Dust separation ventilation equipment for roadway

A technology of dust separation and ventilation equipment, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of low purification efficiency and inconvenient replacement of activated carbon columns, and achieve the effect of avoiding dust flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

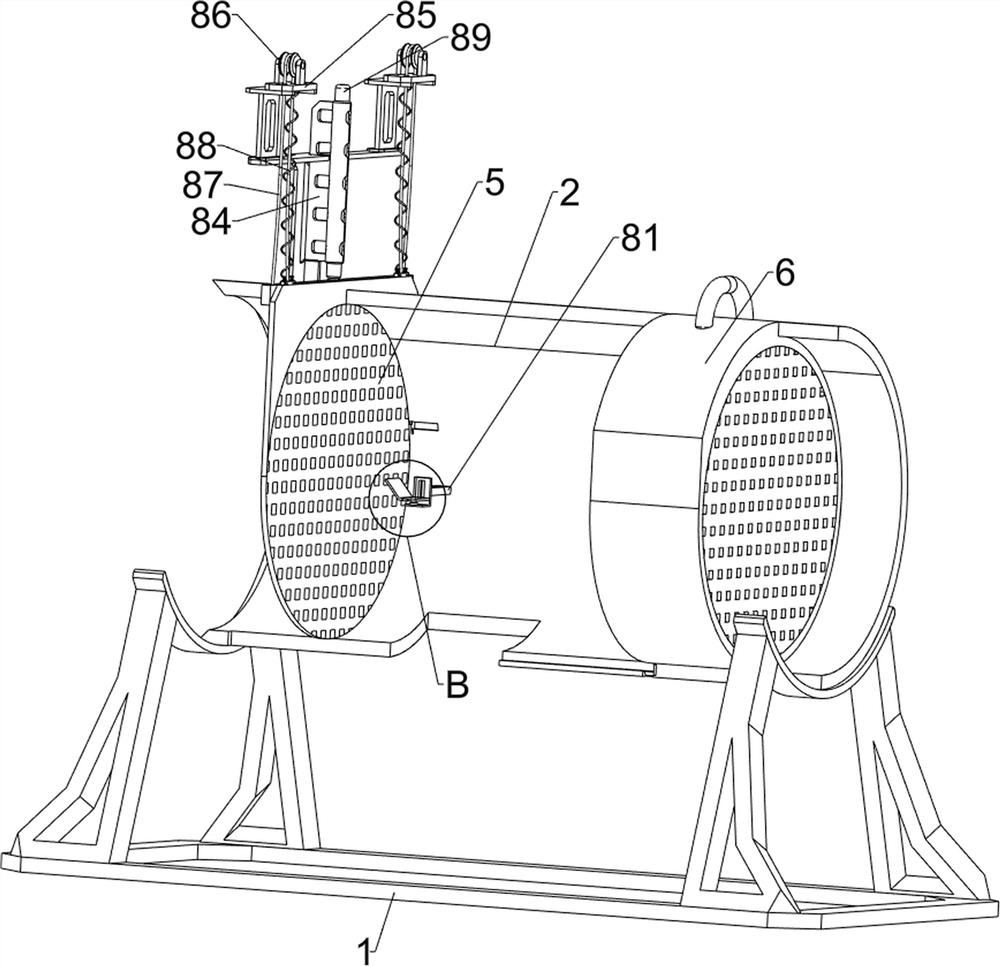

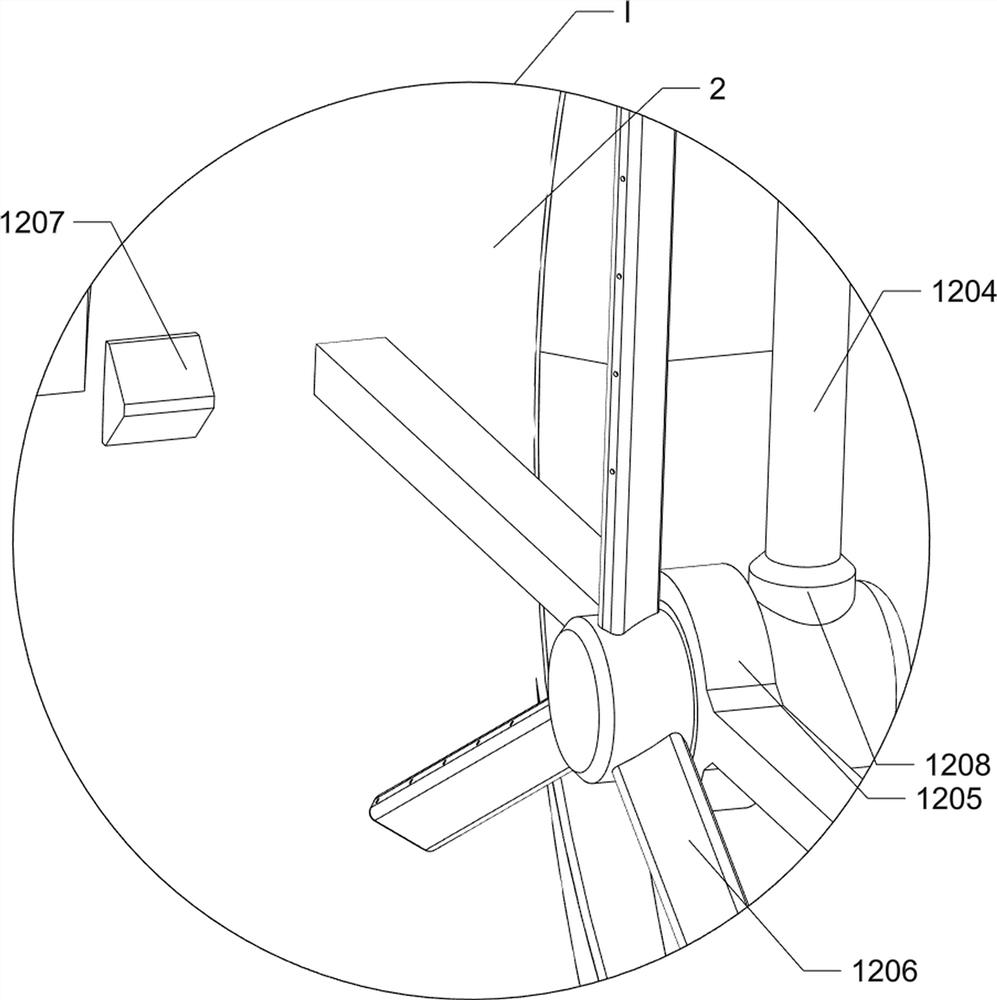

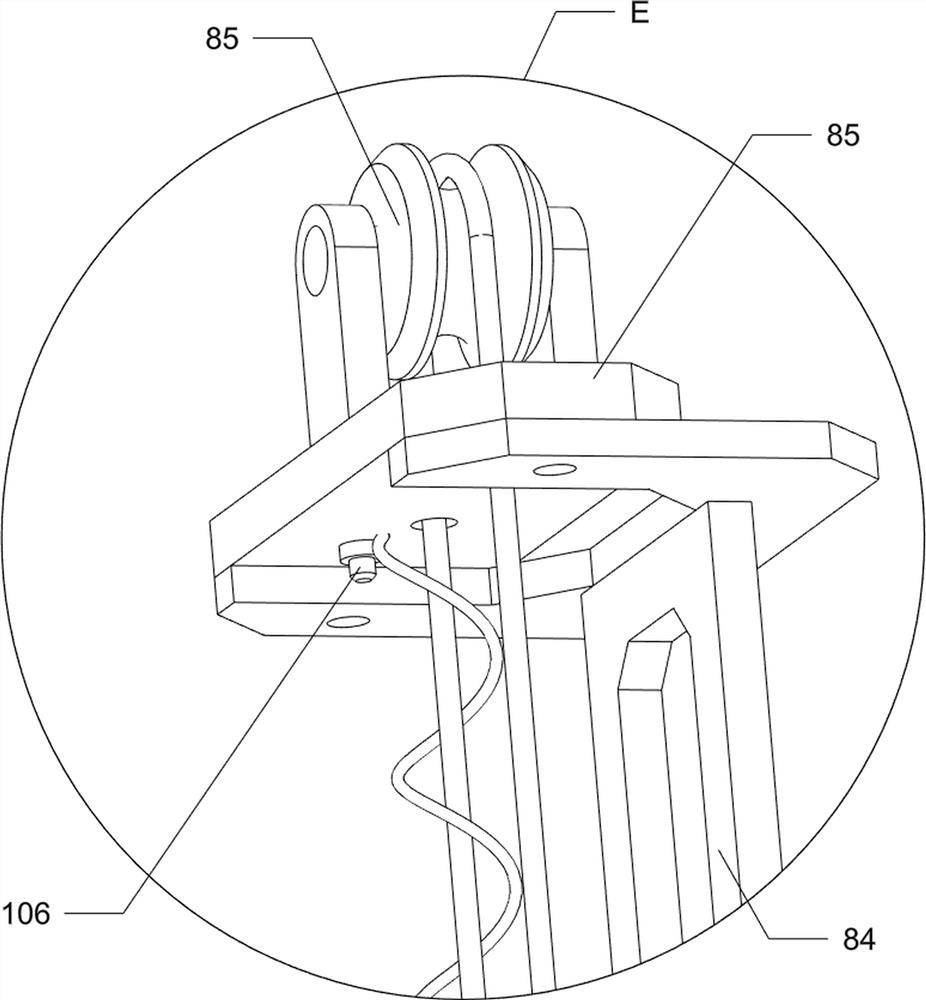

[0041] A roadway with dust separation ventilation equipment, such as Figure 1-21As shown, it includes a base 1, a working hollow column 2, an air intake fan 3, an air outlet fan 31, a start switch 32, a reset switch 33, a filter plate 5, an activated carbon adsorption net 6, a connection assembly 7 and a scraper assembly 8, and the base 1 The top is provided with a working hollow column 2, the rear side of the working hollow column 2 is provided with an intake fan 3, the front side of the working hollow column 2 is provided with an outlet fan 31, the right rear side of the intake fan 3 is provided with a start switch 32, and the intake fan 3 The right front side is provided with a reset switch 33, the inner rear side of the working hollow column 2 is slidingly connected with a filter plate 5, the inner front side of the working hollow column 2 is placed with an activated carbon adsorption net 6, and the top of the filter plate 5 is provided with a connection assembly 7, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com