A device for detecting kinks in the tail rope of a hoisting machine

A detection device, tail rope technology, applied in elevators, transportation and packaging, lifting equipment in mines, etc., can solve the problems of control line breakage, easy to be affected by the external environment and falling rocks, etc., to reduce device damage and installation location. Sophisticated design and high environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, structure and principle of the present invention are described in detail:

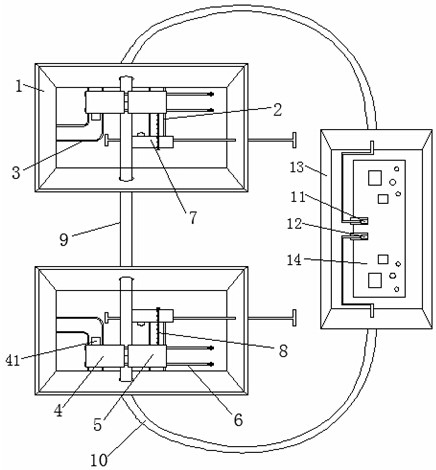

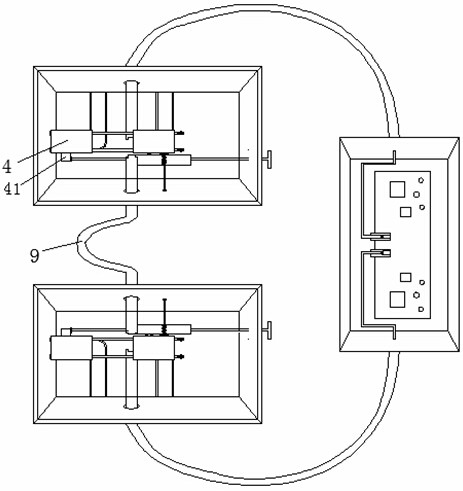

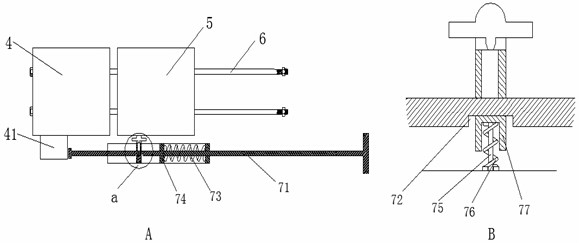

[0021] A kink detection device for the tail rope of a hoisting machine, such as figure 1 As shown, two detection boxes 1, detection optical fibers 9, signal optical fibers 10 and optical transceivers are included, the detection optical fibers 9 are fixed on the isolation sleepers, and the detection boxes 1 are fixed on the steel beams of the fixed isolation sleepers and are located at both ends of the isolation sleepers, Both ends of the detection fiber 9 are respectively connected to the signal fiber 10 in the detection box 1 , and the signal fiber 10 is connected to the optical transceiver. The detection box 1 is provided with a first track 2, a second track 3, a first slider 5 and a second slider 4 that are respectively arranged on the two tracks and can slide along them, and a pushing device. The first track 2 is a straight line. Row track, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com