Rotary bed equipment and method for producing solid-phase fluoride

A rotating bed, fluoride technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of long fluorination reaction time period, uneven fluorination, low production efficiency, etc., and achieve production maintenance. It is convenient and quick, improves the uniformity of fluorination and improves work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

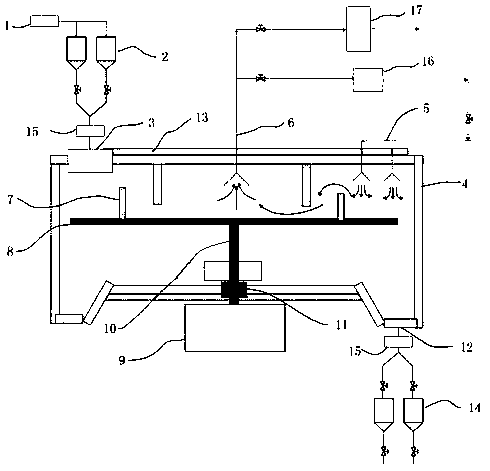

[0037] A rotating bed equipment for producing solid-phase fluorides, comprising a rotating bed, the rotating bed includes a rotating bed shell 4, and the top of the rotating bed shell 4 is respectively provided with a feeding port 3 and a fluorinating agent / diluent gas inlet and gas distribution system 5, The bottom of the rotary bed shell 4 is provided with an electric mechanism 9, and the electric mechanism 9 is connected with the turntable 8 arranged horizontally inside the rotary bed shell 4 through the rotating shaft 10. The top of the rotary bed shell 4 above the turntable 8 is provided with an exhaust gas outlet 6, and the rotary bed shell 4 The bottom is also provided with a discharge port 12.

Embodiment 2

[0039] As attached in the manual figure 1 As shown, a rotating bed equipment for producing solid-phase fluoride includes a rotating bed, and the rotating bed includes a rotating bed shell 4, and the top of the rotating bed shell 4 is respectively provided with a feeding port 3 and a fluorinating agent / diluent gas inlet and gas distribution In system 5, an electric mechanism 9 is provided at the bottom of the rotary bed shell 4, and the electric mechanism 9 is connected to the turntable 8 arranged horizontally inside the rotary bed shell 4 through the rotating shaft 10. The top of the rotary bed shell 4 above the turntable 8 is provided with an exhaust gas outlet 6, and the rotating A discharge port 12 is also provided at the bottom of the bed shell 4 .

[0040] The feed port 3 is connected to the raw material tank 2 through the solid material distributor 15, and the raw material tank 2 is connected to the nitrogen replacement system 1 of the raw material tank. The feed port 3 ...

Embodiment 3

[0052] A method for producing solid-phase fluorides using said rotary bed equipment, comprising the following steps:

[0053] (1) When the raw material is loaded into the raw material tank 2, nitrogen gas is introduced and the material is baked to remove moisture and other impurities in the raw material; after the baking is completed, a nitrogen atmosphere is maintained; the raw material is 10 mesh to 15000 mesh, and the relative density is 1 to 10 At least one of carbon raw materials, cobalt-based, iron-based and nickel-based oxides, chlorides, low-priced fluorides, silver, and alumina, with a feeding amount of 0.1 to 100 kg. The temperature of the baking material in step (1) is 200~400°C.

[0054] (2) The turntable 8 rotates slowly when feeding, and the material in the raw material tank 2 is evenly spread on the rotary bed turntable 8 through the solid material distributor 15;

[0055] (3) Heating up the temperature, feeding the mixed gas of fluorinating agent / diluent gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com