Semi-heat accumulating type rotating bed equipment and process for producing large-size high-activity lime

A rotating bed and heat storage technology, applied in lighting and heating equipment, lime production, furnace types, etc., can solve the problems of high energy consumption of comprehensive finished products, large fluctuations in lime activity, and low utilization rate of ore resources, so as to prevent burnt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

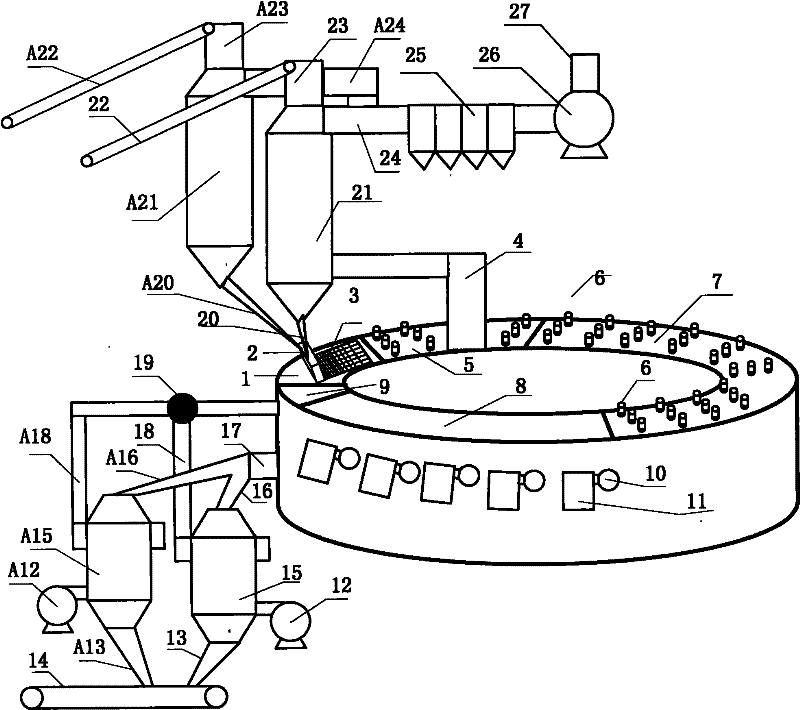

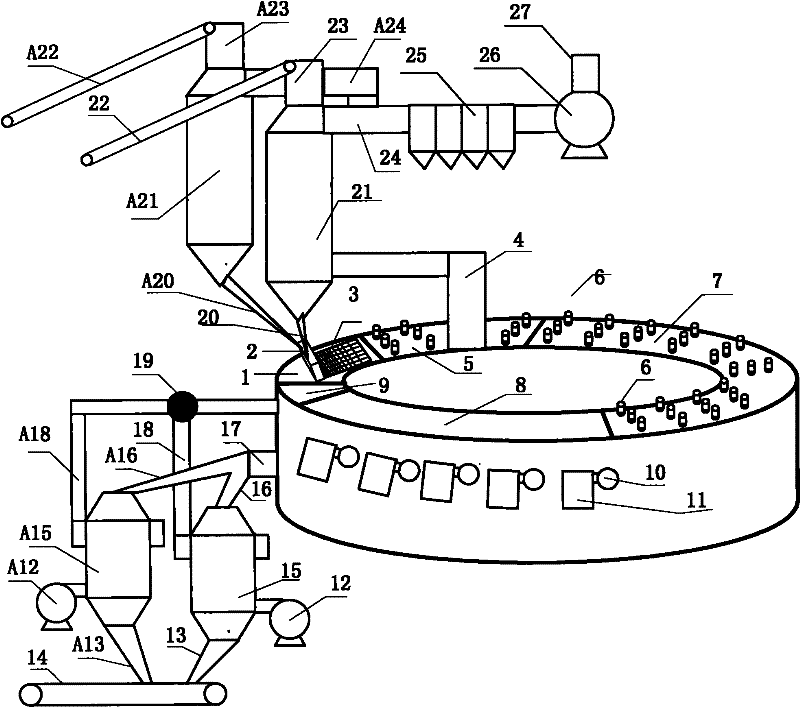

[0043] A semi-regenerative rotary bed equipment, including rotary bed, preheating system, cooling system, dust removal system and finished product delivery system; It is connected to the rotary bed; the dust removal system is connected to the preheating system through the flue gas pipe 24; the cooling system is located below the discharge side of the rotary bed, and is connected to the cooling system through the discharge machine 17 and the discharge chute 16; the cooling system is connected to the cooling system through the finished product chute 13 is connected with the finished product conveying system.

[0044] The rotary bed includes a distribution area 1, a heating area 5, a high temperature area 7, a soaking area 8 and a discharge area 9, and the distribution area 1, the heating area 5, the high temperature area 7, the soaking area 8 and the discharge area 9 are sequentially head to tail Connected; the vibrating screen 3 and the distributor 2 are installed above the dis...

Embodiment 2

[0053] A kind of semi-regenerative rotary bed equipment of the present invention, see figure 1 , including rotary bed, preheating system, cooling system, dust removal system and finished product conveying system; the preheating system is located above the cloth side of the rotary bed, and is connected to the rotary bed through the distributor 2 and the vibrating screen 3; the dust removal system passes through the smoke The air pipeline 24 is connected to the preheating system; the cooling system is located below the discharge side of the rotary bed, and is connected to the discharge chute 16 through the discharge machine 17; the finished product delivery system is connected to the cooling system through the finished product chute 13.

[0054] The rotary bed includes a distribution area 1, a heating area 5, a high temperature area 7, a soaking area 8, and a discharge area 9; The vibrating screen 3 and the distributor 2 are installed above the distribution area 1, the distribut...

Embodiment 3

[0068] In the semi-regenerative rotary bed equipment of the present invention, the preheater 21 adopts a chain grate type preheater, and the discharger 17 adopts a water-cooled screw discharger. The fuel is blast furnace gas. Others are the same as embodiment 1.

[0069] The activity of the lime product is 395-399ml, the powder rate is 3.0%, and the raw and burnt is 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com