Patents

Literature

106results about How to "High quality production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

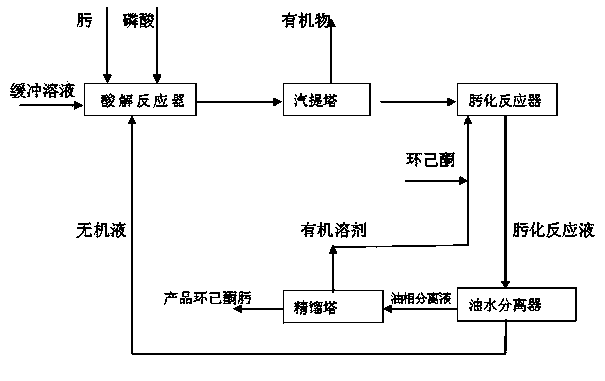

Preparation method of cyclohexanone oxime

The invention provides a new preparation method of cyclohexanone oxime, and the preparation method comprises performing a hydrolysis reaction of 4 or less than 4 carbon atom containing oxime such as acetaldoxime, acetone oxime or butanone oxime and the like which is produced by an ammoxidation method and phosphoric acid added in a phosphate buffer solution to obtain an inorganic liquid containing hydroxylamine phosphate, then performing an oximation reaction of the inorganic liquid and cyclohexanone to obtain the high purity cyclohexanone oxime. According to the preparation method, due to the direct oximation reaction of the hydroxylamine phosphate and the cyclohexanone, the shortcoming that the cyclohexanone oxime prepared by the direct ammoxidation method is high in impurity content and is difficult to separate, and thus affecting the quality of caprolactam prepared from the cyclohexanone oxime can be overcomed; at the same time, the advantages of a plurality of processes for industrial production of the cyclohexanone oxime are combined, the inorganic liquid cycle can be realized, the high purity cyclohexanone oxime is prepared, the process cycle is realized, and the preparation method is conducive to energy saving and consumption reduction, and the realization of safe, environmentally friendly, low-cost and high-quality production.

Owner:刘建青

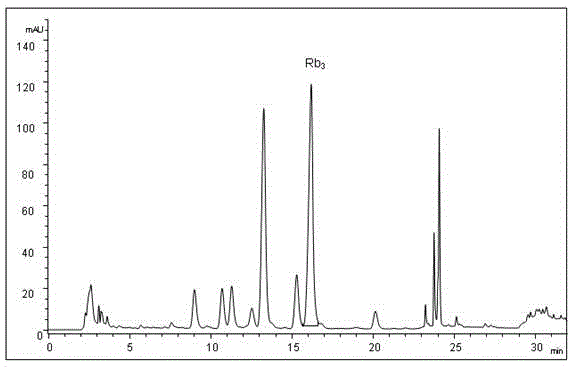

Preparation method of notoginseng leaf total saponins

The invention relates to a preparation method of notoginseng leaf total saponins, and belongs to the technical field of natural medicine extraction. The preparation method comprises the following steps: adding a solvent to notoginseng leaves, carrying out ultrasonic wave countercurrent continuous extraction, filtering, collecting filtrate, concentrating to obtain clear paste, adding a natural clarifying agent for clarification, centrifuging, adding ethyl alcohol to a clear solution to ensure that the ethyl alcohol content of the clear solution is 30-50%, and carrying out alcohol precipitation; and purifying the clear solution subjected to alcohol precipitation by using a desugaring resin column, eluting by using ethyl alcohols with different concentrations, decolorizing by using anion exchange resin after desugaring, finally concentrating, and carrying out microwave drying so as to obtain the notoginseng leaf total saponins. The preparation method has the advantages that the obtained notoginseng leaf total saponins are off-white, the texture of the powder is loose, the yield of total glycosides is above 8%, the content of the total glycosides is not lower than 90% (UV-ultraviolet), the obtained notoginseng leaf total saponins mainly comprise Rb3, Rc, Fc, Fa and the like, and the content of the Rb3 is greater than or equal to 40% (HPLC- High Performance Liquid Chromatography); the process is simple, the realization of industrialization is facilitated, and the product quality is substantially improved.

Owner:YUNNAN WEIHE PHARMA

Preparation method of TC17 titanium alloy flat square section bar

ActiveCN103143660ARefining as-cast structureAddressing inhomogeneityMetal-working apparatusIngotWork in process

The invention provides a preparation method of a TC17 titanium alloy flat square section bar. The preparation method comprises the following steps that (1) a riser and an ingot bottom of a TC17 titanium alloy cast ingot are cut off, and surface defects are removed; (2) billet forging is performed on the TC17 titanium alloy cast ingot, and primary forging stocks are obtained; (3) first middle forging is performed on the primary forging stocks, and first middle forging stocks are obtained; (4) second middle forging is performed on the first middle forging stocks, and second middle forging stocks are obtained; (5) sawing is performed on the second middle forging stocks, then forming forging is performed, and a semi-finished flat square section bar is obtained; and (6) heat treatment is performed on the semi-finished flat square section bar, and the TC17 titanium alloy flat square section bar with the length of 850 mm to 1600 mm, the width of 132 mm and the thickness of 65 mm to 100 mm is obtained. The preparation method has the advantages of integral technical scheme, strong process controllability, uniformity in product texture and shape, excellent overall performance, high batch stability and high yield and is suitable for large-scale industrial production.

Owner:WESTERN TITANIUM TECH

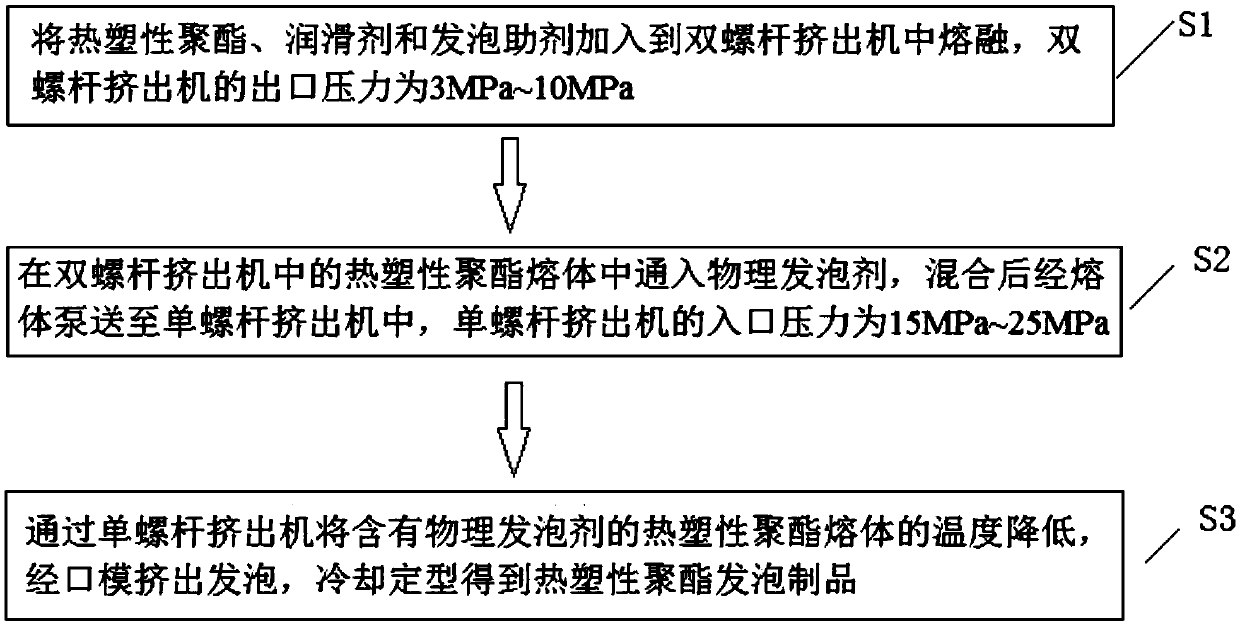

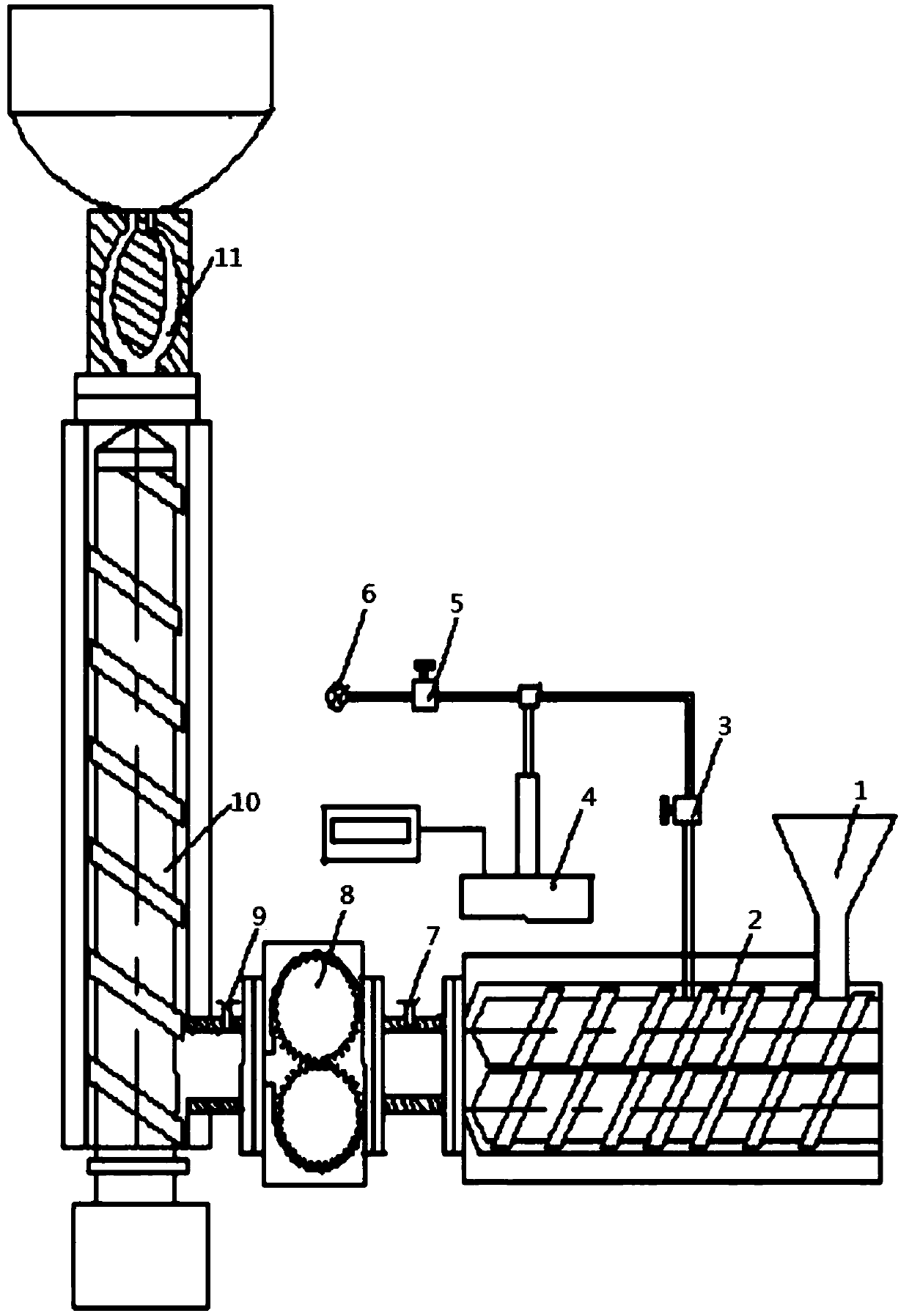

Thermoplastic polyester extrusion foam forming method

The invention provides a thermoplastic polyester extrusion foam forming method. The thermoplastic polyester extrusion foam forming method comprises the following steps that thermoplastic polyester, alubricant and a blowing promoter are added in a double-screw extruder for smelting, wherein the pressure of an outlet of the double-screw extruder is 3MPa-10MPa; a physical blowing agent is introducedin a thermoplastic polyester melt, and the mixture is conveyed to a single-screw extruder by a melt pump after mixing, wherein the pressure of an inlet of the single-screw extruder is 15MPa-25MPa; and the temperature of the thermoplastic polyester melt containing the physical blowing agent is lowered by the single-screw extruder, extruding and foaming are conducted with a die, and a thermoplasticpolyester foamed product is obtained after cooling and forming. The high temperature resistant lubricant is added and the melt pump is adopted for adjusting and controlling, so that efficient, stableand high-quality production of thermoplastic polyester foaming and forming is achieved.

