Compost building method for food waste organic matter aerobic composting

A technology of aerobic composting and organic matter, applied in the direction of organic fertilizers, fertilizers made of biological waste, fertilization devices, etc., can solve the problems of limited popularization and application, high deodorization costs, and investment and operation costs of plant equipment, etc., to achieve fermentation Uniform, conducive to air circulation, shortening the effect of composting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

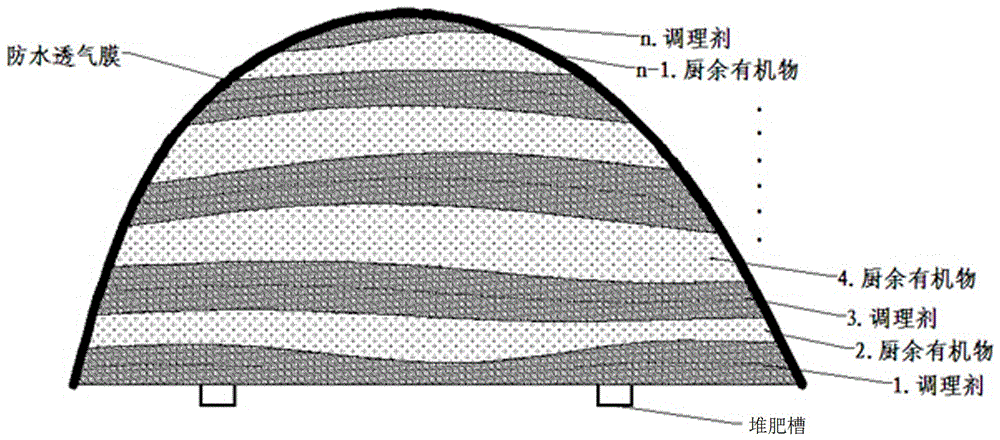

[0030] A composting method for aerobic composting of food waste organic matter, comprising the following steps:

[0031] 1) Lay a layer of conditioner with a thickness of 10cm in the compost tank; the conditioner is obtained by crushing one or more selected from garden waste, branches, straw, tea stalks, and sugarcane stalks to 10cm;

[0032] 2) laying the food waste organic matter on the above-mentioned conditioner; the volume ratio of the food waste organic matter to the conditioner is 1:1;

[0033] 3) Lay a layer of 10cm conditioner on the above-mentioned kitchen waste organic matter; the conditioner is obtained by crushing one or more selected from garden waste, branches, straw, tea stems, and sugarcane stems to 10cm; The volume ratio of described food waste organic matter and conditioning agent is 1: 1;

[0034] 4) Repeat step 2) and step 3) to obtain the mixed material;

[0035] 5) Pile the obtained mixed material into a pile, and the height of the pile pile is 3.0 met...

Embodiment 2

[0040] A method for building aerobic compost of food waste organic matter, comprising the following steps:

[0041] 1) Lay a layer of conditioner with a thickness of 35cm in the compost tank; the conditioner is obtained by crushing one or more selected from garden waste, branches, straw, tea stalks, and sugarcane stalks to 5cm;

[0042] 2) laying the food waste organic matter on the above-mentioned conditioner; the volume ratio of the food waste organic matter to the conditioner is 1:5;

[0043] 3) Lay a layer of conditioner with a thickness of 35cm on the above-mentioned organic food waste; The volume ratio of described food waste organic matter and conditioner is 1:5;

[0044] 4) Repeat step 2) and step 3) to obtain the mixed material;

[0045] 5) Pile the obtained mixed material into a pile, and the height of the pile is 2.5 meters;

[0046] 6) After filling the entire compost tank with materials, cover it with a waterproof and breathable membrane;

[0047] 7) Insert the ...

Embodiment 3

[0050] A composting method for aerobic composting of food waste organic matter, comprising the following steps:

[0051] 1) Lay a layer of conditioner with a thickness of 4cm in the compost tank; the conditioner is obtained by crushing one or more selected from garden waste, branches, straw, tea stalks, and sugarcane stalks to 0.5cm;

[0052] 2) laying the food waste organic matter on the above-mentioned conditioner; the volume ratio of the food waste organic matter to the conditioner is 1:10;

[0053] 3) Lay a layer of conditioner with a thickness of 4cm on the above-mentioned kitchen waste organic matter; Obtained; The volume ratio of the kitchen waste organic matter and the conditioning agent is 1:10;

[0054] 4) Repeat step 2) and step 3) to obtain the mixed material;

[0055] 5) Pile the obtained mixed material into a pile, and the height of the pile is 1.3 meters;

[0056] 6) After filling the entire compost tank with materials, cover it with a waterproof and breathab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com