Patents

Literature

40 results about "Cutting cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cutting cycle includes lower caloric intake and cardiovascular exercise to burn excess fat and reveal newly gained muscle. Bodybuilders will often undertake a cutting cycle in preparation for a competitive event. At first, it may seem counterintuitive to bulk up by eating a lot and gaining fat along with muscle.

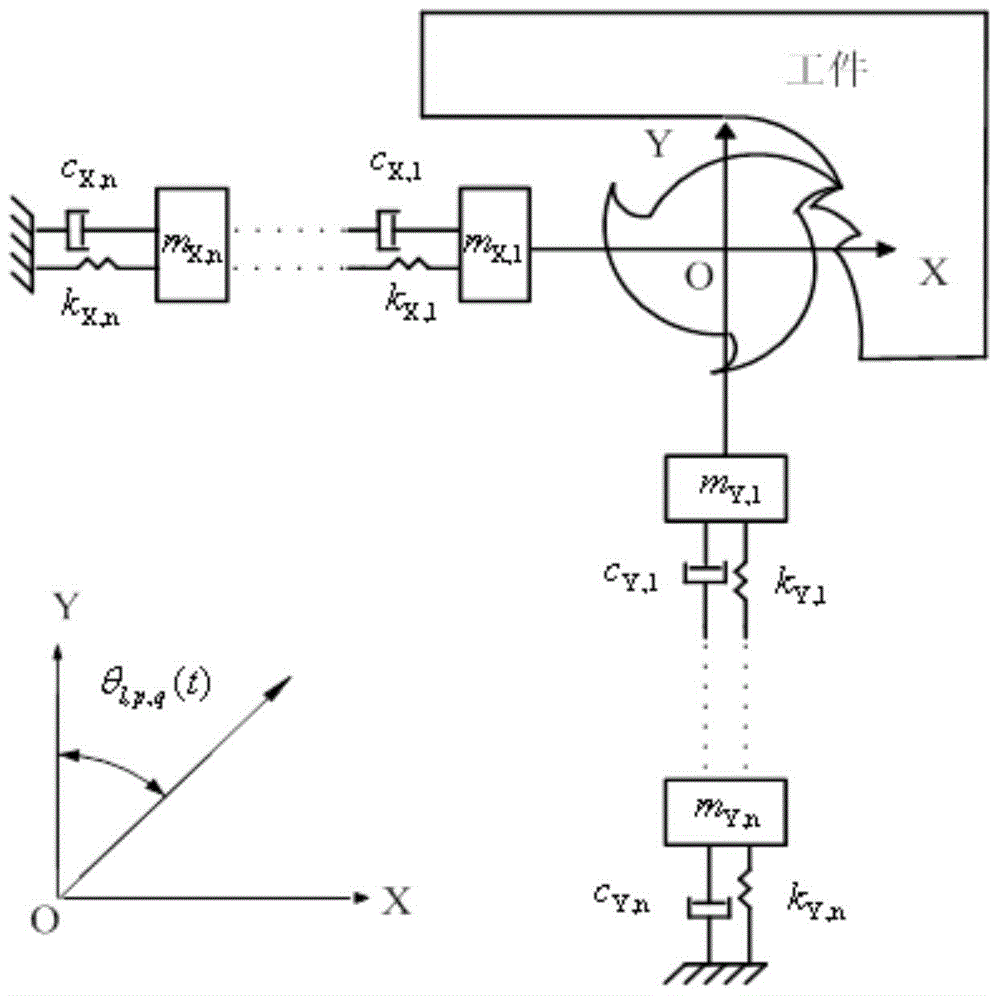

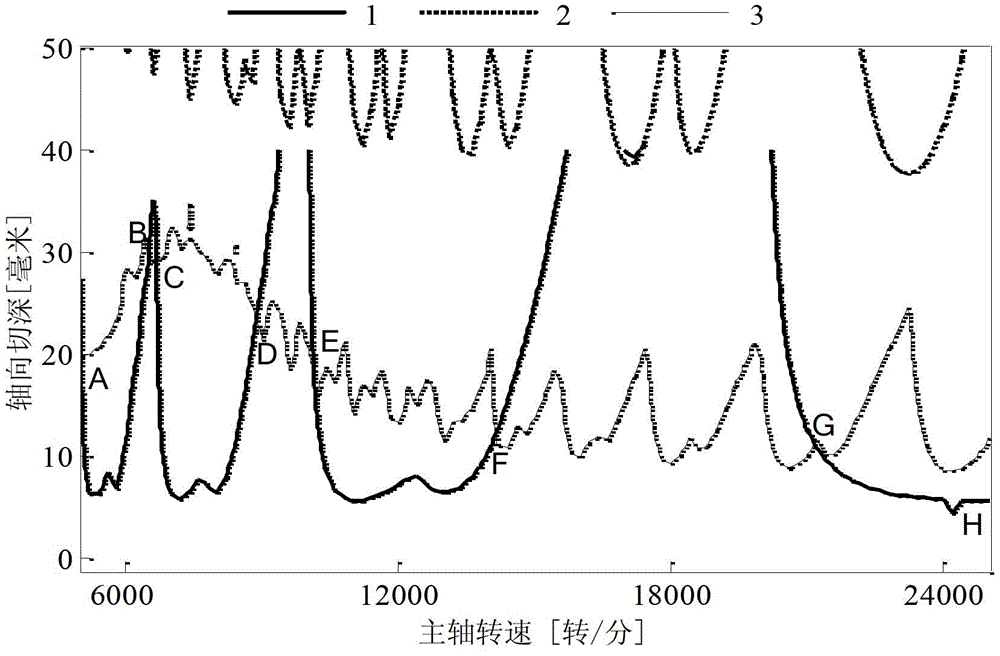

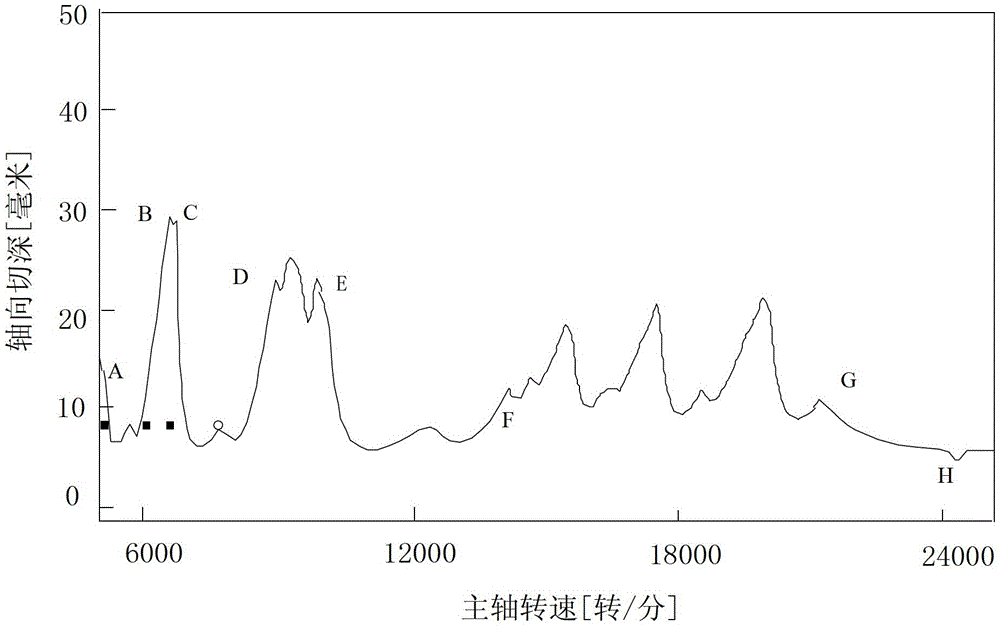

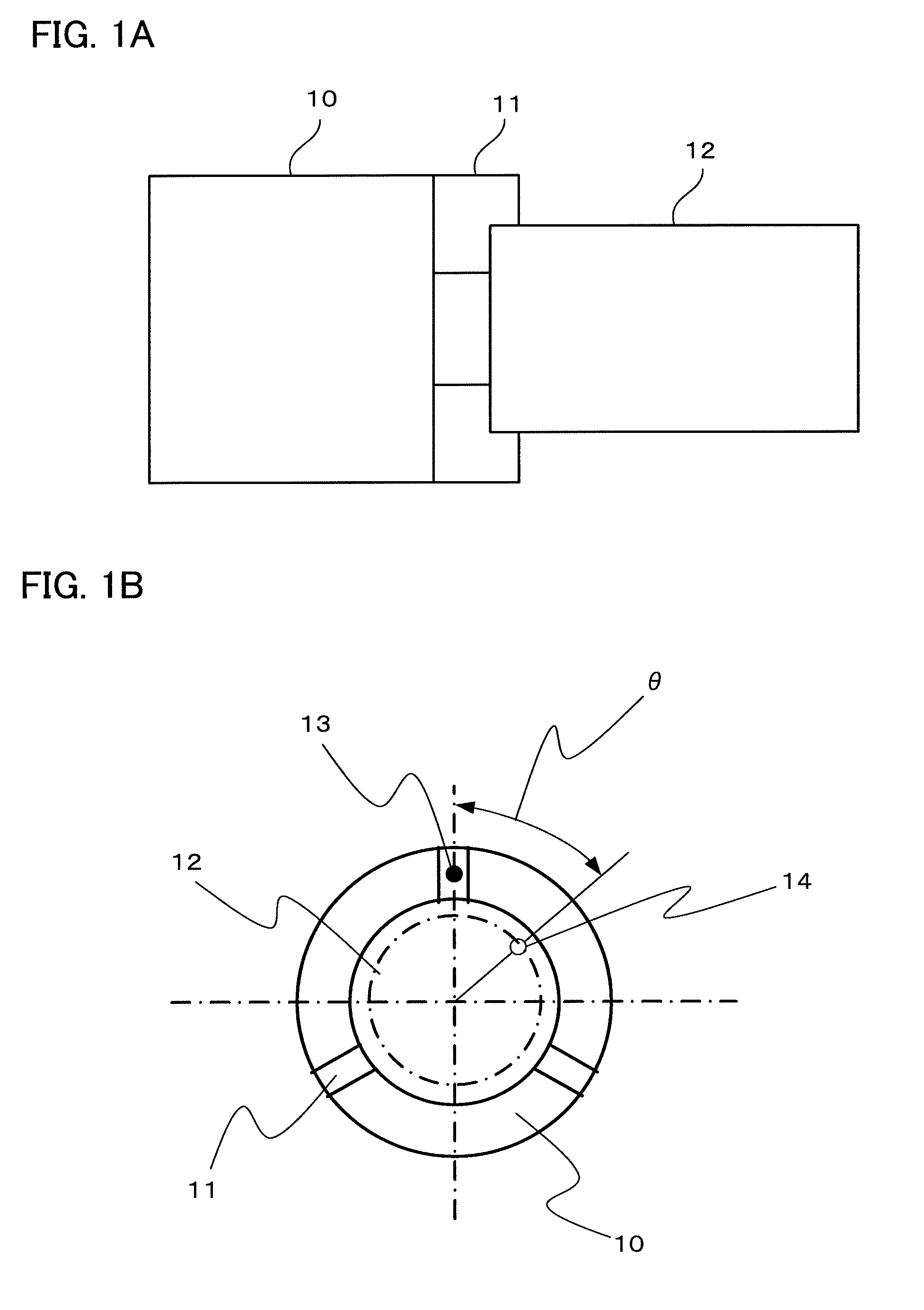

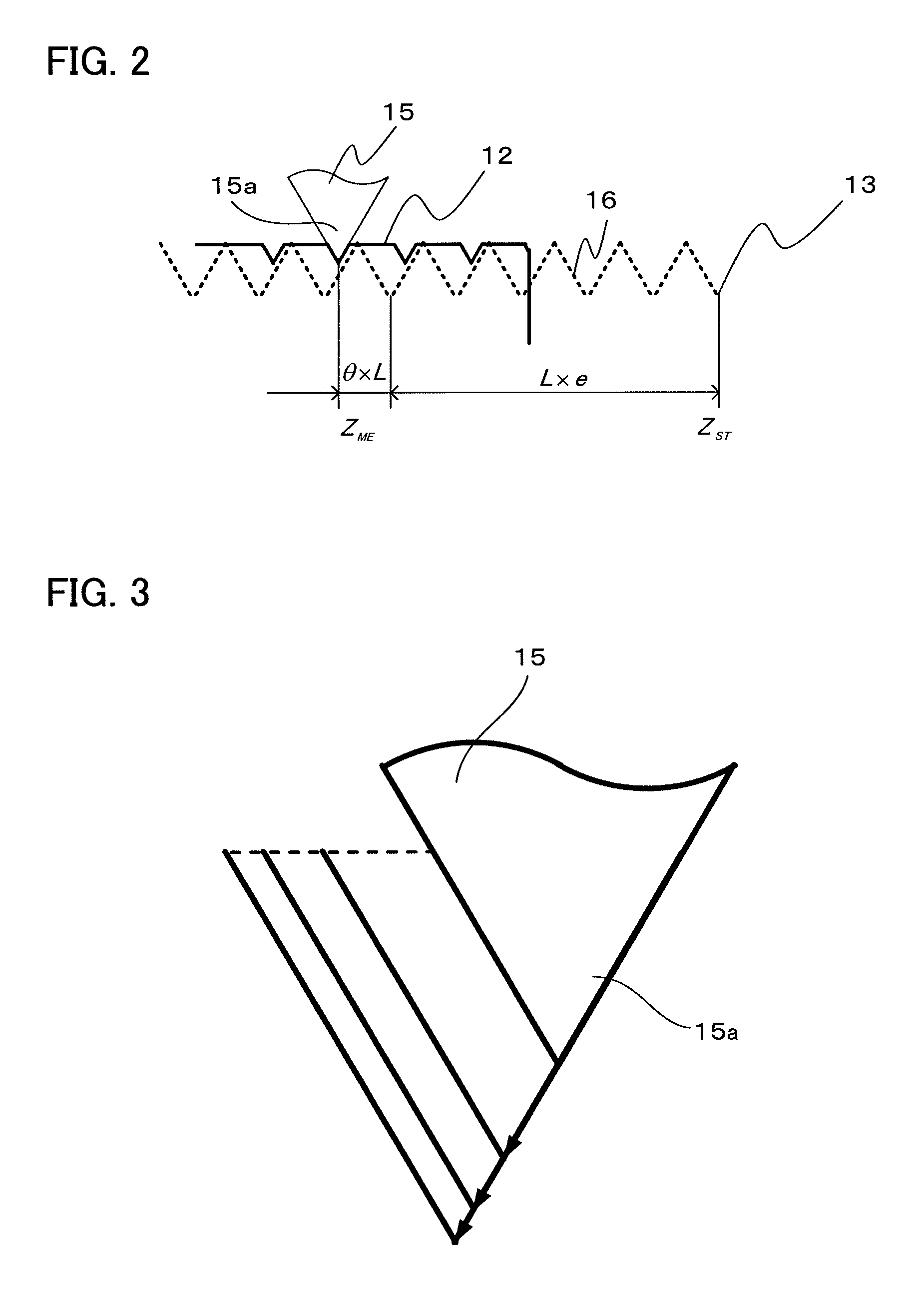

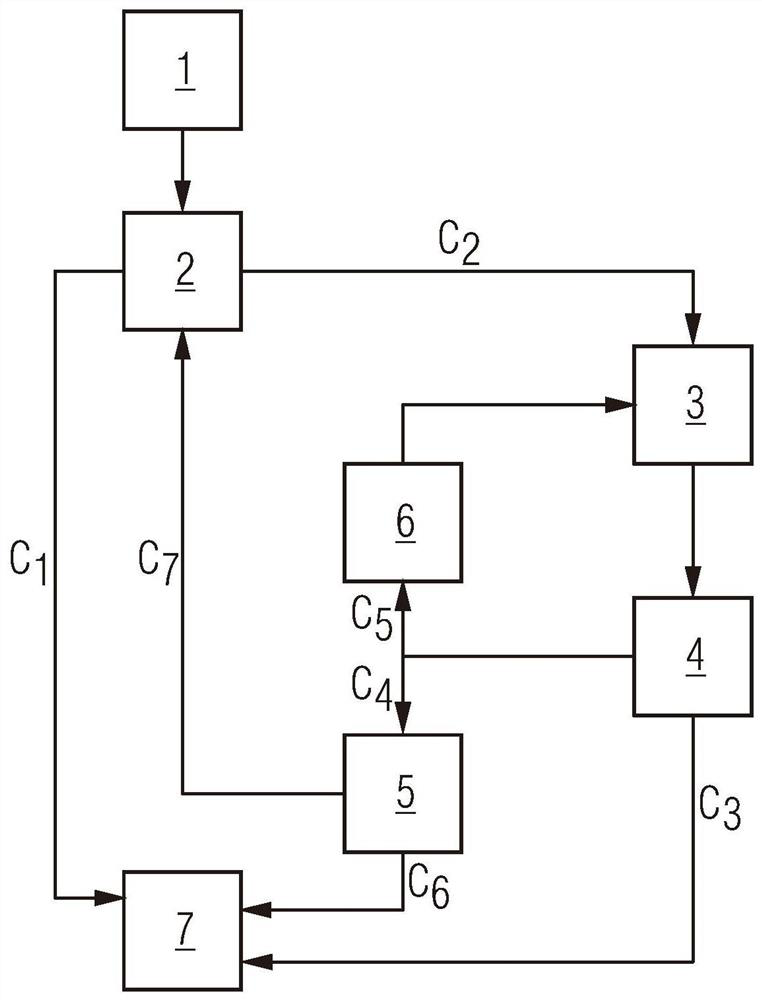

Milling stability domain prediction method under multi-modal coupling

ActiveCN103559550AImprove forecasting efficiencyImprove efficiencyForecastingProcess systemsModal testing