Owner:BEIJING UNIV OF CHEM TECH +1

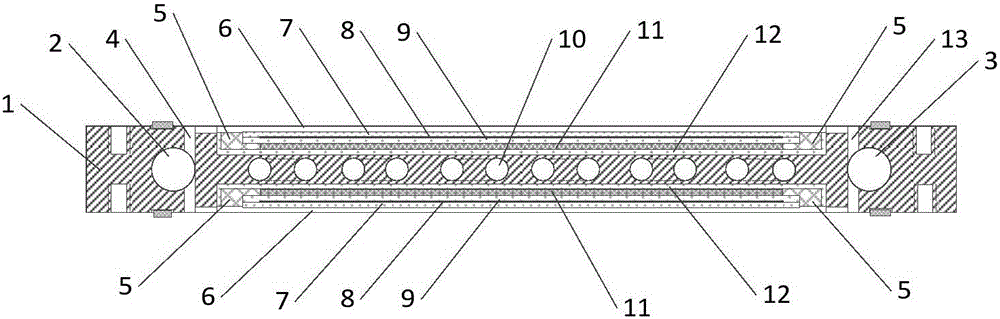

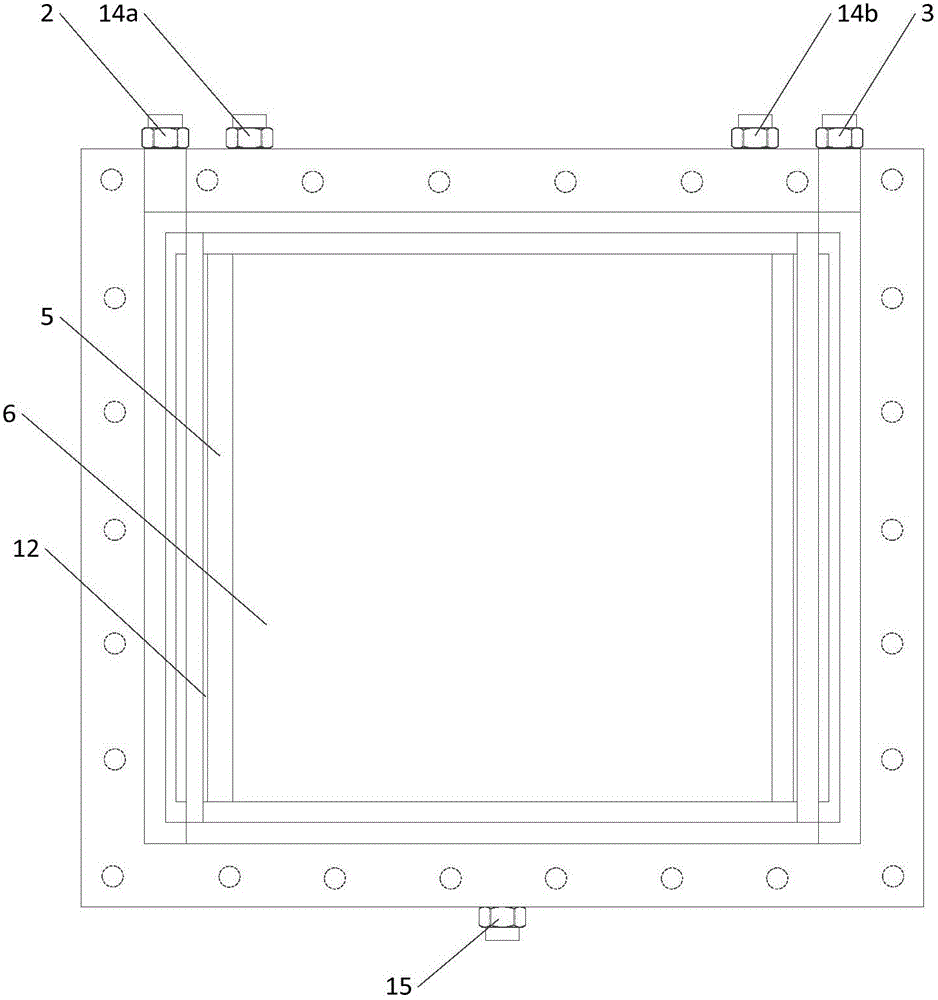

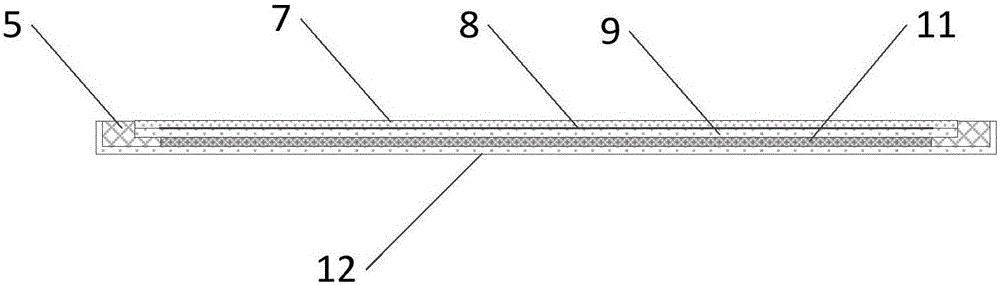

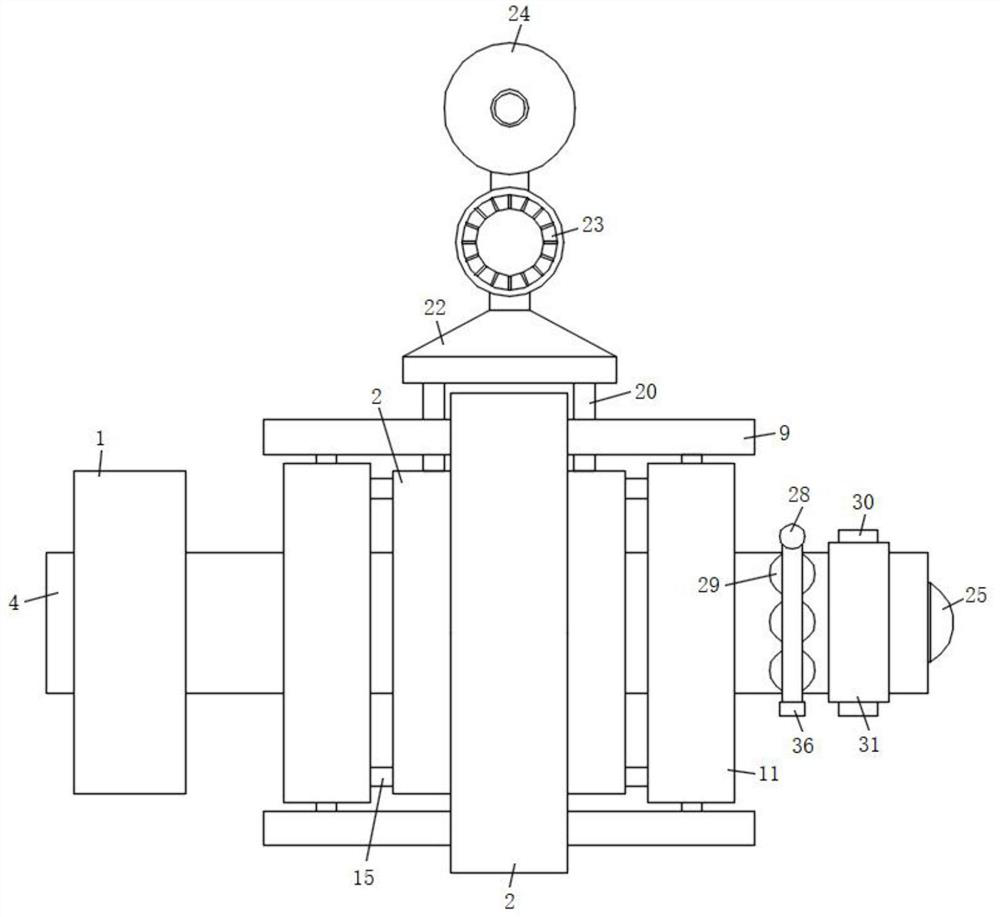

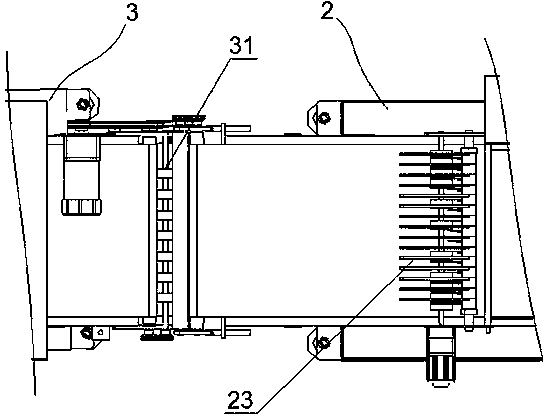

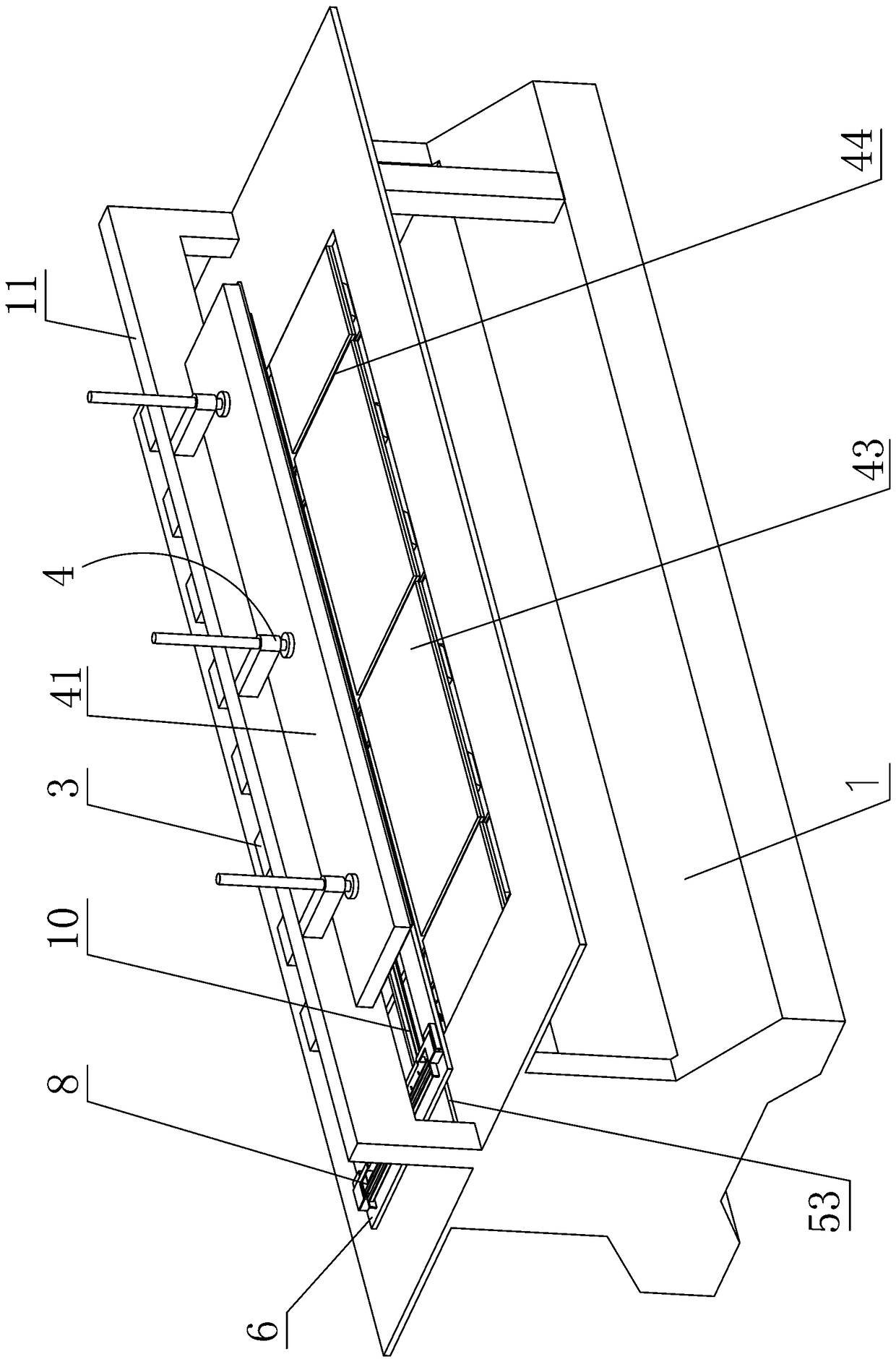

Dielectric barrier discharge plate, basic unit components of plate type ozonator and ozonator module

ActiveCN105692562AGood condition adjustmentEfficient productionElectrical discharge ozone preparationHeat conductingEngineering

The invention discloses a dielectric barrier discharge plate which comprises a plate body. An oxygen inlet, an oxygen outlet, a corresponding oxygen channel and a corresponding ozone channel are formed in the plate body. A cooling channel, a corresponding cooling water inlet and a corresponding cooling water outlet are further formed in the middle of the plate body. The upper face and the lower face of the cooling channel are each provided with a high voltage assembly. Each high voltage assembly comprises a groove-shaped ceramic vessel, and a square rubber gasket, a composite plate electrode and a heat conducting silica gel pad are arranged in a groove of each ceramic vessel, wherein the composite plate electrode and the heat conducting silica gel pad are arranged in the rubber gasket from top to bottom in an overlapped mode. The invention further discloses a plate type ozonator module with at least one set of basic unit components and a large plate type ozonator unit formed by at least one set of plate type ozonator modules.

Owner:北京天择昌宁环境技术股份有限公司

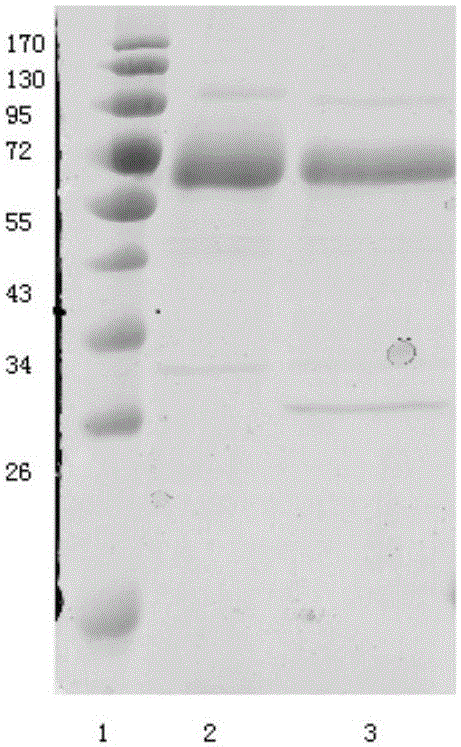

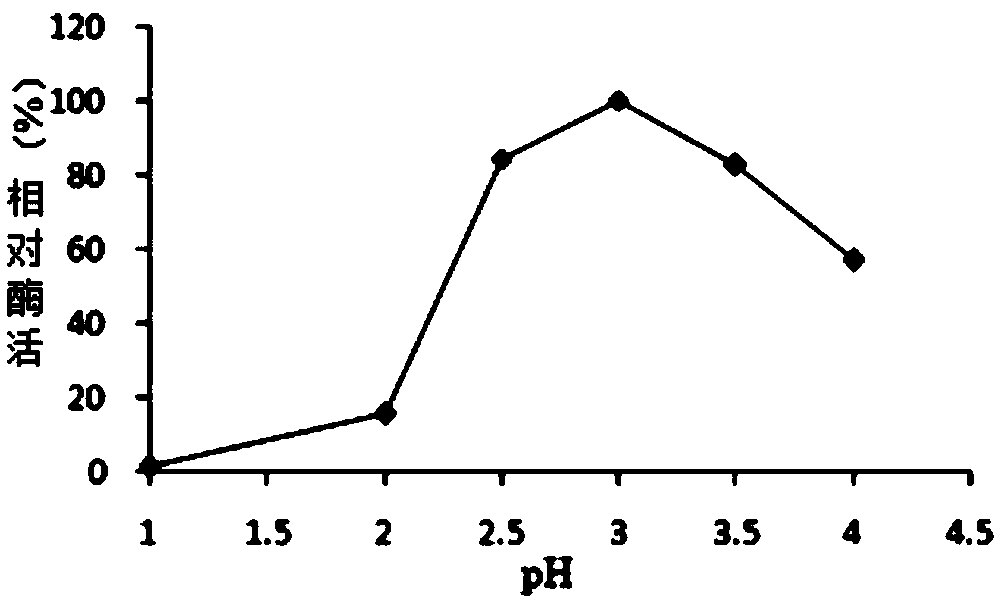

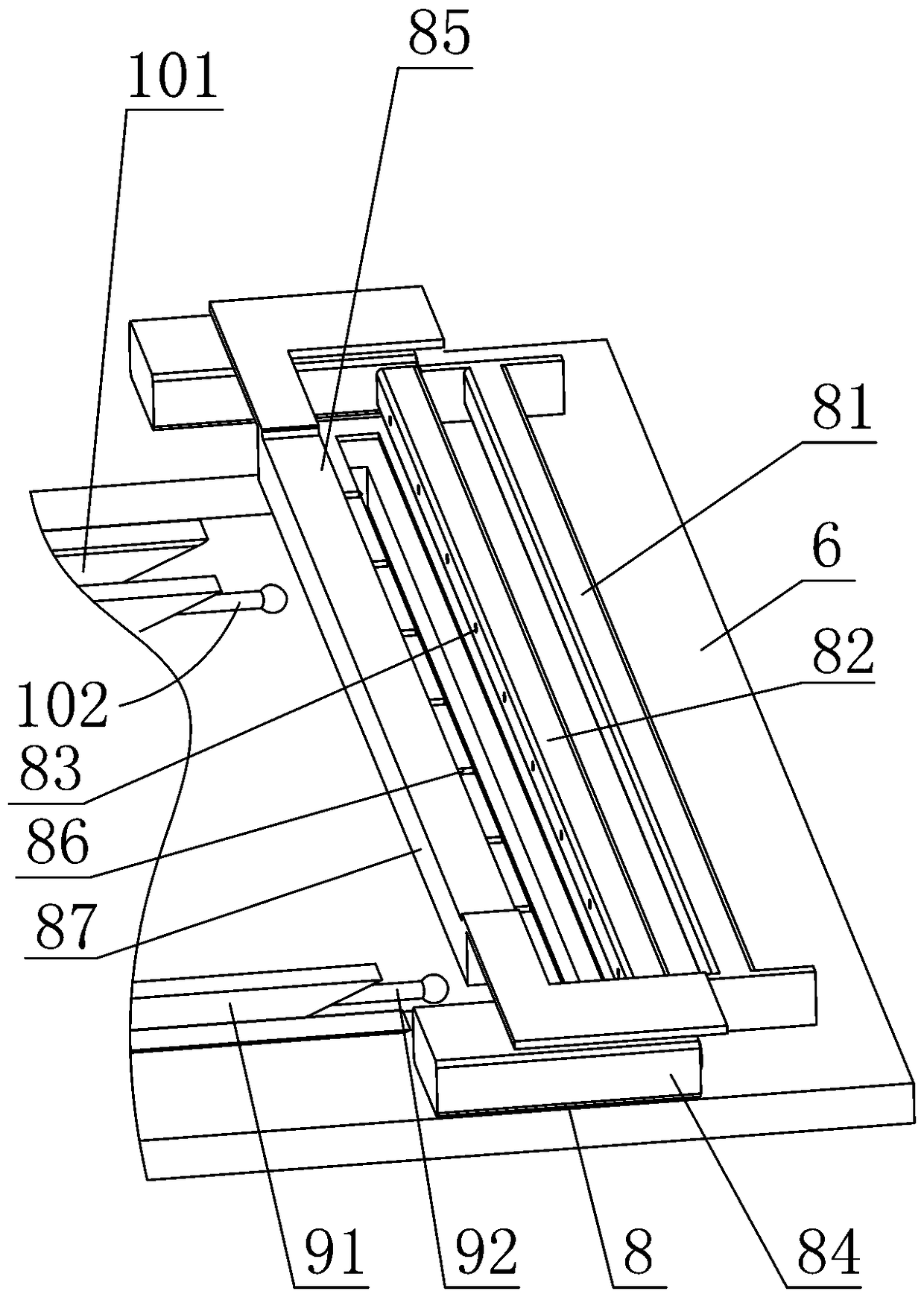

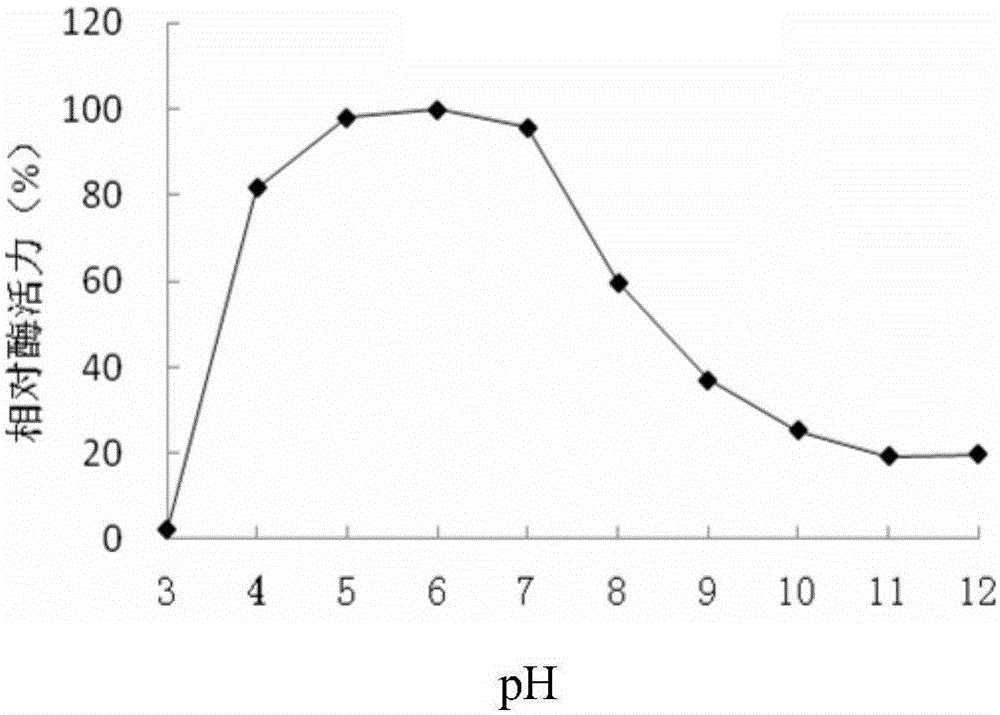

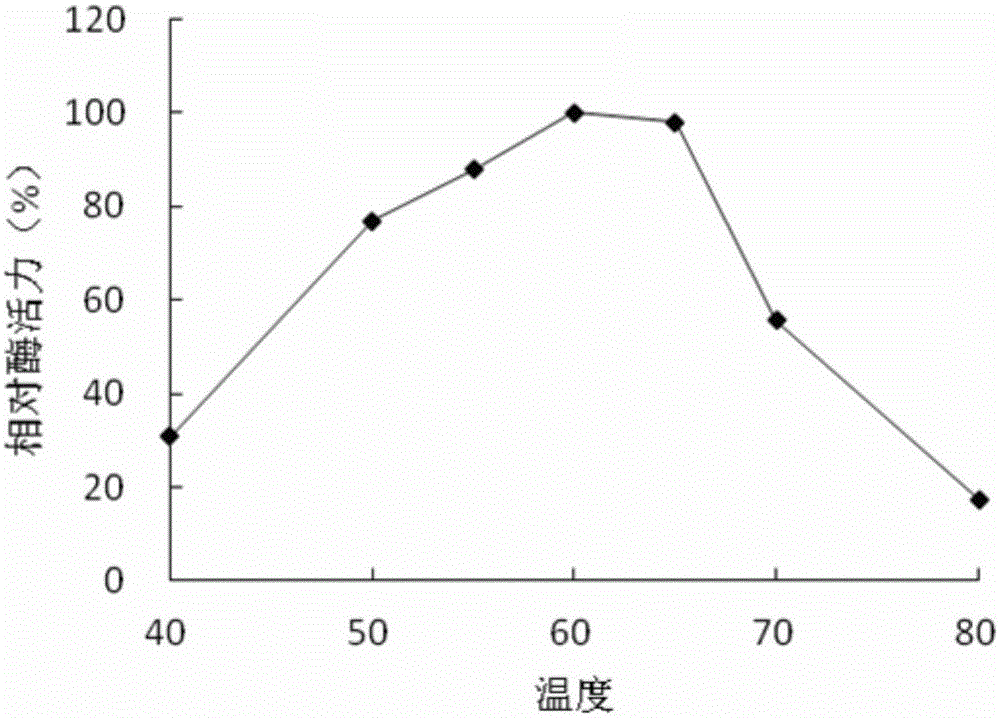

Fungus-derived acid protease 6749 as well as gene and application thereof

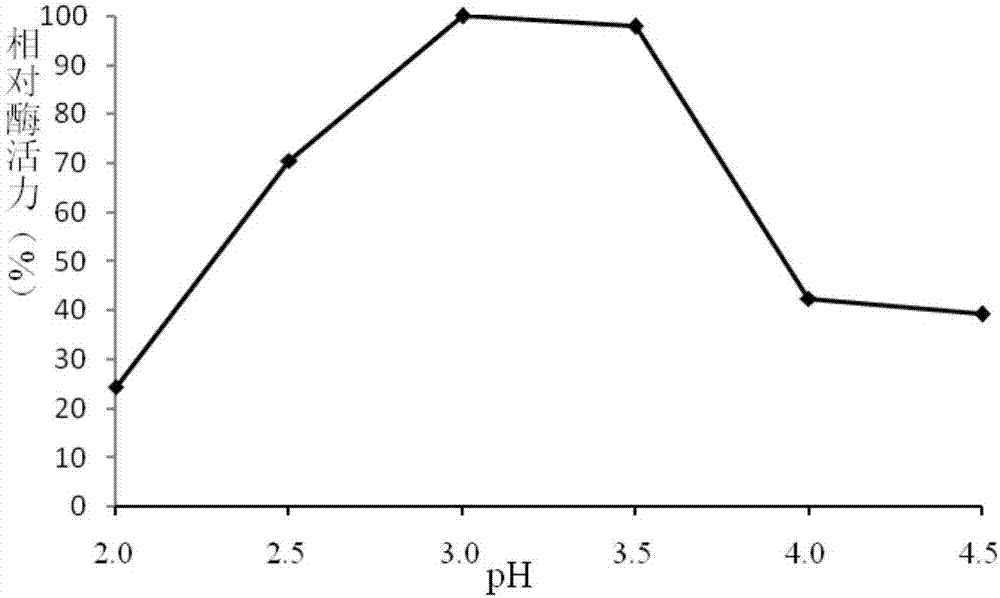

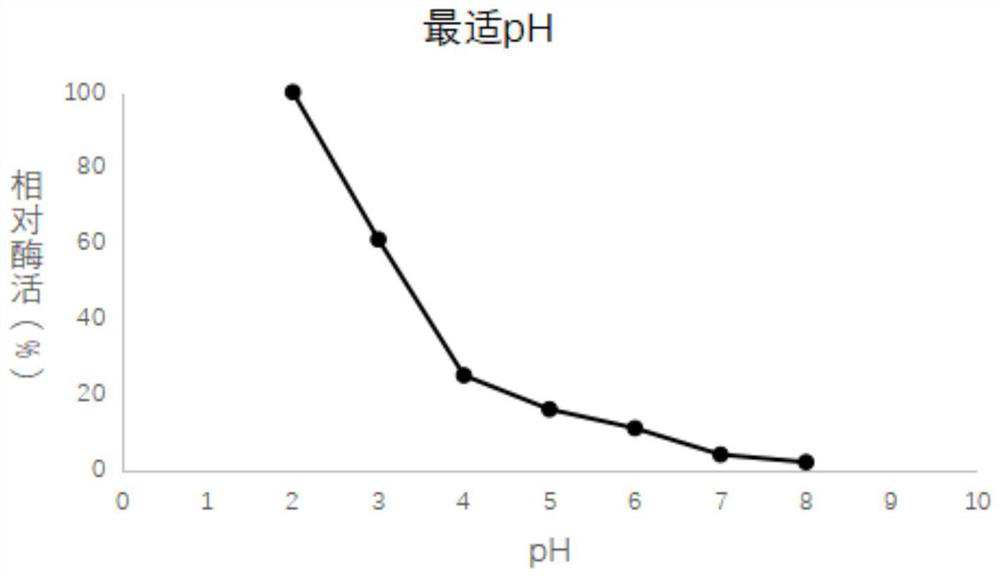

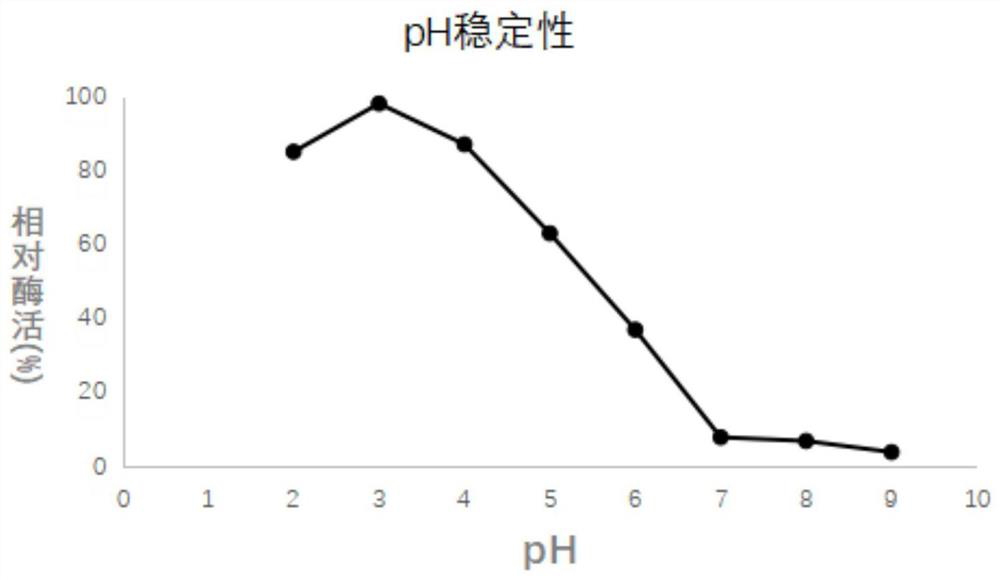

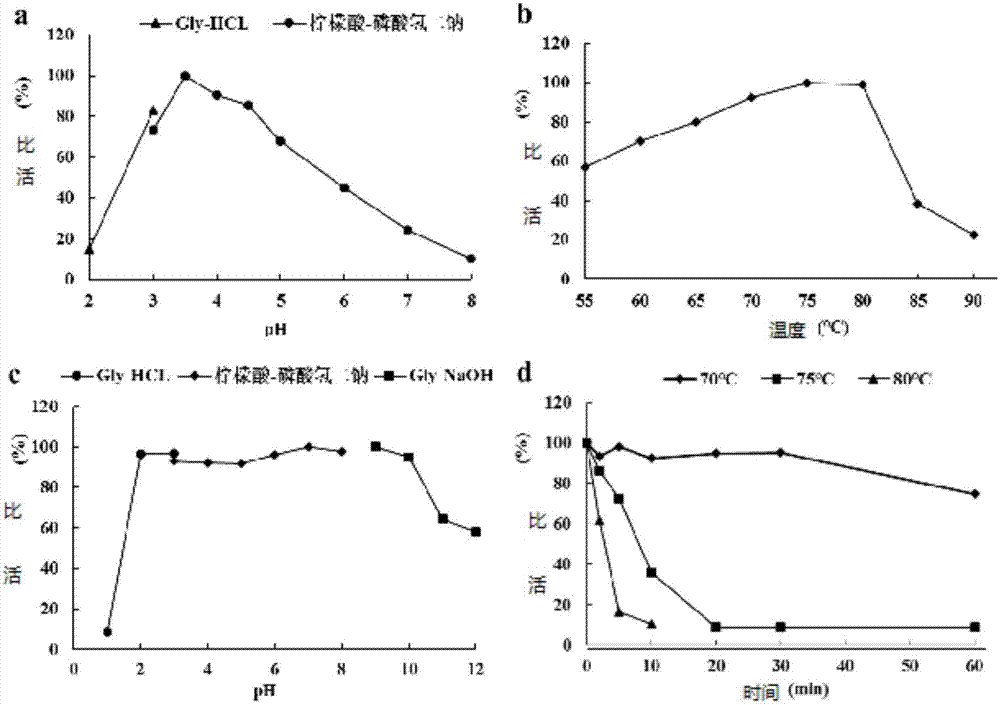

ActiveCN107384900AHigh activityRaise the reaction temperatureHydrolasesFermentationGenetic engineeringAcid protein

The invention relates to the field of genetic engineering. In particular, the invention relates to a fungus-derived acid protease 6749 as well as a gene and application thereof, and the amino acid sequence of the fungus-derived acid protease 6749 is shown as SEQ ID NO.1 or SEQ ID NO.2. The acid protease disclosed by the invention has good properties, and can be applied to industries such as food, feed and pharmacy. According to the technical solution of the invention, a genetic engineering means can be utilized to produce the protease with excellent properties which is suitable for industrial application.

