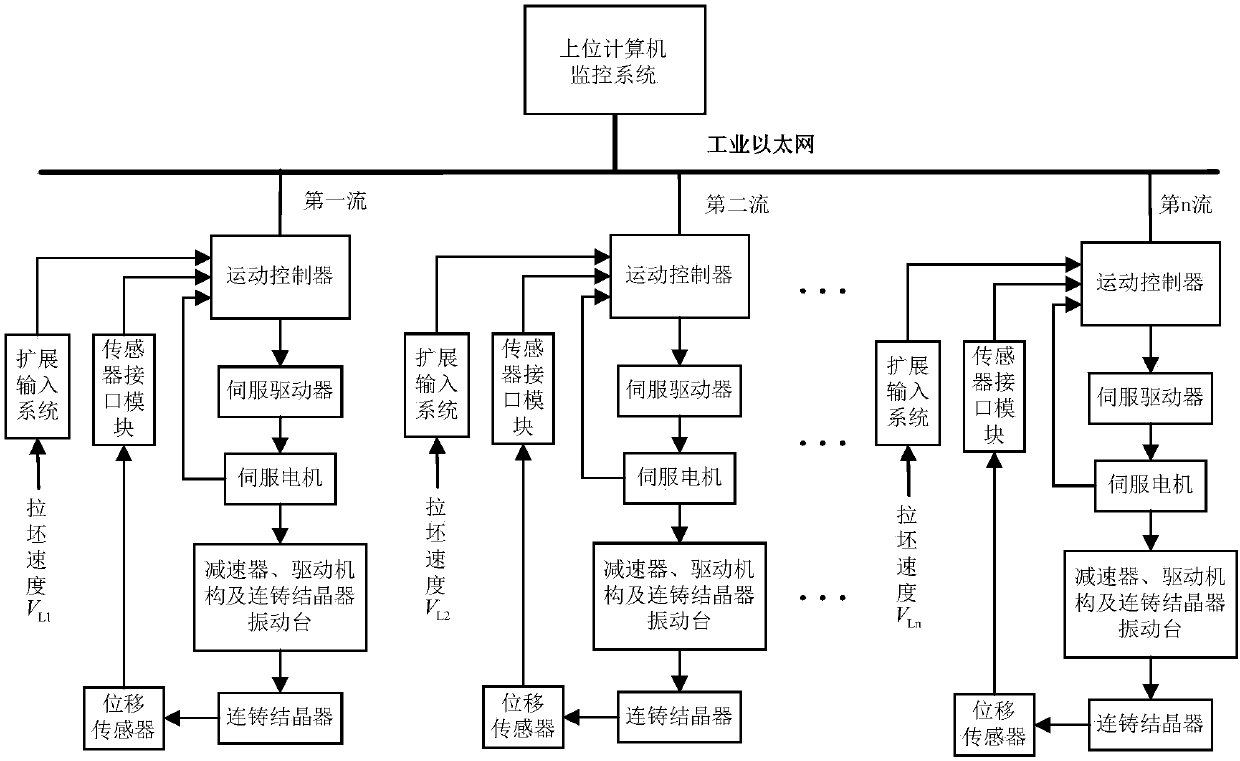

Servo motor driven continuous casting crystallizer non-sinusoidal oscillation distributed control system

A distributed control system and continuous casting crystallizer technology, applied in the field of continuous casting, can solve problems such as safety risks, high cost, complex structure, etc., and achieve the effects of improving safety and reliability, convenient debugging, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

