Preparation method of tablet for increasing bone density

A technology to increase bone density and red deer bone, which is applied in the field of preparation of bone density-enhancing tablets, can solve problems such as inability to perform high-speed tablet compression, drug safety risks, and unsatisfactory particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

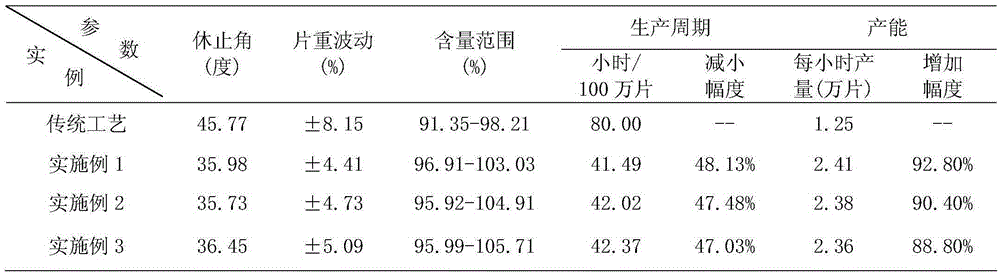

Examples

Embodiment 1

[0016] (1) Preliminary degreasing, crushing, intermediate degreasing, drying at 100°C, coarse crushing, fine degreasing, drying at 100°C, and crushing the red deer bone into fine powder to obtain fine powder A for use;

[0017] (2) Grinding hydrolyzed collagen, calcium carbonate, sodium chondroitin sulfate, casein phosphopeptide, hydroxypropyl cellulose, lactose, and sodium starch glycolate into fine powders respectively, and set aside;

[0018] (3) 0.5g of casein phosphopeptide fine powder and 15g of sodium chondroitin sulfate fine powder are mixed evenly by the method of equal increments to obtain fine powder B, which is set aside;

[0019] (4) Weigh 55g of hydrolyzed collagen fine powder, 65g of fine powder A, 160g of calcium carbonate fine powder, and 15.5g of fine powder B, add the remaining auxiliary materials, put them into a mixer and mix evenly to obtain material C, and set aside;

[0020] (5) Put the obtained material C in a one-step granulator, and feed clean compre...

Embodiment 2

[0024] (1) Preliminary degreasing, crushing, intermediate degreasing, drying at 100°C, coarse crushing, fine degreasing, drying at 100°C, and crushing the red deer bone into fine powder to obtain fine powder A for use;

[0025] (2) Grinding hydrolyzed collagen, calcium carbonate, sodium chondroitin sulfate, casein phosphopeptide, hydroxypropyl cellulose, lactose, and sodium starch glycolate into fine powders respectively, and set aside;

[0026] (3) 1.8g of casein phosphopeptide fine powder and 20g of sodium chondroitin sulfate fine powder were mixed evenly by the method of equal increments to obtain fine powder B, which was set aside;

[0027] (4) Weigh 60g hydrolyzed collagen fine powder, 70g fine powder A, 180g calcium carbonate fine powder, 21.8g fine powder B, add remaining auxiliary materials, put into the mixer and mix evenly to obtain material C, set aside;

[0028] (5) Put the obtained material C in a one-step granulator, and feed clean compressed air into the pressur...

Embodiment 3

[0032] (1) Preliminary degreasing, crushing, intermediate degreasing, drying at 100°C, coarse crushing, fine degreasing, drying at 100°C, and crushing the red deer bone into fine powder to obtain fine powder A for use;

[0033] (2) Grinding hydrolyzed collagen, calcium carbonate, sodium chondroitin sulfate, casein phosphopeptide, hydroxypropyl cellulose, lactose, and sodium starch glycolate into fine powders respectively, and set aside;

[0034] (3) 2.0g of casein phosphopeptide fine powder and 22g of sodium chondroitin sulfate fine powder are mixed evenly by the method of equal increments to obtain fine powder B, which is set aside;

[0035] (4) Weigh 70g of hydrolyzed collagen fine powder, 80g of fine powder A, 200g of calcium carbonate fine powder, and 24.0g of fine powder B, add the remaining auxiliary materials, put them into a mixer and mix evenly to obtain material C, and set aside;

[0036] (5) Put the obtained material C in a one-step granulator, and feed clean compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com