Non-woven fabric production line

A production line, non-woven technology, applied in textile and papermaking, textile material processing, liquid/gas/steam textile processing and other directions, can solve the problems of poor quality of non-woven products, low production efficiency, etc. , high-efficiency non-woven fabric, the effect of high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

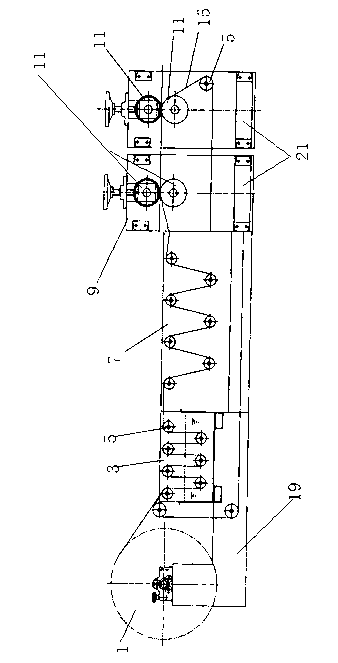

[0015] see figure 1 As shown, a non-woven fabric production line includes an unwinder 1, a dye vat 3, a roll 5, a driving conveyor belt 7, a rolling section 9, a roll 11, and a mesh belt 15. The right end of the unwinder 1 is connected to a dye vat 3 , the right end of the dyeing vat 3 is connected with a driving conveyor belt 7, the right end of the driving conveyor belt 7 is connected with a rolling section 9, the mesh belt 15 is connected on the roll 5, the roll 11, and the unwinding machine 1 is equipped with Underframe 19, base 21 is connected on the described rolling stem 9, and described roll 11 is four, and its pressure is 2-6kg / cm 2 , there are 17 rolls 5, and the mesh belt 15 is polyester cotton cloth.

[0016] During specific operation: Mesh belt 15 is exactly that polyester-cotton cloth is finally made finished product by the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com