The invention discloses a milling stability domain prediction method under multi-modal coupling to solve a technical problem that the efficiency of an existing milling stability domain prediction method is low. The technical scheme is that firstly the transmission function of a process system is determined through a modal test experiment, then modal parameters are extracted from the transmission function and two orthogonal direction modal parameters are paired and combined, a milling test is carried out to calibrate a milling force coefficient, based on the milling force coefficient and each scale of modal parameters, an improved semi discrete method is employed to obtain a stability lobe diagram under each scale of modals, and finally lobe diagrams under obtained from each scale of modals are drawn in a same coordinate system to obtain a stable domain under multi modal coupling. Through a test, when a cutting cycle is divided into 40 sections, 80 sections and 120 sections, compared with a background technology method, the method can save time for 4949.6 seconds, 74200.4 seconds and 344699.5 seconds, and the efficiency is increased by 85.9%, 92% and 88.5%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

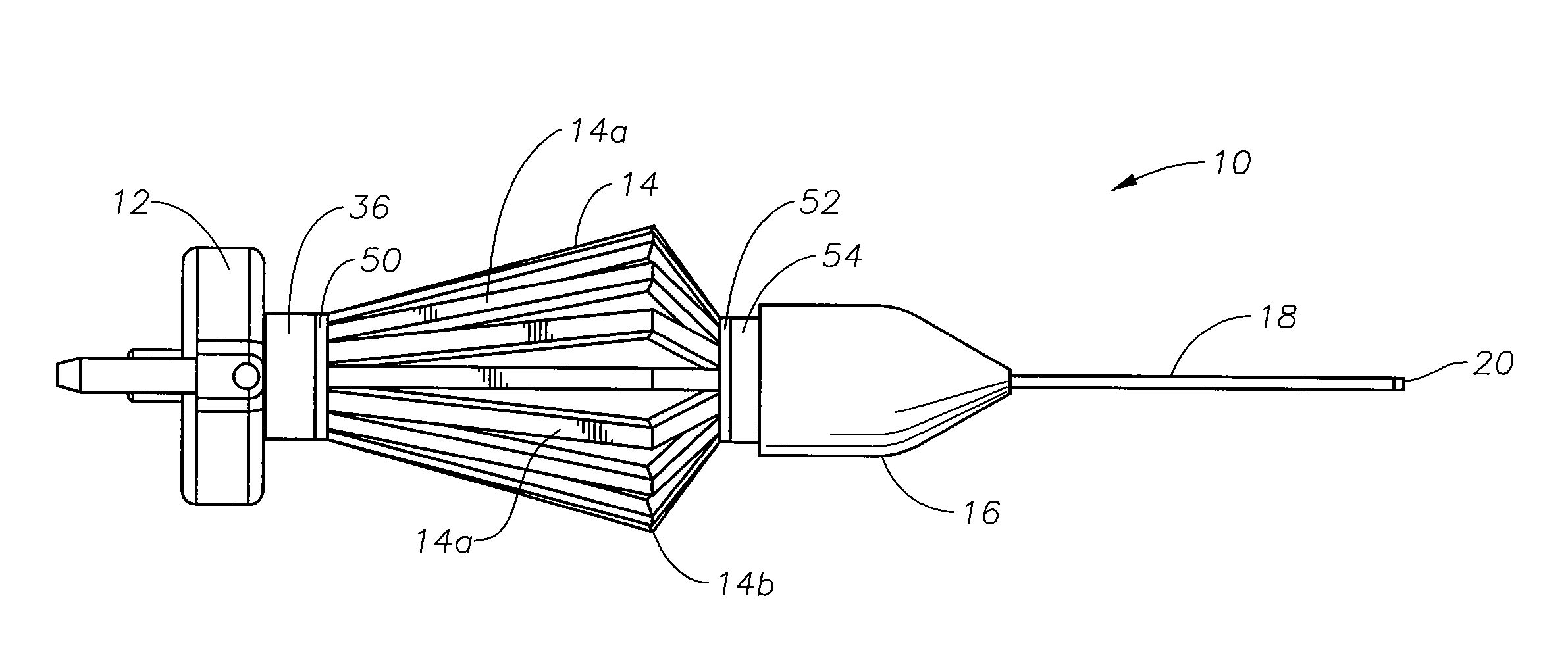

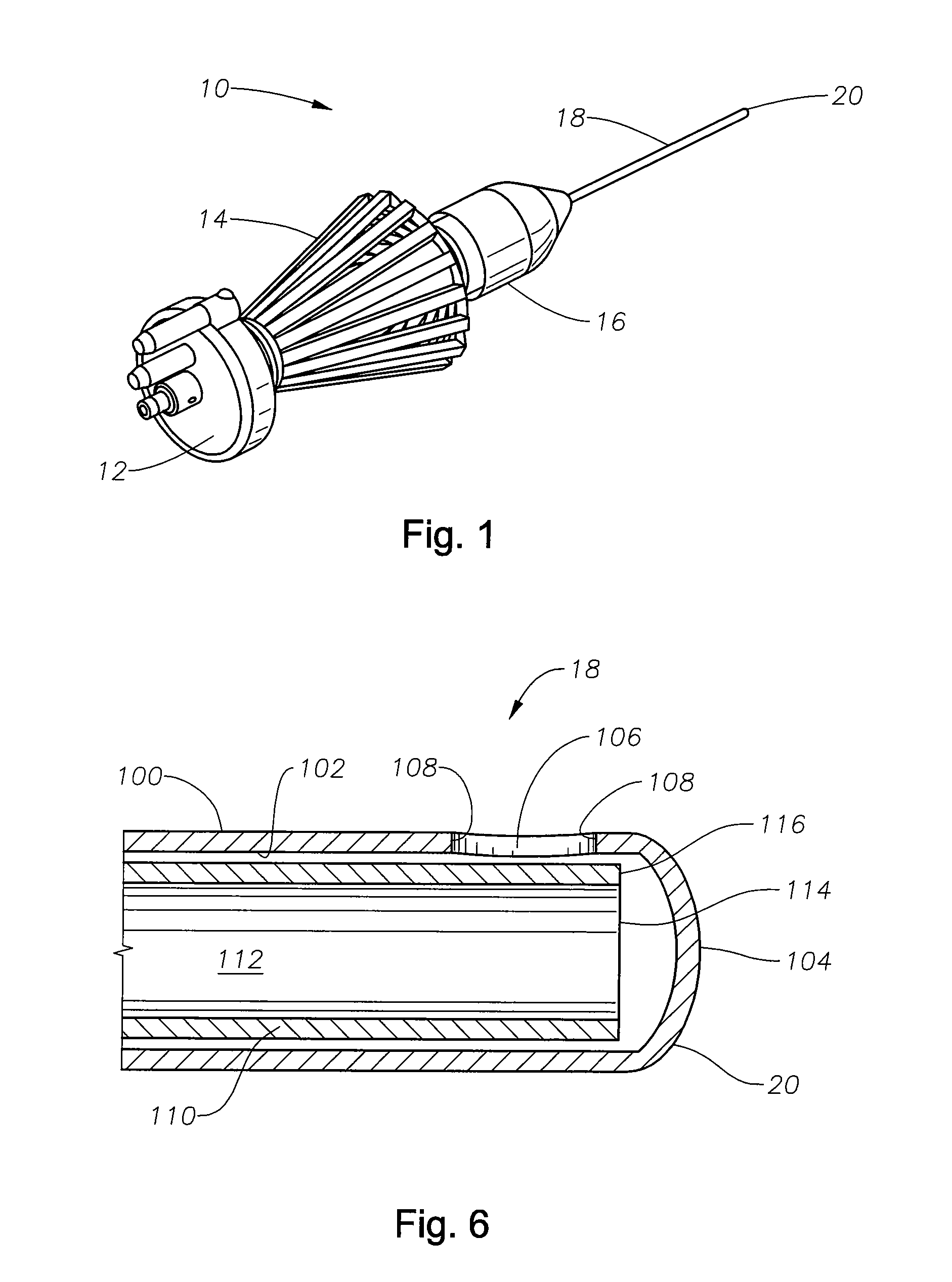

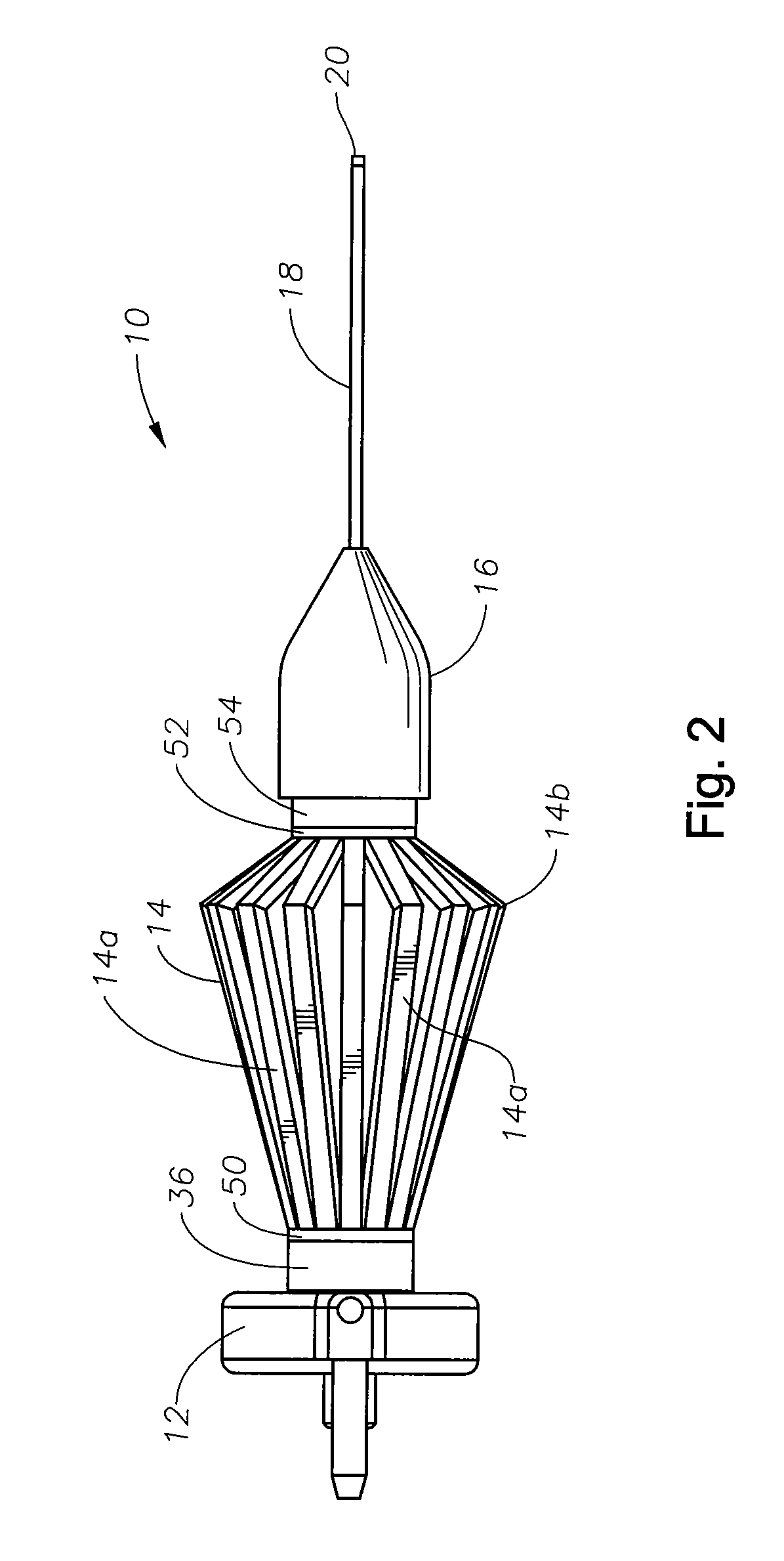

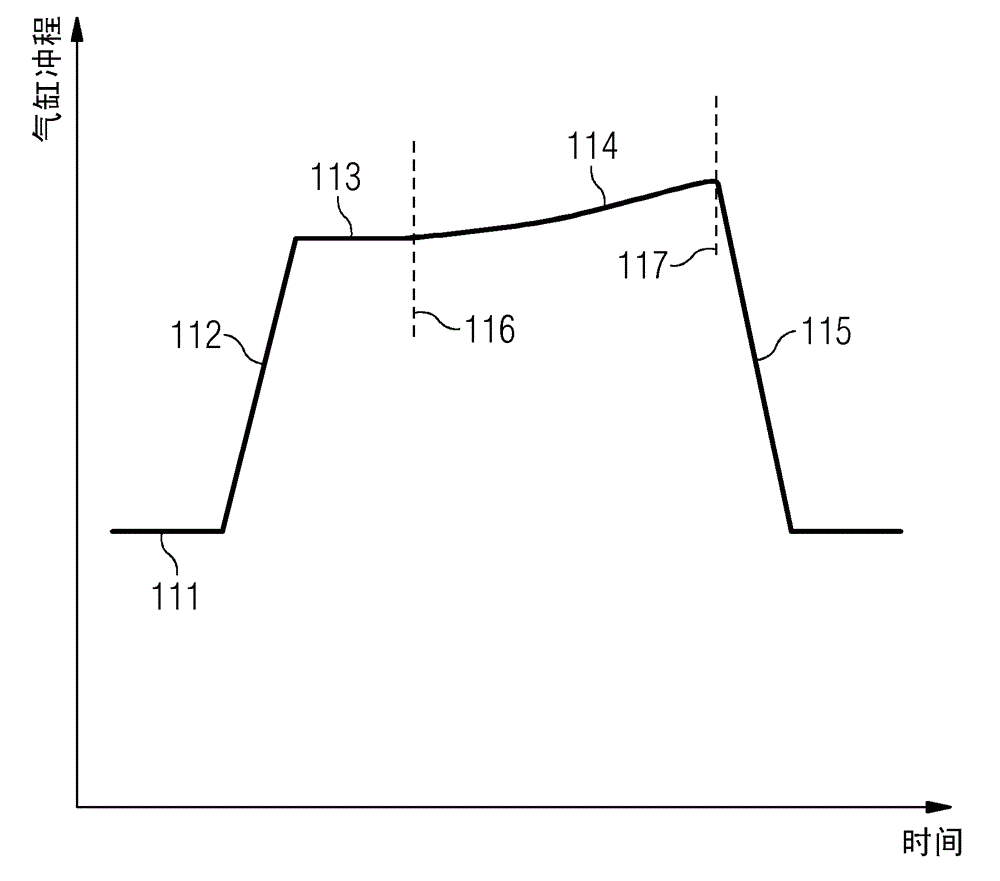

Method of operating a vitrectomy probe

An improved method of operating a vitrectomy probe is disclosed in which the amount of time that the probe port is open during each cut cycle of the probe is fixed and minimized over all cut rates of the probe.

Owner:ALCON RES LTD

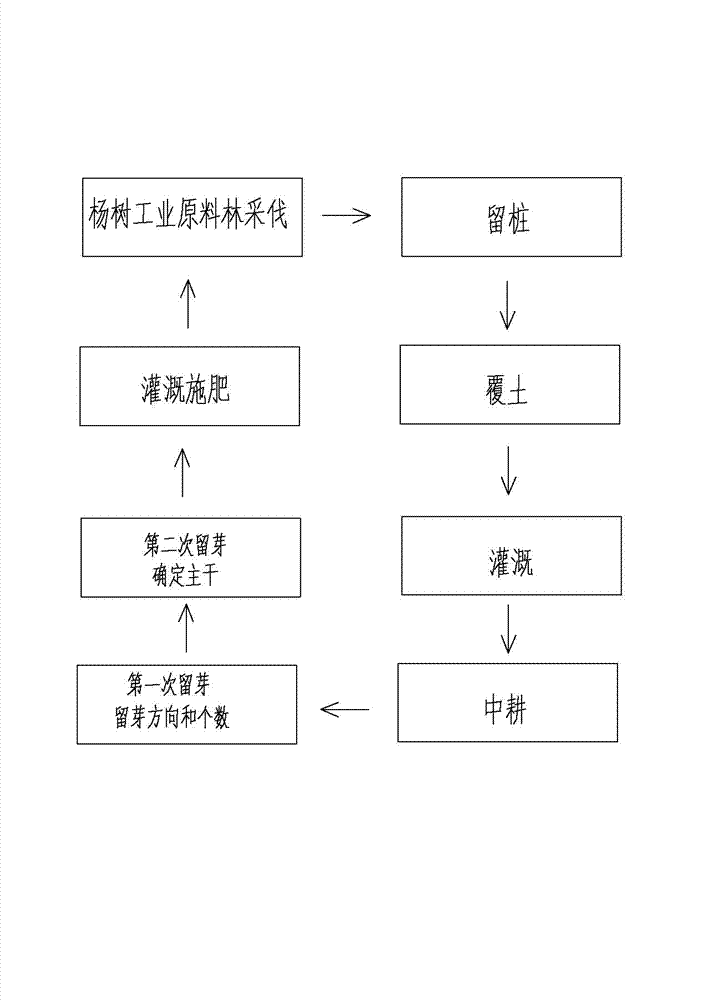

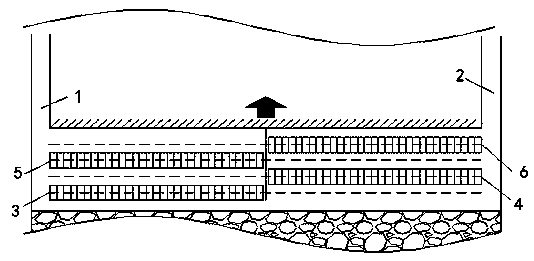

Stump reserving bud afforestation method for cutting poplar industry raw material forest

InactiveCN102771354ALarge nutrient absorption areaPromote growthClimate change adaptationAfforestationGrowth heightCutting cycle

The invention relates to the technical field of afforestation, in particular to a stump reserving bud afforestation method for cutting a poplar industry raw material forest. The stump reserving bud afforestation method comprises a first step of cutting poplars in the poplar industry raw material forest before sap flows in spring, reserving stumps, and enabling the tops of the stumps to be higher than the ground; a second step of enabling the soil to be covered on the stumps, and enabling the thickness of the covering soil to be higher than the tops of the stumps; a third step of instantly irrigating the poplar industry raw material forest where the soil is covered; a fourth step of performing intertillage on the poplar industry raw material forest undergoing natural reforestation; and a fifth step of enabling the growth height of buds of the stumps to be 8cm to 10cm. According to the stump reserving bud afforestation method, the complex afforestation process of digging original stumps, flattening land, digging planting holes, purchasing seedlings and planting is not required, the afforestation cost is reduced, the tree nutrition absorption area is large by reserving huge root systems of the original trees, growth of the trees is accelerated after the renewed trees grow normally, the cutting cycle is shortened simultaneously, and production benefit is greatly improved.