Owner:INST OF ANIMAL SCI CAAS

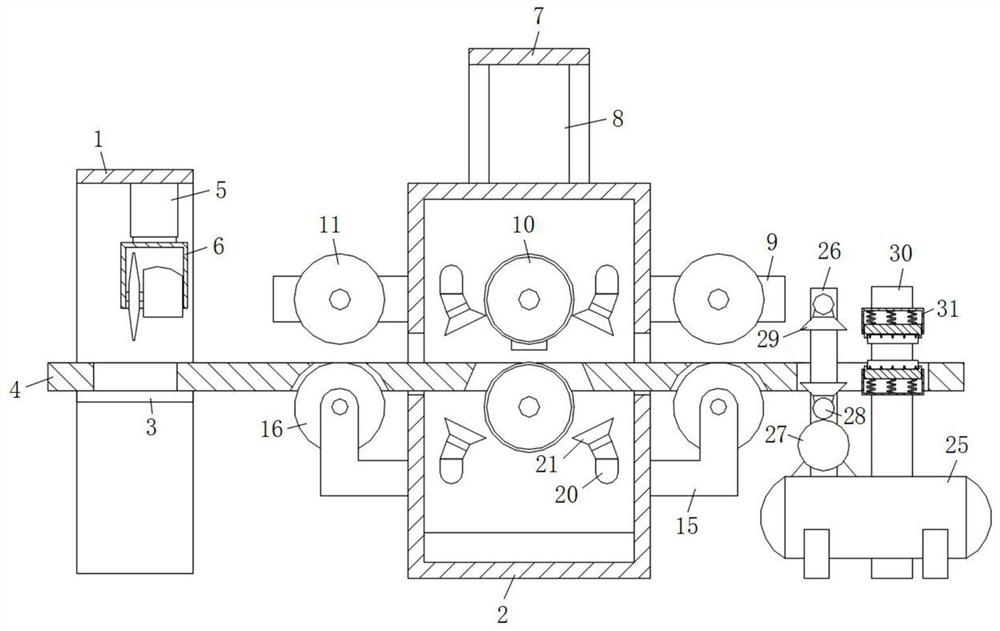

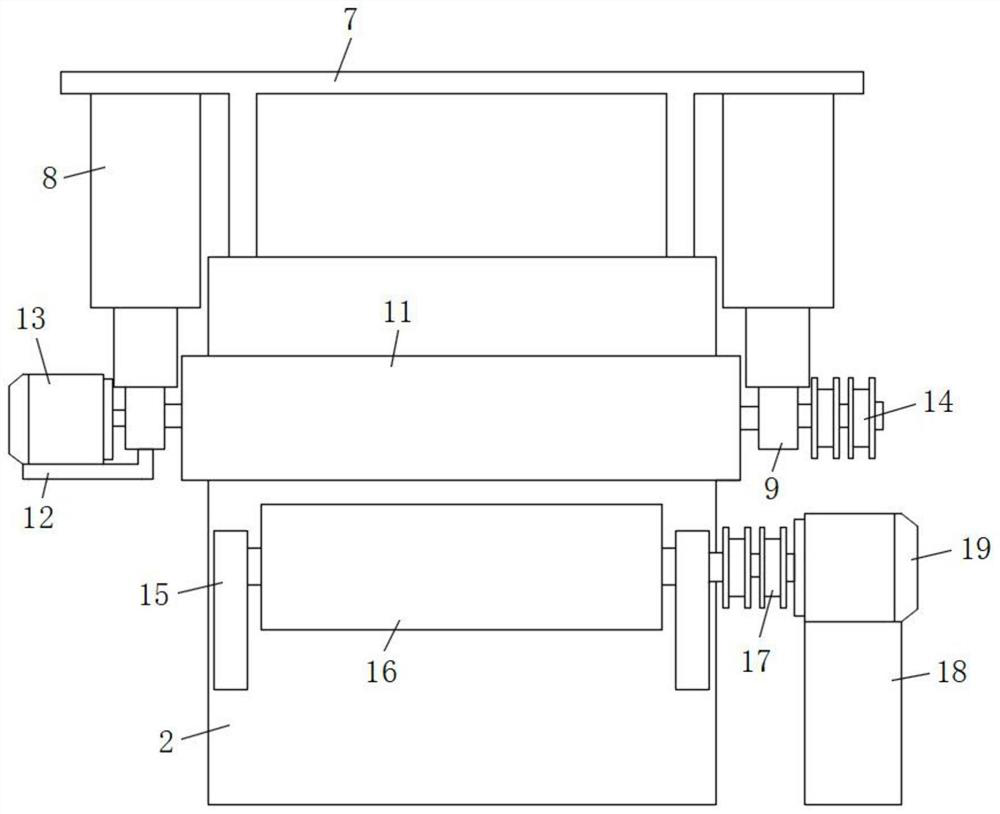

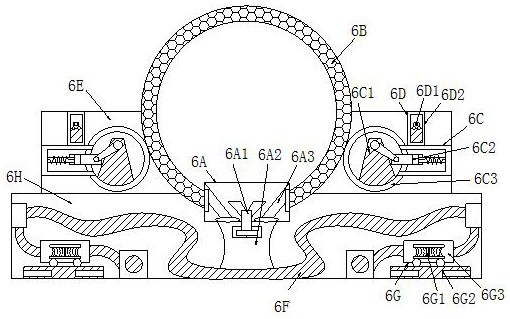

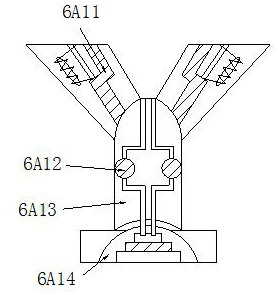

Wood board surface machining treatment device

InactiveCN112496909AContinuous processing is easy to operateAchieve double-sided grindingGrinding drivesProfiling/shaping machinesPolishingWood plank

The invention discloses a wood board surface machining treatment device which comprises a cutting frame and a polishing chamber; a supporting plate is further fixedly connected to the middle of the inner wall of the front end and the middle of the inner wall of the rear end of the cutting frame, rectangular holes are formed in the two sides of a polishing chamber in a penetrating mode, and a working plate is further fixedly connected between the bottom faces of the interiors of the rectangular holes and the top face of the supporting plate; a first air cylinder is fixedly connected to the inner top face of the cutting frame through screws, a cutting machine is fixedly connected to the output end of the first air cylinder through screws, a mounting frame is fixedly connected to the outer top face of the polishing chamber, second air cylinders are fixedly connected to the front side and the rear side of the bottom face of the mounting frame through screws, and mounting strips are fixedlyconnected to the output ends of the second air cylinders through screws; and polishing rollers are rotatably connected to the middles of the two mounting strips and the lower sides of the inner wallsof the front end and the rear end of the polishing chamber correspondingly, and first pushing rollers are further rotatably connected to the two sides of the two mounting strips. The wood board surface machining treatment device is reasonable in design and stable, continuous machining operation of wood boards is easy and convenient, double-face polishing and waxing operation of the wood boards can be achieved at the same time, and the working efficiency of wood board machining is greatly improved.

Owner:怀宁县三兴木业有限公司

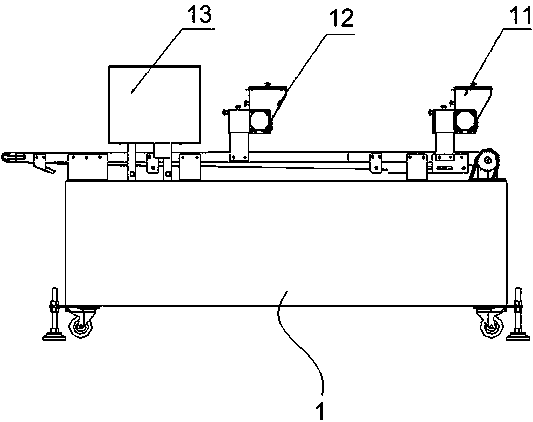

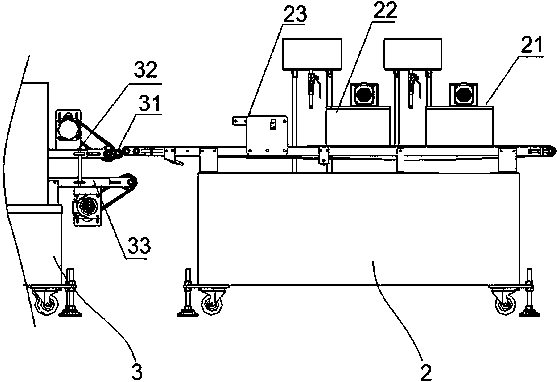

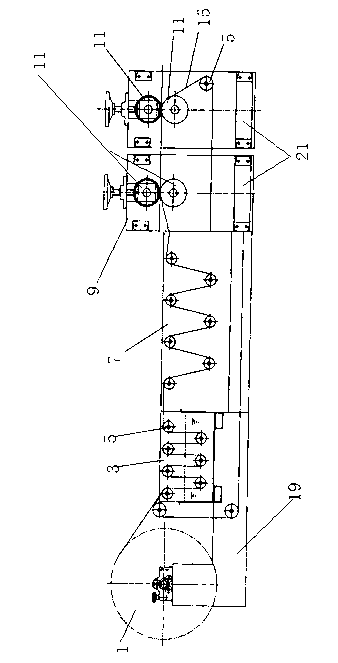

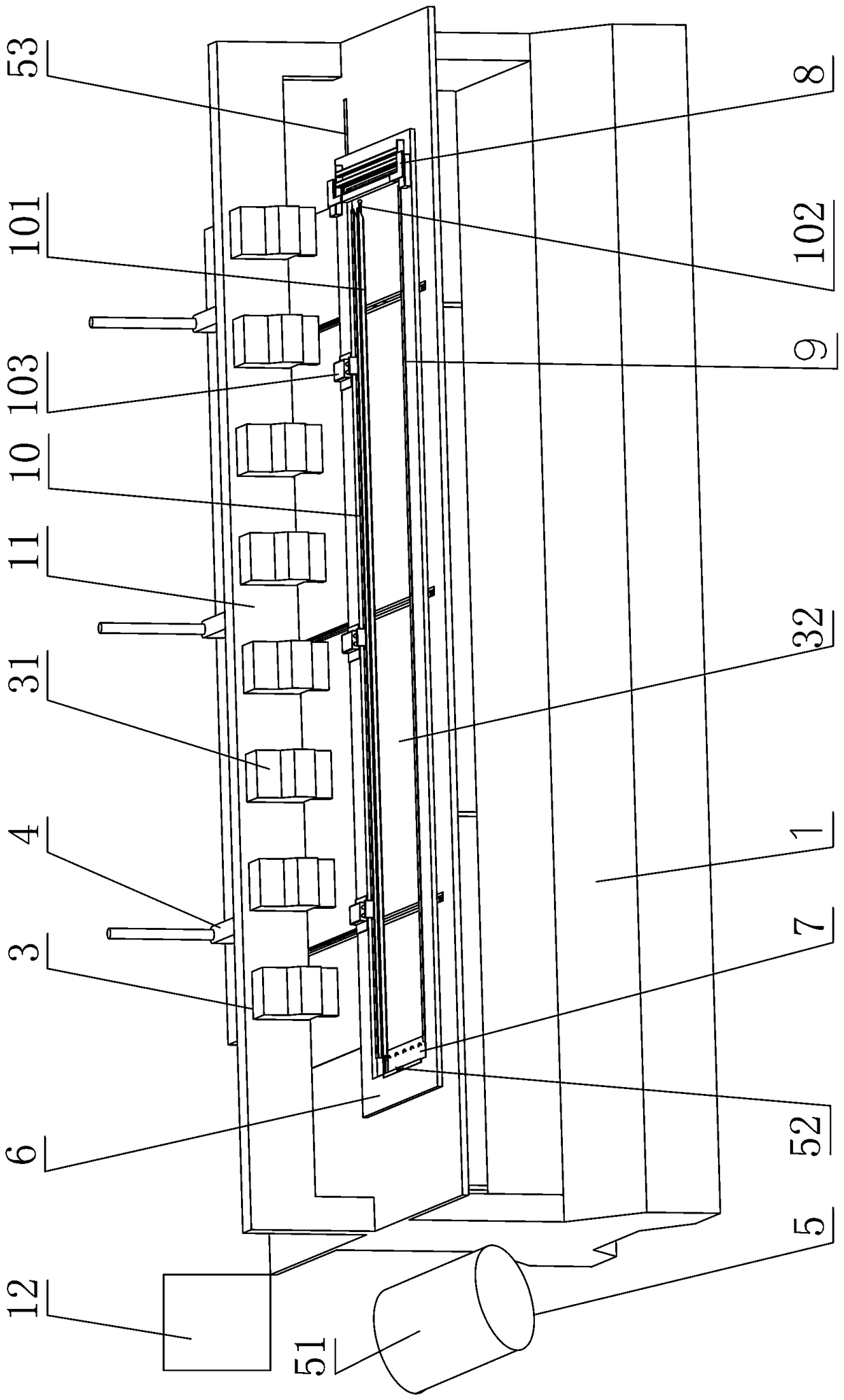

Imitating handmade full-automatic raw twisted cruller production line

ActiveCN111374155AReduce stressOvercome partial shrinkageDough-sheeters/rolling-machines/rolling-pinsDough dividingMechanical engineeringFully automated

The invention discloses an imitating handmade full-automatic raw twisted cruller production line which at least includes a horizontal reciprocating dough rolling device, an interval oil-water brushingcutting device, a stacking creasing device, a stretching device and a cutting device. A reciprocating dough rolling mechanism applies reciprocating rolling non-parallel to the conveying direction ona dough material to form a dough strip; the interval oil-water brushing cutting device brushes water and oil at intervals along the dough strip conveying direction and divides the dough strip into a plurality of dough strips; stacked two-layer dough strips are pressed for creasing through the stacking creasing device; the stretching device elongates the dough strips; and the cutting device cuts the elongated dough strips to form raw twisted cruller. According to the structural design of the imitating handmade full-automatic raw twisted cruller production line, full-automatic production is realized, the quality that the produced raw twisted cruller imitates hand-made raw twisted cruller is achieved, the produced raw twisted cruller are better than hand-made, the taste of the fried raw twisted cruller is the same as that of the hand-made, even better, and efficiency and high-quality production are achieved.

Owner:SUZHOU GUOEN FOOD MACHINERY

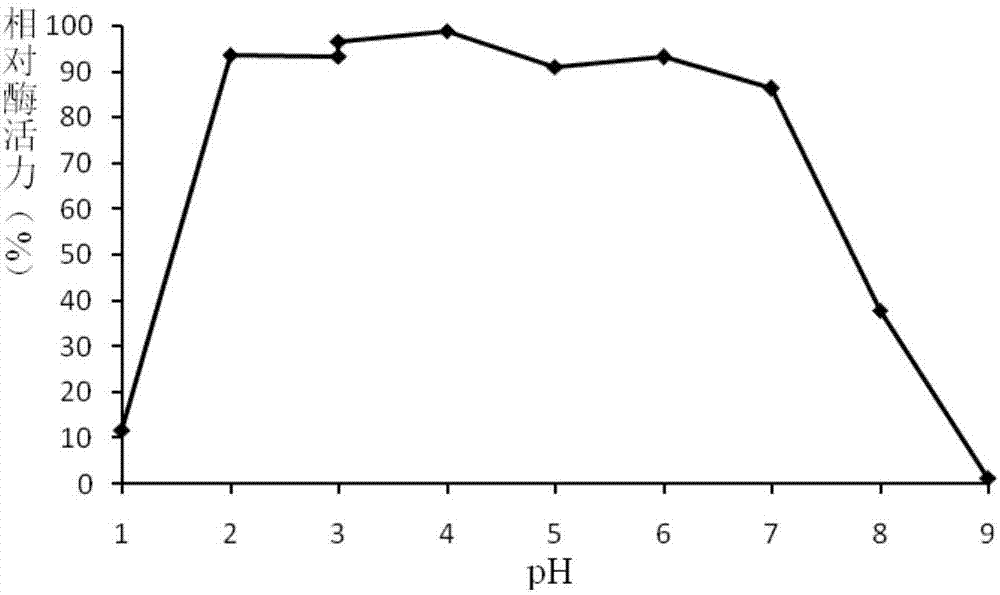

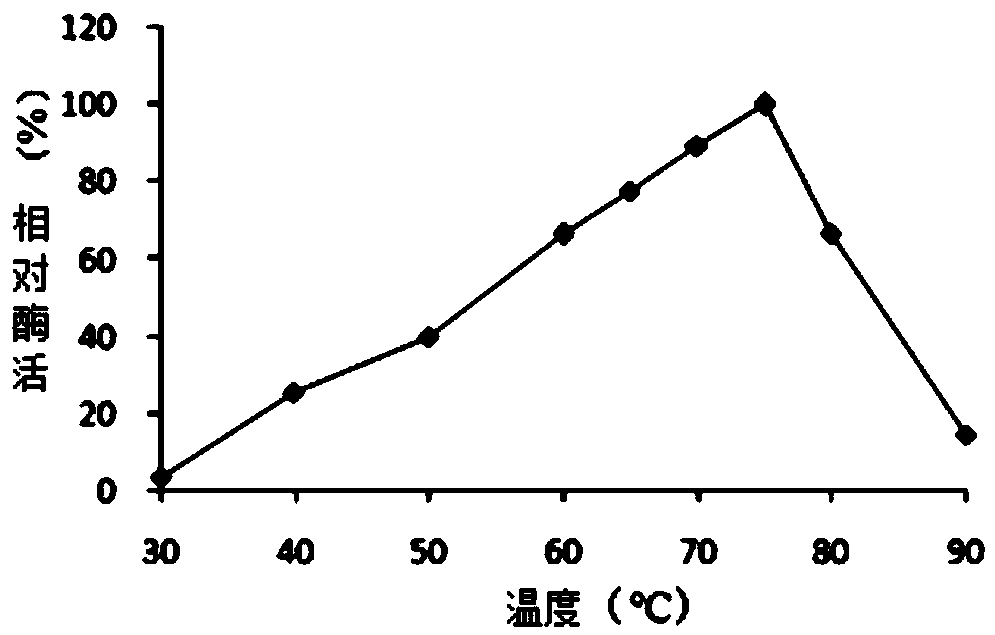

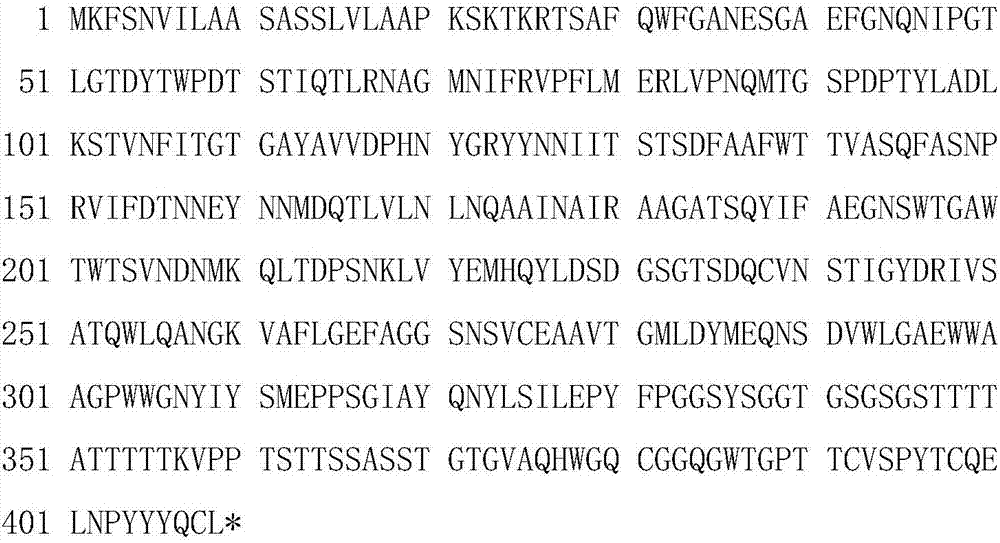

Heat-resisting acidic cellulase of fungus source and gene and application thereof

ActiveCN105018448AHigh quality productionExcellent production properties suitable forFungiMicroorganism based processesAmino acidCellulase

The invention relates to the field of gene engineering, in particular to heat-resisting acidic cellulase of a fungus source and a gene and application thereof. The amino acid sequence of the heat-resisting acidic cellulase is showed as in SEQ ID NO.1 or SEQ ID NO.2. According to the novel gene of the cellulase, the coded cellulase of the novel gene has good performance and can be applied to industries of feedstuff, foods, medicine and others. According to the technical scheme, by the means of gene engineering, the cellulase excellent in performance and suitable for industrial application can be produced.

