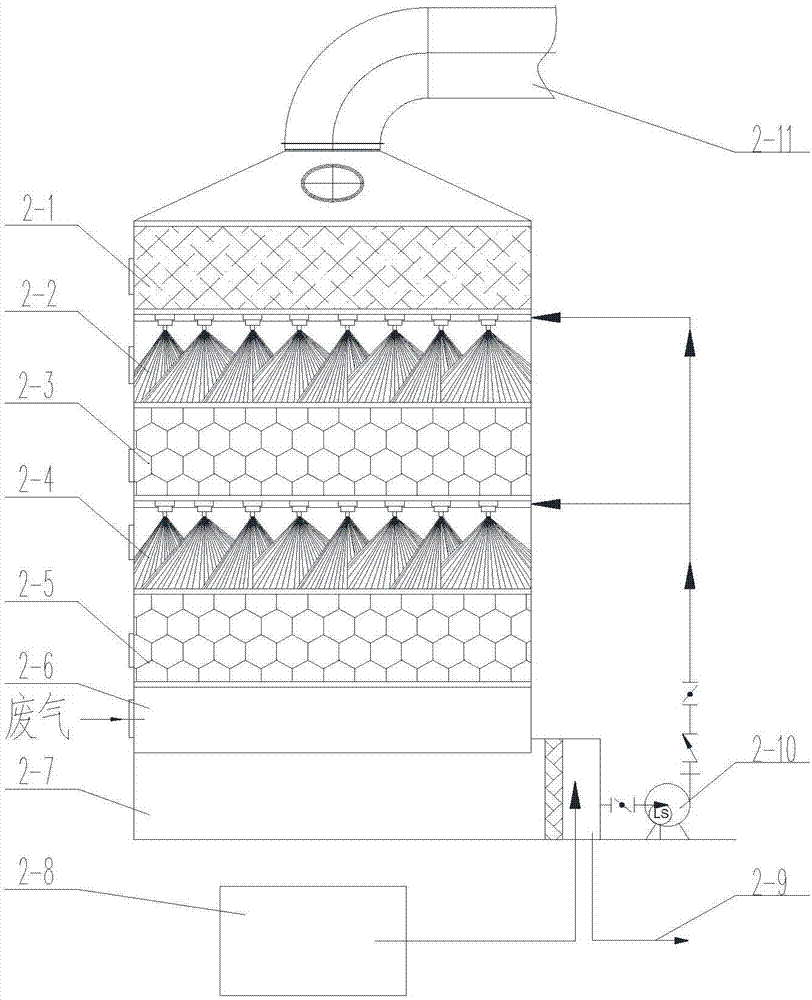

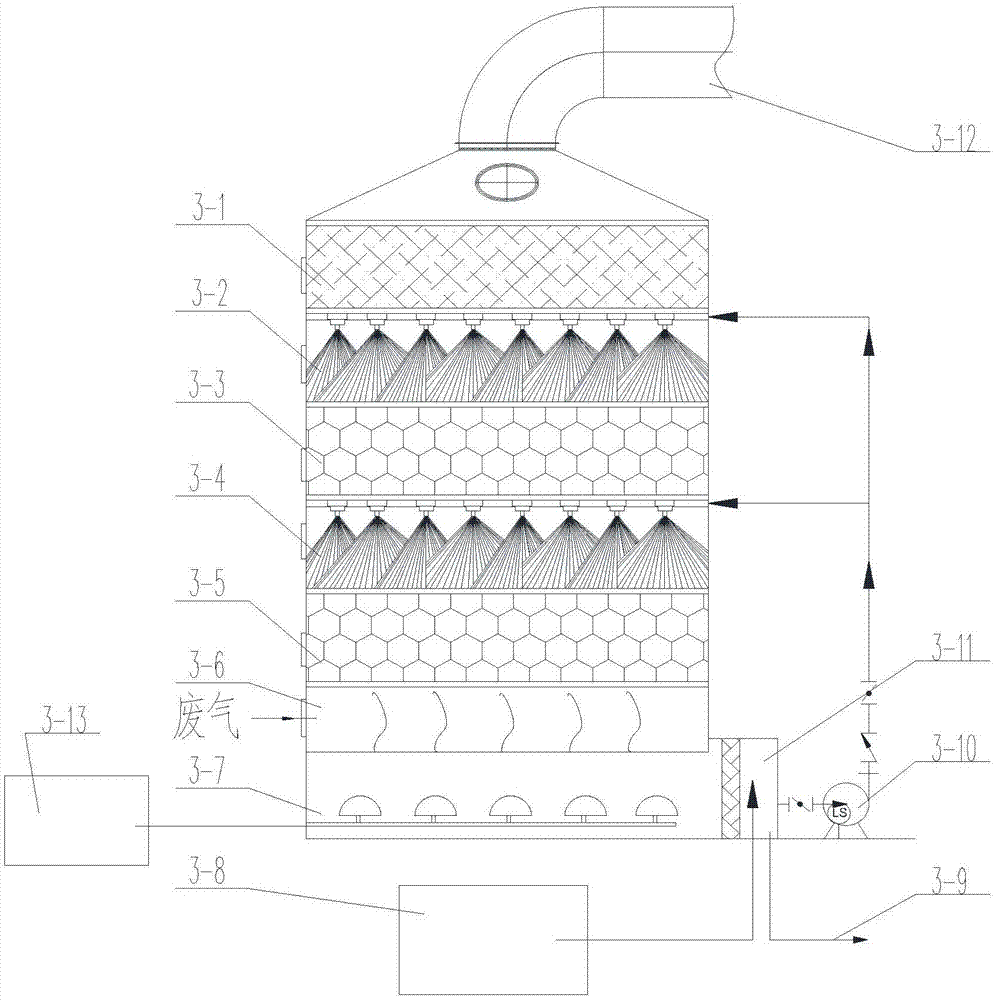

[0111] The oxidation treatment system includes a waste gas collection area 1, a pickling spray tower 2, and is characterized in that it also includes an oxidation spray tower 3, an acid-base neutralization tower 4, an exhaust fan 5, a chimney 6 and a positively charged ozone generator 7;

[0112] The waste gas collection area 1 is connected to the pickling spray tower 2 through the induced draft fan and the exhaust pipe through the waste gas inlet 2-6 of the pickling spray tower 2; the pickling spray tower 2, the oxidation spray tower 3 and the acid-base neutralization tower 4 are connected by pipelines in sequence; the exhaust port 4-11 of the acid-base neutralization tower 4 is connected to the chimney 6 through the exhaust fan 5; the positive charge ozone generator 7 is connected to the oxidation spray tower 3 through the ...

Embodiment 2

[0130] Embodiment 2: Exhaust gas oxidation treatment system of the present invention

[0131] The implementation mode of this embodiment is identical with embodiment 1 implementation mode, just in pickling spray tower 2, the spray liquid of spray liquid storage tank 2-7 is the dilute sulfuric acid aqueous solution that pH is 3.6; The size of this packing is 50mm×100mm. In the oxidation spray tower 3, the spray liquid in the spray liquid storage tank 3-11 is a pH 7.5 aqueous solution containing 1.5% catalyst by weight, and the catalyst is made