Owner:INST OF AFFORESTATION & DESERTIFICATION PREVENTION & CONTROL XINJIANG ACADEMY OF FOREST SCI

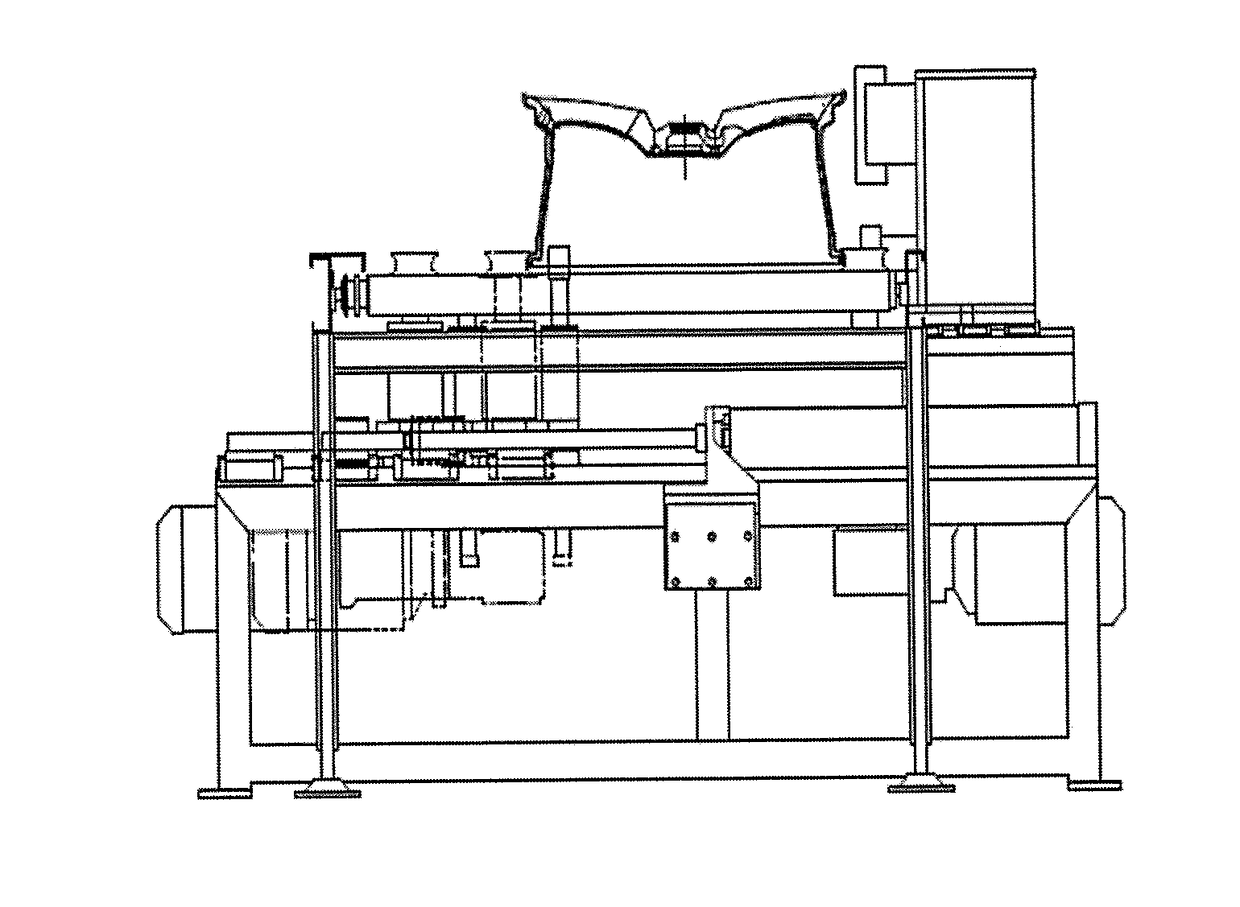

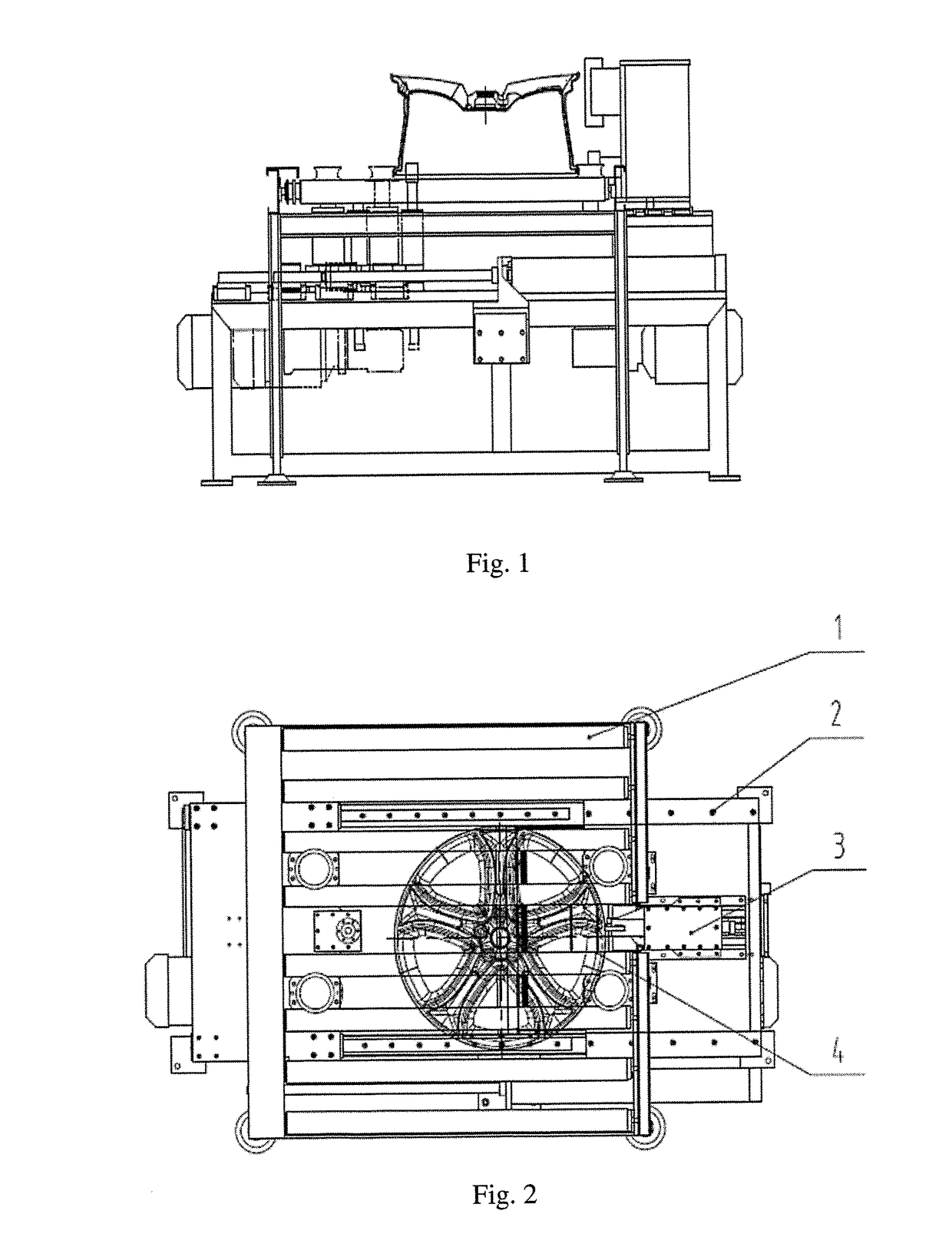

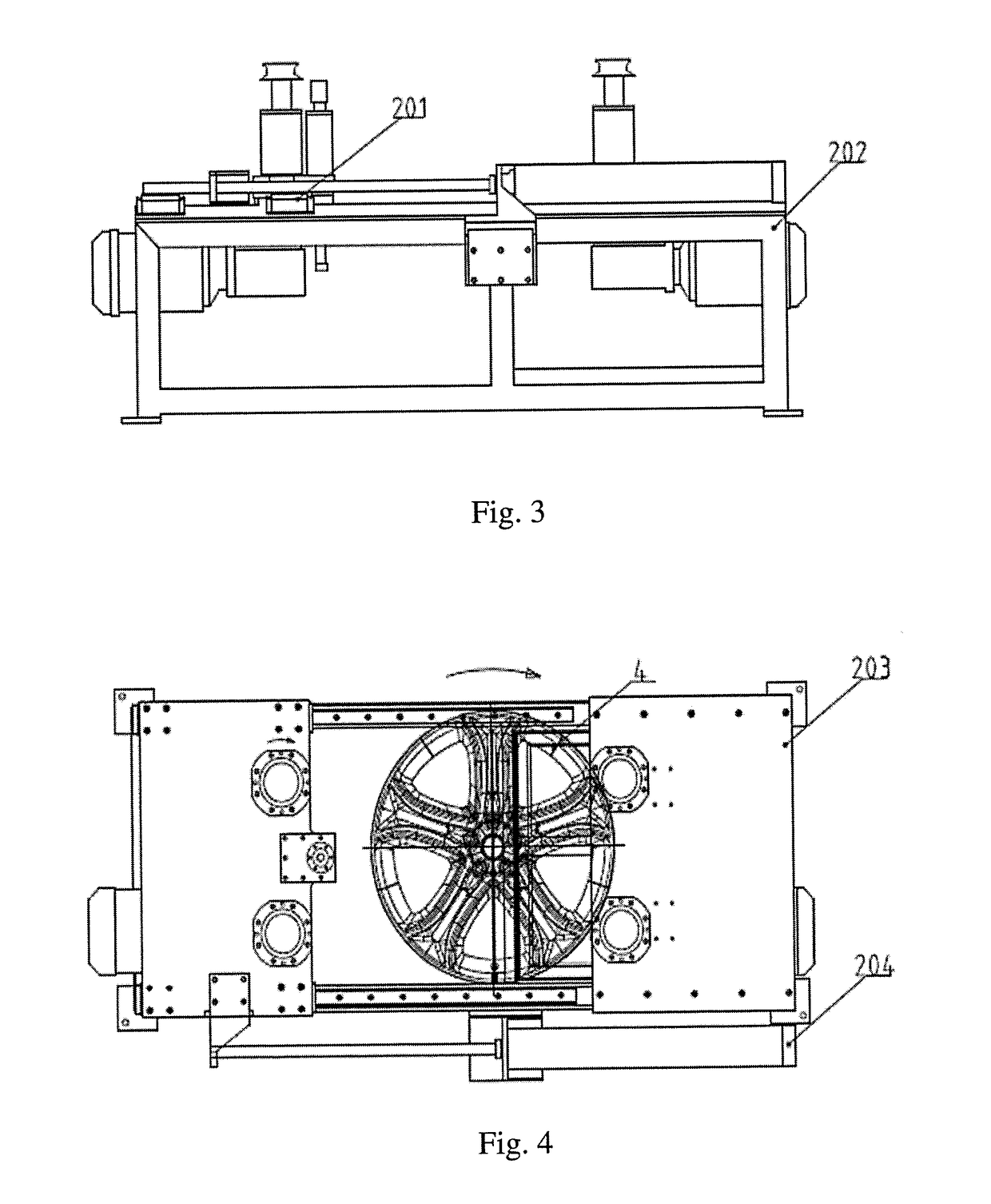

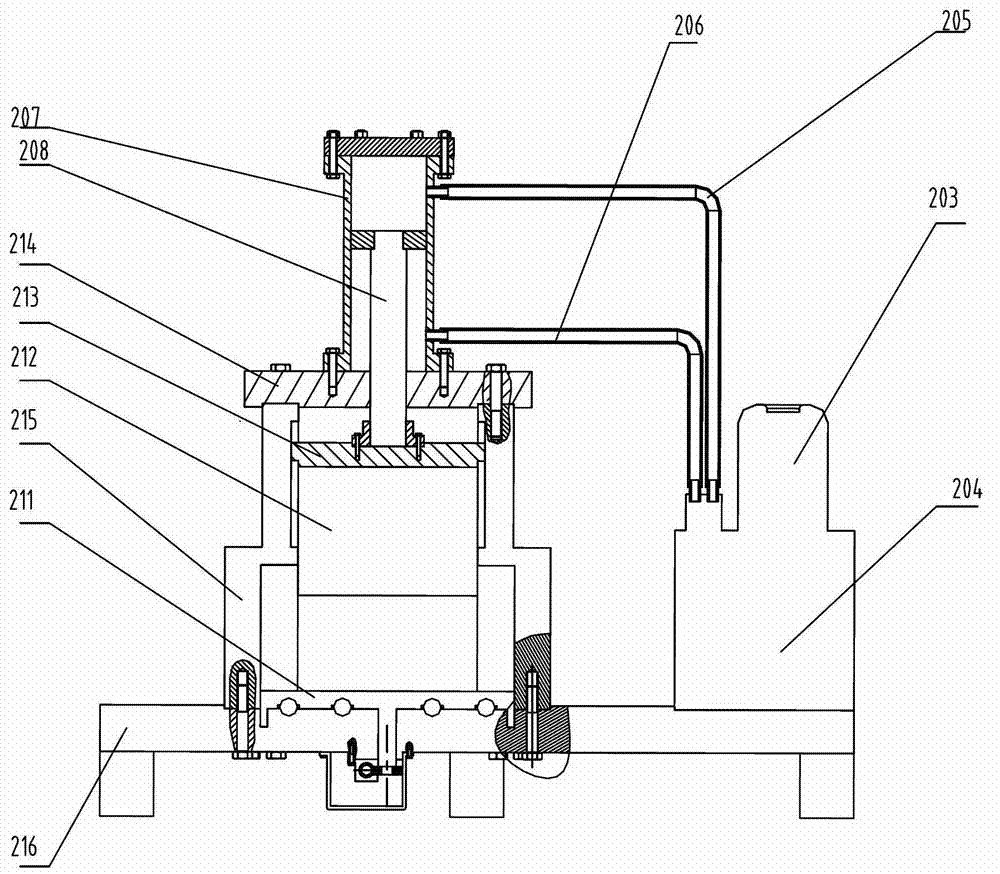

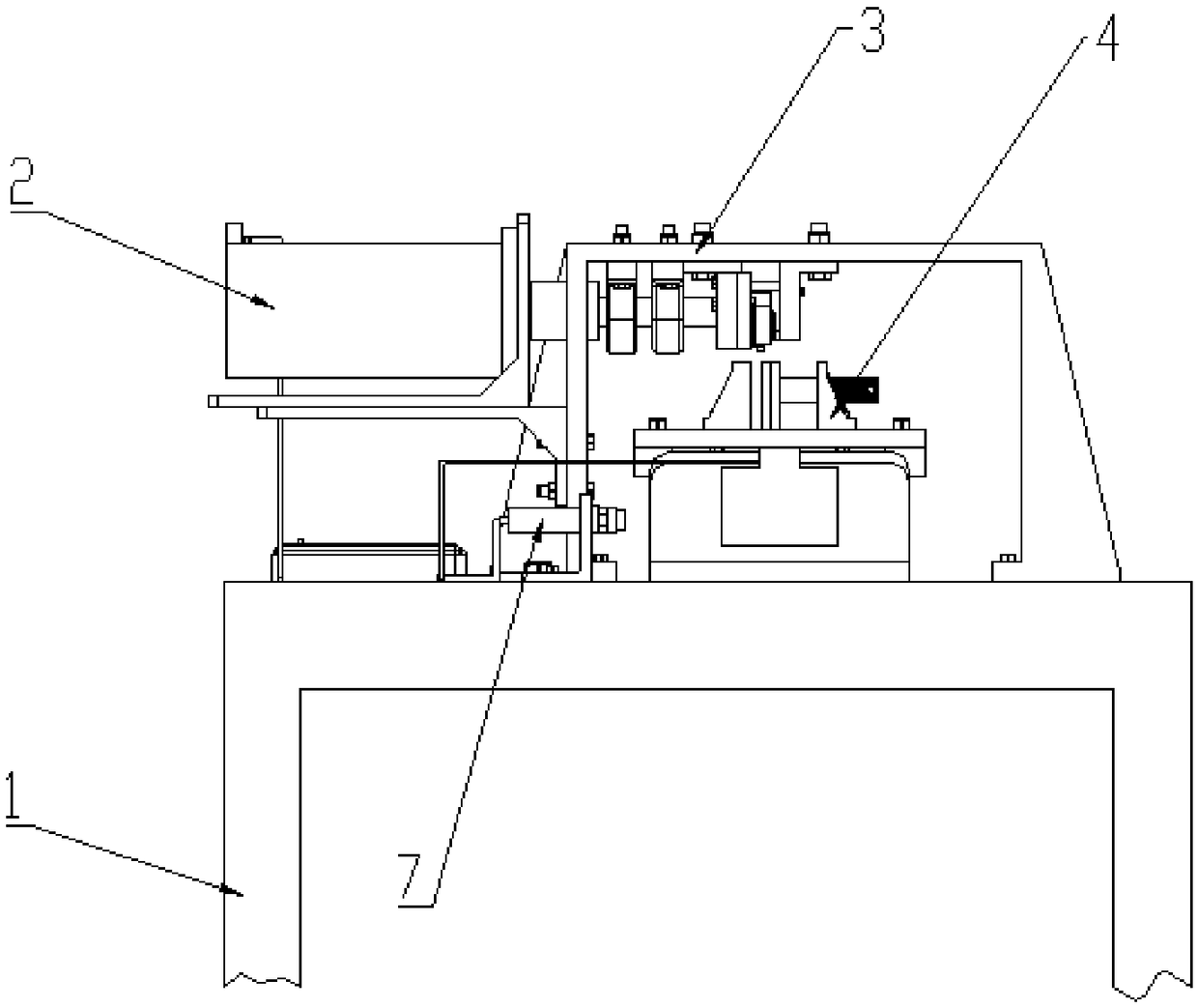

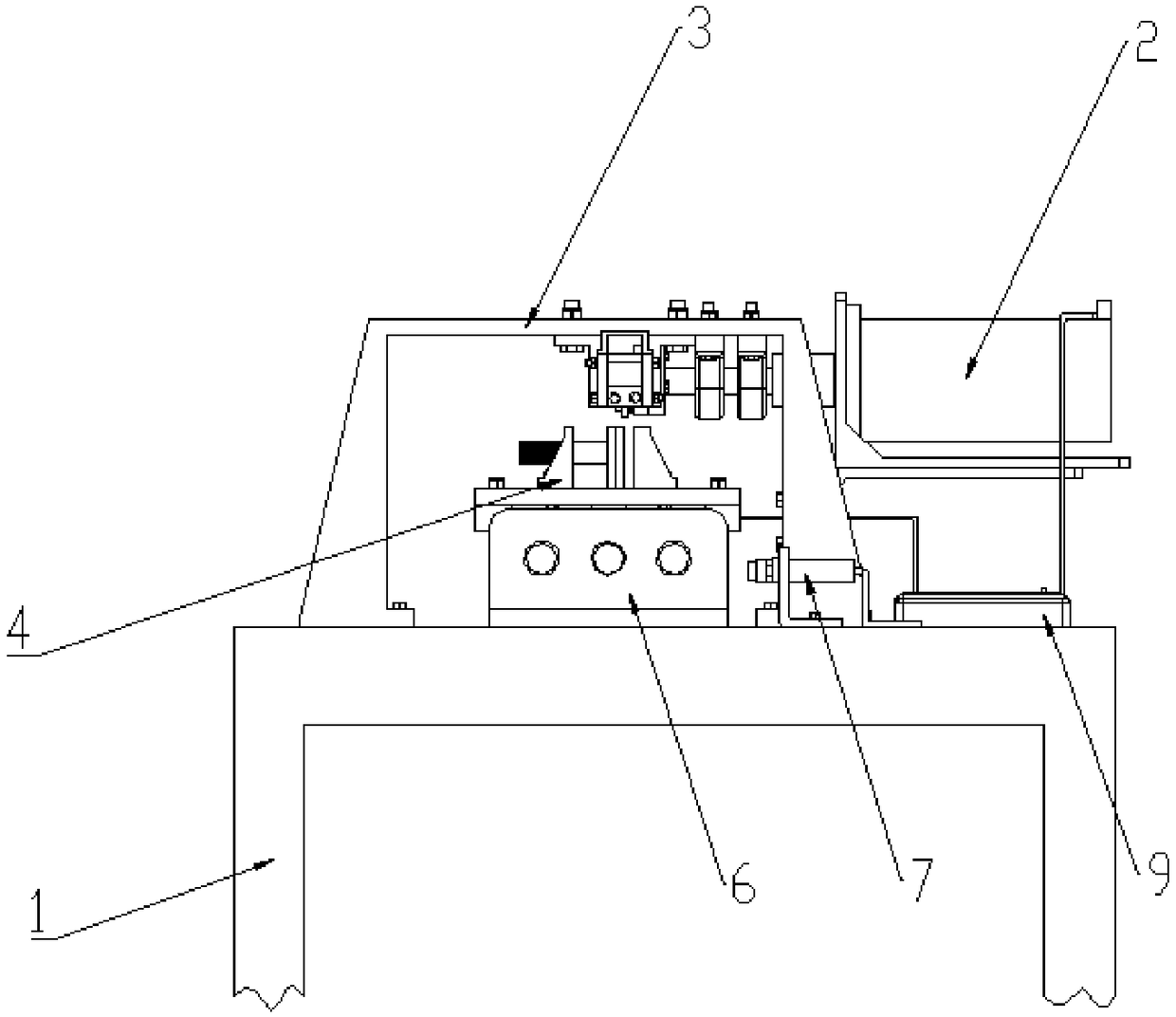

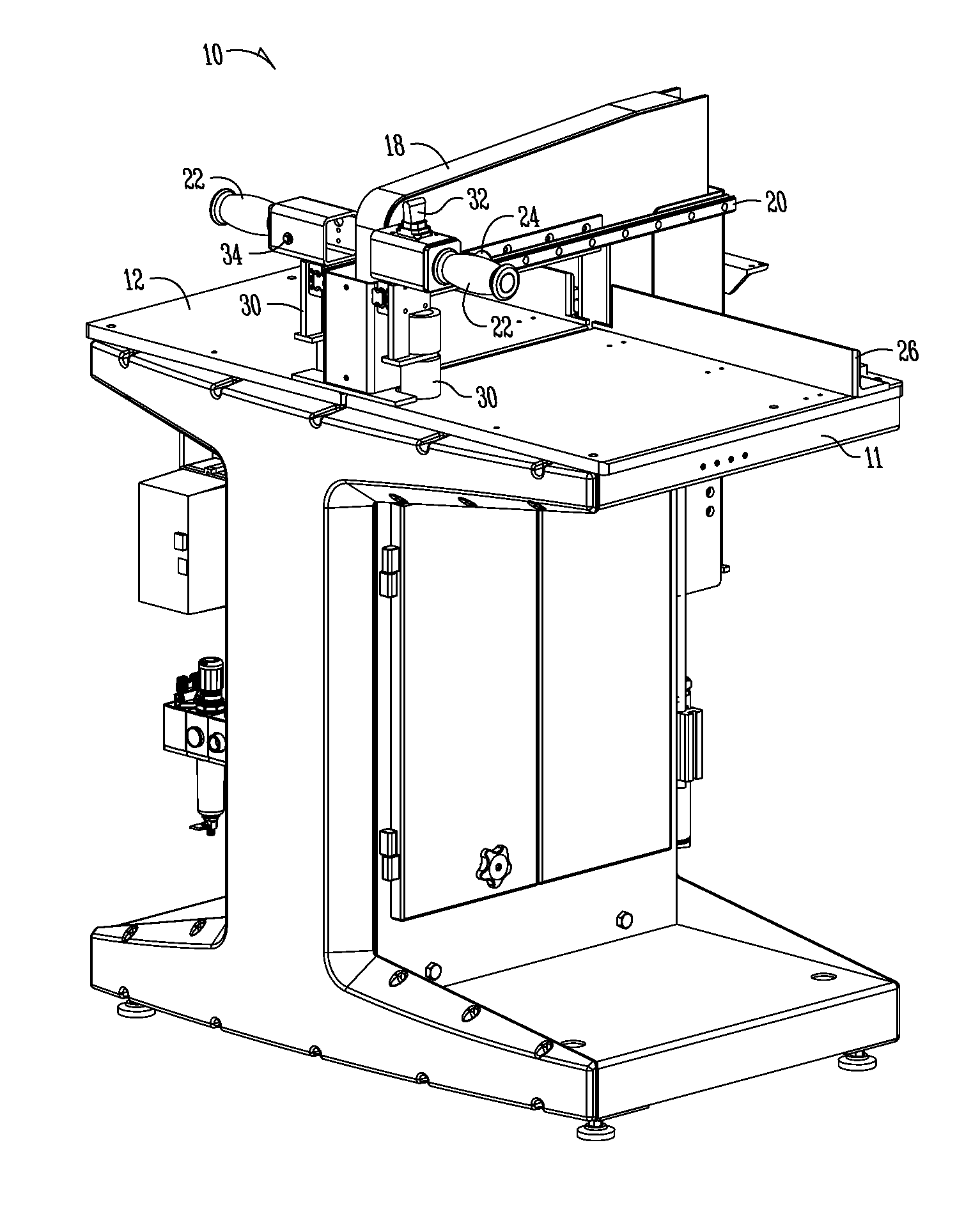

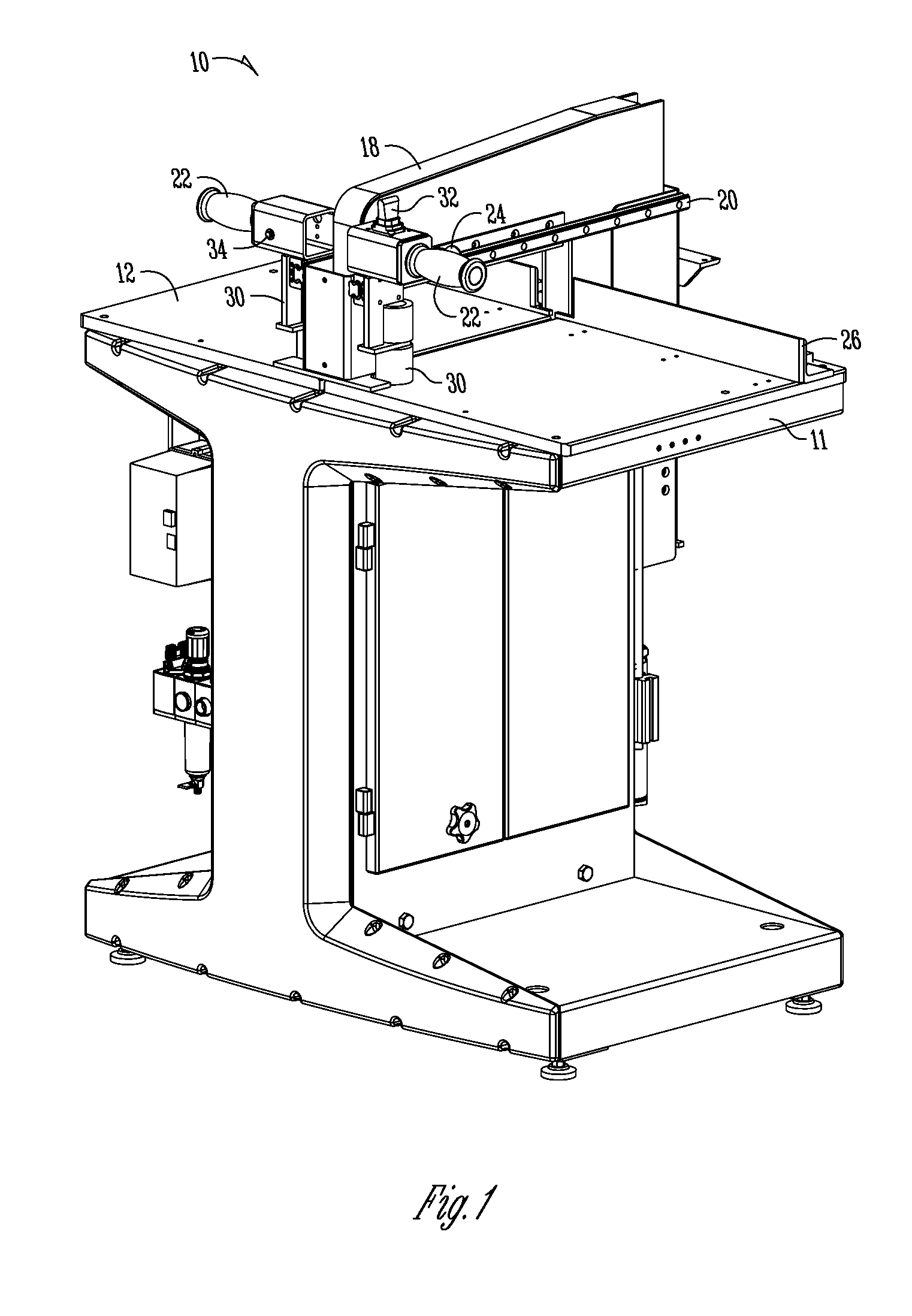

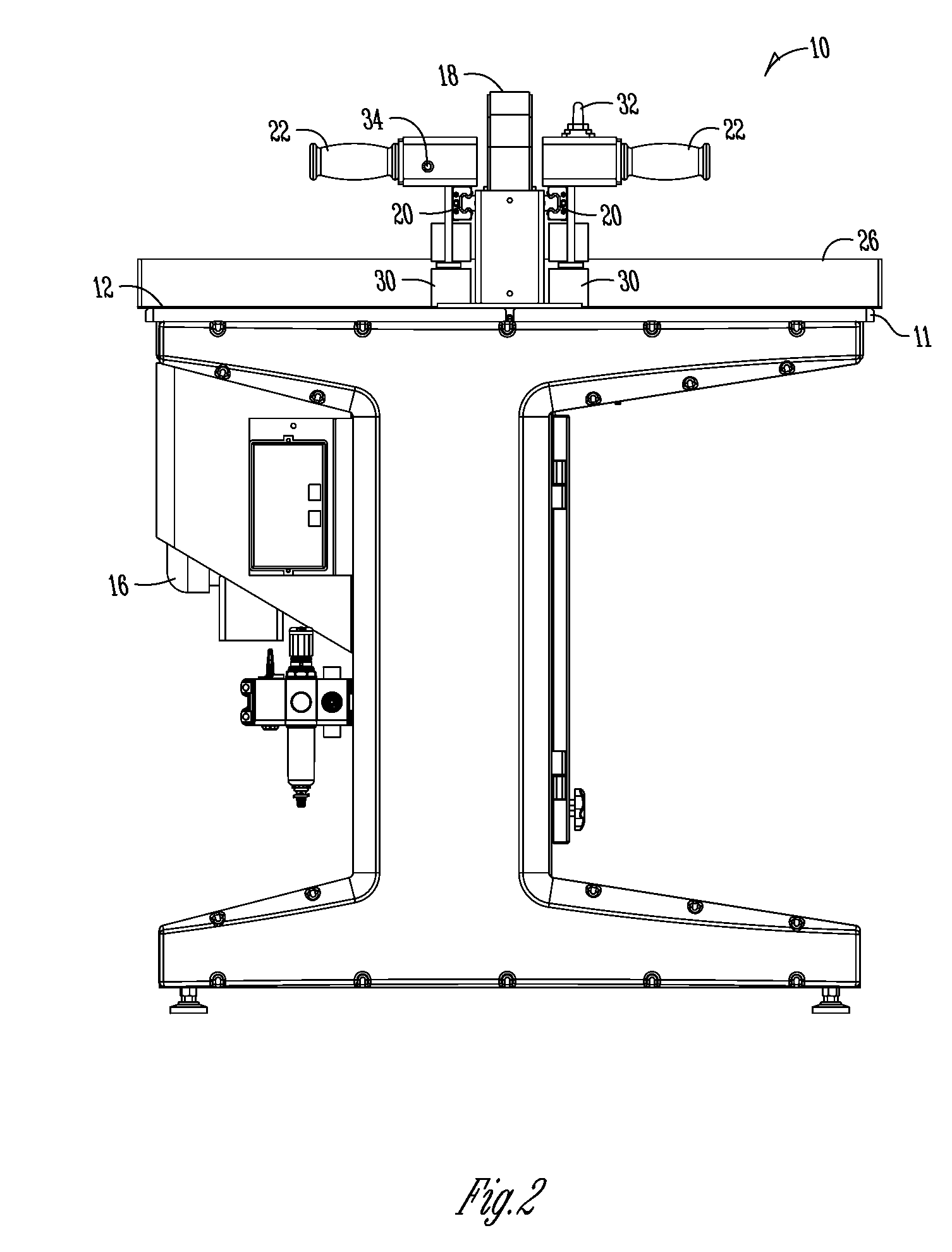

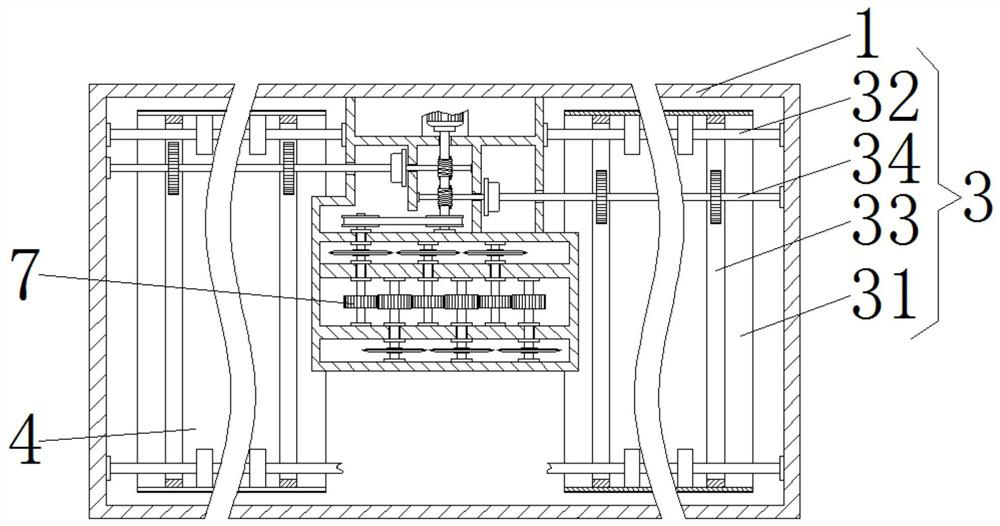

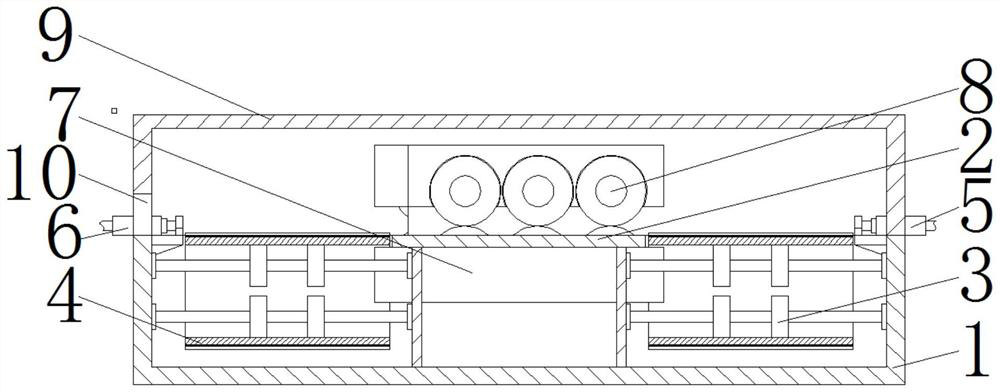

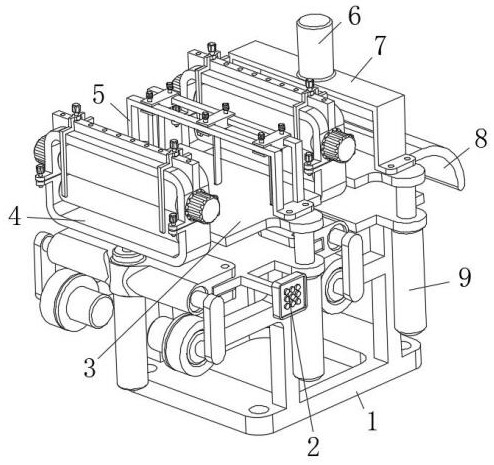

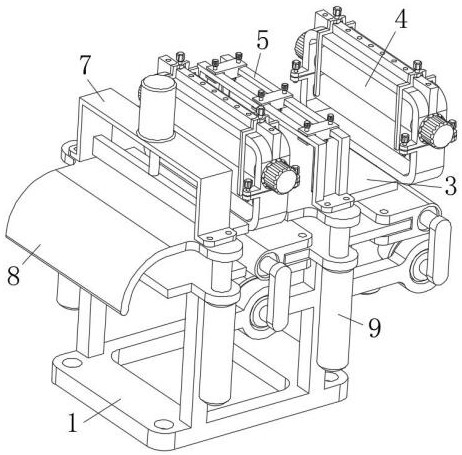

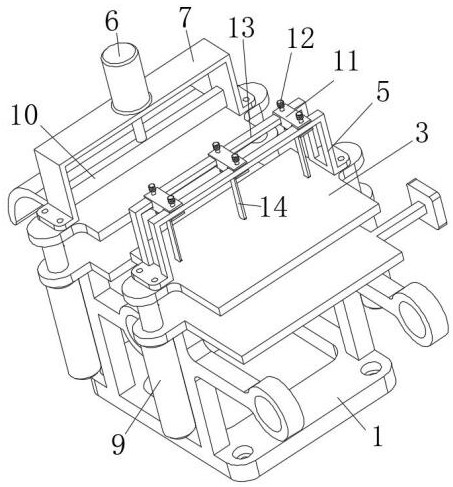

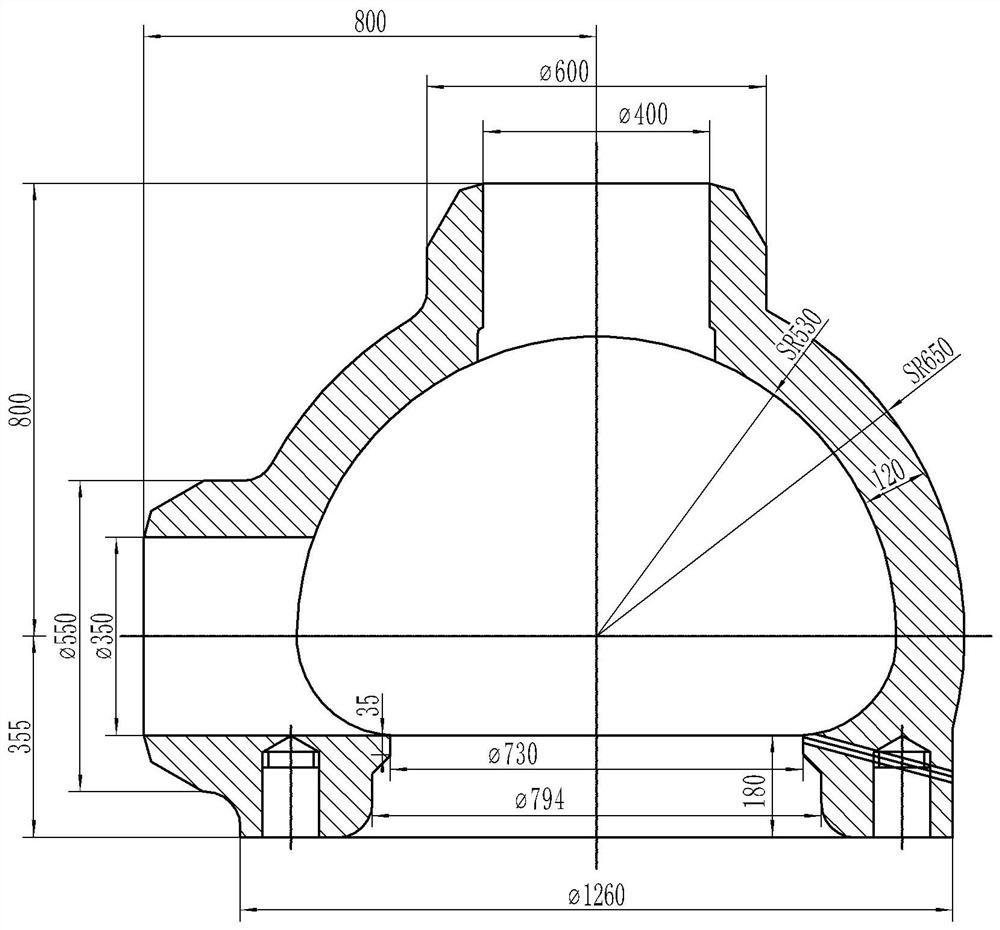

Online aluminum wheel burr removing machine

ActiveUS20180071828A1Reduce labor costsQuality improvementEdge grinding machinesWorkpiecesEngineeringCutting cycle

The present invention provides an online aluminum wheel burr removing machine which includes a roller bed device (1), a positioning and rotating device (2) and a knife box device (3). A wheel (4) is conveyed to a specified position by the roller bed device (1), the positioning and rotating mechanism (2) clamps and rotates the wheel (4), the knife box device (3) horizontally feeds to cut burrs of the wheel (4), the roller bed device (1) conveys the wheel to next station, meanwhile, next wheel enters the roller bed device (1), and next cutting cycle is carried out. The machining time of the present invention is 25-30 seconds, so that the manpower cost is reduced, the machining efficiency is improved, and positive effects are achieved in hub burr removal.

Owner:QINHUANGDAO XINYUE INTELLIGENT EQUIP CO LTD