Owner:INST OF ANIMAL SCI CAAS

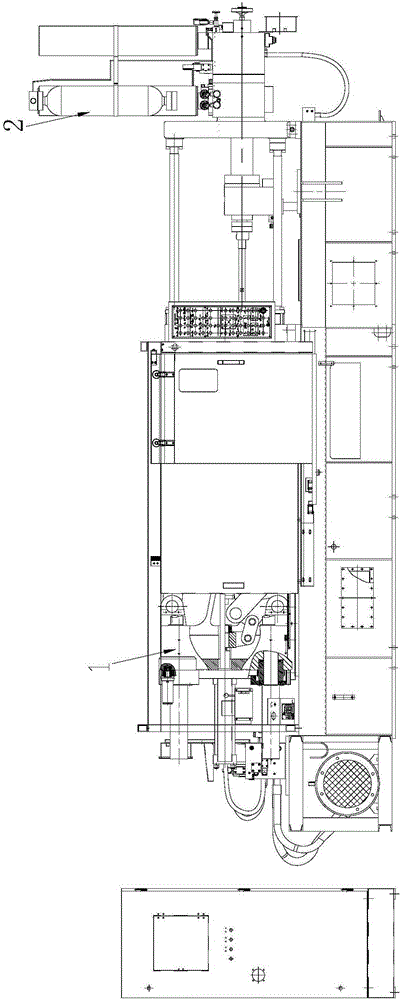

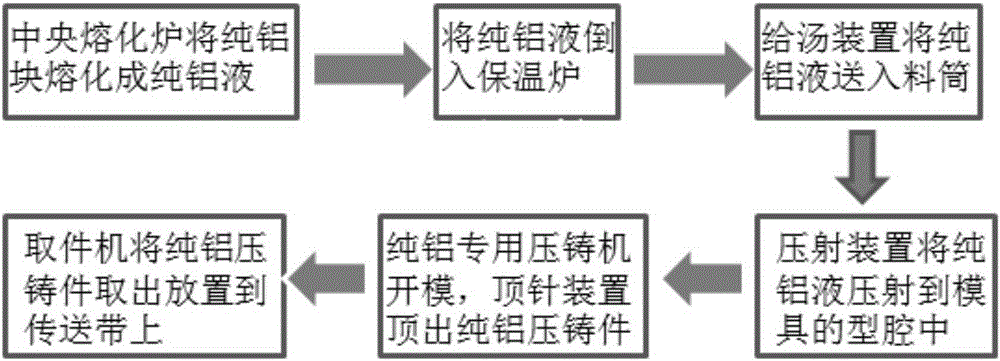

Pure-aluminium die casting equipment and pure-aluminium die casting technology

InactiveCN105234368AOvercome the problem of high resistance caused by poor liquidityImprove performanceDie castingElectro hydraulic

The invention is applicable to the technical field of pure-aluminium die casting, and discloses pure-aluminium die casting equipment and a pure-aluminium die casting technology. The pure-aluminium die casting equipment comprises a die-casting machine connected with a die-casting die; the die-casting machine comprises a material feeding barrel; the pure-aluminium die casting equipment further comprises a central melting furnace used for heating and melting an aluminium block, a heat preserving furnace used for performing heat preservation on molten aluminium, a molten aluminium feeding device used for conveying the molten aluminium into the material feeding barrel and a press-shooting device used for press-shooting the molten aluminium from the material feeding barrel to the die cavity of the die casting die; an ejecting device used for ejecting a formed product from the die cavity is arranged on one side of the die casting die; and the press-shooting device is provided with an electro-hydraulic proportional throttle valve with valve core position feedback. The above pure-aluminium die casting equipment is adopted in the pure-aluminium die casting technology. By adopting the pure-aluminium die casting equipment and the pure-aluminium die casting technology provided by the invention, the production qualification rate is high; the cost is low; and the requirement of markets on volume production of pure-aluminium parts is met.

Owner:SHENZHEN LEADWELL TECH CO LTD

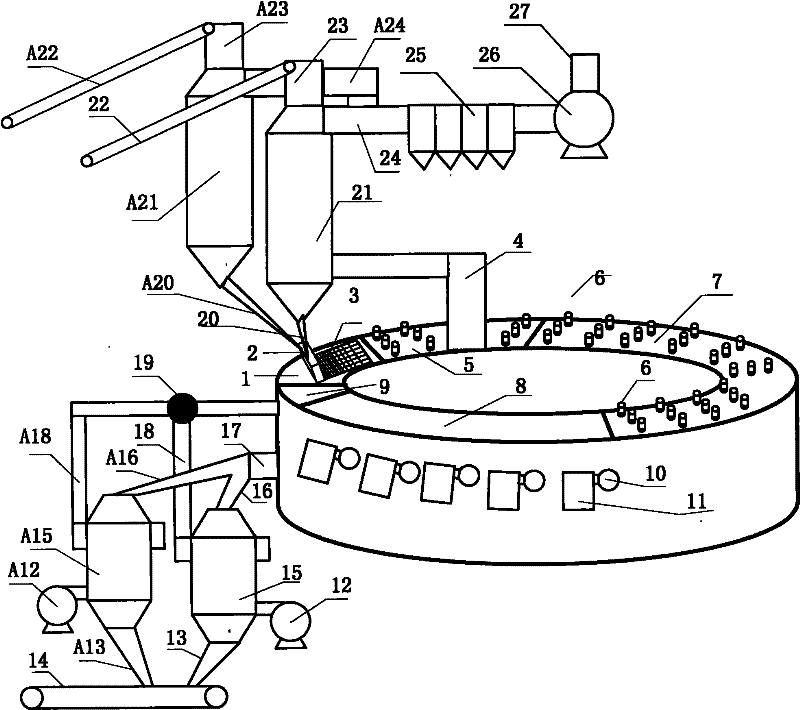

Semi-heat accumulating type rotating bed equipment and process for producing large-size high-activity lime

InactiveCN102183142AEfficient recyclingHigh activityFurnace typesLime productionSocial benefitsCombustion

The invention relates to semi-heat accumulating type rotating bed equipment and a process for producing large-size high-activity lime. Due to the application of a top combustion nozzle and a heat accumulating combustion nozzle as well as the design of a rotating bed in a longer soaking area, lime with the particle sizes of 10-200mm can be burnt at the same time, and mineral resources are utilizedsufficiently. Small-sized, medium-sized and large-sized lime can be arranged at different layers, so that overburning and unburnt problems are effectively prevented, the unburnt rate is smaller than 0.5%, and the activity of the lime is increased to 380-420ml. Due to the application of the technology of the rotating bed, powder of the lime product is reduced from 12-30% to 3.0-5.0% compared with that of the traditional equipment, the daily output of the lime reaches 1500-4000 tons, and high-efficiency and high-quality production of the lime is realized. High-temperature smoke of the rotating bed is used for preheating limestone; the heat of high-temperature lime is used for preheating combustion supporting air; and the heat in the system is utilized effectively and comprehensively; moreover, the semi-heat accumulating type rotating bed equipment has the advantages of low comprehensive energy consumption, low production cost and obvious economic and social benefits.

Owner:周生献

acid protease Bs2688 and gene and application thereof

PendingCN108893458AHigh quality productionHydrolasesMicroorganism based processesBiotechnologyGenetic engineering

The invention belongs to the technical field of agro-biology and particularly relates to fungus-originated acid protease Bs2688 and gene and application thereof. An amino acid sequence of the acid protease is shown as SEQ ID NO. 1 or SEQ ID NO. 2. The invention provides a new protease gene; proteinases with good character are produced by means of genetic engineering; the new protease gene is applicable to the industries, such as feed, food and medicine.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Non-woven fabric production line

InactiveCN103215776AEasy to operateEfficient productionLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor textile treatmentWoven fabricProduction line

The invention discloses a non-woven fabric production line which comprises an uncoiling machine, a dye vat, a roller, a driving conveyer belt, a wringing part, a nip roll and a wire belt. The non-woven fabric production line is characterized in that the right end of the uncoiling machine is connected with the dye vat, the right end of the dye vat is connected with the driving conveyer belt, the right end of the driving conveyer belt is connected with the wringing part, and the wire belt is connected to the roller and the nip roll. The non-woven fabric production line disclosed by the invention is convenient to operate; and due to a technical scheme provided by the invention, the deficiency of the existing non-woven fabric production is solved, and the high-quality and efficient production of non-woven fabrics can be realized.

Owner:江苏三羊纺织机械有限公司

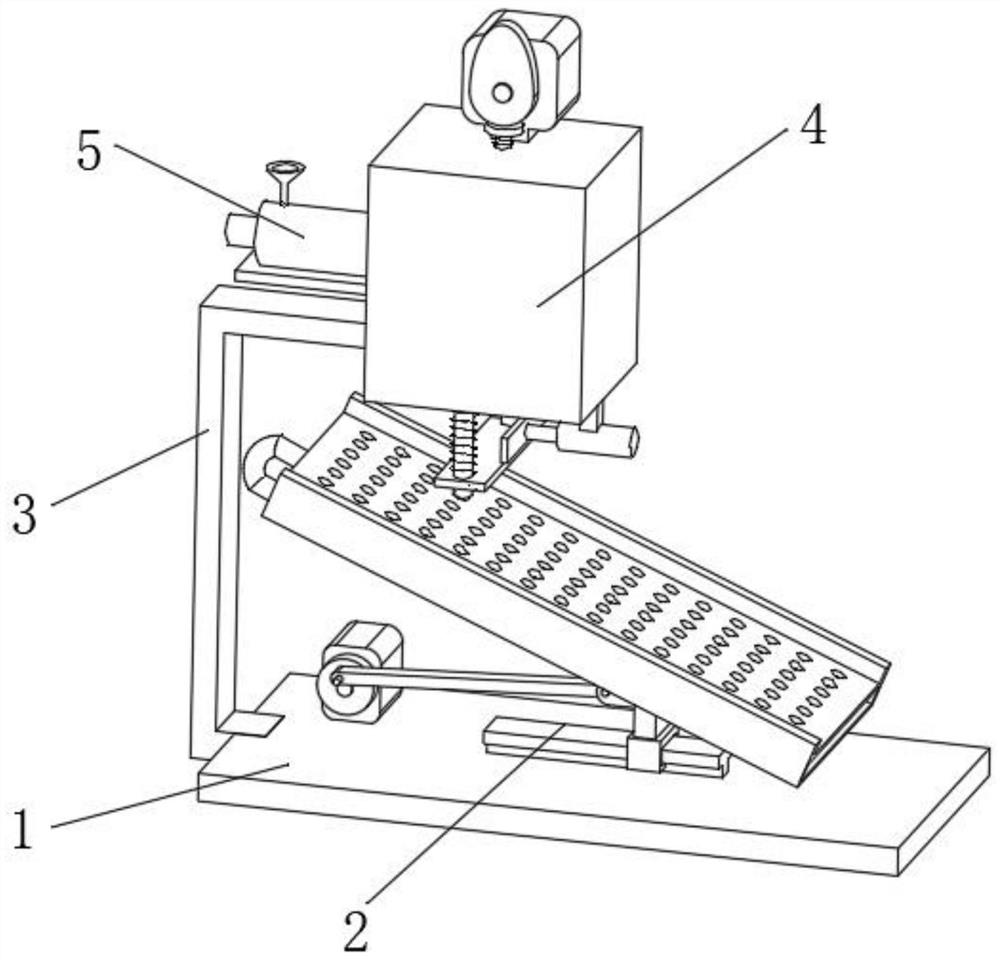

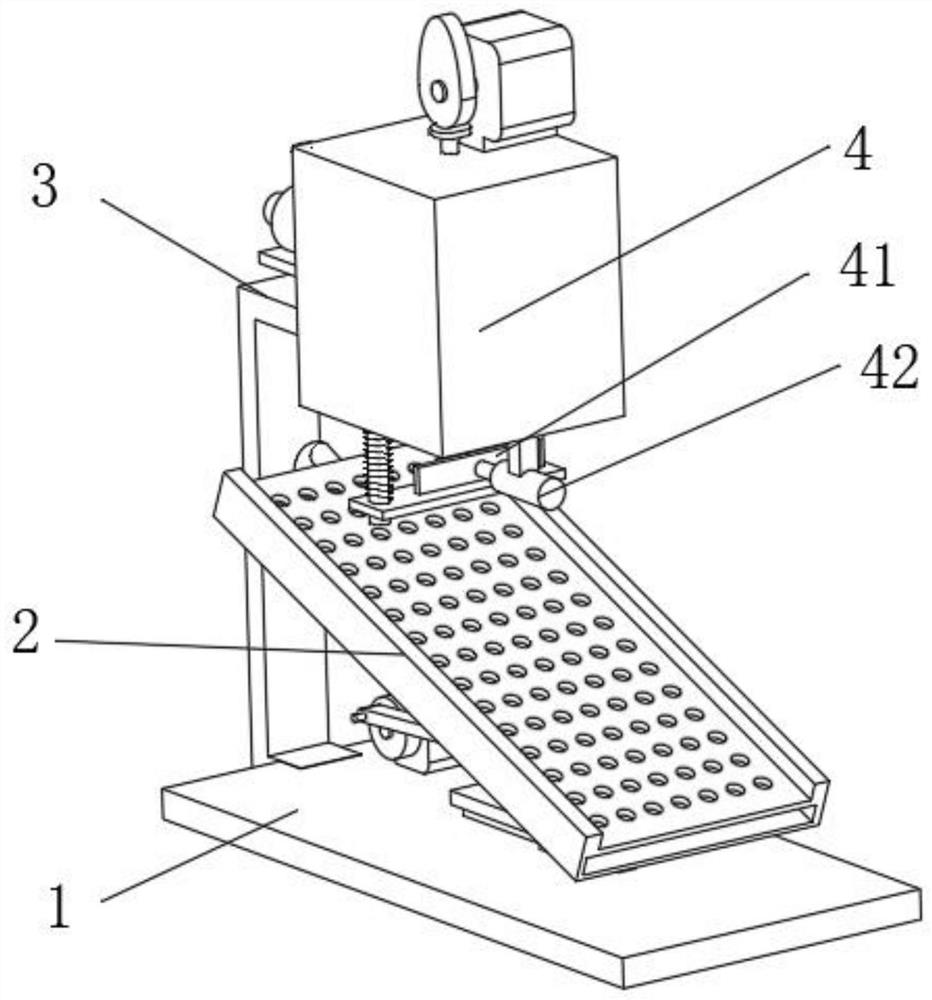

Tension-feeding and die-cutting automatic embroidering machine and operation method thereof

PendingCN108166180AIncrease adaptive strengthGuaranteed embroidery effectSevering textilesAutomatic machinesEngineeringAutomation

The invention provides a tension-feeding and die-cutting automatic embroidering machine and an operation method thereof. The tension-feeding and die-cutting automatic embroidering machine comprises amachine frame, a movable processing component, a tensioning component, a movable driving component, an embroidering component, a profiling cutting component and a material winding component, wherein amonitoring component connected with each component and used for controlling the running order of each component is arranged on the machine frame, so that automatic and cyclic completion of a series of processes of feeding, tensioning, embroidering, profiling cutting and material winding is achieved; furthermore, the tension-feeding and die-cutting automatic embroidering machine can also control the tension of the material according to the characteristics of the material to be processed so as to ensure the flatness during processing, is strong in adaptability and guarantees the embroidering effect; in addition, the tension-feeding and die-cutting automatic embroidering machine can also use a stamping cutting die for performing one-time overall profiling and cutting on a product, achieves precise and high-efficiency cutting and yclic automation, and is strong in adaptability, high in quality and high in efficiency.

Owner:严伟强

Acidic cellulose from fungus and gene and application thereof

ActiveCN105154417AHigh quality productionExcellent production properties suitable forFungiMicroorganism based processesCellulaseGenetic engineering

The invention relates to the field of genetic engineering, in particular to acidic cellulose from a fungus and a gene and application thereof. The amino acid sequence of the acidic cellulose is shown as SEQ ID NO. 1 or SEQ ID NO. 2. The invention further provides the novel acidic cellulose gene. The acidic cellulose encoded by the acidic cellulose gene has good property and can be applied to feeds, foods, pharmaceuticals and other industries. By means of the technical scheme, the acidic cellulose having excellent property and suitable for industrial application can be produced by adopting a genetic engineering means.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Production method and production equipment of special compound fertilizer for lotus roots.

InactiveCN112250504AImprove decomposition abilityImprove toughnessSievingBio-organic fraction processingAgricultural engineeringPoultry manure

The invention discloses a production method of a special compound fertilizer for lotus roots. The method comprises the following steps: S1, uniformly mixing livestock and poultry manure and crushed straw according to a mass ratio of 2: 1 to obtain an organic matter mixture; placing microbial strains into a culture medium and comprising saccharomycetes, photosynthetic bacteria, rhizobium and sporebacteria, wherein the content of microorganisms in lotus root growth sludge is supplemented, the decomposition capacity of nutrient substances is improved, absorption of lotus roots is facilitated, and phosphorus-potassium fertilizer, urea, microelements, hexaurea ferric trinitrate and plant ash are mixed into a fermentation product; fully stirring and mixing the raw materials, then adding the radix puerariae powder and the tapioca flour, and fully and uniformly stirring to obtain a viscous mixed material, so that the toughness of the fertilizer can be improved, the loose texture of the fertilizer can be avoided, and slowly decomposing the fertilizer, continuously and efficiently providing nutrients for lotus roots, bysetting the extrusion granulation components, it is possible to push thefertilizer after molding, preparing fertilizer particles with uniform texture and balanced compactness , and realizing high-quality production of the fertilizer.

