Induction device applicable to wafer photolithography process

A lithography process and sensing device technology, which is applied to the sensing device field of wafer lithography process, can solve the problems of uncertainty of reflection angle, rough surface of wafer, difficult to guarantee sensing accuracy, etc. The effect of precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

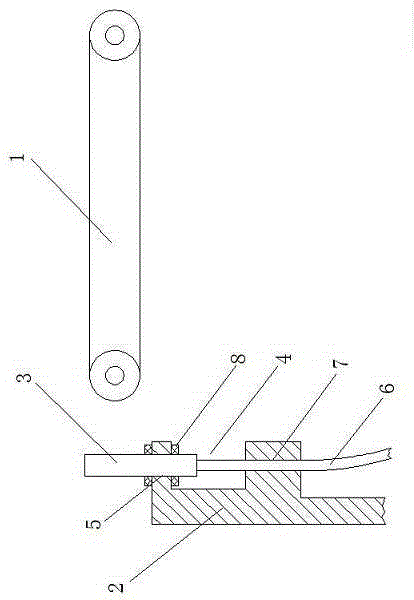

[0014] like figure 1 A kind of induction device suitable for wafer lithography process is shown, and it comprises the feeding device 1 that is used for transferring wafer; The front end portion of described feeding device 1 is provided with induction support 2, and A proximity switch 3 is arranged on the top, and the proximity switch 3 and the feeding device 1 are opposite to each other.

[0015] As an improvement of the present invention, a placement tank 4 is provided on the opposite end surface of the induction bracket 2 and the feeding device 1, and the upper end surface of the placement tank 4 is provided with a placement hole 5, and the proximity switch 3 is installed The hole 4 is connected to the induction bracket 2 , and the lower end of the proximity switch 3 extends to the interior of the placement tank 4 . With the above design, it can form the installation position corresponding to the proximity switch through the setting of the placement groove in the induction ...

Embodiment 2

[0019] As an improvement of the present invention, the connection positions between the proximity switch 3 and the upper and lower ends of the placement hole 5 are respectively provided with rubber damping rings 8, which can prevent the proximity switch from falling or even being damaged due to factors such as mechanical vibration, thereby The service life of the induction device is improved.

[0020] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com