Hydraulic pressure rubber cutting machine and use method thereof

The invention relates to a hydraulic pressure rubber cutting machine and a use method thereof. A hydraulic pressure drive system and a hydraulic pressure control system drive a rubber cutter to cut rubber blocks on a rubber cutting plate and are arranged on a machine frame of the hydraulic pressure cutting machine. The hydraulic pressure control system and the hydraulic pressure drive system drive the rubber cutter and the rubber cutting plate to relatively rotate 90 degrees along the axial direction between two times of rubber cutting operation. The hydraulic pressure rubber cutting machine and the use method thereof have the advantages that structure is simple and design is reasonable. Moreover, due to the fact that the rubber blocks are cut into pieces in one cutting cycle, bonding phenomenon occurrence is lowered, the use amount of isolation agents is reduced, and on-line continuous cutting production is achieved; due to the fact that the smaller rubber blocks after being cut do not need to be baked softly, the smaller rubber blocks can be directly used in follow-up production, process is simplified, and rubber compound quality is improved; due to the fact that the horizontal sections of a cutter frame and the machine frame inner cavity are round, large abrasion is not caused after a blade is used many times, and service life of the rubber cutter is prolonged; due to the fact that the surface, bearing the cut rubber blocks, of the rubber cutting plate is provided with a nylon layer, multiplicity cutting of the rubber cutting plate does not cause surface abrasion or damage.