Owner:ANHUI SIERTE FERTILIZER IND

Prodn. technique of hollowed-out plane thin sheet metallic handicraft

InactiveCN1833881AHigh precisionImprove the finishDecorative surface effectsSpecial ornamental structuresMetal sheetThin sheet

Owner:TIANHUYINLOW

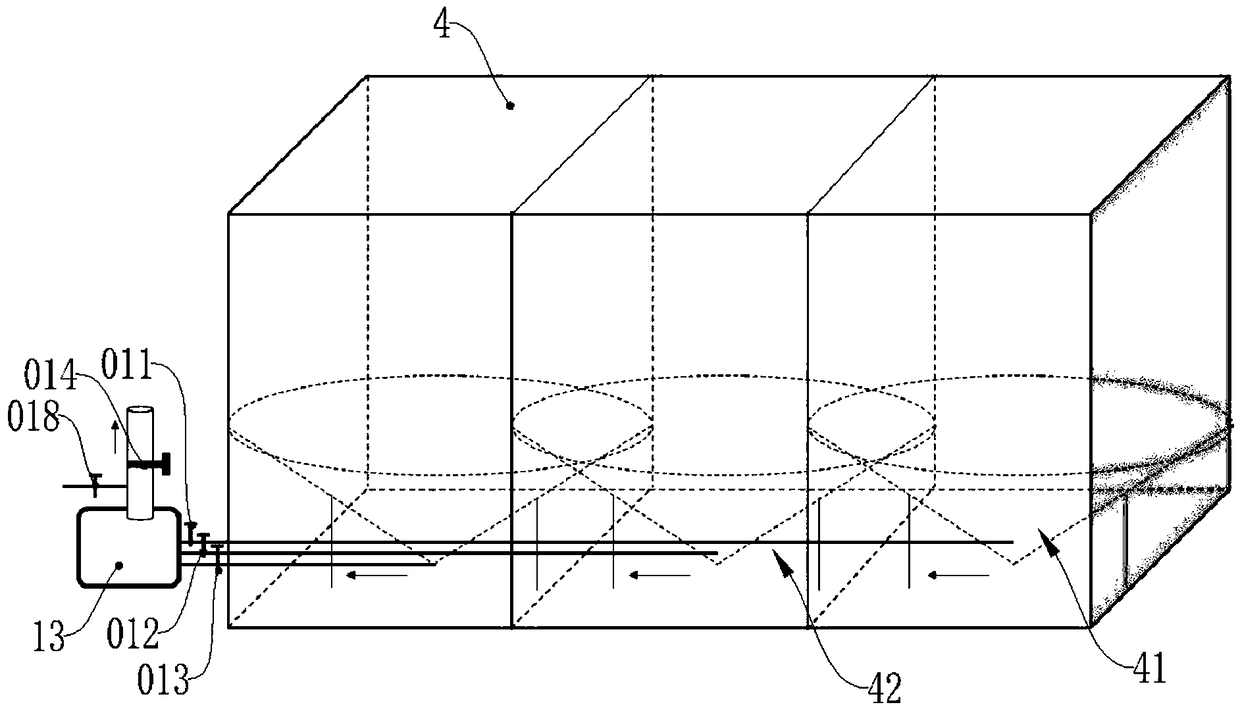

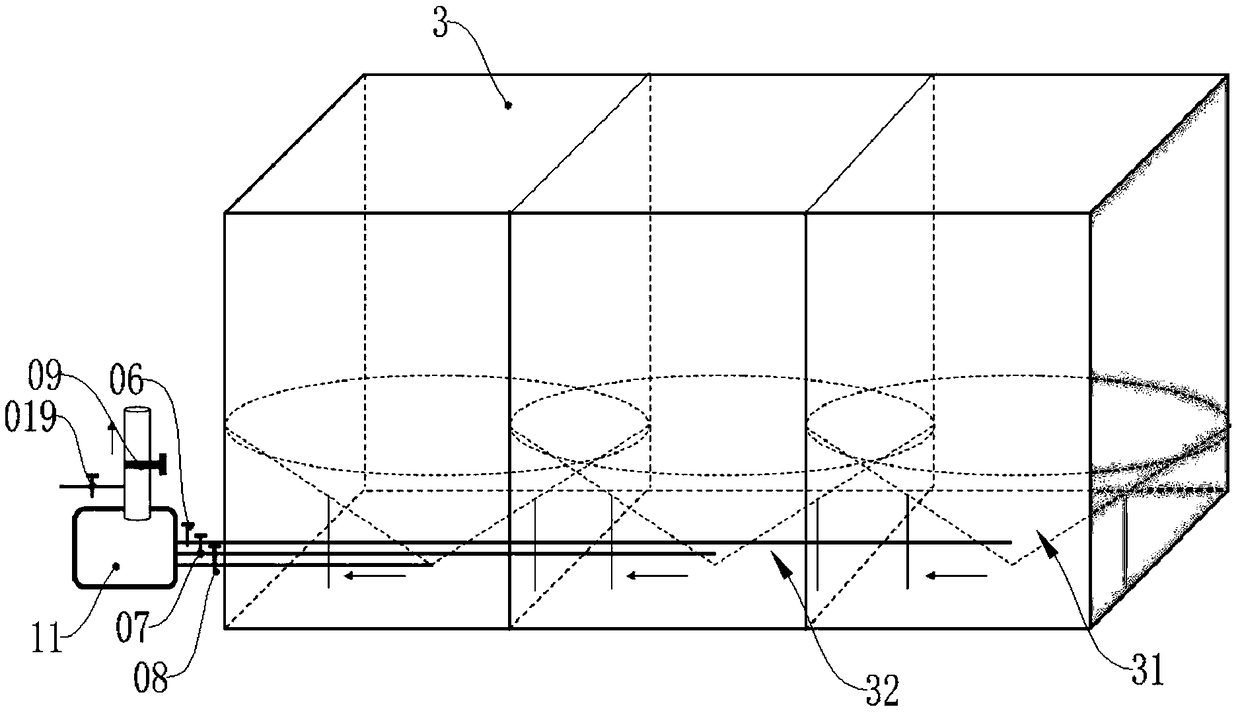

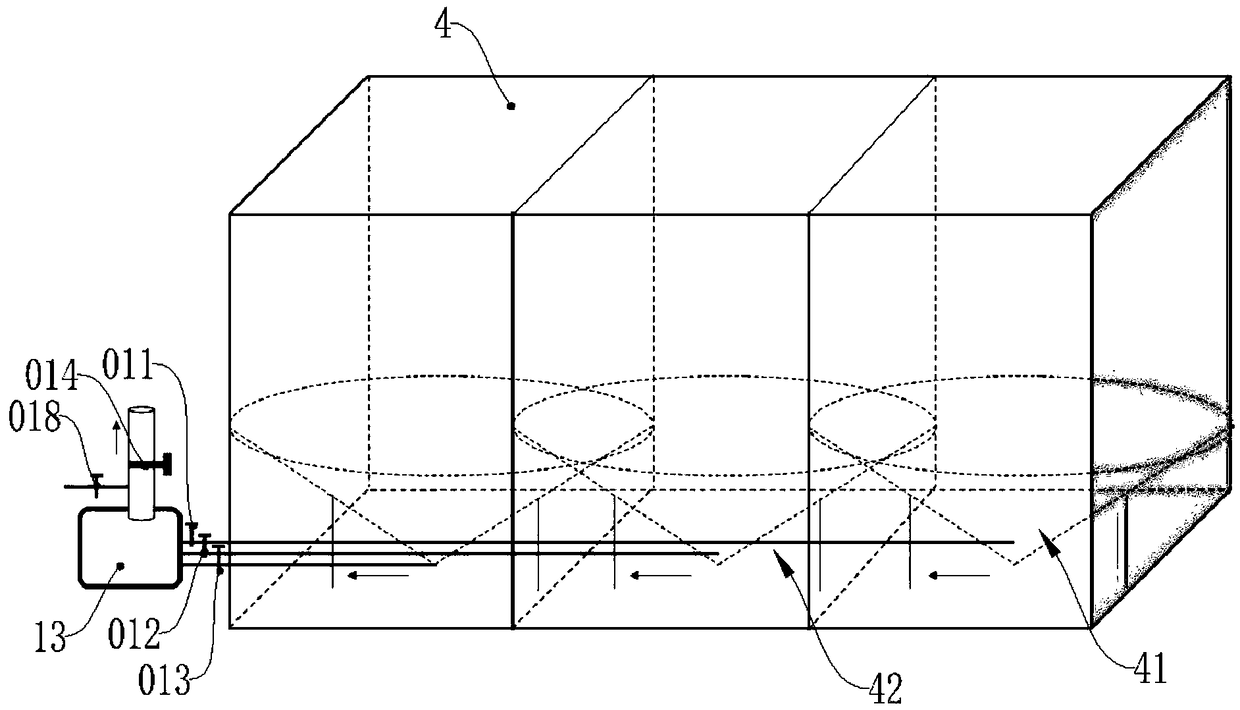

Rotary bed equipment and method for producing solid-phase fluoride

PendingCN108889252ASimple structureEasy to make and maintainDispersed particle separationVapor condensationDistribution systemDiluent

The invention discloses rotary bed equipment and method for producing solid-phase fluoride. The rotary bed equipment comprises a rotary bed, the rotary bed comprises a rotary bed housing, the top of the rotary bed housing is provided with a feeding port and a fluorating agent / diluent gas inlet and distribution system, the bottom of the rotary bed housing is provided with an electric mechanism, theelectric mechanism is connected with a horizontally arranged rotary disc in the rotary bed housing through a rotary shaft, an end gas outlet is formed in the part, located on the top of the rotary bed housing, of the upper portion of the rotary disc, and a discharging port is formed in the bottom of the rotary bed housing. The equipment has the advantages of high continuous mechanization and highreaction efficiency, and high-efficiency and high-quality production of the solid-phase fluoride is easily achieved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

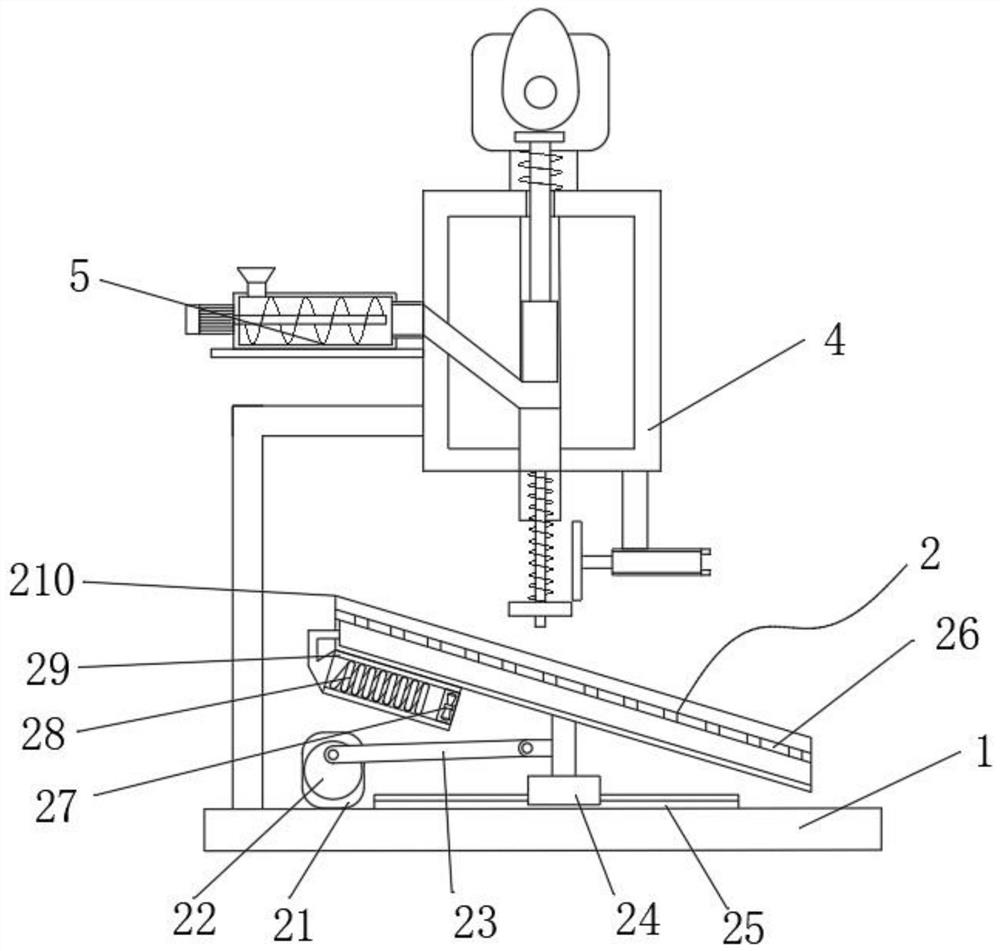

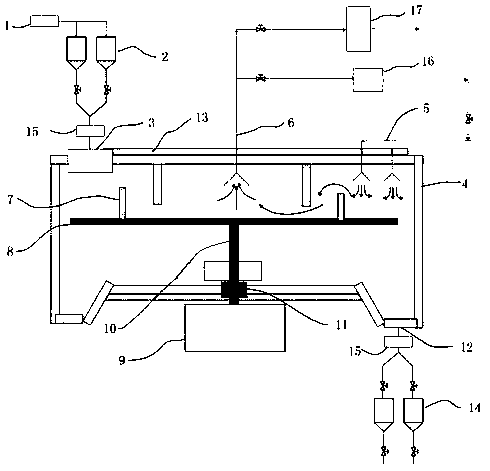

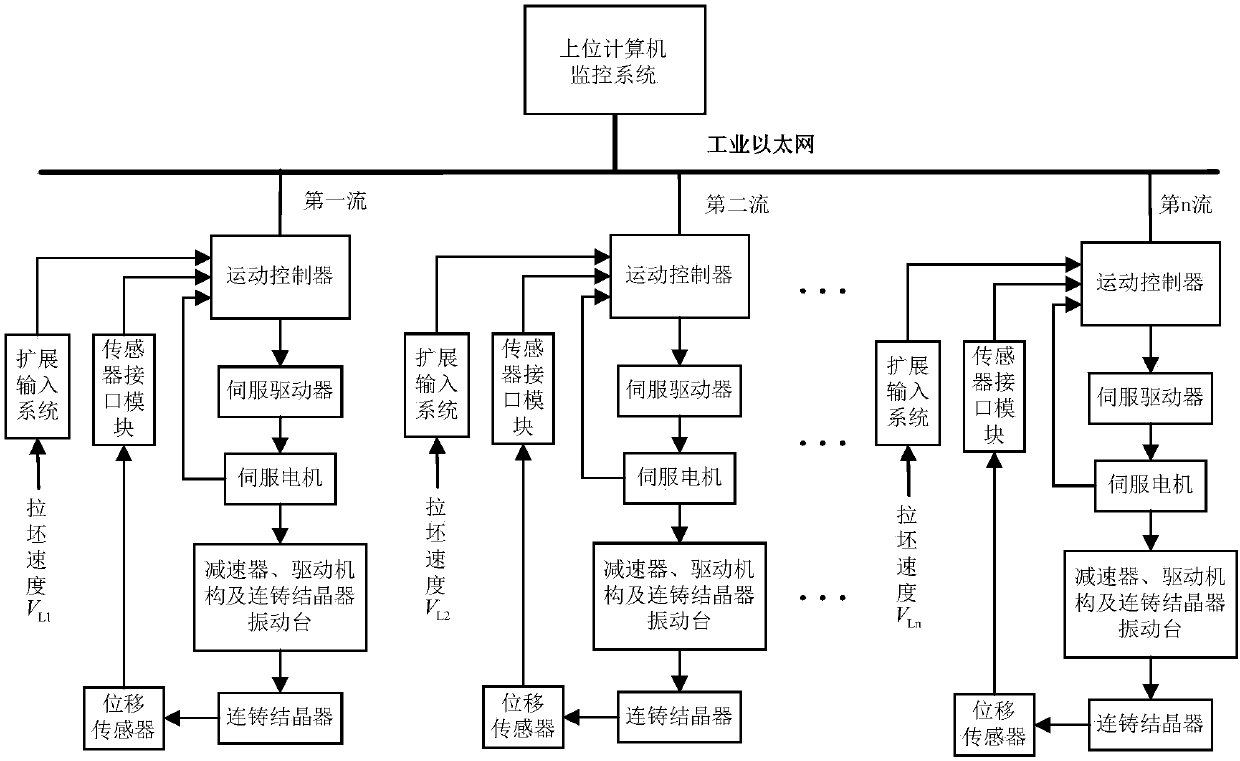

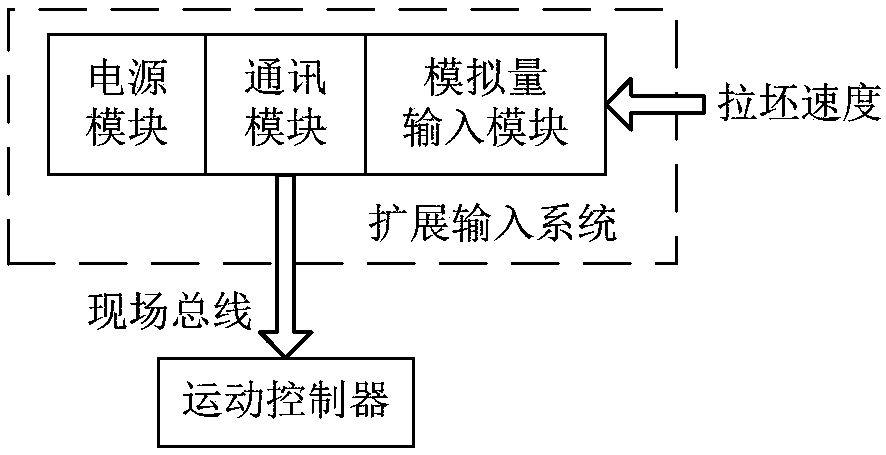

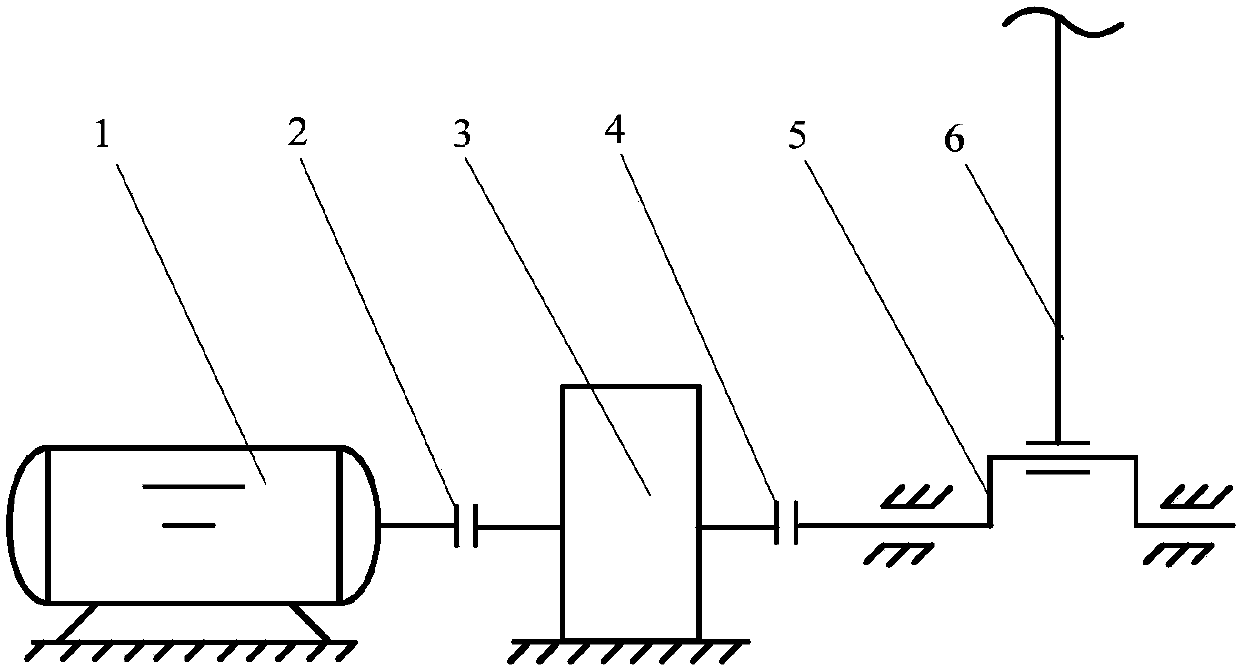

Servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system

PendingCN107900296AReal-time monitoring of non-sinusoidal vibrationCircumstances affecting productionMotor driveComputer monitoring

The invention discloses a servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system which comprises an upper computer monitoring system and n flows of continuous casting crystallizer non-sinusoidal oscillation control systems; each flow of continuous casting crystallizer non-sinusoidal oscillation control system comprises a motion controller, a servodriver, a servo motor, a speed reducer, a driving mechanism, a continuous casting crystallizer vibrating table, a continuous casting crystallizer, a displacement sensor and the like; each flow of continuous casting crystallizer non-sinusoidal oscillation control system is independently controlled by the corresponding motion controller; the upper computer monitoring system monitors non-sinusoidal oscillation situations of all flows of continuous casting crystallizers; and when one flow of motion controller breaks down, the upper computer monitoring system gives an alarm, while normal working ofthe other continuous casting flows are not affected. Compared with a centralized control system based on a high-performance programmable logic controller, the situation that production of all continuous casting flows is affected due to a programmable logic controller failure can be avoided, the safety and the reliability of the servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system are improved and the servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system has the advantages of low cost, simplicity in structure and the like.