of titanium dioxide TiO 2 , Titanium-zirconium composite oxide TiO 2 -ZrO 2 , Titanium-tungsten composite oxide TiO 2 -WO 3 And titanium-silicon composite oxide TiO 2 -SiO 2 A honeycomb metal mixed oxide composed of a weight ratio of 1:5:5:3:3.

[0132] The exhaust gas oxidation treatment system of this embodiment can remove 99.6% by weight of ammonia gas NH in the exhaust gas produced during the harmless treatment of livestock and...

Embodiment 3

[0133] Embodiment 3: Exhaust gas oxidation treatment system of the present invention

[0134] The implementation mode of this embodiment is identical with embodiment 1 implementation mode, just in pickling spray tower 2, the spray liquid of spray liquid storage tank 2-7 is the dilute sulfuric acid aqueous solution that pH is 4.4; The size of this packing is 75mm×50mm. In the oxidation spray tower 3, the spray liquid in the spray liquid storage tank 3-11 is a pH 7.0 aqueous solution containing 2% catalyst by weight. The catalyst is based on titanium dioxide TiO 2 , Titanium-zirconium composite oxide TiO 2 -ZrO 2 , Titanium-tungsten composite oxide TiO 2 -WO 3 And titanium-silicon composite oxide TiO 2 -SiO 2 A honeycomb ceramic mixed oxide composed of a weight ratio of 1:8:8:6:5.

[0135] The exhaust gas oxidation treatment system of this embodiment can remove 99.4% by weight of ammonia gas NH in the exhaust gas produced during the harmless treatment of livestock and po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com