Heat-resisting acidic cellulase of fungus source and gene and application thereof

A cellulase and gene technology, applied in the field of genetic engineering, can solve the problems of low expression, inappropriate pH range, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Cloning of embodiment 1 cellulase coding gene cel5

[0054] Extraction of Bispora sp.MEY-1 Genomic DNA

[0055] Centrifuge the bacteria cultured in liquid for 3 days at 12,000rpm for 10min, collect the mycelia and extract DNA, wash twice with 70% ethanol, dry in vacuum, add appropriate amount of dd H 2 O was dissolved and stored at -20°C for later use.

[0056] Degenerate primers were designed, and PCR amplification was performed using the total DNA of Bispora sp.MEY-1 as a template. A fragment of about 451bp was obtained, which was recovered and sequenced.

[0057] TAIL-PCR primers uspl, usp2, us3; dsp1, dsp2, dsp3 were designed according to the nucleotide sequence obtained by sequencing (see Table 1). The flanking sequence of the known gene sequence was obtained by TAIL-PCR, and the amplified product was recovered and sent to Sanbo Biotechnology Co., Ltd. for sequencing. The correctly sequenced fragments were spliced to obtain the full-length gene.

[0058] Tab...

Embodiment 2

[0063] The construction of embodiment 2 cellulase engineering strains

[0064] (1) Construction of expression vector and expression in yeast

[0065] Using the cDNA of the correctly sequenced cellulase Cel5 as a template, primers F and R (see Table 1) with EcoR I and Not I restriction sites were designed and synthesized to amplify the coding region of the mature protein of Cel5. increase. And utilize EcoR I and Not I to cut PCR product, link into expression vector pPIC9 (Invitrogen, San Diego), the sequence of cellulase Cel5 mature protein is inserted into the downstream of the signal peptide sequence of above-mentioned expression vector, and signal peptide forms correct The reading frame was constructed into a yeast expression vector pPIC9-cel5, and transformed into Escherichia coli competent cell Trans1. The positive transformants were subjected to DNA sequencing, and the transformants with the correct sequence were used for large-scale preparation of recombinant plasmids....

Embodiment 3

[0069] The preparation of embodiment 3 recombinant cellulase

[0070] (1) Massive expression of cellulase gene Cel5 at shake flask level in Pichia pastoris

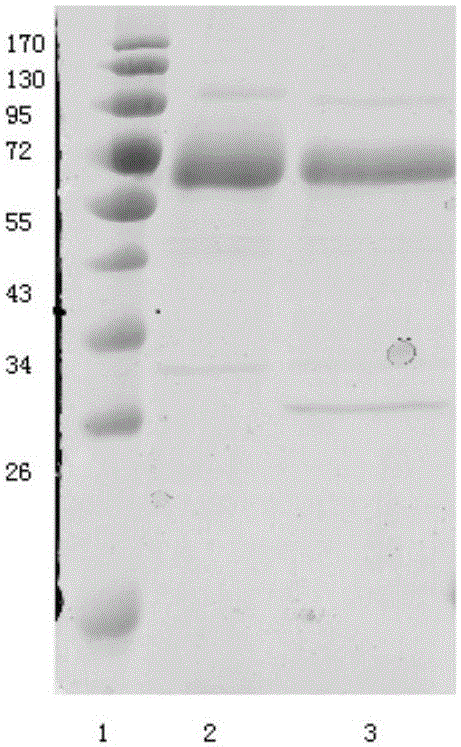

[0071] The transformant with high enzyme activity was screened out, inoculated into a 1L Erlenmeyer flask with 300mL of BMGY liquid medium, cultured on a shaking table at 30°C at 220rpm for 48h; centrifuged at 5,000rpm for 5min, discarded the supernatant gently, and then added 100mL containing 0.5% methanol BMMY liquid medium, 30°C, 220rpm induction culture for 72h. During the induction culture period, add methanol solution once every 24 hours to compensate for the loss of methanol, and keep the methanol concentration at about 0.5%; (3) Centrifuge at 12,000×g for 10 minutes, collect the supernatant fermentation liquid, detect the enzyme activity and perform SDS-PAGE protein Electrophoretic analysis.

[0072] (2) Purification of recombinant cellulase

[0073] The supernatant of the recombinant cellulase expressed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com