High-voltage transmission line maintenance equipment

A technology for high-voltage transmission lines and transmission lines, which is applied to overhead lines/cable equipment, injection devices, etc., and can solve problems such as poor work reliability, inability to drive the drive wheel, and inability to hold down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

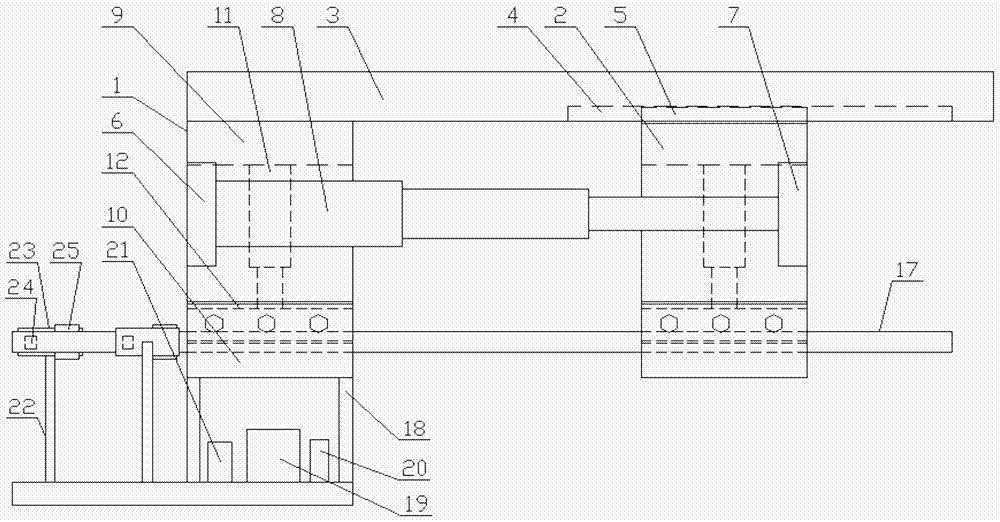

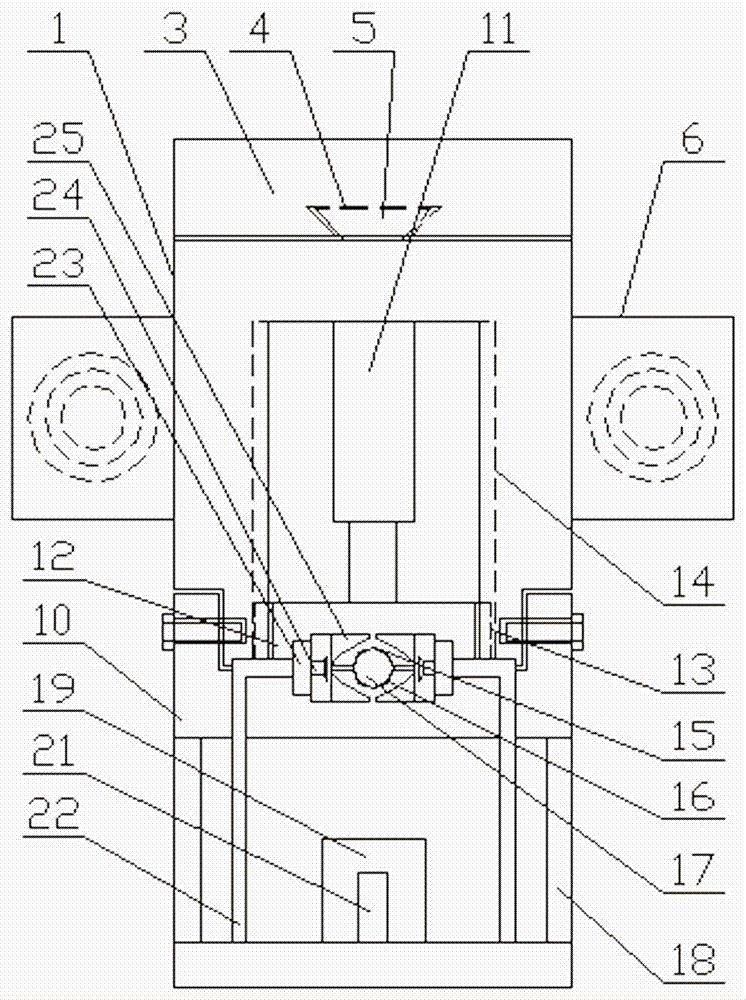

[0037] Such as figure 1 and figure 2 As shown, a high-voltage transmission line maintenance equipment includes a traveling mechanism and a spraying mechanism arranged on the traveling mechanism. The traveling mechanism includes a left traveling support 1 and a right traveling support 2, and a crossbeam is arranged on the upper part of the left traveling support 1 3. A first dovetail groove 4 is provided on the bottom surface of the right side of the beam 3 , and a first dovetail tenon 5 matching the first dovetail groove 4 is arranged on the top of the right traveling support 2 .

