Thermoplastic polyester extrusion foam forming method

A thermoplastic polyester and extrusion foaming technology, which is applied in the field of thermoplastic polyester extrusion foaming, can solve the problems of difficulty in obtaining foamed products, rough product surfaces, and difficulty in melt transportation, avoiding thermal decomposition, The effect of high-quality production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

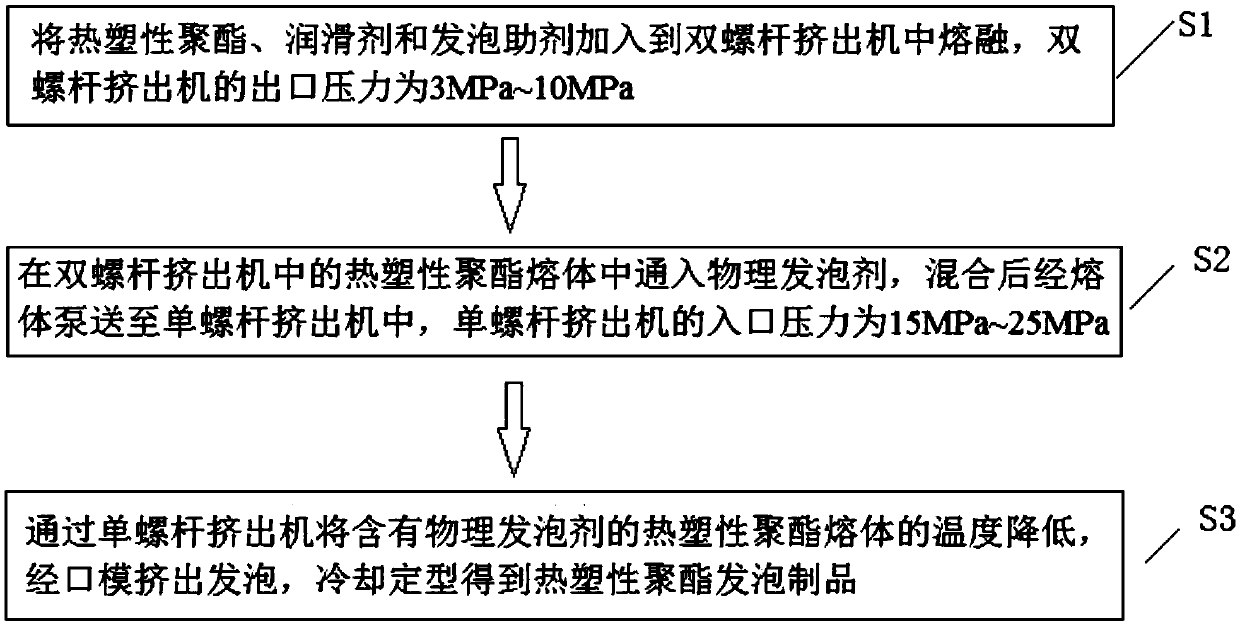

