Tension-feeding and die-cutting automatic embroidering machine and operation method thereof

A technology for feeding dies and embroidery machines, which is applied in the direction of automatic control embroidery machines, embroidery machines, embroidery machine mechanisms, etc., which can solve the problems of long cutting cycle, high alignment accuracy requirements, cumbersome operation, etc. Cutting precision, high cutting precision of pressing shape, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

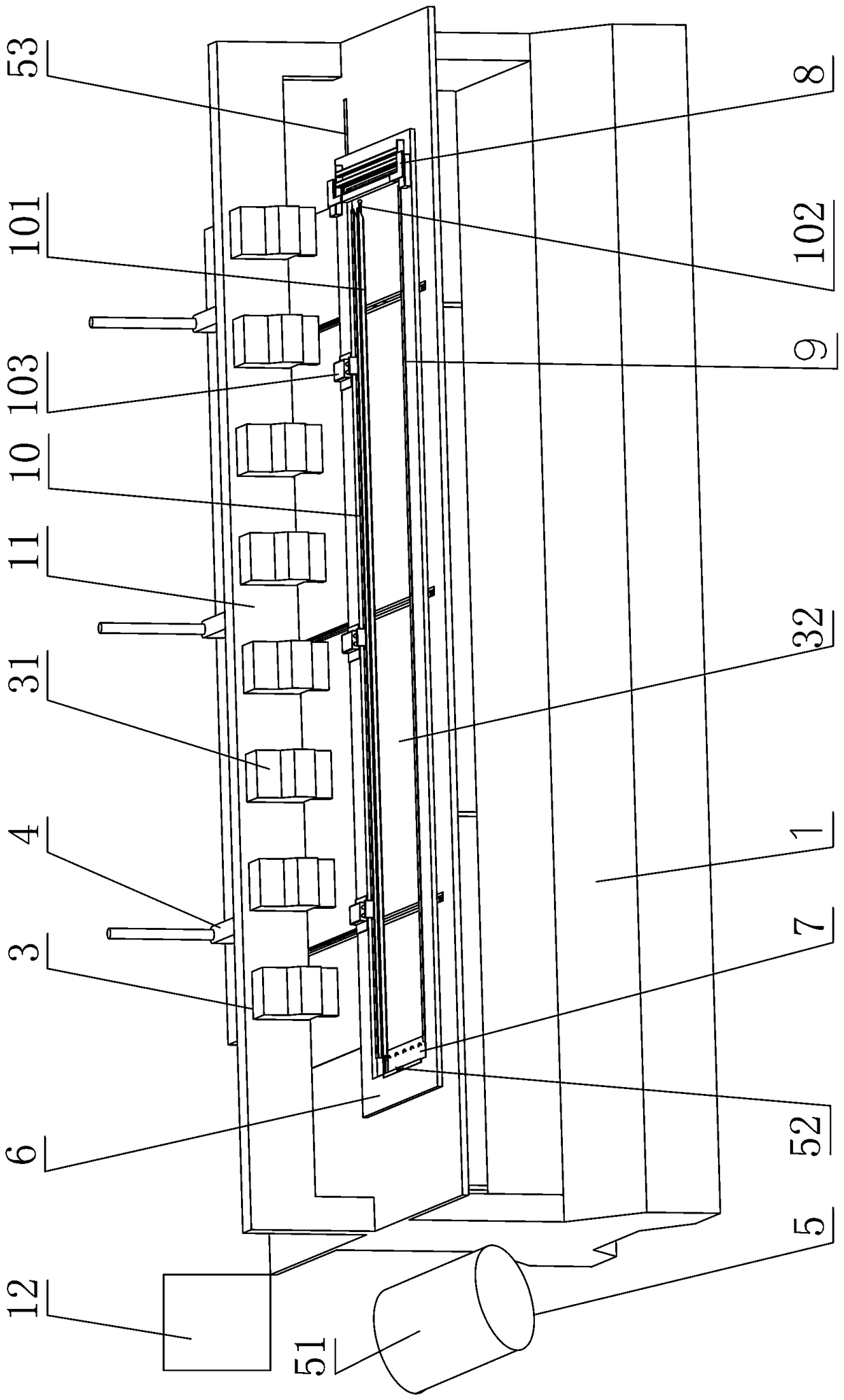