Owner:QINGDAO UNIV OF SCI & TECH

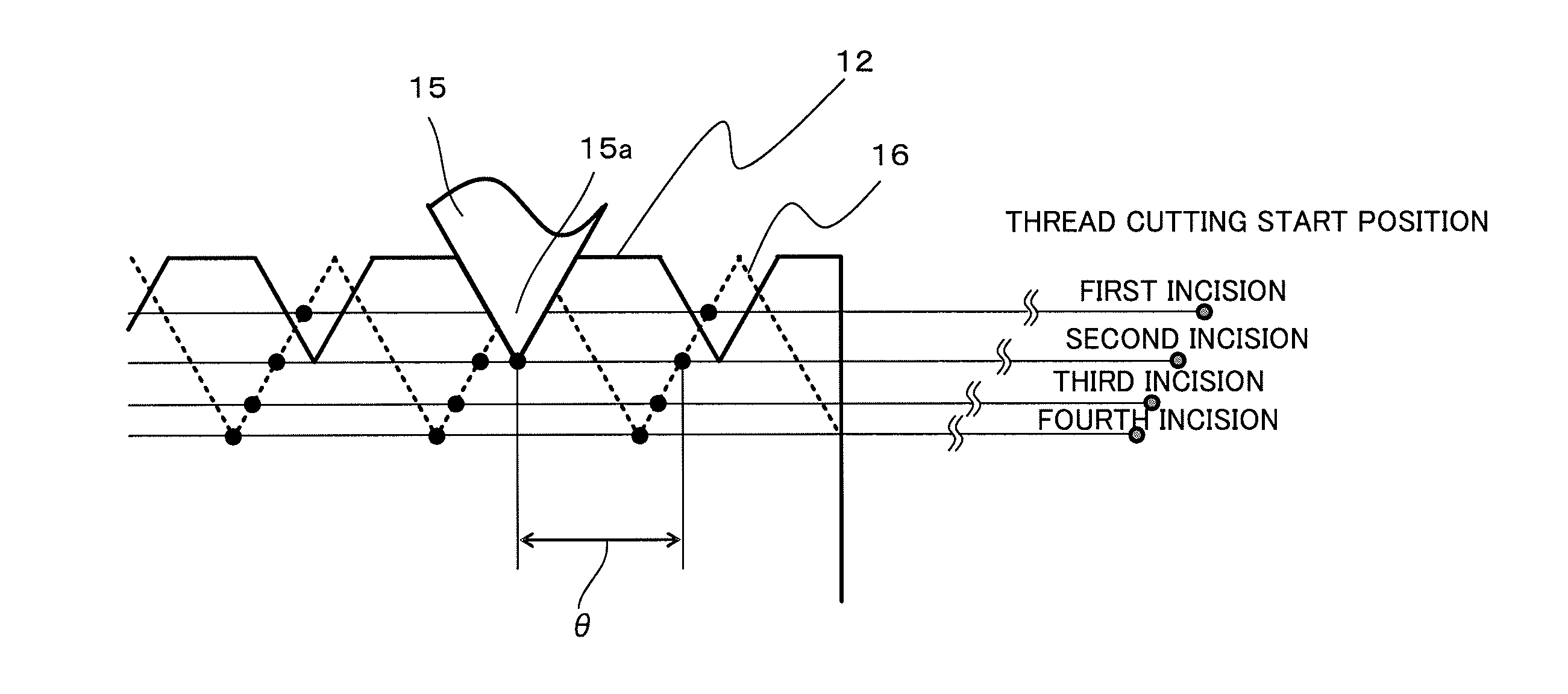

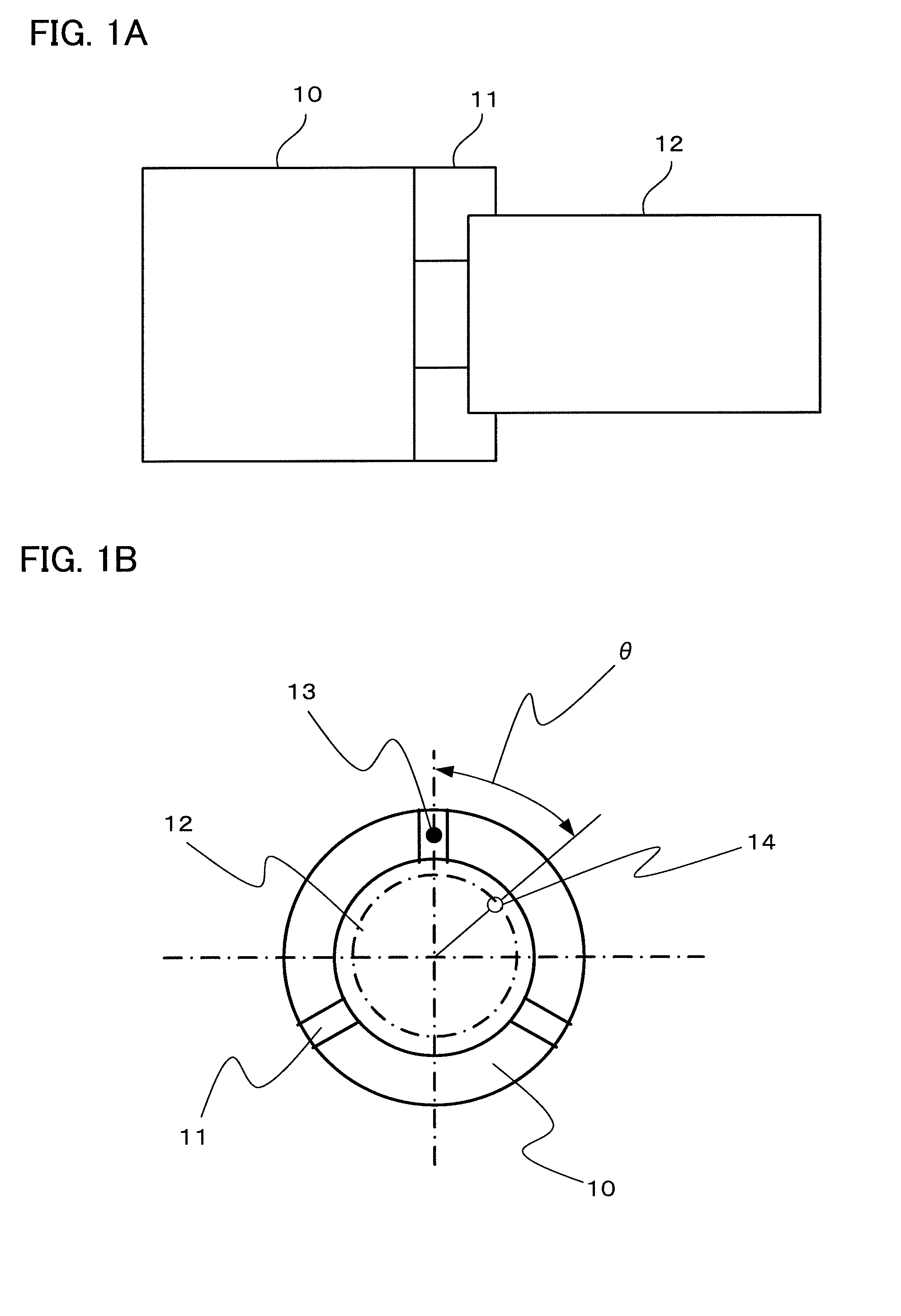

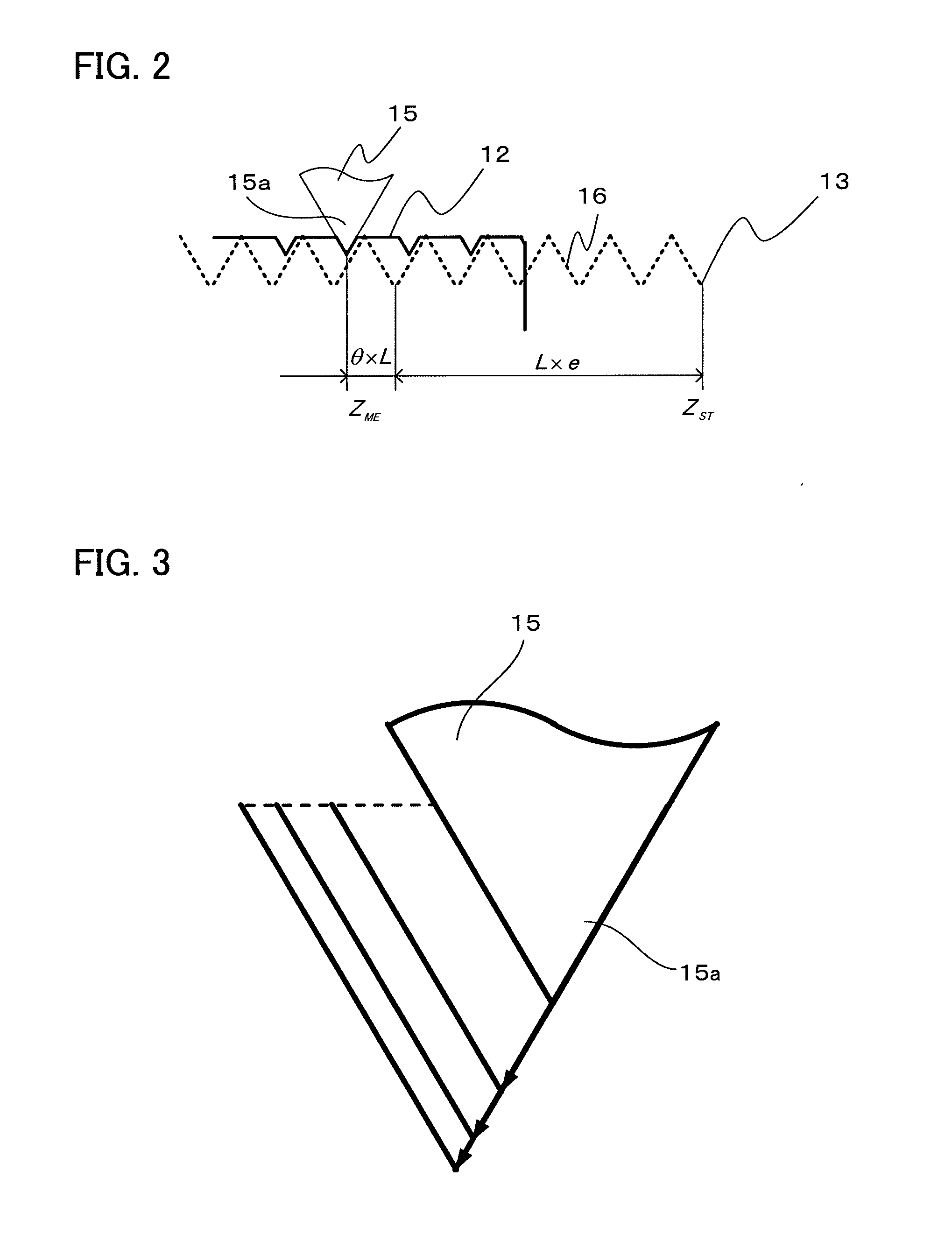

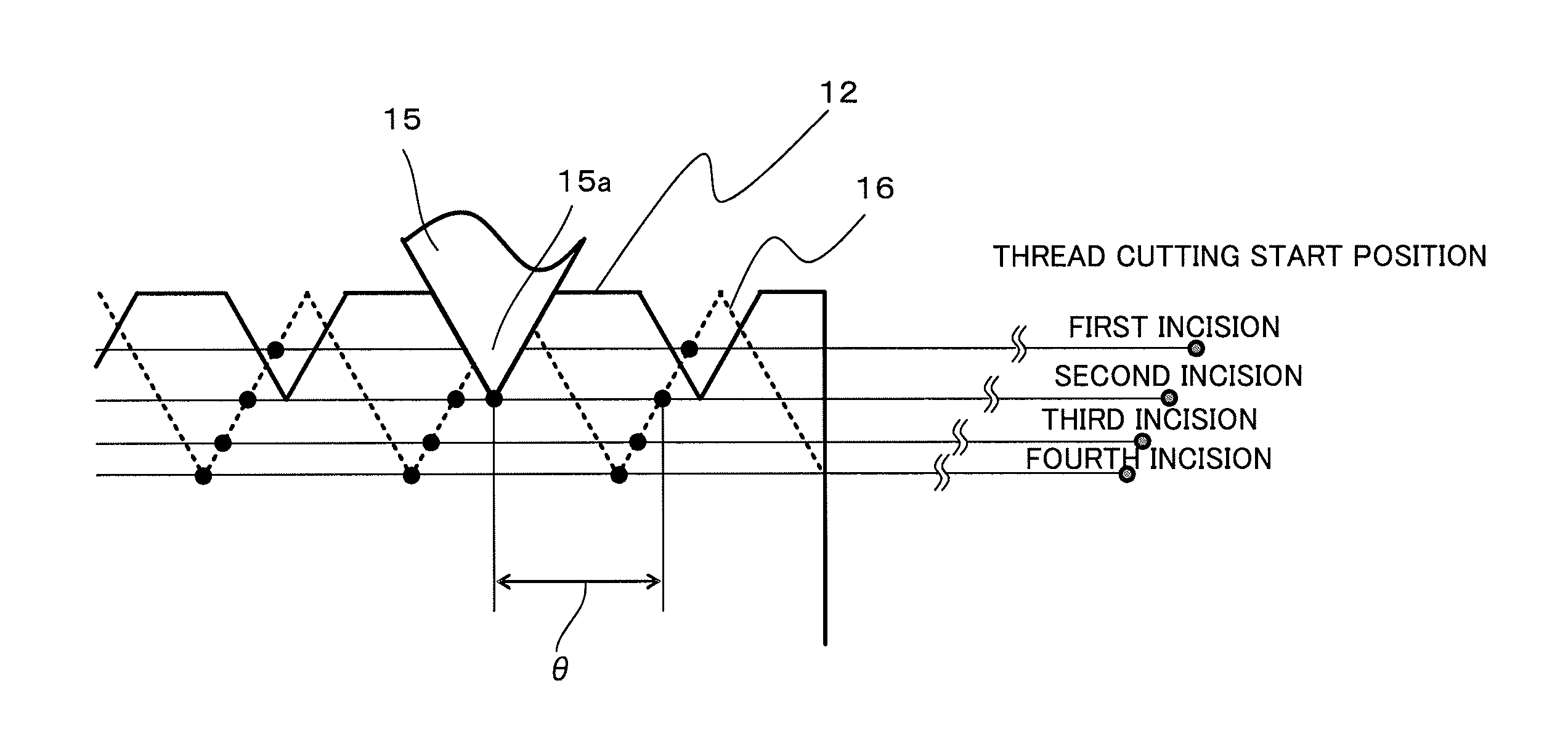

Numerical controller having function of re-machining thread cutting cycle

A numerical controller controlling a machine tool calculates a number of incisions to a thread on the basis of an incision start position in a feed axis direction and an incision start position in a direction of an incision axis of a thread which are measured in a state in which a workpiece (a thread in the process of machining) is attached to a chuck of the machine tool, calculates an amount of phase deviation of a screw thread caused by reattachment of the workpiece on the basis of the calculated number of incisions, and re-machines the thread by positioning the workpiece and the tool while taking into consideration of the amount of phase deviation.

Owner:FANUC CORP

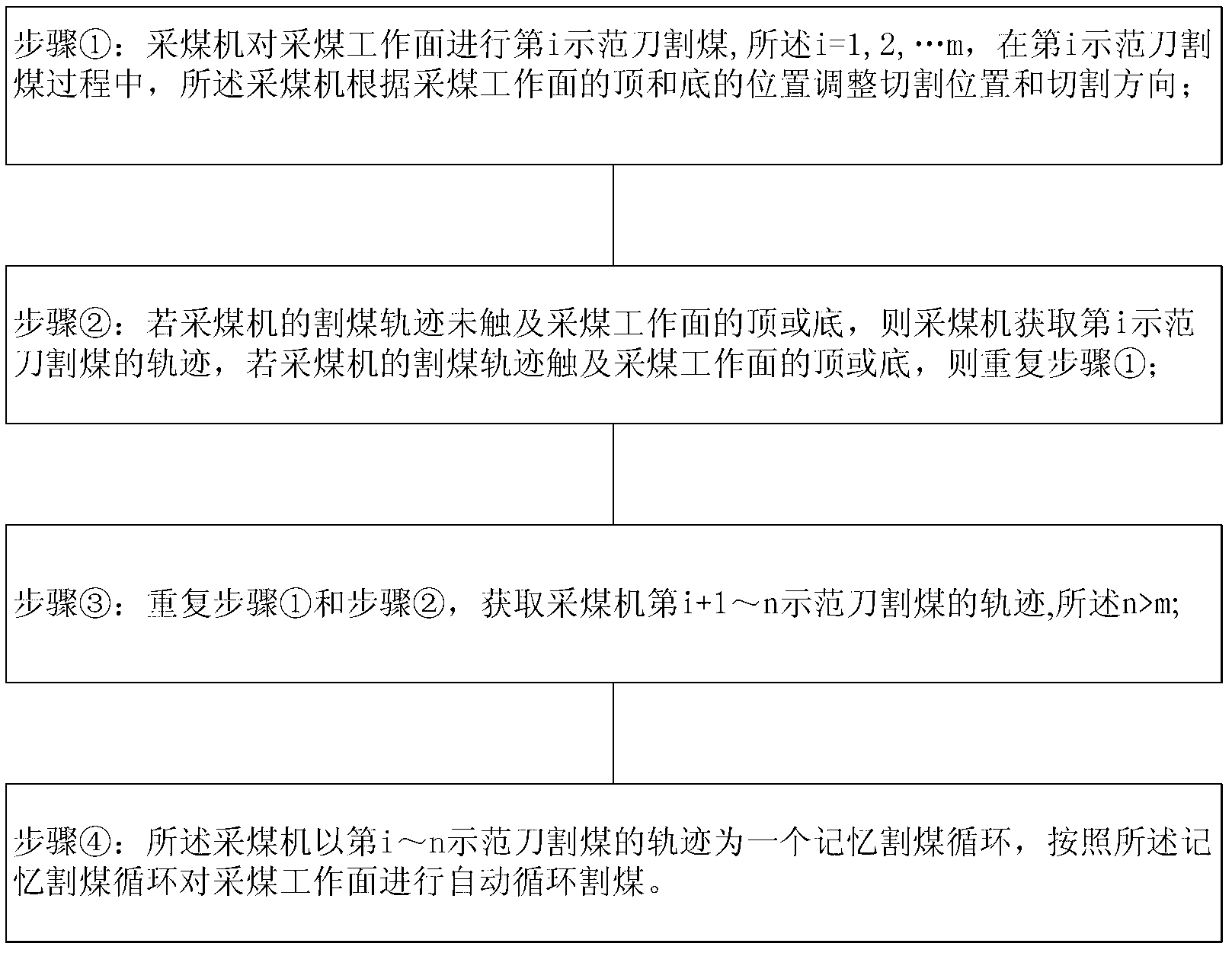

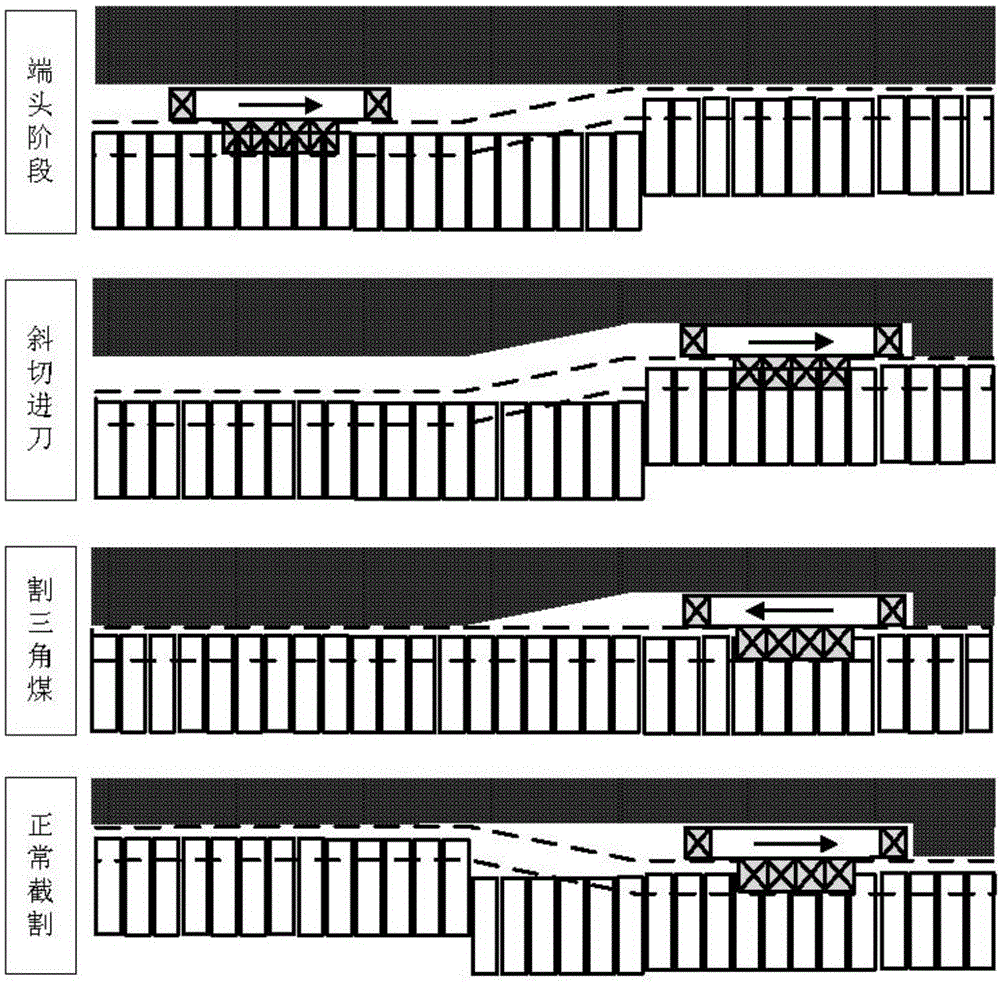

Coal cutting method with multiple demonstration knifes

The invention discloses a coal cutting method with multiple demonstration knifes, which comprises: the step (1): a coal cutter carries out coal cutting for the coal mining working face with the first i demonstration knife, wherein, i=1, 2,...m, and the coal cutter adjusts the cutting position and cutting direction according to the top and the bottom of the coal mining working surface; step (2): if the coal cutting locus of the coal cutter does not contact the top or bottom of the coal mining working surface, the coal cutting track of the ith demonstration knife is obtained, and if the coal cutting track of the coal cutter contacts the top or bottom of the coal mining working surface, the step (1) is repeated; the step (3): the step (1) and the step (2) are repeated, and the coal cutting tracks of the i+1-n demonstration knife of the coal cutter are obtained, wherein the n>m; the step (4): the coal cutter uses the coal cutting tracks of the i-n demonstration knifes as a memory coal cutting cycle, and carries automatically