Low-temperature-resistant dust suppression system for unloading of grab bucket of traveling crane

A technology of low temperature resistance and water storage device, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problems of large water consumption, abnormal use, and poor dust suppression effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

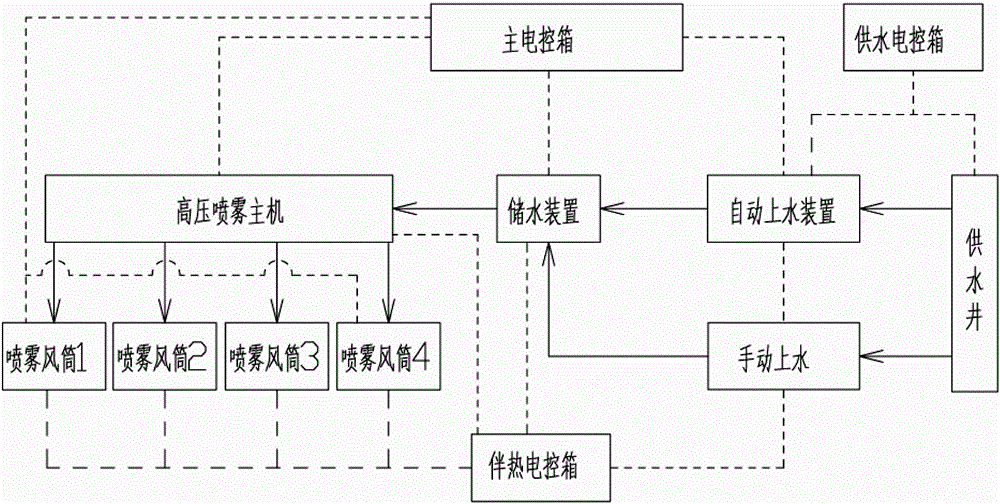

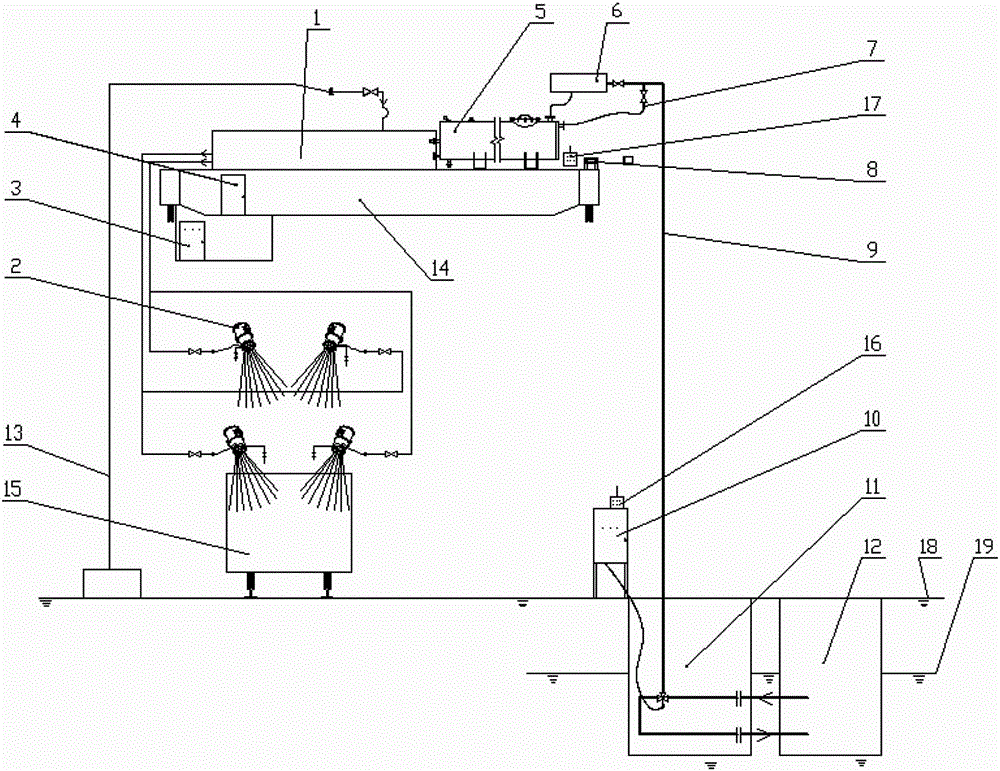

[0020] Such as figure 1 and figure 2 As shown, a low-temperature resistant dust suppression system for driving grab discharge, including high-pressure spray host 1, spray fan 2, main electric control box 3, water storage device 5, heat tracing device, water inlet device, water supply and return Water supply and return water pipeline 9, water supply electric control box 10, water supply dry well 11, water supply wet well 12, blowback device 13, water supply remote control receiver 16 and water supply remote control transmitter 17, high pressure spray host 1 will store After the water in the water device 5 is pressurized, filtered and pressurized, the mist is spraye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com