Owner:YANSHAN UNIV

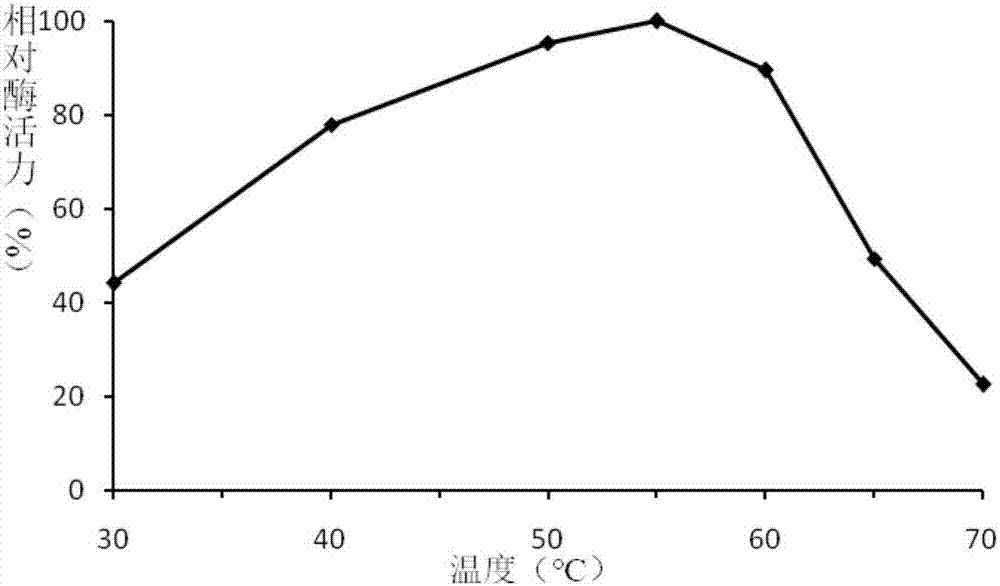

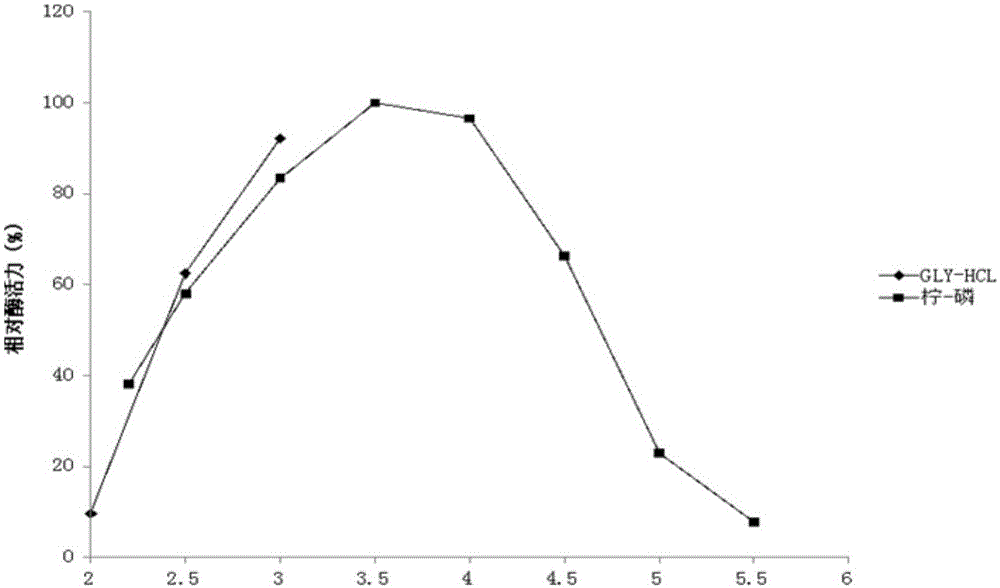

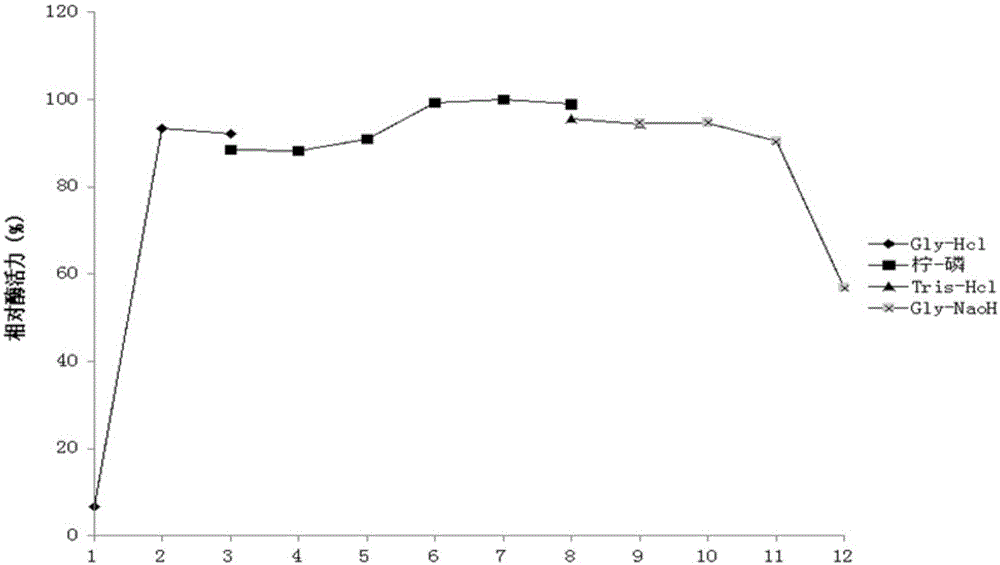

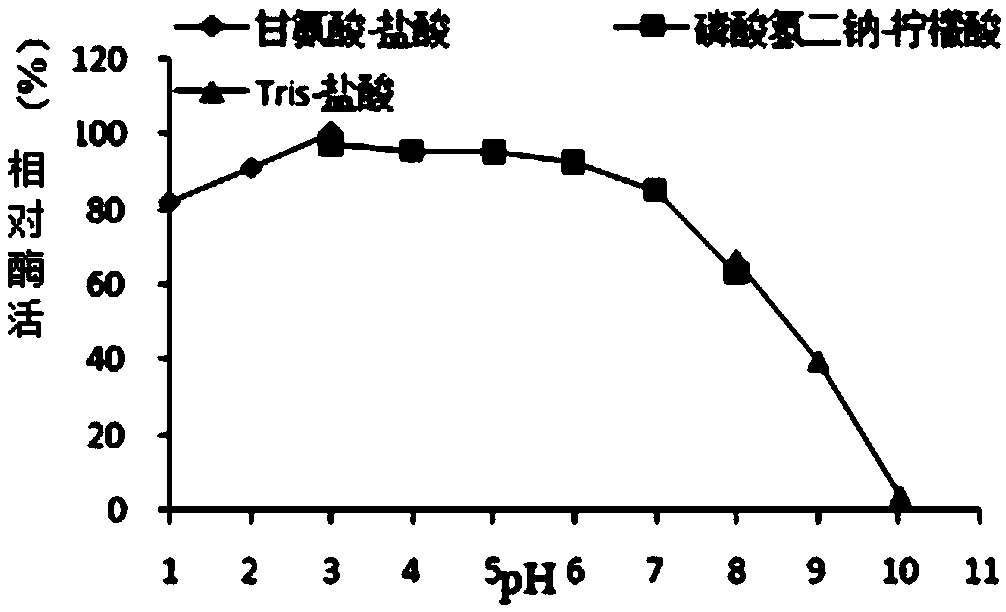

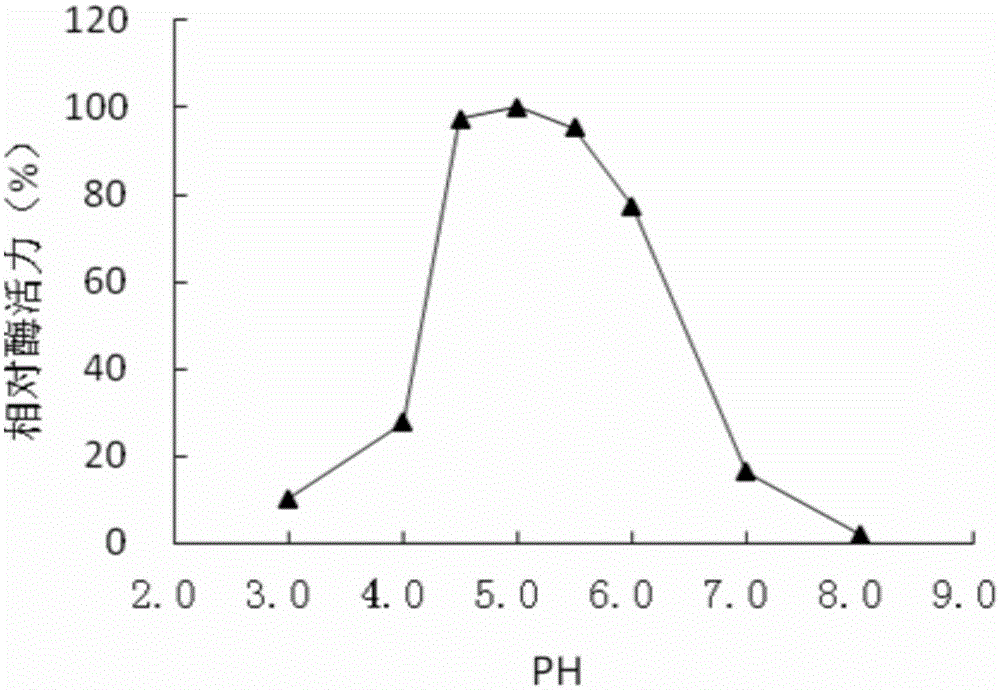

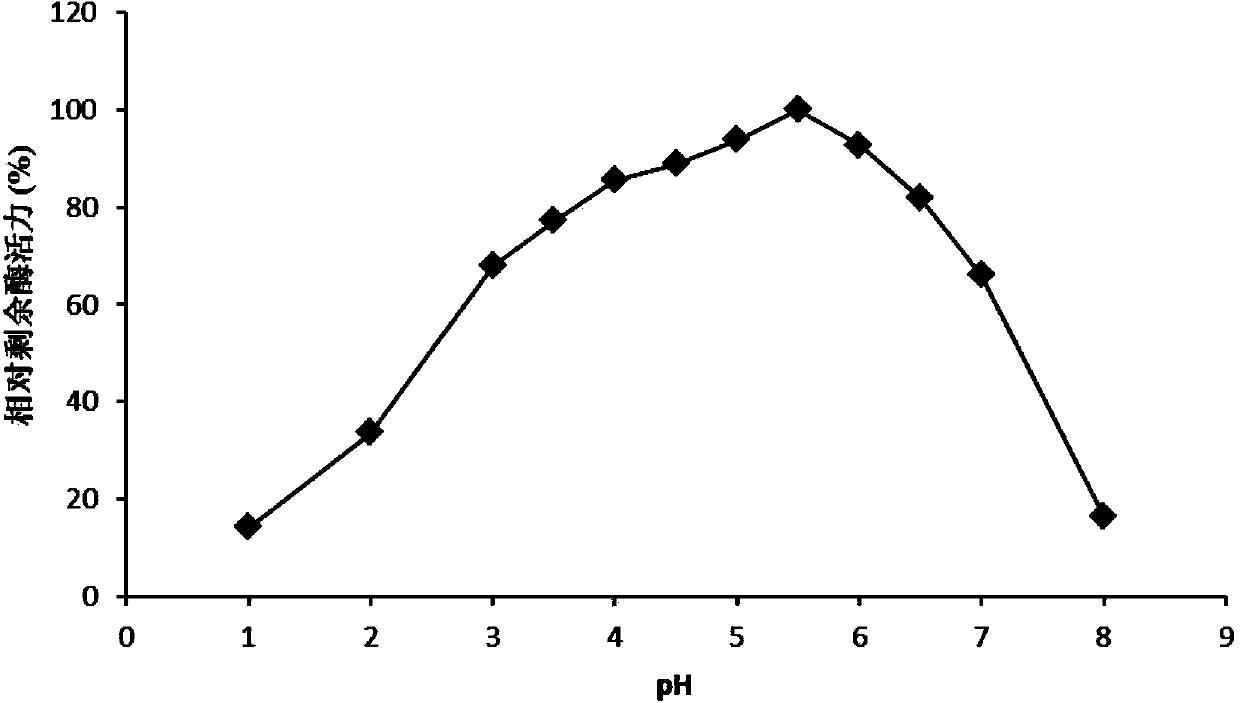

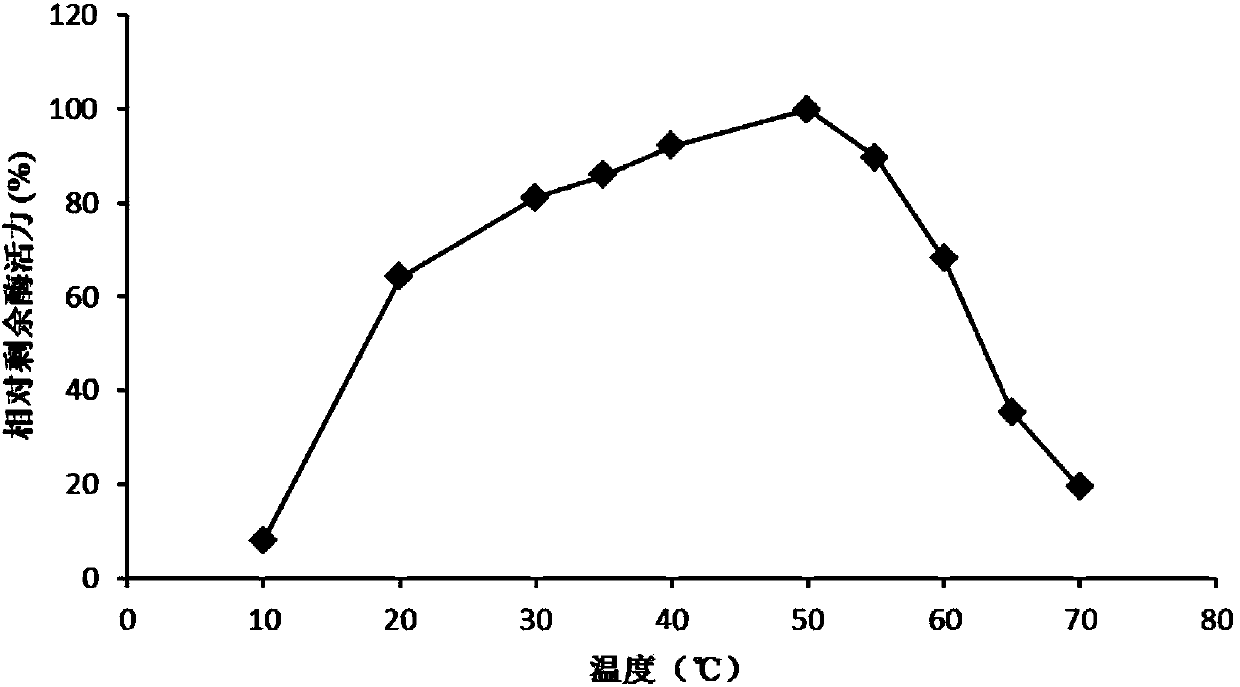

High-temperature resistant acidic beta-mannase Man-L30 and gene and application thereof

ActiveCN103740682AHigh temperature resistantImprove stabilityFungiMicroorganism based processesBiotechnologyNucleotide

The invention relates to the field of genetic engineering, and in particular relates to high-temperature resistant acidic beta-mannase Man-L30 and a gene and application thereof. The high-temperature resistant acidic beta-mannase Man-L30 is characterized in that the amino acid sequence is as shown in SEQ ID No.1 or 2. The high-temperature resistant acidic beta-mannase gene man-L30 encodes the high-temperature resistant acidic beta-mannase Man-L30 as disclosed in claim 1 and has the nucleotide sequence as shown in SEQ ID No.4 or 5. The beta-mannase Man-L30 also has the characteristics of being resistant to high temperature, high in pH (Power of Hydrogen) stability, high in protease resistance, etc.; the pH is preferably 5.5; the enzyme can remain more than 65% of activity under the pH of 2.5 to 6.5; the temperature is preferably 50 DEG C, and the antipepsin and trypsin processing capacity is relatively high under such temperature. The high-temperature resistant acidic beta-mannase Man-L30 is applicable to the feeds, foods, medicines and other industrial fields.

Owner:北京科为博生物科技有限公司

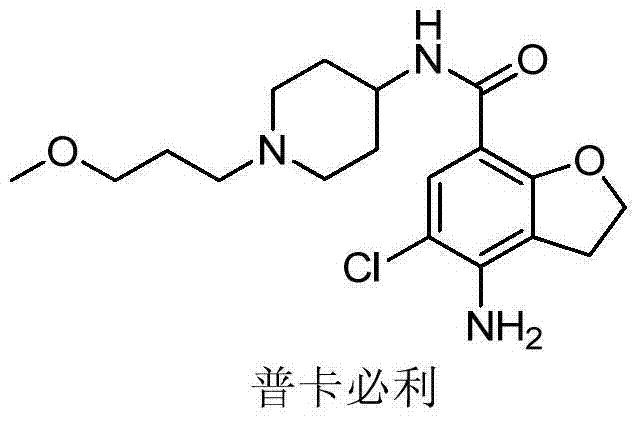

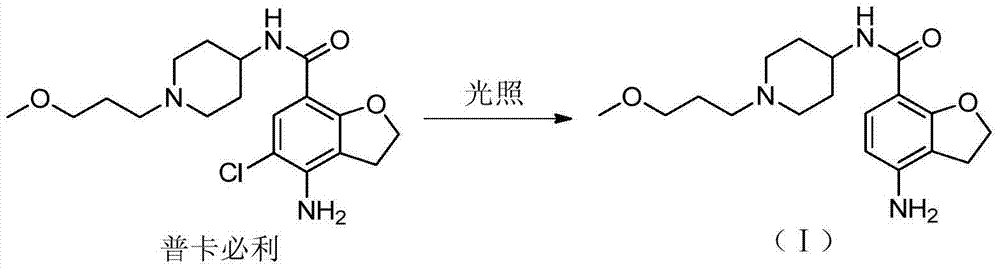

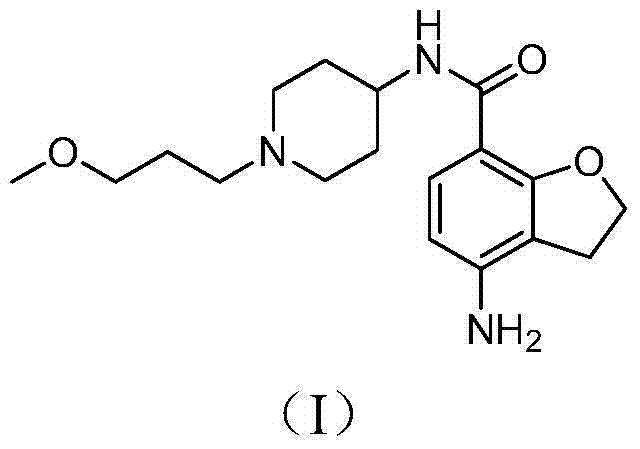

Preparation method for prucalopride degradation impurities

ActiveCN103755689AQuality productionHigh-quality productionOrganic chemistryChemical synthesisHydrogen

The invention relates to a preparation method for prucalopride degradation impurities. Particularly, the invention discloses a synthesis method for degradation impurity compound (I) of drug prucalopride (namely 4-amino-5-chloro-2,3-dihydro-N-[1-(3--methoxypropyl)-4-piperidyl]-7-benzofurancarboxamide succinate) used for treating the constipation of women, and applications in prucalopride research. According to the method, a target compound is obtained by prucalopride through hydrogenation reduction. The compound (I) can be obtained through chemical synthesis for the first time by adopting the method, and the target compound can be obtained through efficient and fast separation.

