Sludge composting and fermenting integrated treatment device

A processing device and composting technology, applied in fertilization devices, sewage/sludge fertilizers, organic fertilizers, etc., can solve the problems of strict site requirements, fast heat conduction, and excessive temperature loss of fermentation tanks, etc., to maintain microbial activity and improve composting Efficiency and shortening of composting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

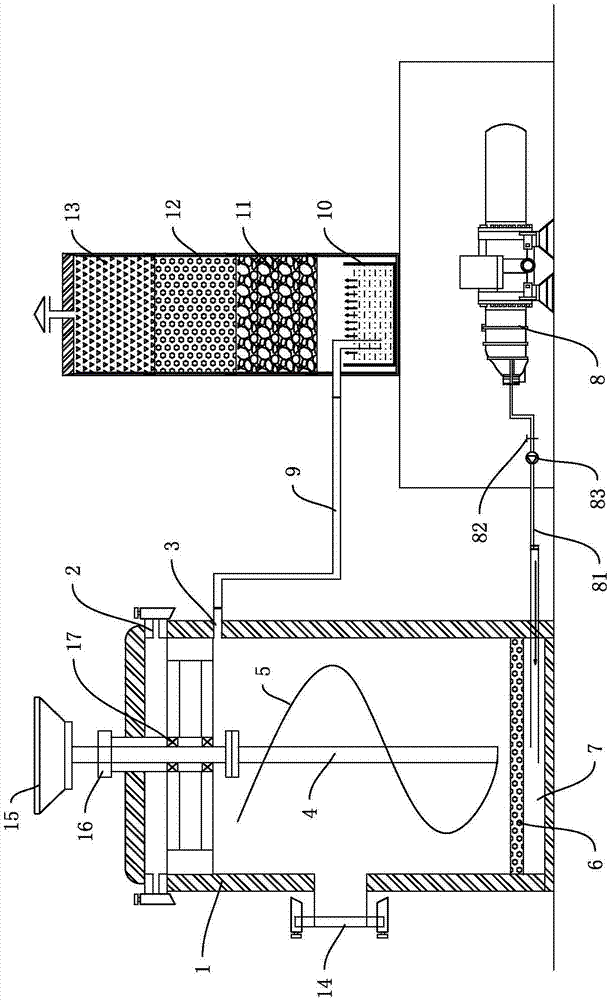

[0020] Such as figure 1 The shown sludge composting and fermentation integrated treatment device includes a fermenter 1 and a deodorizing component.

[0021] The fermenter 1 is provided with a feed port 2 and an exhaust port 3 . Feed inlet 2 is positioned at the top position, can be one or two, and it is used for throwing sludge, fertilizer in the tank. Each feed port 2 can be disassembled and provided with a sealing part. For example, if the feed port 2 is a flange, the sealing part can be a flange cover, and a sealing colloid is provided between the flange plate and the flange cover. Reduce gas leakage.

[0022] The above-mentioned exhaust port 3 is located at the top and is externally connected to the deodorizing component. During the composting process, the tail gas produced by the sludge is discharged from the exhaust port 3 into the deodorizing component for deodorization treatment, and finally discharged into the atmosphere, so that the exhaust gas odors and pollutan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com