Production method and production equipment of special compound fertilizer for lotus roots.

The technology of a production method and production equipment is applied in the production method and production equipment field of lotus root special compound fertilizer, which can solve the problems of uneven heating, easy dispersion and loss, and difficult storage, so as to improve the decomposition ability, realize air intake operation, and avoid texture loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A method for producing special compound fertilizer for lotus root, comprising the following steps;

[0036]Step S1: uniformly mixing livestock and poultry manure and crushed straw according to a mass ratio of 2:1 to obtain an organic matter mixture;

[0037] Step S2: After obtaining the culture material in S1, after the culture medium is cooled, put microbial strains into the culture medium. The microbial strains include yeast, photosynthetic bacteria, rhizobia and spores. ℃ into the reactor for fermentation and cultivation;

[0038] Step S3: Transfer the mixed liquid obtained in S2 to a fermentation reactor, stir thoroughly, and ferment at 25-35°C for 5 days to obtain a fermented product;

[0039] Step S4: Squeeze and filter the fermented product to obtain a dry fermented product, mix phosphorus and potassium fertilizer, urea, trace elements, hexurea iron trinitrate and plant ash into the fermented product, stir and mix thoroughly, and then mix in kudzu root powder an...

Embodiment approach

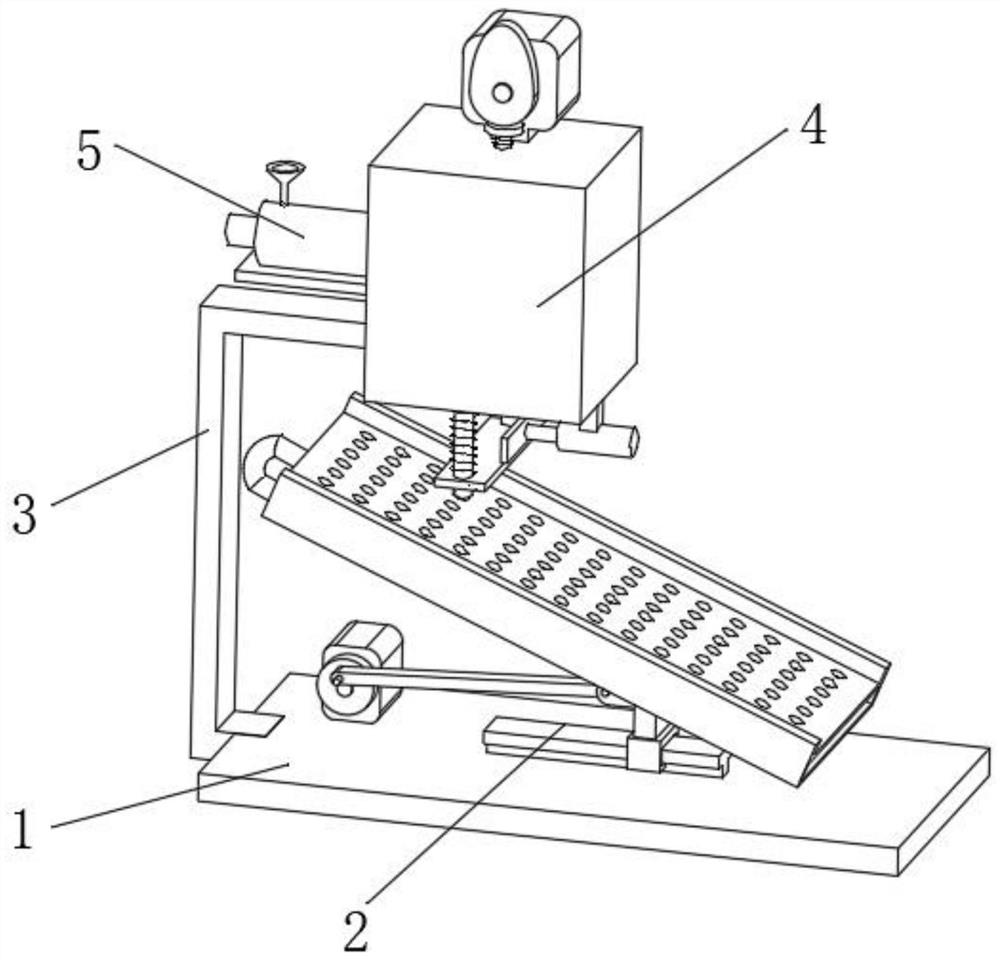

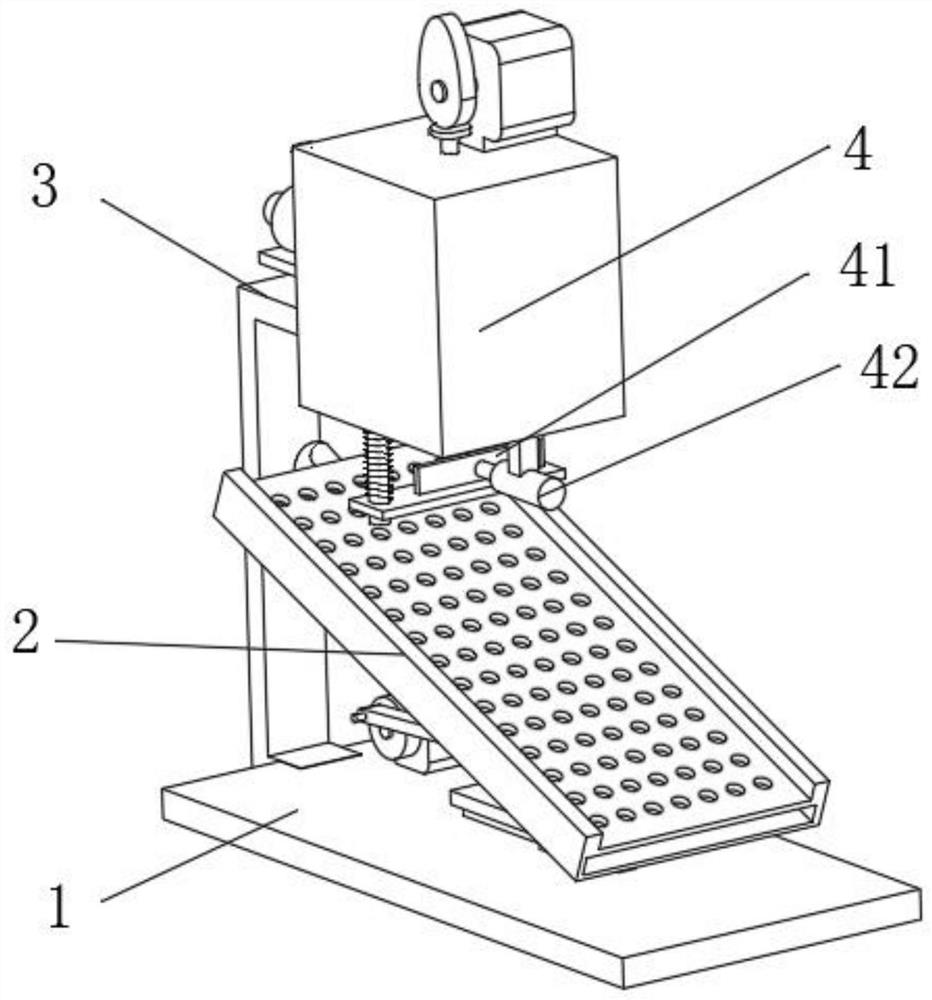

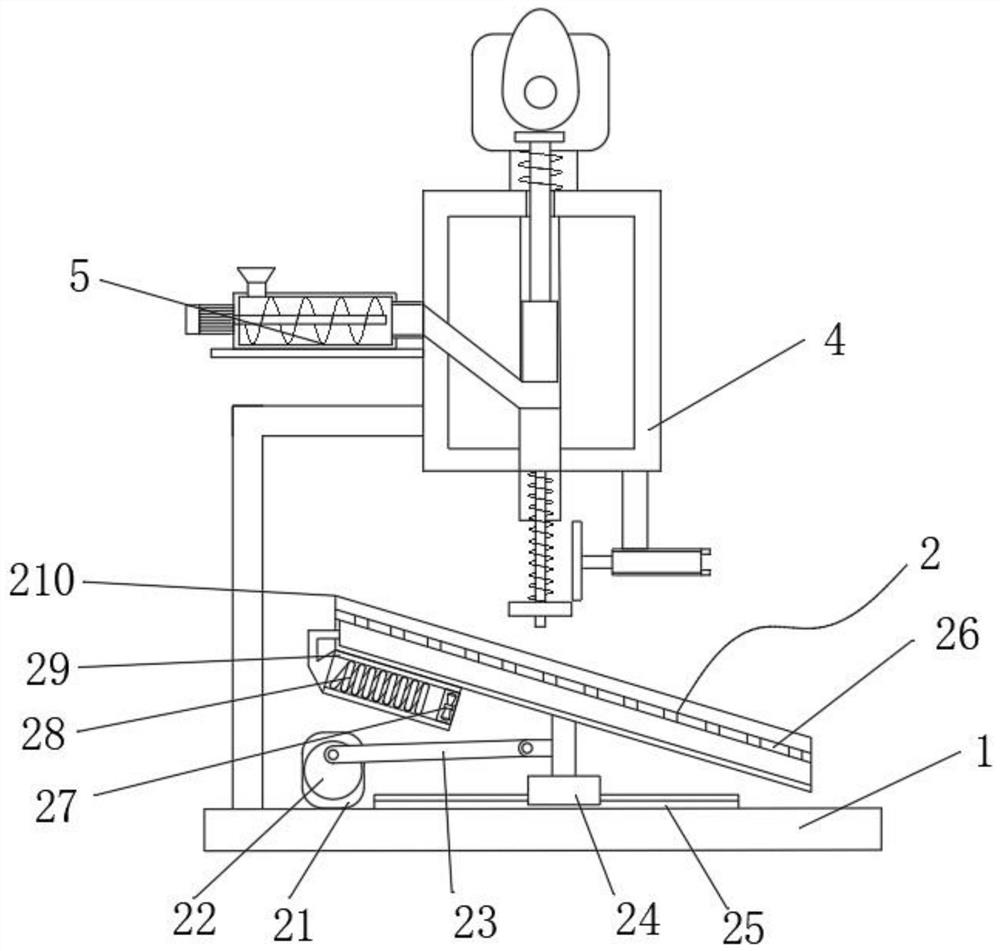

[0049] As an embodiment of the present invention, the vibration drying structure 2 includes a vibration motor 21, a rotating wheel 22, a linkage rod 23, a slider 24, a slide rail 25, a sieve plate 26, an air intake fan 27, a heating wire 28, a guide The air cylinder 29 and the slide plate 210, the slide rail 25 are arranged on the top side of the base 1, the slide block 24 is matched and clamped on the slide rail 25, the vibration motor 21 is mounted on the top side of the base 1 through bolts, and the rotating wheel 22 is mounted on the On the rotating shaft of the vibrating motor 21, the top of the slide plate 210 is mounted on the sieve plate 26 through the connecting frame, one end of the connecting rod 23 is hinged on the connecting frame, and the other end of the connecting rod 23 is mounted on the rotating wheel 22 through a pin. The sieve plate 26 is erected on the slide plate 210 , the air guide tube 29 is fixed on the bottom top side of the slide plate 210 , the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com