Owner:连云港恒运药业有限公司

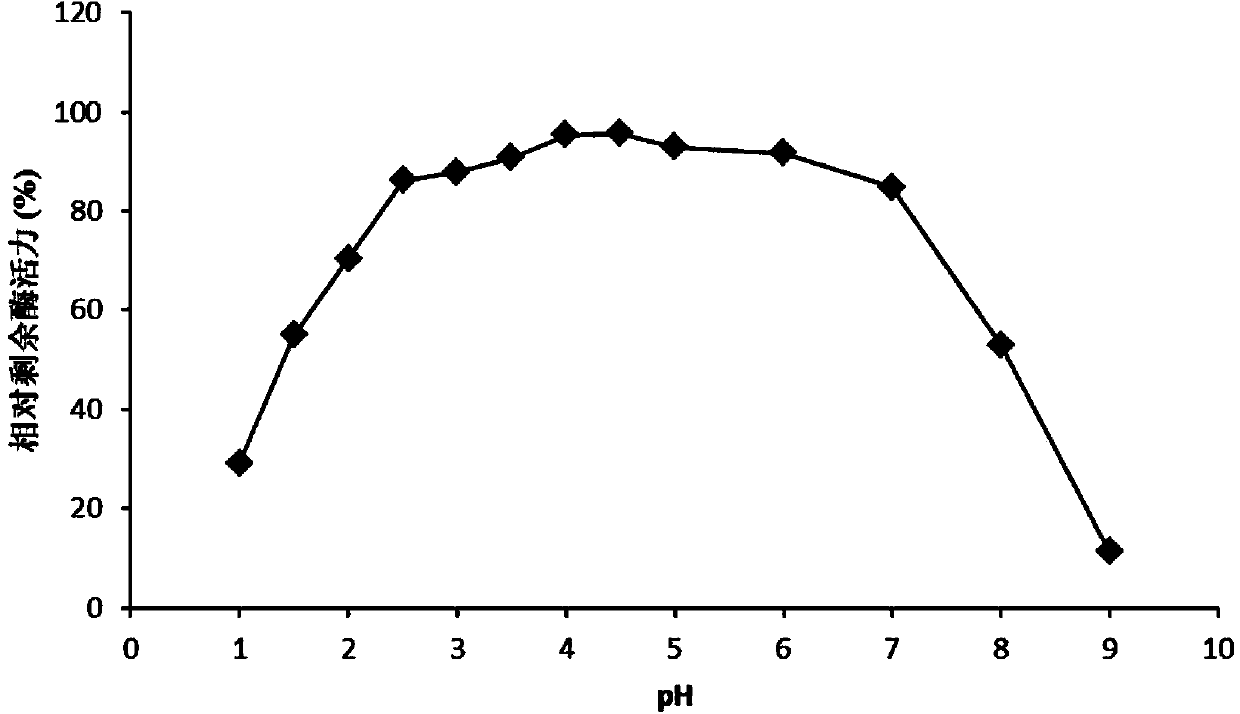

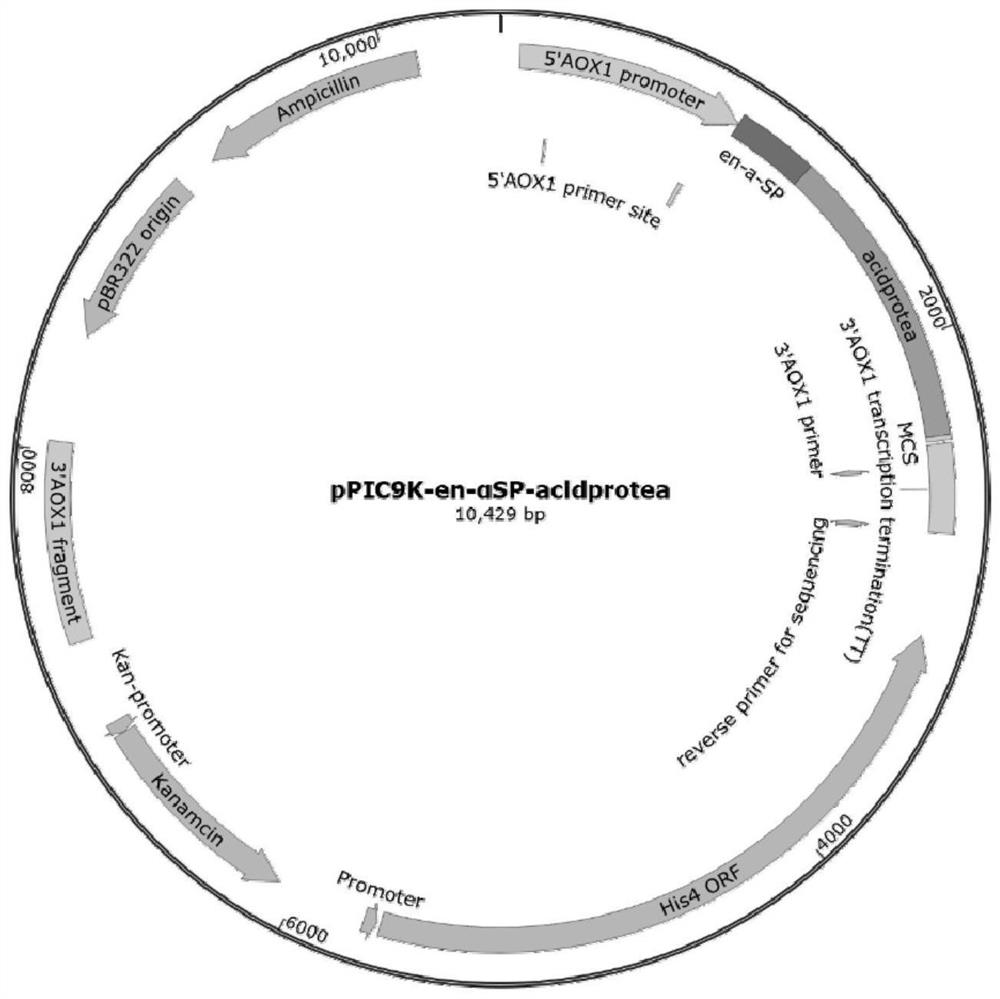

Method for efficiently expressing acid protease and application thereof

ActiveCN112920280AIncrease enzyme activityHigh quality productionPolypeptide with localisation/targeting motifFungiPichia pastorisGene engineering

The invention discloses a method for efficiently expressing acid protease and application thereof, and belongs to the field of gene engineering. The expression enzyme activity of the recombinant pichia pastoris P.pastoris GS115 / pPIC9K-en-alpha SP-acidprotea provided by the invention reaches 5395U / mL and is improved by 109% compared with the enzyme activity of a control strain containing original alpha-signal peptide; the acidic protein disclosed by the invention is in a pH range of 1-5, the enzyme can maintain the enzyme activity of 60% or more, the residual enzyme activity is 80% or more after the enzyme is treated at 20-40 DEG C for 30 minutes, and the acid protease can be suitable for industries such as food, feed or brewing and the like. According to the technical scheme provided by the invention, the acid protease suitable for industrial application can be produced by utilizing a genetic engineering means.

Owner:JIANGNAN UNIV

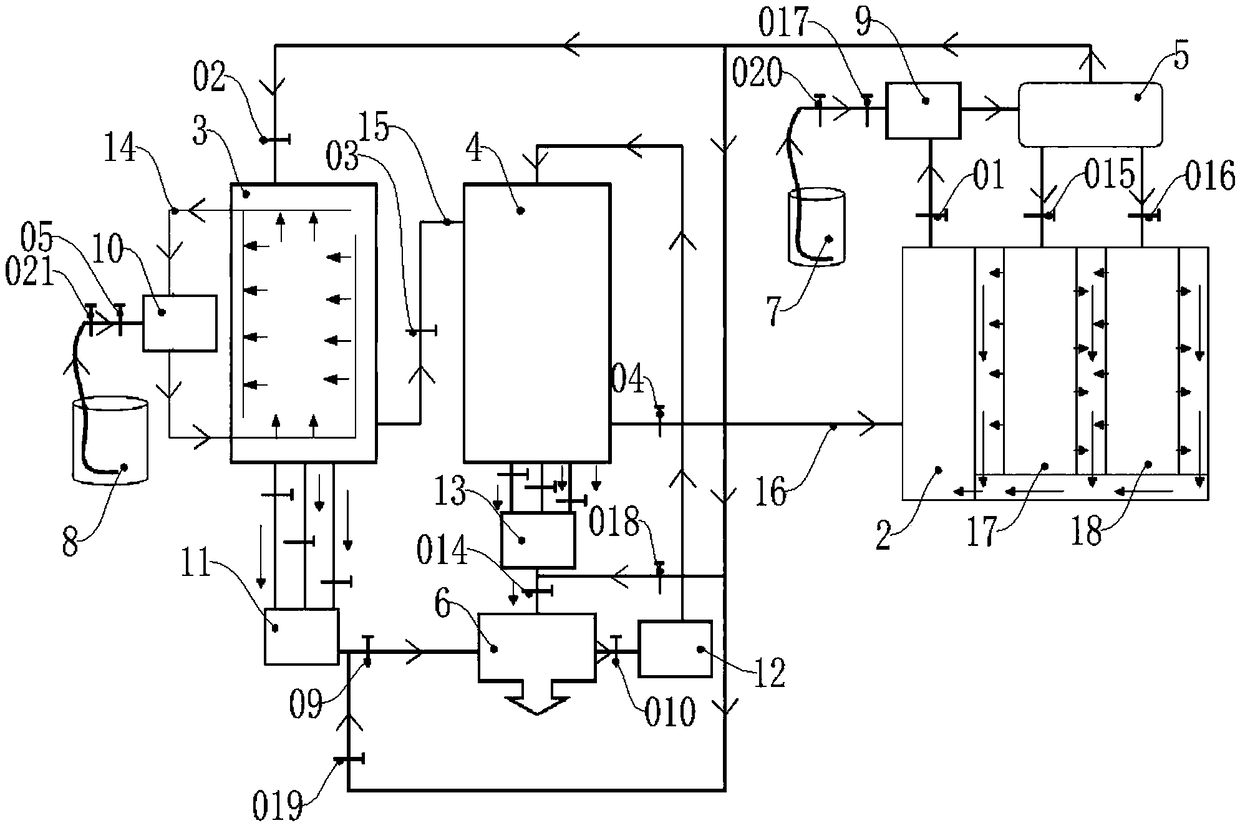

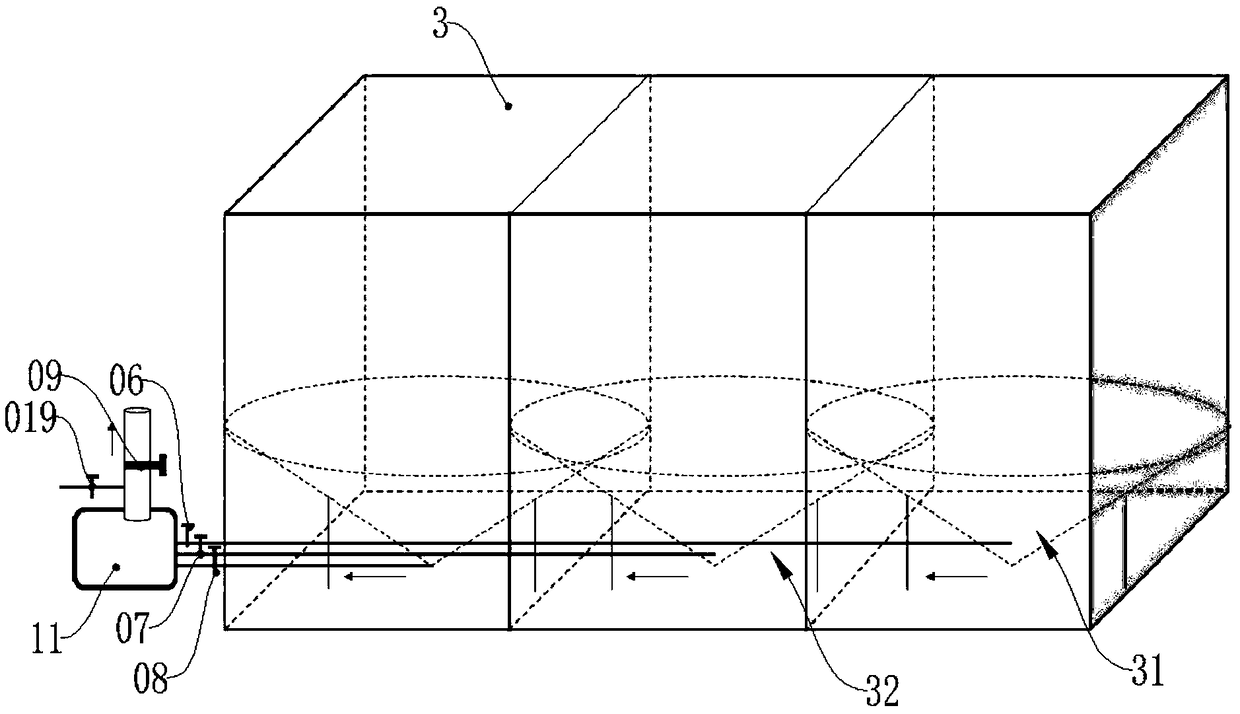

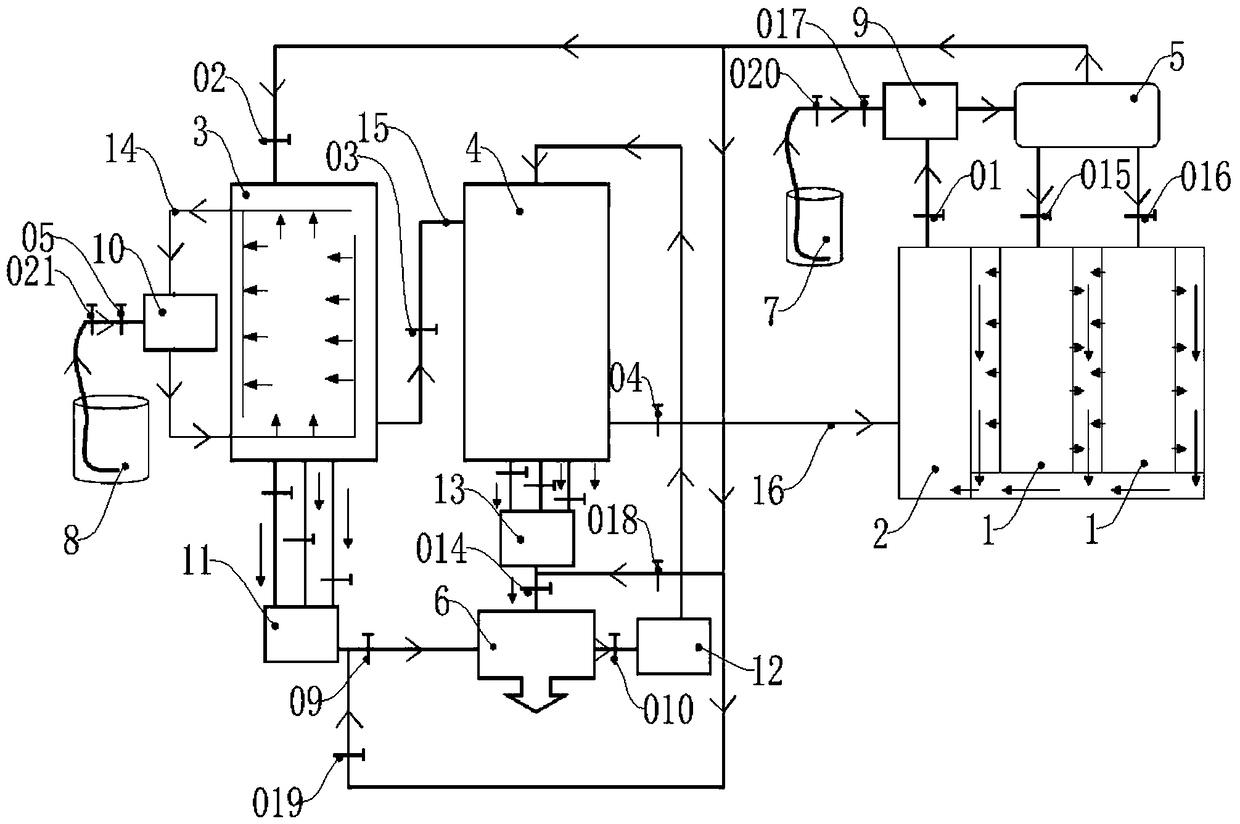

A configuration and method for recovering oxidation liquid in a transformed oxidation line and protecting a single-nickel-salt coloring tank

A configuration for recovering oxidation liquid in a transformed oxidation line and protecting a single-nickel-salt coloring tank is disclosed. The configuration includes an oxidation liquid collection system, an oxidation liquid circulating and cooling system, an oxidation liquid treatment system, an oxidation liquid separation system, an oxidation liquid recovery and recrystallization system anda single-nickel-salt coloring tank protecting system. The invention further discloses a method adopting the configuration to recover the oxidation liquid and protect the single-nickel-salt coloring tank. The method includes oxidation liquid collecting, oxidation liquid circulating and cooling, oxidation liquid treatment and separation, oxidation liquid recovery and recrystallization, and single-nickel-salt coloring tank protection steps. The configuration and method achieve on-line crystallization and separation of aluminum ions and cyclic use of the oxidation liquid, can effectively reduce resistance of the oxidation liquid, greatly reduce the risk that the single-nickel-salt coloring tank is polluted, save water and achieve low-cost high-quality production.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

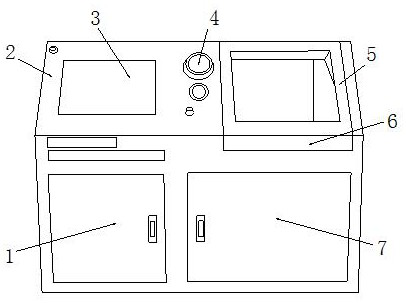

Intelligent manufacturing application platform

InactiveCN111795898AGuaranteed hot pressure surge effectEasy to operateCasings with display/control unitsCasings/cabinets/drawers detailsPressure riseHuman–machine interface

The invention discloses an intelligent manufacturing application platform. The structure of the platform comprises a motor box, a case shell, a human-computer interface, a pressure gauge, an observation window, a pipe blasting platform and a storage box groove. According to the invention, the human-computer interface matches the pipe blasting platform; a transverse airflow channel of a ventilationbottom groove base and a pressurizing alignment pouring internal combustion ball cylinder frame of a blasting pouring table are regulated and controlled to be pneumatic through the human-computer interface, and a spark plug type internal heating sudden pressure rising operation is formed between the two parts; the rapidity of the blasting performance of a pipe is improved; a floating block scalelifting effect is formed by a side temperature detection pipe; the precise value of the blasting moment is guaranteed to be accurately collected, the internal pressure difference is balanced, the blasting precision is improved, blasting fragments form a bagging, bundling and cleaning effect through the thick-wall air bag, and continuous high-quality production is guaranteed to be achieved by modulating pipe blasting and batch assembling and machining through the intelligent manufacturing application platform.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