circulated coal cutting on the coal mining working face. The method provided by the invention carries out memory coal cutting by multiple demonstration knifes, thereby effectively reducing the influence on memory coal cutting caused by single demonstration knife, and minimizing cutting of rocks at the coal mining working face bottom, improving the coal cutting effect, and improving the coal cutting stability.

Owner:CHINA SHENHUA ENERGY CO LTD +1

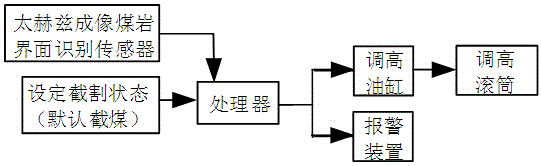

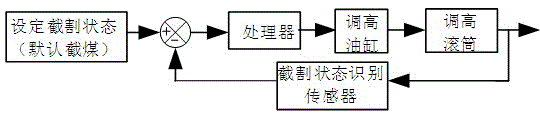

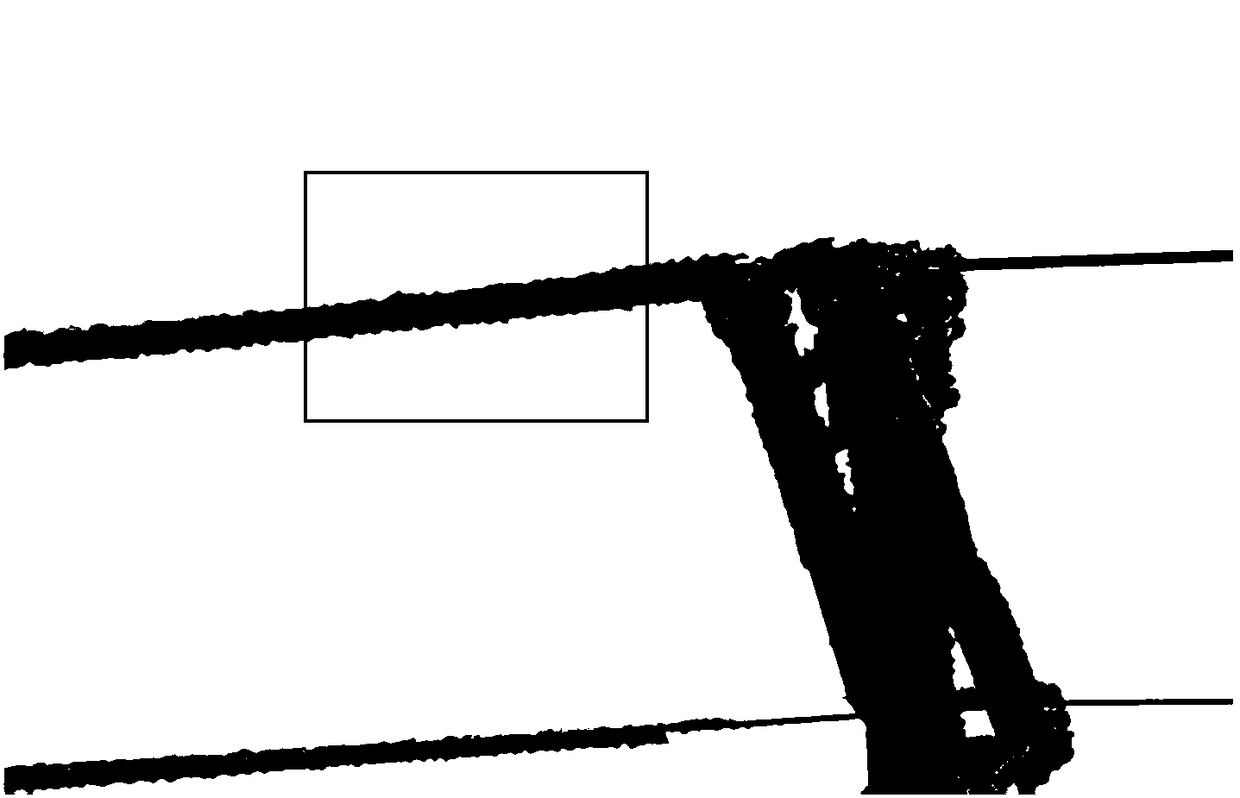

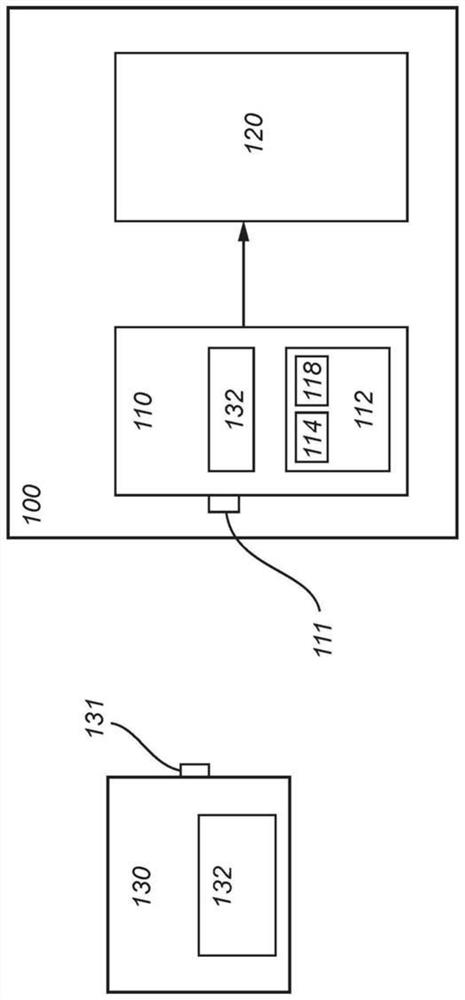

Coalcutter coal rock distribution recognition device and method adopting terahertz imaging technology

InactiveCN105569658AOvercoming the disadvantages of the truncated stateAvoid cutsMining devicesTesting machinesState parameterRock cutting

The invention discloses a coalcutter coal rock distribution recognition device and method adopting terahertz imaging technology. The device comprises a terahertz imaging coal rock recognition sensor, a processor, a heightening oil cylinder, a heightening roller and an alarm device; set cutting state parameters of the roller at each cutting position are stored in the processor; the terahertz imaging coal rock recognition sensor recognizes the coal rock distribution condition of a coalcutter at each cutting position in the next cutting cycle and outputs a recognition result to the processor; the processor processes and stores the recognition result according to a coal rock distribution recognition method, and a storage result serves as a basis at the processor outputs a signal to the heightening oil cylinder, the heightening roller or the alarm device at the corresponding position in the next cutting cycle. The coal rock distribution condition in the next cutting cycle is recognized in advance, a roller height is determined in advance and cutting into rock is avoided. A defect that only after roller cutting teeth cut into the rock, the rock cutting can be recognized under a memory coal rock cutting interface recognition technology is overcome.

