Preparation method of cyclohexanone oxime

A technology of cyclohexanone oxime and cyclohexanone, which is applied in the field of preparation of organic compounds, can solve the problems of difficult separation of impurities, poor product quality, and many impurities, and achieve the effect of low-cost and high-quality production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

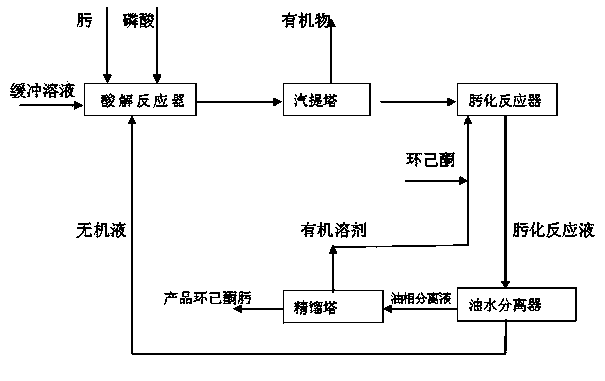

[0034] As shown in the attached figure, 100 g of phosphoric acid with a concentration of 85% by mass and 300 g of aqueous ammonia with a concentration of 5% by mass were prepared to prepare 400 g of phosphate buffer solution (phosphate concentration 2.2 mol / kg).

[0035] In the acidolysis reactor, drop 40g of butanone oxime into a mixture containing 400g of phosphate buffer solution and 65g of 85% phosphoric acid for reaction (the molar ratio of oxime to free phosphoric acid is 0.8:1) to obtain of inorganic fluids. The reaction temperature is controlled at 110° C., and the reaction time is 3 hours; the obtained reaction solution is passed through a stripping tower to remove organic matter butanone oxime and butanone by stripping.

[0036] Dissolve 50g of cyclohexanone in 200g of toluene, and then drop it into an oximation reactor equipped with 400g of inorganic liquid for removing organic matter to perform oximation reaction to obtain a reaction mixture. The reaction temperatu...

Embodiment 2

[0041] 346g of phosphoric acid with a mass percent concentration of 50% and 200g of ammonia water with a mass percent concentration of 15% were configured to form 546g of phosphate buffer solution (phosphate concentration: 3.23mol / kg).

[0042] Add 95g of butanone oxime dropwise to the mixed solution containing 500g of phosphate buffer solution and 65g of 85% phosphoric acid (the molar ratio of oxime to free phosphoric acid is 1.95:1) to obtain an inorganic liquid containing hydroxylamine phosphate. The reaction temperature was controlled at 60° C., and the reaction time was 4 hours; the obtained reaction solution was stripped to remove organic matter.

[0043] Dissolve 50g of cyclohexanone in 200g of toluene, and then drop it into a reactor equipped with 400g of inorganic liquid to remove organic matter for oximation reaction to obtain a reaction mixture. The reaction temperature is 90°C and the reaction time is 1h. The reaction mixture is separated from oil and water, and th...

Embodiment 3

[0047] 247g of phosphoric acid with a mass percent concentration of 70% and 100g of ammonia water with a mass percent concentration of 30% were prepared to form 347g of phosphate buffer solution (phosphate concentration 5.0mol / kg).

[0048]Add 25g of butanone oxime dropwise to a mixed solution containing 300g of phosphate buffer solution and 65g of 85% phosphoric acid (the molar ratio of oxime to free phosphoric acid is 0.5:1) to obtain an inorganic liquid containing hydroxylamine phosphate. The reaction temperature was controlled at 140° C., and the reaction time was 1 h; the obtained reaction solution was stripped to remove organic matter.

[0049] 50g of cyclohexanone was dissolved in 200g of toluene, and then dropped into a reactor equipped with 400g of inorganic liquid to remove organic matter for oximation reaction to obtain a reaction mixture. The reaction temperature was 30°C and the reaction time was 3h. The reaction mixture is separated from oil and water, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com