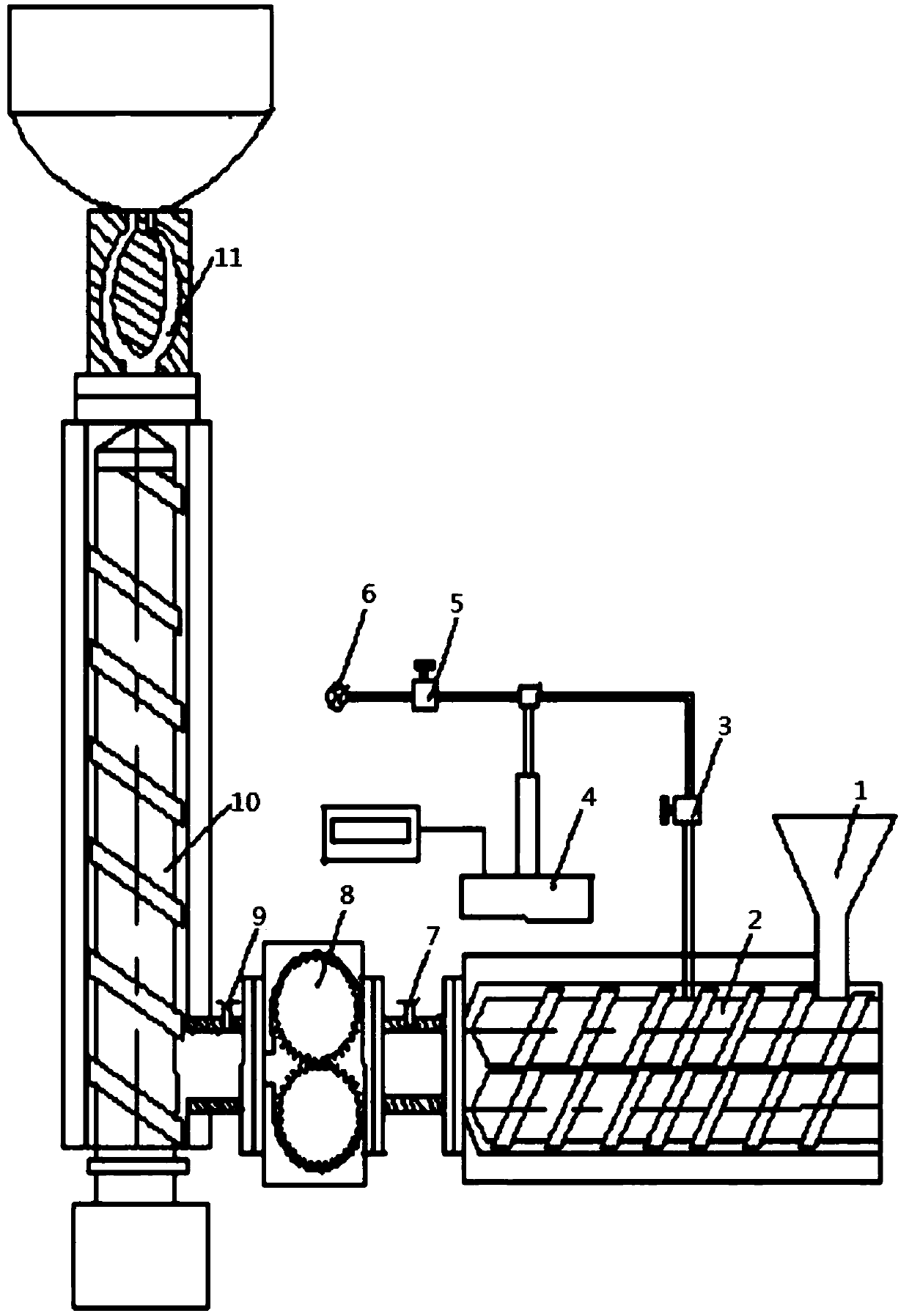

Method used

Image

Examples

Embodiment 1

[0040] Raw materials: polyethylene terephthalate (PET), BG80, Sinopec Yizheng Chemical Fiber Co., Ltd., intrinsic viscosity 0.8dl / g;

[0041] Chain extender, pyromellitic anhydride (PMDA), Sinopharm Chemical Reagent Co., Ltd.;

[0042] Nucleating agent: talcum powder, 1000 mesh;

[0043] Antioxidant: tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester (antioxidant 1010), Nanjing Hualiming Chemical Co., Ltd.;

