Smelting control method of bake hardening steel

A control method and bake hardening technology, which is applied in the field of refining technology in the metallurgical industry, can solve the problems of large deviation between the actual value and the theoretical value, affecting the smelting rate of bake hardened steel, and the low pass rate of BH value, so as to reduce the smelting process. cycle, shorten decarburization time, and improve the effect of molten steel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

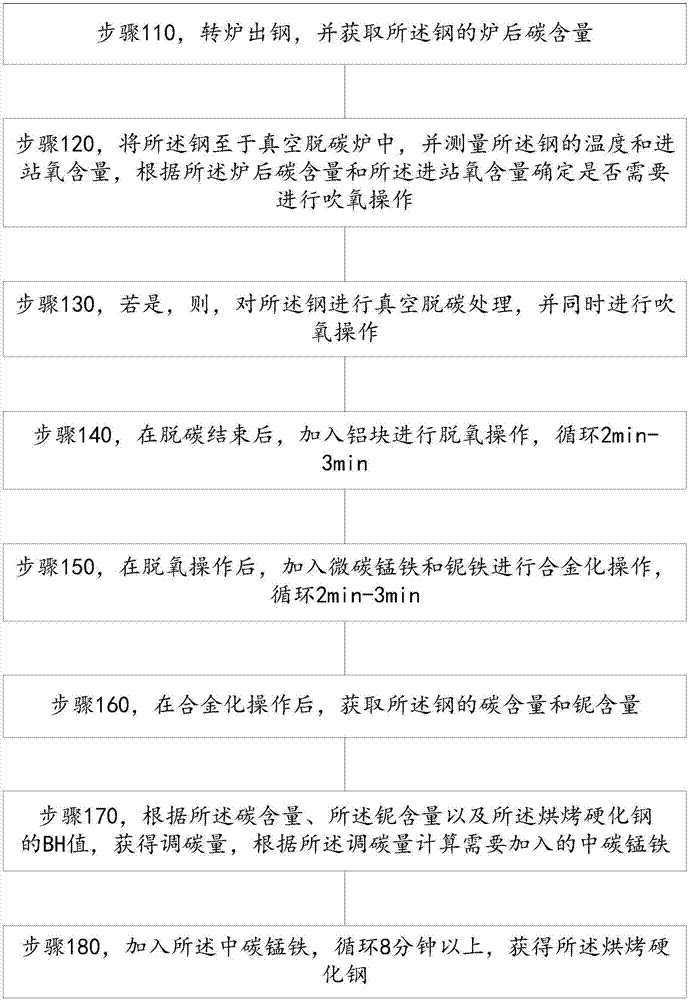

[0030] The embodiment of the present application provides a smelting control method for bake-hardened steel, which solves the problems in the prior art due to fluctuations in niobium absorption rate and medium-carbon ferromanganese carbon content, which lead to a large deviation between the actual value and the theoretical value, and the BH value is qualified. The rate is low, which affects the refining rate of bake-hardened steel, and the process takes a long time, and the aluminum loss is relatively large. The secondary aluminum adjustment in the later stage affects the quality of molten steel.

[0031] The technical solutions in the embodiments of the present application are the above-mentioned technical problems, and the general idea is as follows:

[0032] By supplying oxygen during the vacuum decarburization treatment, the controllability of the decarburization rate and the oxygen activity at the end of decarburization is improved. In addition, the order of alloy addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com