Owner:XUZHOU NORMAL UNIVERSITY

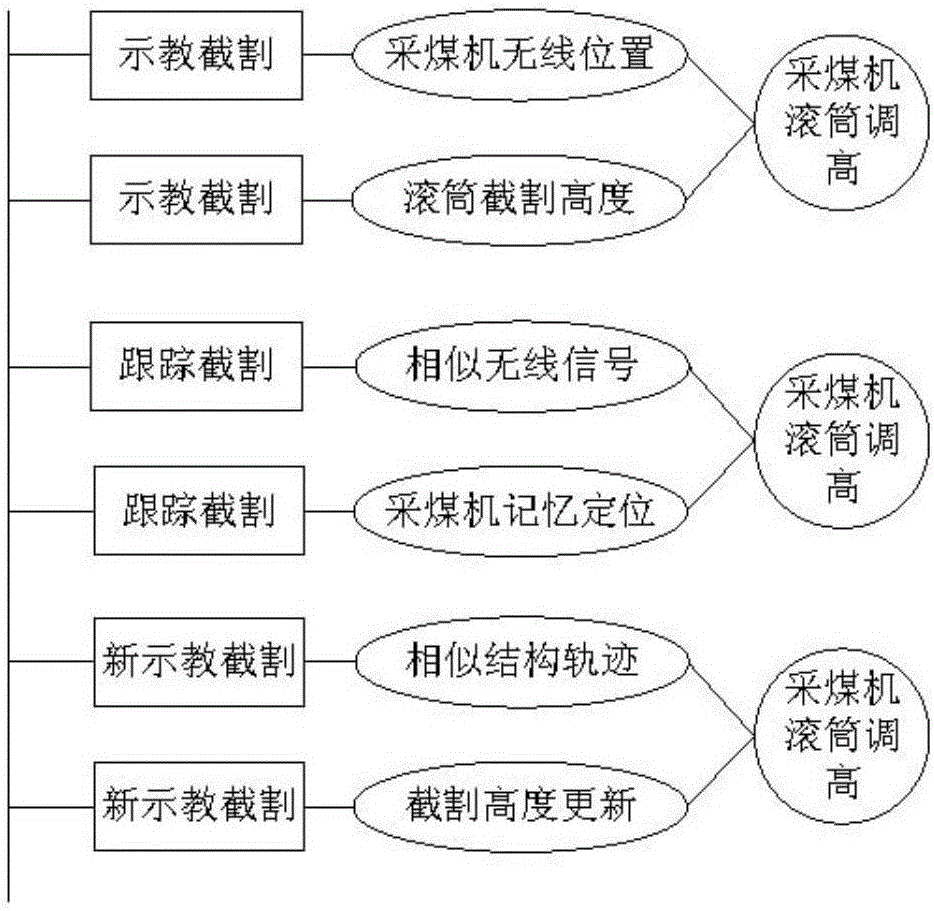

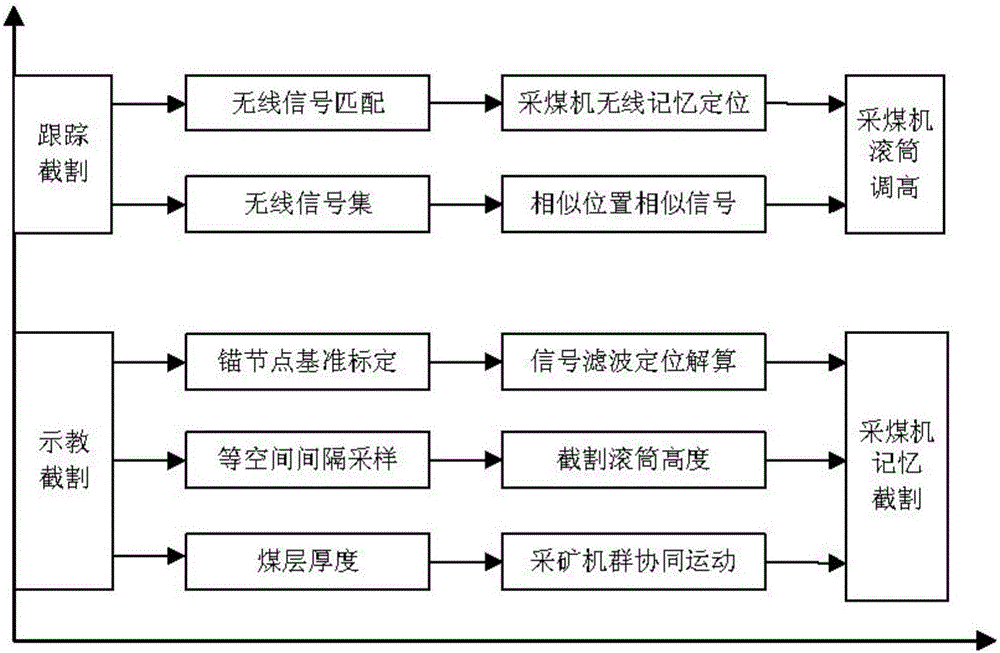

Coal cutter memory cutting and memory positioning combination learning method

The invention discloses a coal cutter memory cutting and memory positioning combination learning method. The method comprises the following steps that memory cutting containing demonstration-tracking strategies is adopted for performing self-adaptation height adjustment on a coal cutter roller, dual mapping between the wireless position and the height of the coal cutter roller height is built in the demonstration cutting stage, coal cutter memory positioning is performed at the similar position in the tracking cutting stage, and on the basis of the novel demonstration cutting cycle stage, the height of the coal cutter roller is updated through adjacent coal seams. According to coal cutter memory cutting and memory positioning, correlation between wireless position data and cutting height data is subjected to combination learning, wireless signal matching is used for coal cutter memory positioning in the tracking cutting stage, the frequency of manual adjusting the coal cutter roller cutting height by a coal cutter driver is lowered in the novel demonstration cutting stage, and the coal cutter memory cutting strategy practicability is improved.

Owner:HOHAI UNIV CHANGZHOU

Method for fast breeding Chinese jongye poplar in coastal region

InactiveCN106171729AShort reproductive cycleImprove disease resistanceCultivating equipmentsBudCutting cycle

The present invention relates to a rapid propagation method of poplar with red leaves in the coastal area. The method comprises nursery selection, nursery arrangement, cutting cutting production, cutting, and post-planting management; the cutting cutting production includes the following steps: in February to March, Choose hard branches with a diameter of 1-2cm, soak the branches in clean water for 3 days before cutting, change the water once a day, after soaking, cut into cuttings with a length of 10-15cm each, with 3-4 buds per section , the upper incision is 1-1.5cm away from the top bud, and the lower incision is 0.5-1cm away from the bottom bud, all of which are cut flat with sharp scissors without leaving any splitting wounds; the prepared cuttings are used with a concentration of 100-200mg / g Soak in naphthalene acetic acid solution for 12-24 hours. According to the method of the present invention to propagate the red leaf poplar, on the one hand, the emergence rate of the cuttings can be guaranteed, and the emergence rate can reach more than 90%;

Owner:TIANJIN TEDA GREEN GRP CO LTD

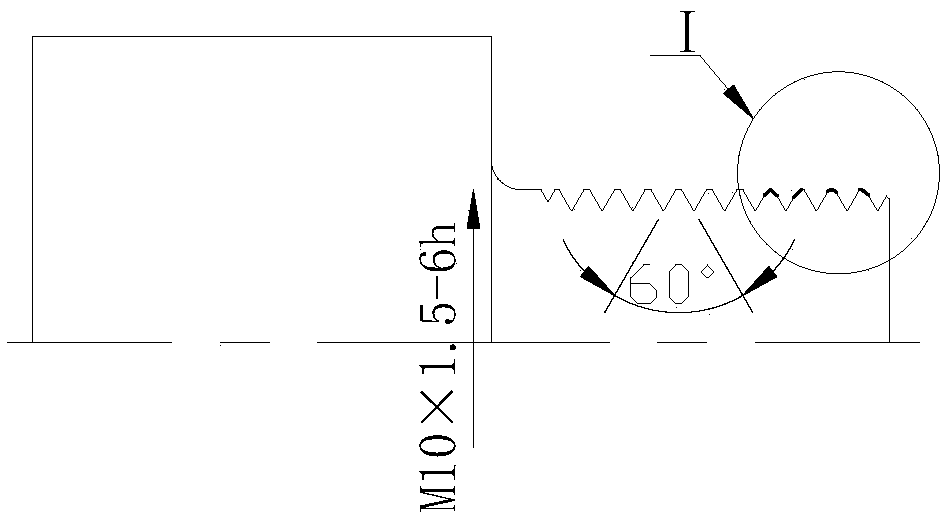

Method for machining soft aluminum part threads through turning

InactiveCN108637404ASolve the problem of rotten teethOptimize the processing systemThread cutting machinesMaintainance and safety accessoriesEngineeringBack cutting

The invention discloses a method for machining soft aluminum part threads through turning. The method comprises the following steps that a cooling liquid with relatively strong viscosity is selected;a thread blade with the thread pitch larger by 1 grade is selected to replace a thread blade with the thread pitch required by normal machining; a lateral cutter feeding mode is adopted, and the tooth-shaped angle, which is smaller than a rear angle, of the blade is fed for machining; the cutting parameters comprise the following parameters of the thread single-cycle back cutting depth ap being 0.05mm-0.07mm and the linear speed Vc being 55-60rpm; a G76 multi-thread cutting cycle instruction is adopted for thread machining; and the size of the top diameter polish rod of the soft aluminum partthreads is machined in place during thread machining, and the allowance is not reserved. According to the method, the cooling liquid, the blade, the programming mode and the cutting parameters are reasonably selected, so that the whole machining process system for machining the soft aluminum part threads through turning is optimized, the problem of thread rotting of the machined threads of a softaluminum part is effectively solved, and the product quality is guaranteed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

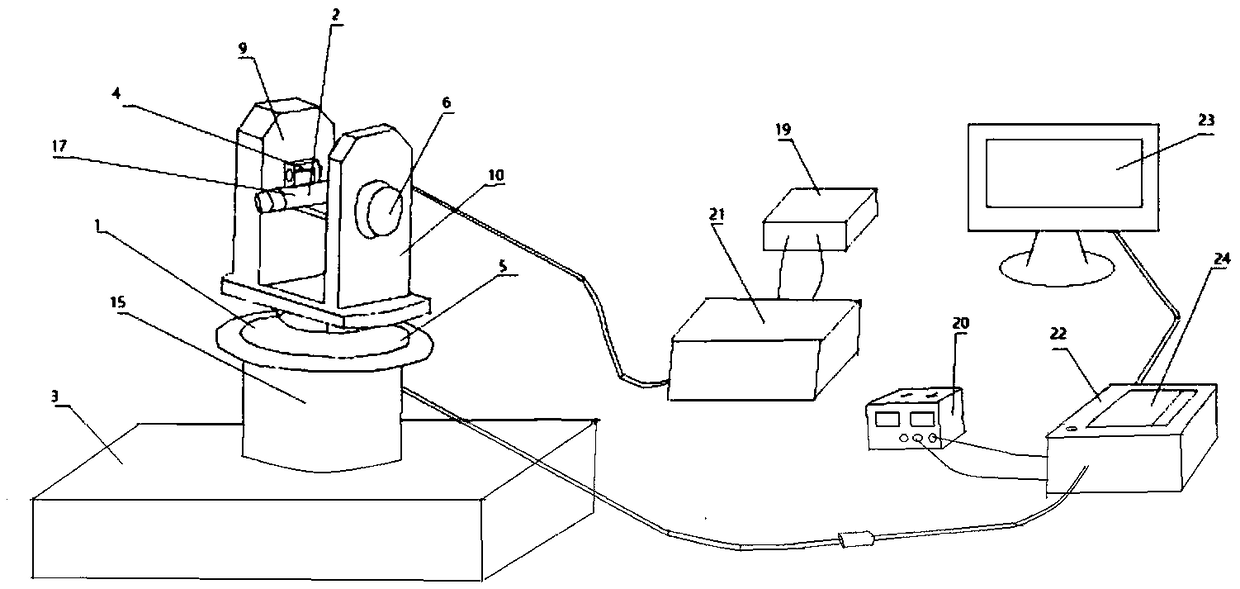

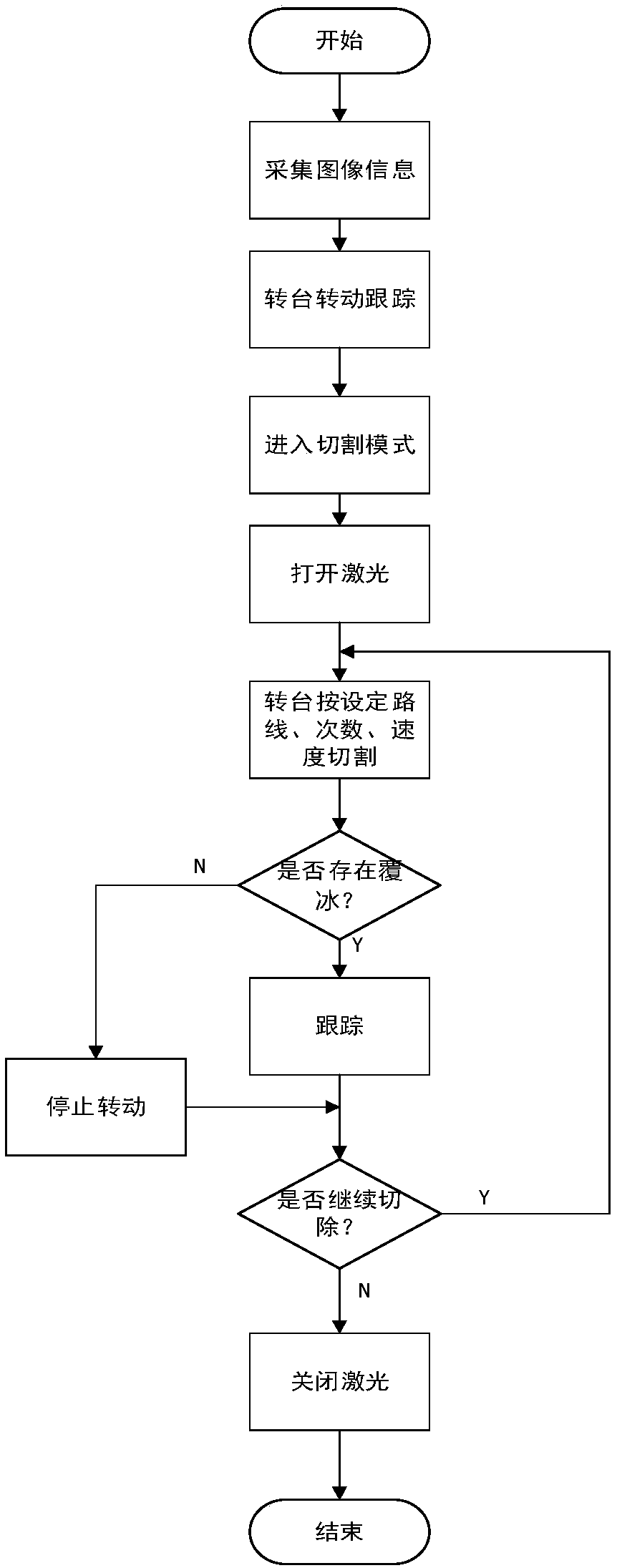

Semi-automatic foreign matter removing method of laser foreign matter removing device

InactiveCN108808550AIncrease flexibilityHigh control precisionLaser beam welding apparatusApparatus for overhead lines/cablesForeign matterDisplay device

The invention discloses a semi-automatic foreign matter removing method of a laser foreign matter removing device. The method includes that a visual sensor collects and a displayer displays current image information; a control system performs image recognition to acquire foreign matter point winding information, resolves the same, converts the information into angular coordinates and sends an instruction to a turntable to enable to same to rotate to track a foreign matter winding point; according to information input into the device, entering of a cutting mode is realized; the control system calculates out a corresponding turntable instruction according to a cutting cycle index and cutting speed instruction which are received and clicks a starting point and an end point of a cutting path,and the control system calculates to acquire angle information according to pixel information of the starting point and the end point and calculates out a turntable instruction corresponding to each time moment; a laser part emits laser, and the control system sends corresponding angle instructions to the turntable and controls the turntable to drive the laser part to rotate to complete cutting task. The position of the target is displayed through the visual sensor, and the laser foreign matter removing device is controlled through a user end on the basis of automatic tracking, so that adaptability of the device to complex foreign matters is improved, and cutting efficiency is improved.

