Dust suppression crusher and control system thereof

A control system and crusher technology, applied in grain processing, etc., can solve problems such as large dust, affecting the heat dissipation and lubrication of the crusher, and the crusher cannot obtain the desired crushing degree, so as to achieve a small footprint and improve the crushing degree , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

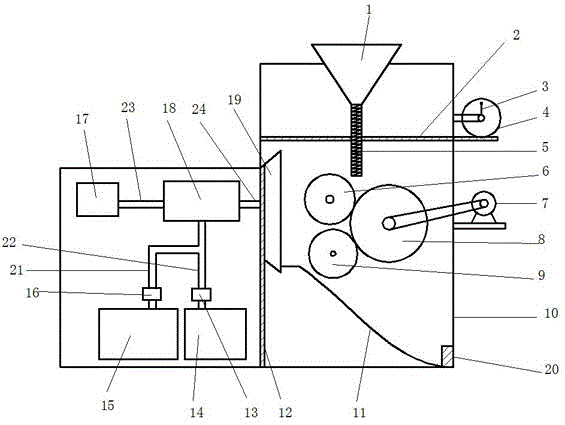

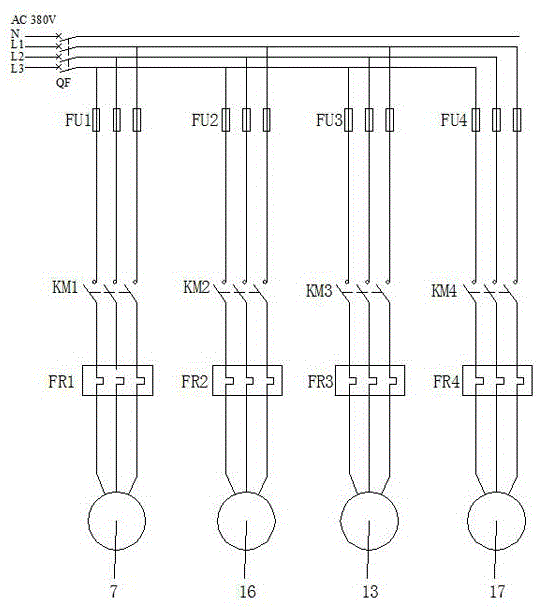

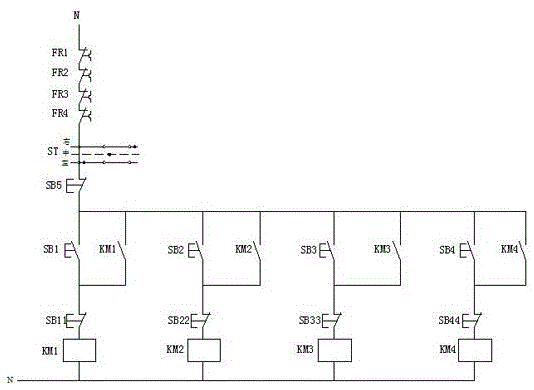

[0028] Such as Figure 1-3As shown, the dust reduction crusher includes a hopper 1, an adjustment rack 2, an adjustment handle 3, an adjustment gear 4, a metal hose 5, a first crushing gear 8, a second crushing gear 6, a third crushing gear 9, and a crushing motor 7 , body 10, hopper 11, partition 12, foaming agent box 14, water tank 15, foaming agent pump 13, water pump 16, blower fan 17, foaming device 18, shower nozzle 19, described hopper is positioned at the upper end of the body, The metal hose 5 is connected to the outlet of the lower end of the hopper 1, and the metal hose 5 is fixed on the rack 2. There are a pair of holes on the left and right sides of the upper part of the body 10, and the rack 2 is installed on the body 10 through the two holes. An adjustment gear 4 is fixed on the body 10 by means of hinged joints. The adjustment gear 4 and the rack 2 form a meshing relationship. An adjustment handle 3 is installed on the adjustment gear 4. The adjustment handle 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com