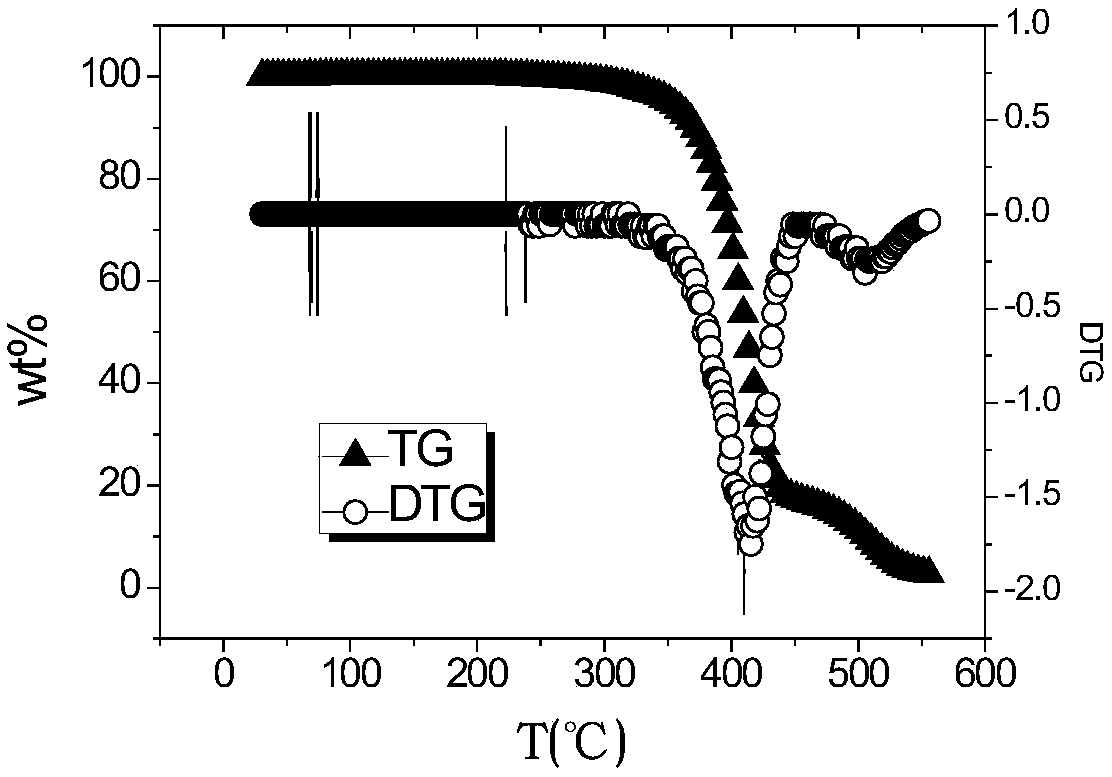

[0044] Lubricant: Pentaerythritol stearate PETs, Jiangsu Xingtai Photochemical Auxiliary Co., Ltd., thermal decomposition temperature 400 ° C. The decomposition temperature was tested by a thermogravimetric analyzer, the heating rate was 10°C / min, the atmosphere was nitrogen, and the temperature at which the thermogravimetric rate was the largest on the TG temperature curve was defined as the thermal decomposition temperature. image 3 It is the thermal weight loss curve of pentaerythritol stearate.

[0045] Foaming process: Preheat the e...

Embodiment 2

[0049] Raw materials and technology are with embodiment 1, and difference is that lubricant pentaerythritol stearate is added in the form of master batch, master batch concentration 50wt%, master batch matrix is PET, and addition is 6% of PET gross weight, adds up to pentaerythritol The added amount of stearic acid ester is 3wt% of the total weight of PET.

Embodiment 3

[0051] The raw materials and process are the same as in Example 1, except that the chain extender adopts epoxy-based chain extender, ADR4368 of BASF Company, and the addition amount is 1wt%; the lubricant adopts modified ethylene bis stearic acid amide EBS, and thermally decomposes The temperature is 300°C, added in the form of 50% masterbatch concentration, the amount of masterbatch added is 10wt% of the total weight of PET, and the foaming agent is CO 2and cyclopentane, injected from two sets of pumping systems and two gas injection ports respectively, CO 2 The injection amount of the injection is 1wt% of the total weight of PET, and the injection amount of cyclopentane is 2wt% of the total weight of PET.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com