Intelligent manufacturing application platform

An application platform and intelligent manufacturing technology, which is applied in the direction of housing with display/control unit, program control device, user interface execution, etc., can solve the problems of batch pass rate reduction, detection data deviation, pressure difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

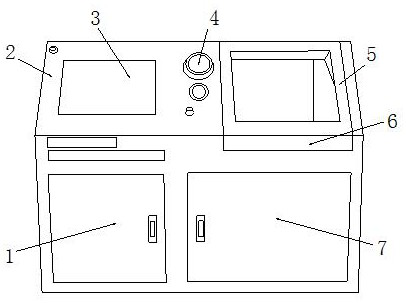

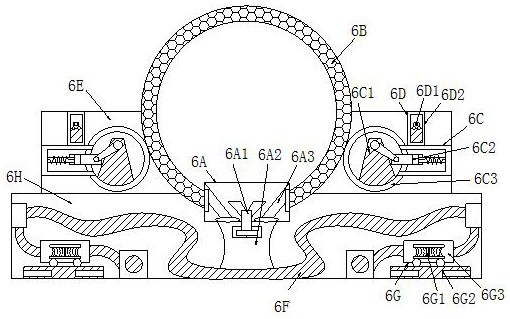

[0033] see Figure 1-Figure 6, the present invention provides an application platform for intelligent manufacturing, the structure of which includes: a motor box 1, a box shell 2, a man-machine interface 3, a pressure gauge 4, an observation window 5, a pipe blasting platform 6, and a storage tank 7. The pipe blasting platform 6 is embedded in the observation window 5. The man-machine interface 3 and the observation window 5 are respectively nested in the left and right upper corners of the chassis shell 2 and are on the same slope. The motor box 1 and the storage box slot 7 are all inserted and embedded in the bottom of the case casing 2, the casing casing 2 and the pressure gauge 4 are fastened together, and the pipe blasting platform 6 is provided with a paddle beam tube 6A, a compressed airbag casing 6B, an internal combustion ball Cylinder frame 6C, temperature detection tube 6D, blasting and filling pressure table 6E, ventilation elbow frame 6F, advection pressure regula...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides an application platform for intelligent manufacturing, which is the same as Embodiment 1 in other respects, except that:

[0041] see figure 2 , the advection pressure regulating seat 6G is composed of a finned wheel groove seat 6G1, an I-shaped base 6G2, and a horizontal groove chamber 6G3, and the finned wheel groove seat 6G1 is installed inside the horizontal groove chamber 6G3, and the horizontal groove chamber 6G3 It is movably connected with the I-shaped base 6G2 and is on the same vertical plane. Through the finned wheel groove seat 6G1, it runs horizontally through the internal pressure storage chamber 6G3 in the horizontal tank chamber 6G3, so that the pneumatic conduction can be improved efficiently.

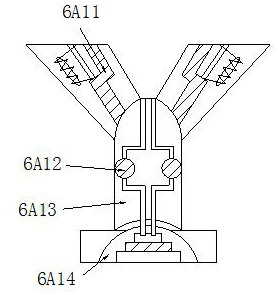

[0042] see Figure 6 The fin wheel groove seat 6G1 is composed of an arc groove wheel 6G11, a pressure plate 6G12, a threaded shaft rod 6G13, and a guide fin 6G14. The two pressure plates 6G12 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com