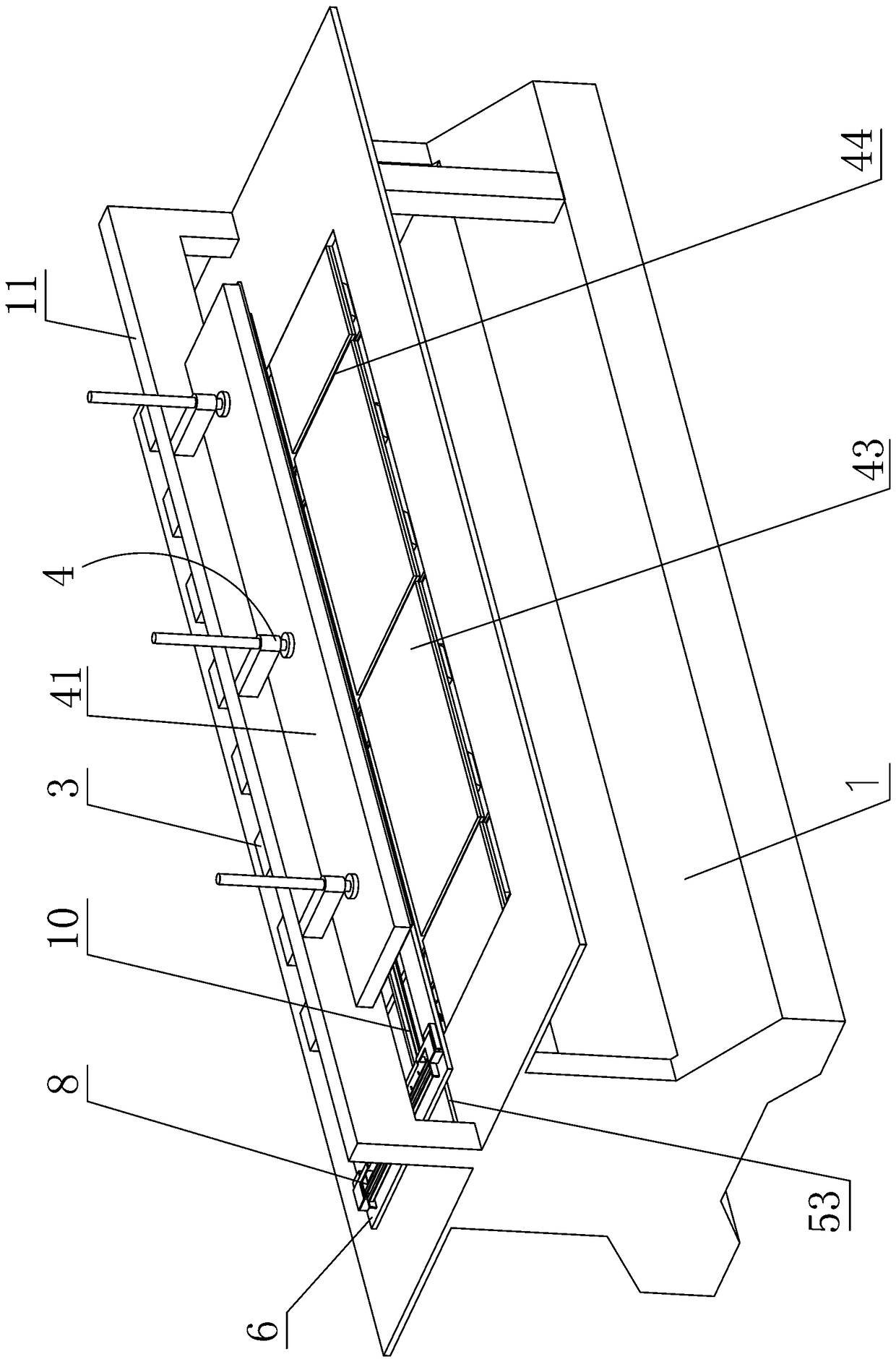

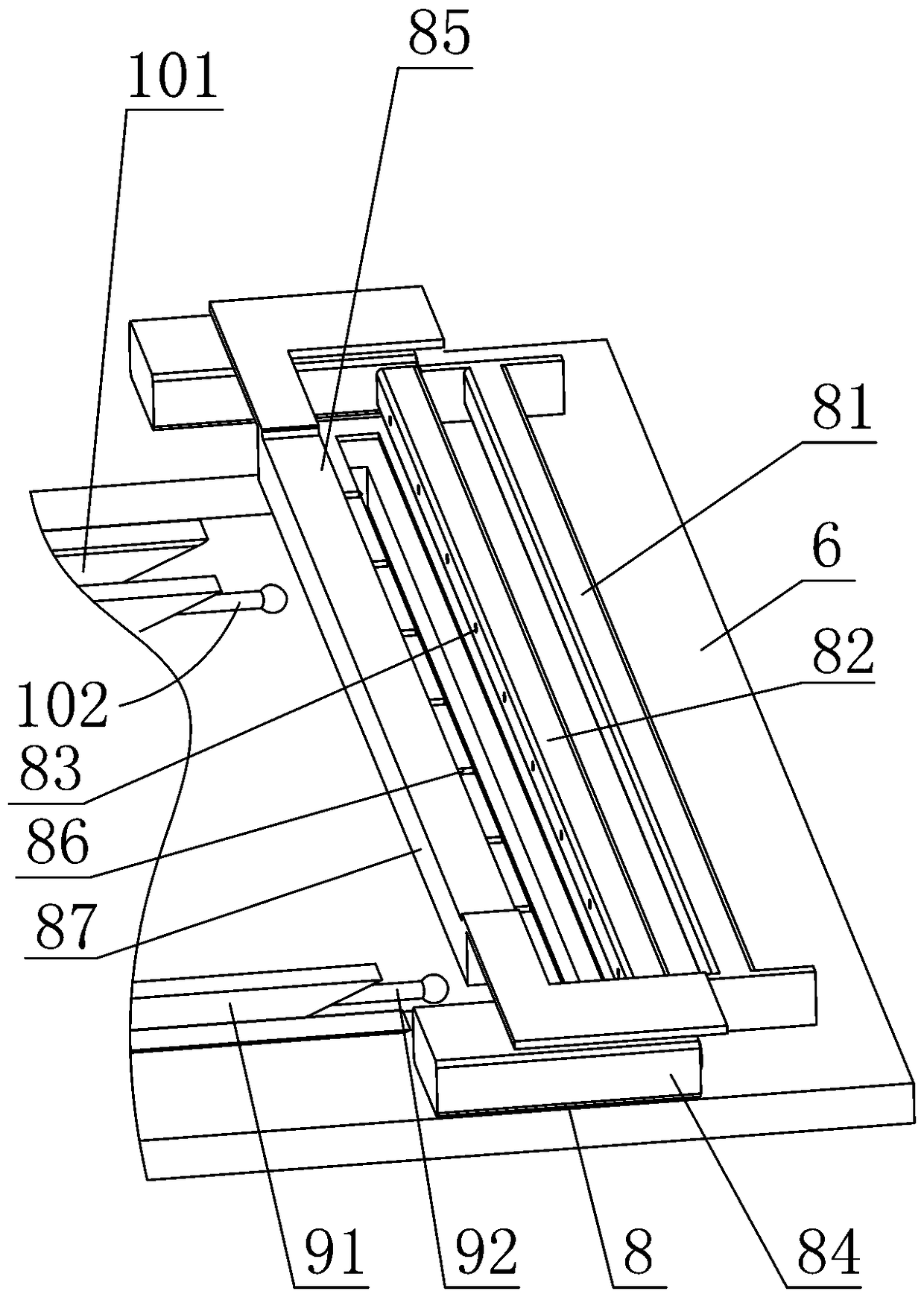

[0054] The present invention will be further described below in conjunction with accompanying drawing, according to Figure 1 to Figure 13 As shown, the tension feeding die-cutting automatic embroidery machine of the present invention includes a frame 1, a moving processing part, a tensioning part, a moving driving part 2, an embroidery part 3, and a pressing and cutting part 4 , receiving part 5.

[0055] The material receiving part 5 is installed on the left side of the frame, and the material receiving part 5 is provided with a tail hook knife 52 on the left side of the embroidery frame 6 .

[0056] Moreover, the embroidery component 3 and the pressure-cutting component 4 are respectively installed on the front side and the rear side of the beam 11 of the frame 1 . The mobile driving part 2 is equipped with a horizontal power conveyor belt 21 and a vertical power conveyor belt 22 connected to the bottom of the mobile processing part.

[0057] Wherein, the mobile processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com