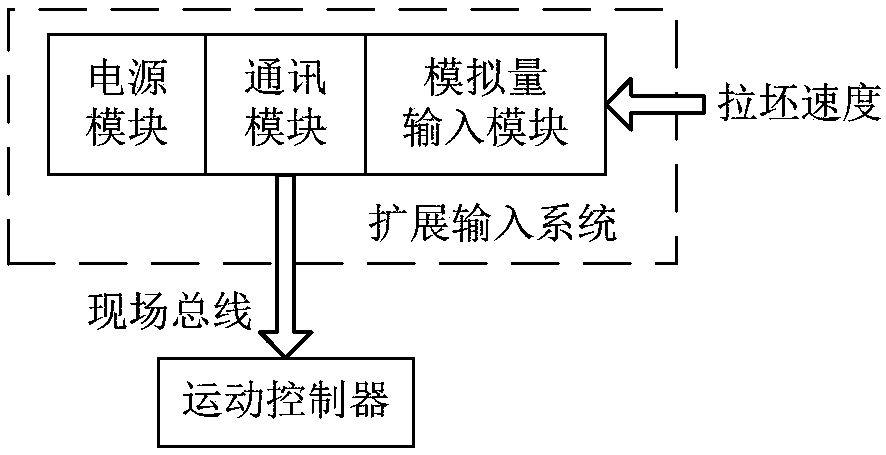

Method used

Image

Examples

Embodiment

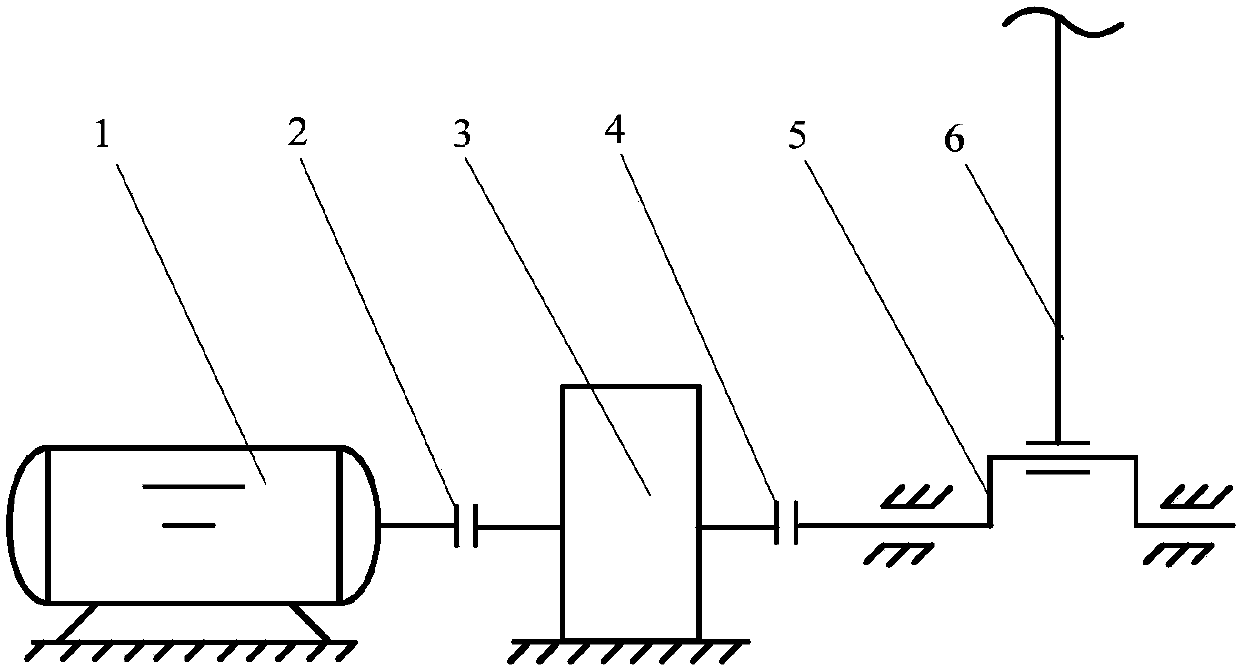

[0047] A steel plant has a full-arc billet continuous casting machine mold, casting 150*150 billets, the type of non-sinusoidal vibration waveform of the continuous casting mold can be selected through the host computer monitoring system, and the expected displacement adopted by the non-sinusoidal vibration of the mold The waveform can be one of Demark non-sinusoidal vibration waveform or Li Xiankui non-sinusoidal vibration waveform. In this embodiment, the amplitude of non-sinusoidal vibration of the continuous casting mold h=4mm, the waveform deflection rate α=0.2, the reduction ratio i=5, the process parameters a=43.67, b=36.33, the casting speed V L =2.4m / min, the vibration frequency f=141.14 can be obtained by calculation, the parameters A=0.33, E=0.158.

[0048] The above-mentioned full-arc billet continuous casting machine adopts the non-sinusoidal vibration collection and distribution control system of the continuous casting mold driven by the servo motor of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com