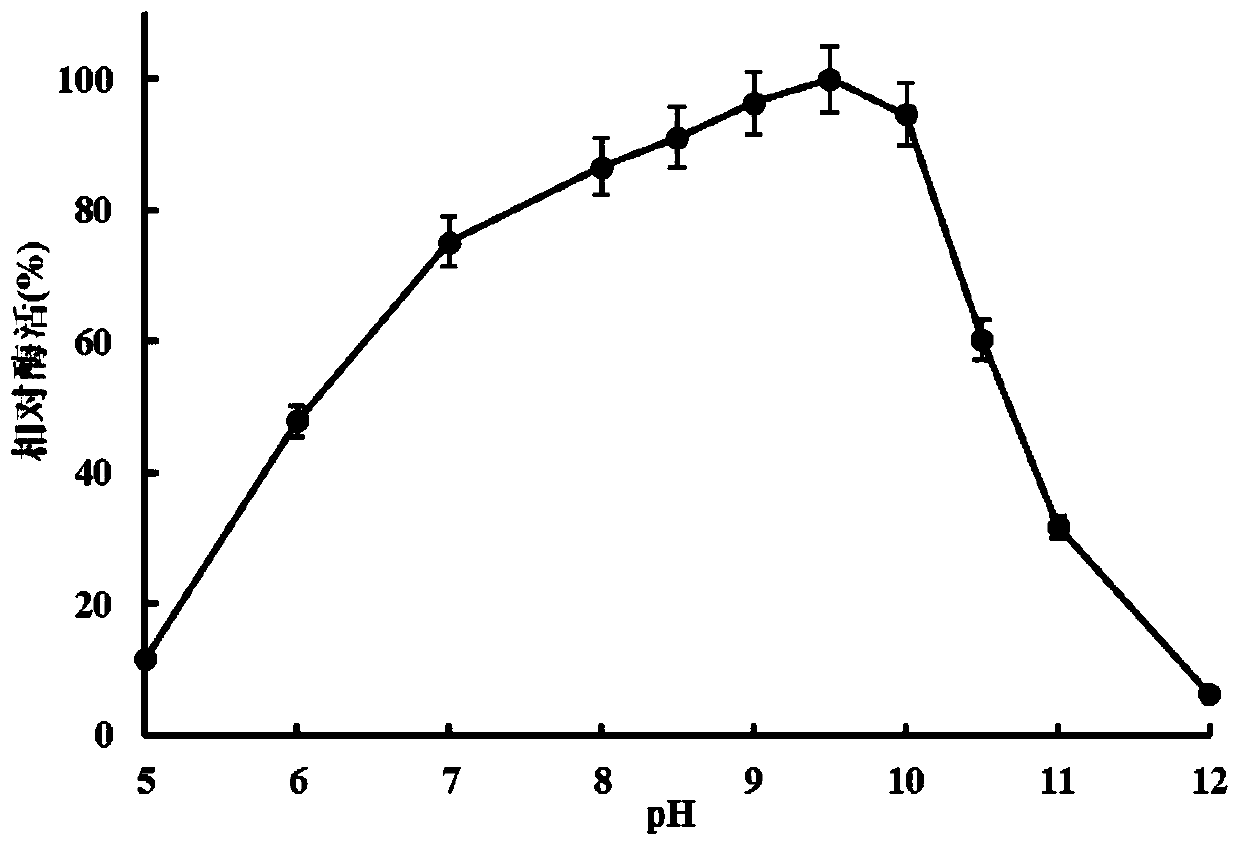

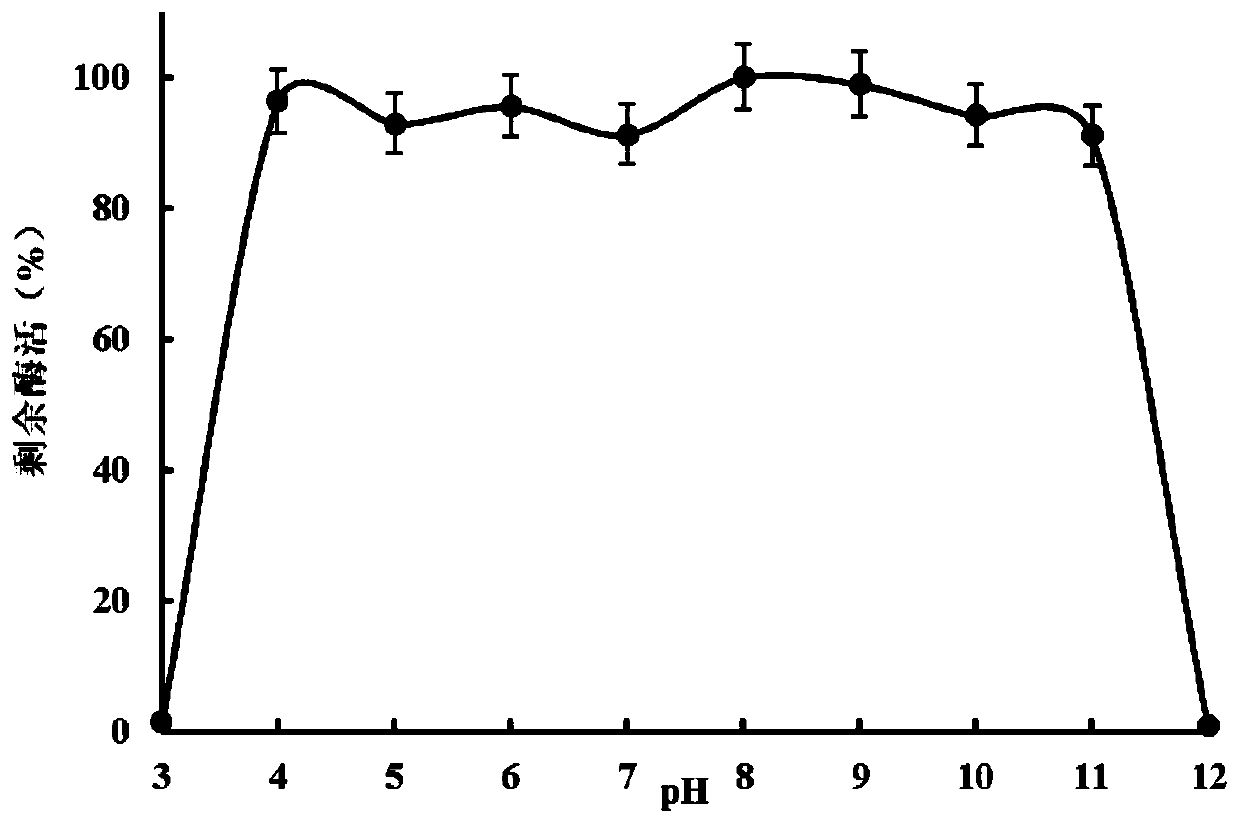

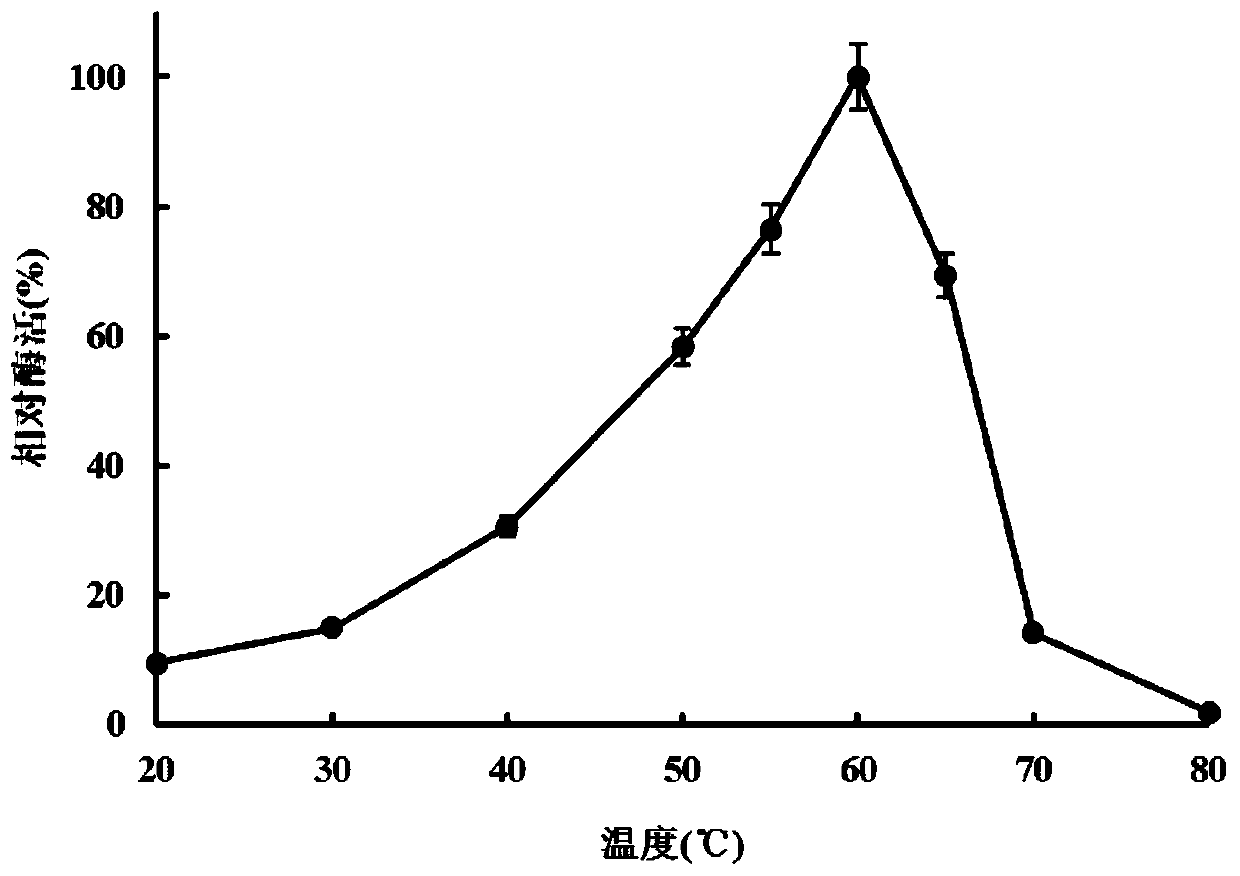

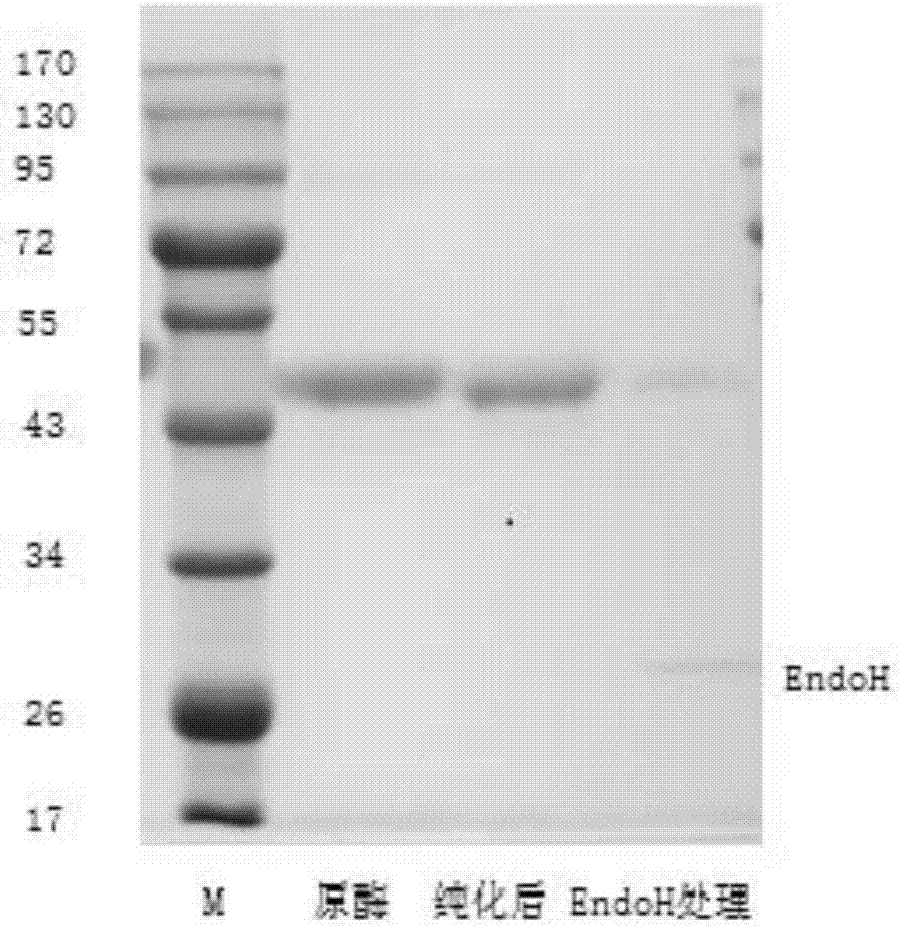

Alkaline protease PA3 and its coding gene and application thereof

The invention belongs to the technical field of agro-ecology, and particularly relates to alkaline protease PA3 and its coding gene and an application thereof. The present invention provides an alkaline protease PA3 derived from Torrubiella hemipterigena, an amino acid sequence of which is shown as SEQ ID NO. 1 or SEQ ID NO. 2, the alkaline protease PA3 has good properties and can be applied to many fields such as food, feed, leather production, washing, medicine and the like. According to the technical solution of the present invention, the alkaline protease PA3 which is excellent in properties and suitable for industrial application can be produced by genetic engineering means.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

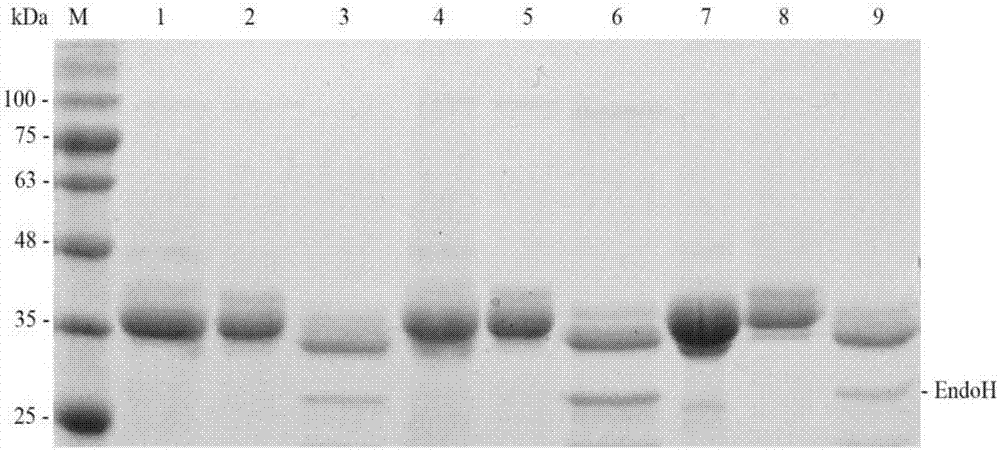

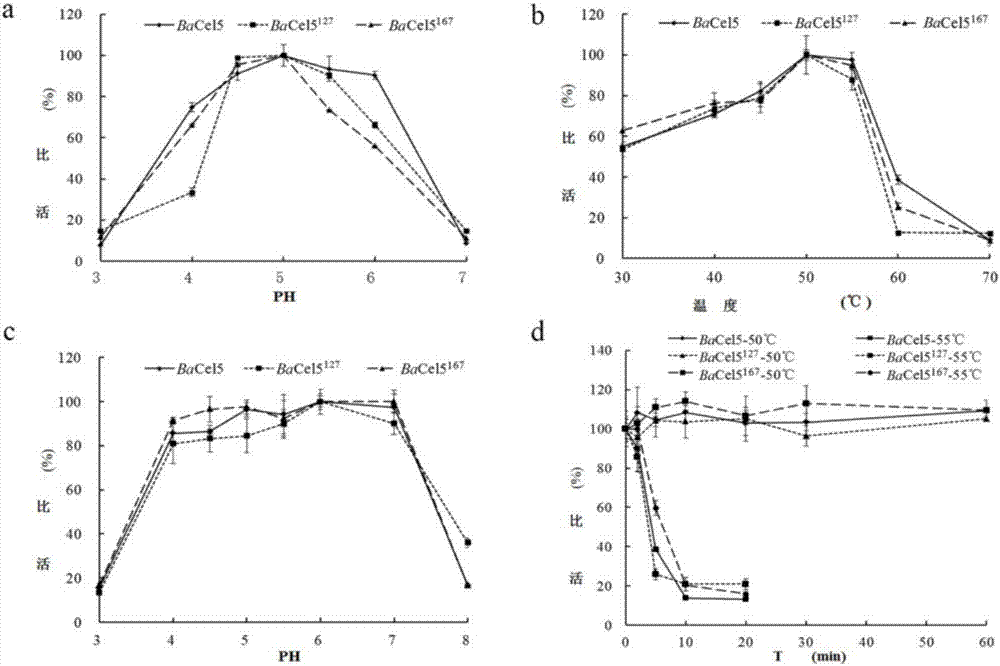

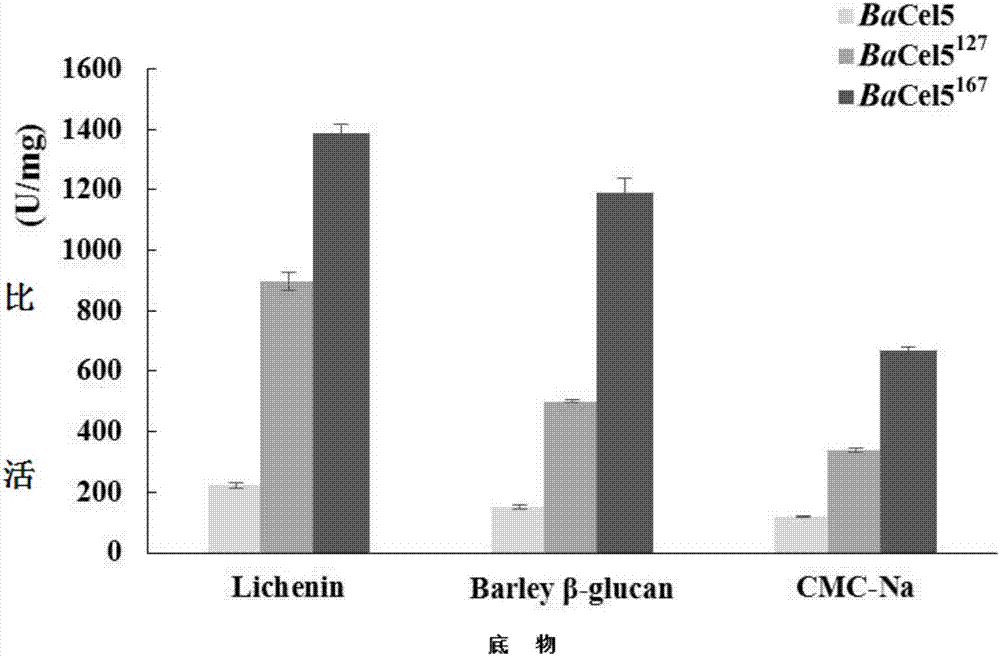

Acidic high-temperature-resistant cellulase Cel5 and gene and application thereof

ActiveCN106967701AEasy to produce by fermentationHigh quality productionMicroorganism based processesEnzymesGenetic engineeringChemistry

The invention relates to the field of genetic engineering, in particular to an acidic high-temperature-resistant cellulase Cel5 and a gene and application thereof. The amino acid sequence of the cellulase is shown as SEQ ID NO.1 or SEQ ID NO.2. The invention provides a new cellulase gene. The cellulase encoded by the gene has good properties, can be applied to feeds, foods, medicines and other industries. According to the technical scheme, it can be achieved that the cellulase having good properties and suitable for industrial application is produced by utilizing a gene engineering means.

Owner:INST OF ANIMAL SCI CAAS

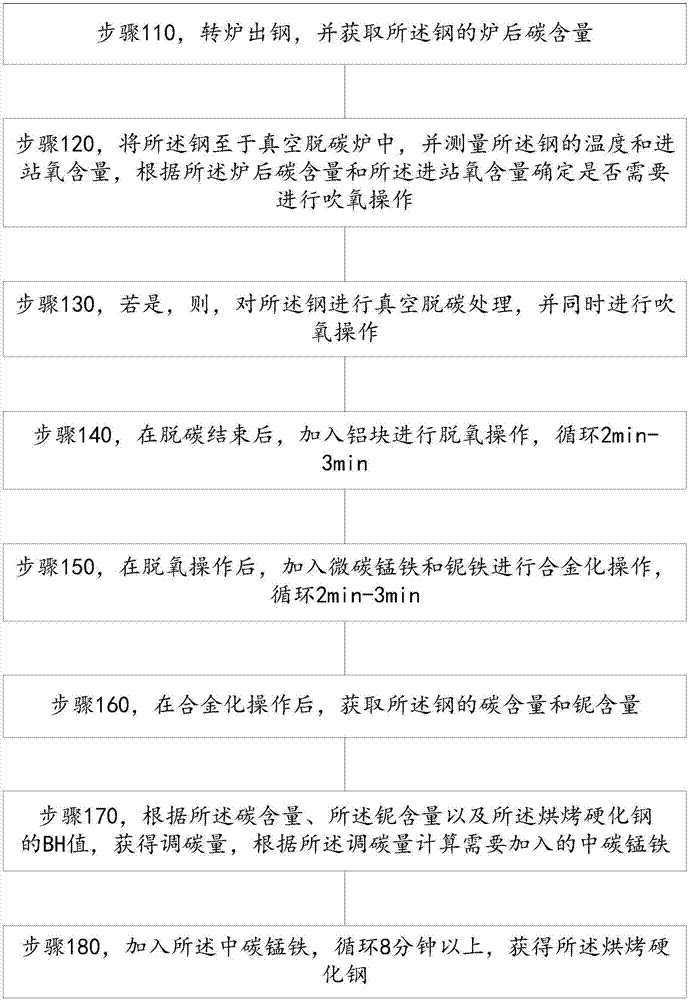

Smelting control method of bake hardening steel

The invention discloses a smelting control method of bake hardening steel. The method includes the steps that converter tapping is conducted, and post-converter carbon content is obtained; the temperature and arrival oxygen content of steel are measured, and whether the oxygen blowing operation needs to be conducted or not is determined according to the post-converter carbon content and the arrival oxygen content; if yes, vacuum decarburization processing is conducted on the steel, and the oxygen blowing operation is conducted at the same time; an aluminum block is added to conduct the deoxygenation operation, and circulation is conducted for 2 min to 3 min; micro-carbon ferromanganese and ferroniobium are added to conduct the alloying operation, and circulation is conducted for 2 min to 3 min; the carbon content and the niobium content of the steel are obtained; the amount of medium-carbon ferromanganese needing to be added is calculated according to the carbon content, the niobium content and the BH value of the bake hardening steel; and circulation is conducted for 8 or more minutes. The decarburization speed and the controllability of oxygen activity obtained after decarburization is finished are increased by supplying oxygen in vacuum decarburization processing, the alloy addition sequence is adjusted, the carbon adjustment amount is calculated according to the carbon content and the niobium content and through the combination with the requirement for the BH value, the influence of fluctuation of the niobium absorption rate on BH value control is avoided, the processing time is shortened, aluminum only needs to be added once, and influences on the quality of molten steel are reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

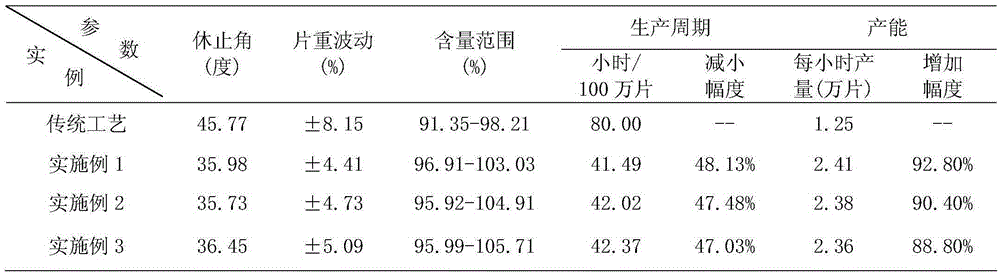

Preparation method of tablet for increasing bone density

The invention discloses a preparation method of a tablet for increasing the bone density. The table is mainly composed of red deer bone, calcium carbonate, hydrolyzed collagen, and sodium chondroitin sulfate. A boiling one-step granulation method is adopted. Three steps: mixing, granulation, and drying are carried out in a boiling enclosed chamber at a time. The prepared particles are uniform, the fluidity is good, the weight difference is small, and the dissolution rate is good. Compared with the conventional wet process granulation technology, the provided method has the advantages of fewer steps, less production equipment, higher safety, more output, and shorter production period, and the quality of obtained product is stable and controllable.

Owner:HARBIN PHARM GROUP SANJING PHARMACEUTICAL CO LTD

Cellulase mutant with high catalytic efficiency as well as coding genes and application thereof

InactiveCN107043759AHigh catalytic efficiencyShorten retrofit timeFungiMicroorganism based processesBiotechnologyWild type

The invention relates to the field of genetic engineering and in particular relates to a cellulase mutant with high catalytic efficiency as well as coding genes and application thereof. The mutant has an amino acid sequence shown as SEQ ID NO.3 or SEQ ID NO.4. Compared with an activity ratio female parent wild type, the cellulase mutant has the advantage that the catalytic efficiency and specific activity are obviously improved. The catalytic efficiency and action conditions of the cellulase can be greatly improved, and a basis is provided for application of the cellulase in the field of industrial production.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Configuration of improving existing oxidation tank to recover anode oxidation solution and method

ActiveCN109137034AEfficient handlingEfficient recyclingAnodisationCellsSolution treatmentAluminum Ion

The invention discloses a configuration of improving an existing oxidation tank to recover an anode oxidation solution. An oxidation solution collecting system, an oxidation solution circulation cooling system, an oxidation solution treatment system, an oxidation solution separation system and an oxidation solution recovering and recrystallizing system are included. The invention further disclosesa method for recovering the anode oxidation solution using the configuration of improving the existing oxidation tank to recover the anode oxidation solution. The method comprises the steps of oxidation solution collecting, oxidation solution circularly cooling, oxidation solution processing and separating, and oxidation solution recovery and recrystallizing. By means of the configuration and themethod, online crystal precipitation of aluminum ions and oxidation solution circular use can be achieved to effectively reduce oxidation solution resistance and achieve low-cost high-quality production.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com