[0038] Base 6 is all set on the front and rear sides of described left walking support 1, and push plate 7 is all set on the front and rear sides of described right walking support 2, and the first automatic telescoping link 8 is set on described base 6, and described first automatic The free end of the telescopic rod 8 is arranged on the push plate 7 .

[0039] The structure of the left walking ...

Embodiment 2

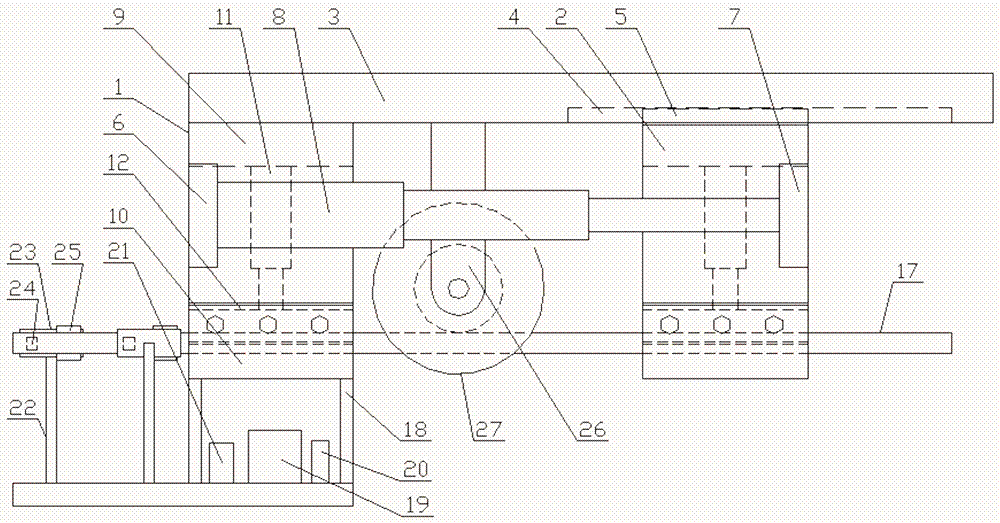

[0050] Such as image 3 and Figure 4 As shown, a high-voltage transmission line maintenance equipment includes a traveling mechanism and a spraying mechanism arranged on the traveling mechanism. The traveling mechanism includes a left traveling support 1 and a right traveling support 2, and a crossbeam is arranged on the upper part of the left traveling support 1 3. A first dovetail groove 4 is provided on the bottom surface of the right side of the beam 3 , and a first dovetail tenon 5 matching the first dovetail groove 4 is arranged on the top of the right traveling support 2 .

[0051] Base 6 is all set on the front and rear sides of described left walking support 1, and push plate 7 is all set on the front and rear sides of described right walking support 2, and the first automatic telescoping link 8 is set on described base 6, and described first automatic The free end of the telescopic rod 8 is arranged on the push plate 7 .

[0052] The structure of the left walking ...

Embodiment 3

[0061] Such as Figure 5 and Figure 6 As shown, the difference between it and Embodiment 2 is that a traction plate 28 is provided on the front and rear sides of the bottom of the spraying bracket 18, and a traction hole 29 is provided on the traction plate 28, and a traction rope 30 is arranged in the traction hole 29.

[0062] An anchor rod or an anchor is arranged at the lower end of the traction rope 30 .

[0063] A position sensor 31 and an alarm 32 are arranged on the lower part of the beam 3 , and both the position sensor 31 and the alarm 32 are electrically connected to the CPU module 21 .

[0064] In this embodiment, traction plates are provided on the front and rear sides of the bottom of the spraying bracket, and traction holes are provided on the traction plates to facilitate fixing the traction rope on the traction plate, so that the ground personnel can prevent the equipment from galloping during the work process through the traction rope. Anchor rods are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com