Owner:NANJING UNIV OF SCI & TECH

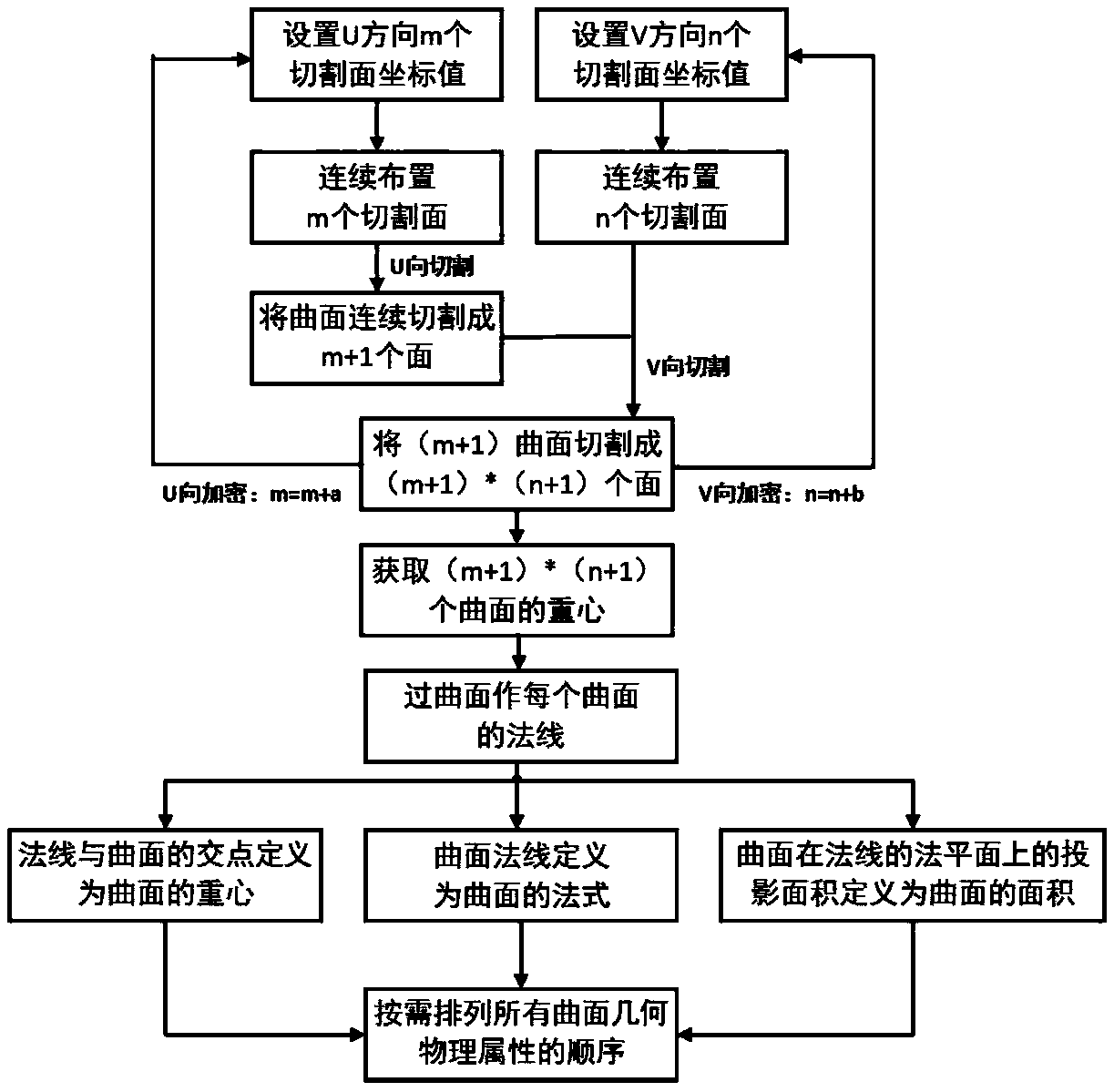

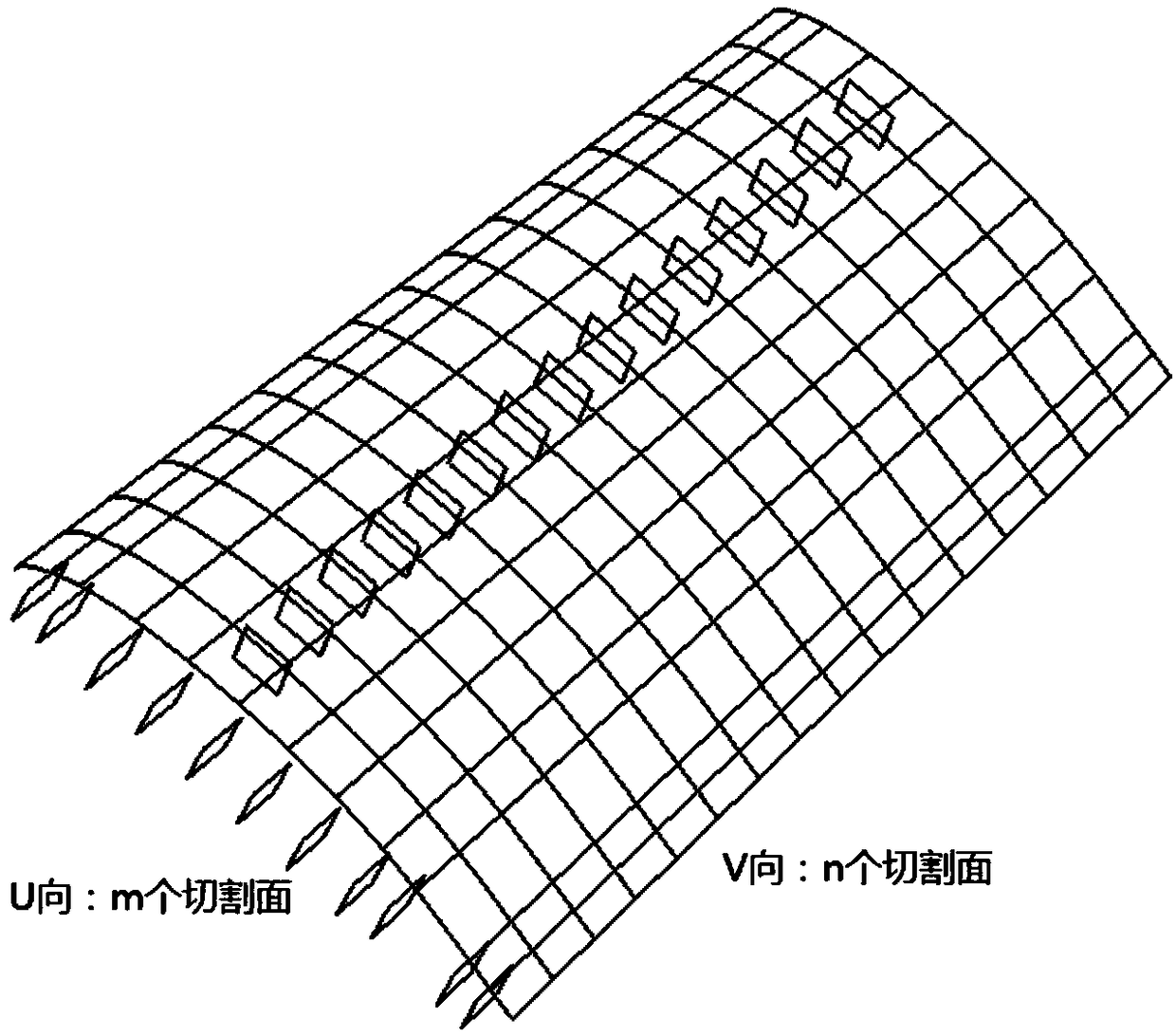

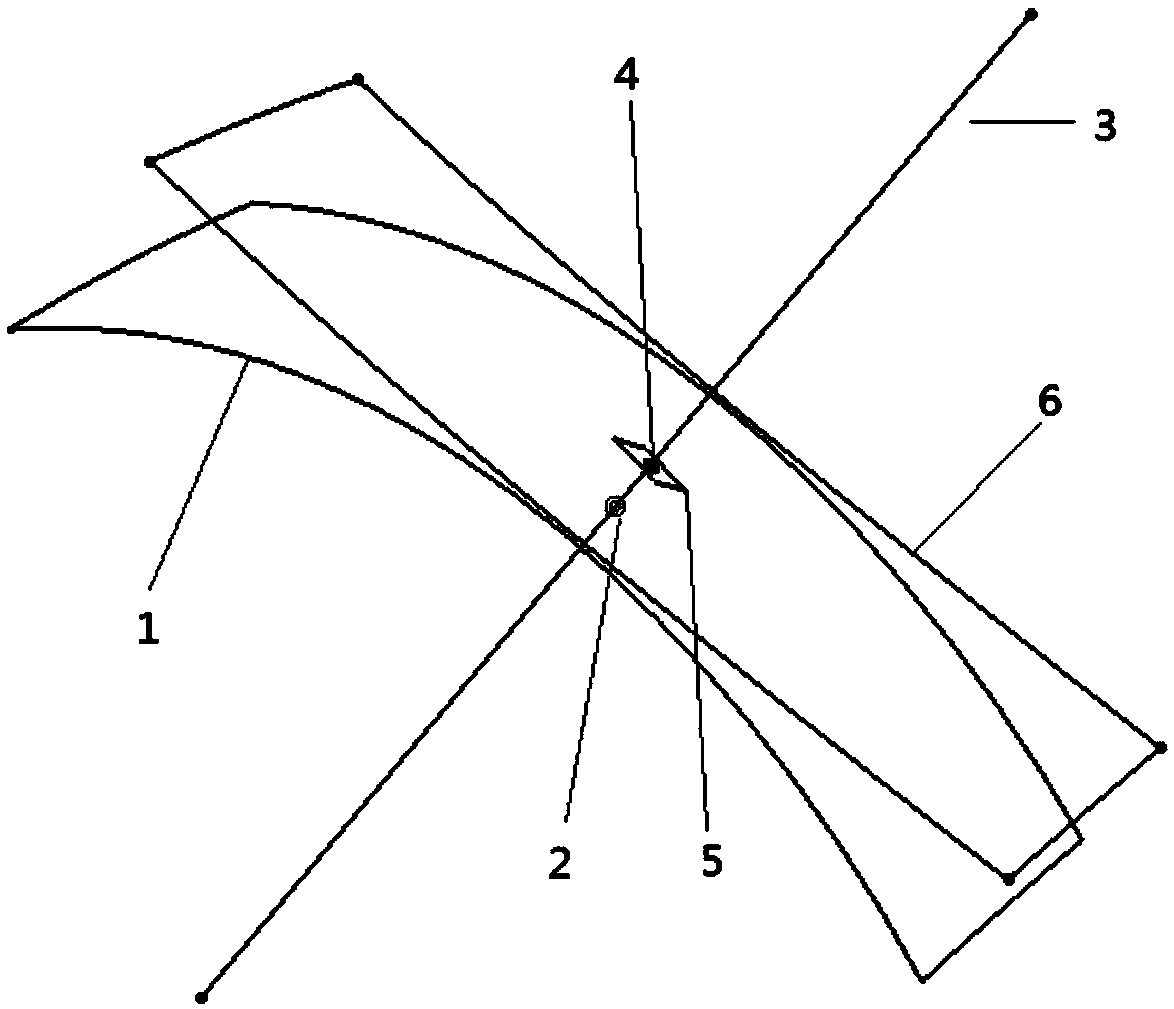

Modeling method for rapidly generating flight load analysis model

The invention relates to the big data field and discloses a modeling method for rapidly generating a flight load analysis model. The method includes the following steps of 1 arranging cutting surfacesin two directions of each component by taking each component of an aircraft as a unit, and forming a discrete small curved surface after the cutting cycle operation; 2 performing the same operation on each discrete small surface by using the MATLAB program: obtaining the normals of the discrete small surfaces, and obtaining the geometrical and physical attributes of the discrete small surfaces ofthe face center, the normal vector and the small block area according to the normals; 3, taking all that components of the aircraft as units, discretely cutting all the components of the aircraft, obtaining the face center, the normal vector and the small block area attributes of all the components, and reasonably ordering and establishing a flight load analysis model. The technical proposal of the invention establishes the discrete model with reasonable and moderate mesh quantity, remarkably improves the modeling speed of the flight load analysis model through the cycle of the program, and lays a good foundation for the subsequent flight load analysis and design work.

Owner:四川腾盾科技有限公司

Numerical controller having function of re-machining thread cutting cycle

ActiveUS9417619B2Multiple dynamo-electric motors speed regulationTurning machinesCutting cycleScrew thread

A numerical controller controlling a machine tool calculates a number of incisions to a thread on the basis of an incision start position in a feed axis direction and an incision start position in a direction of an incision axis of a thread which are measured in a state in which a workpiece (a thread in the process of machining) is attached to a chuck of the machine tool, calculates an amount of phase deviation of a screw thread caused by reattachment of the workpiece on the basis of the calculated number of incisions, and re-machines the thread by positioning the workpiece and the tool while taking into consideration of the amount of phase deviation.

Owner:FANUC LTD

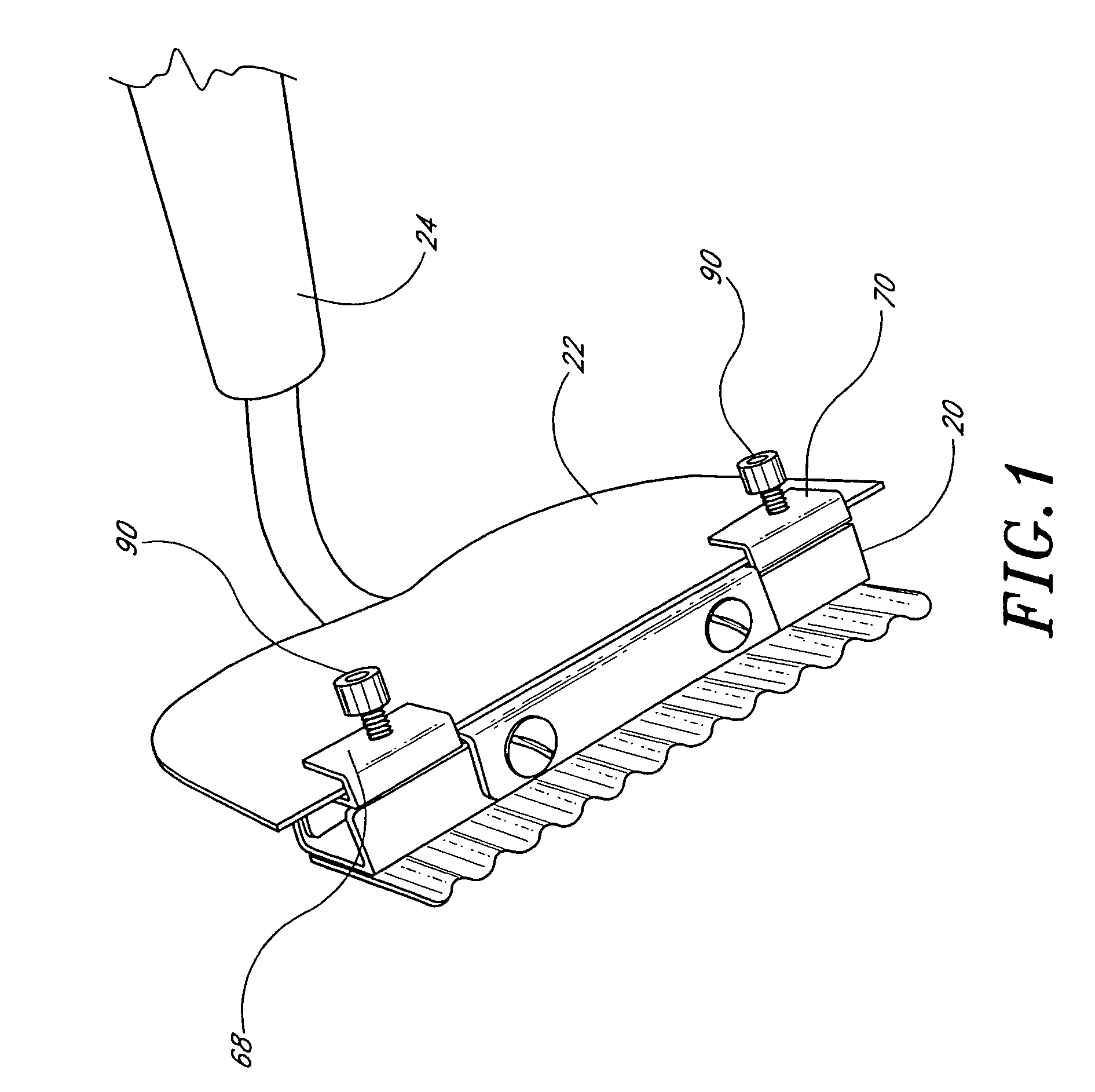

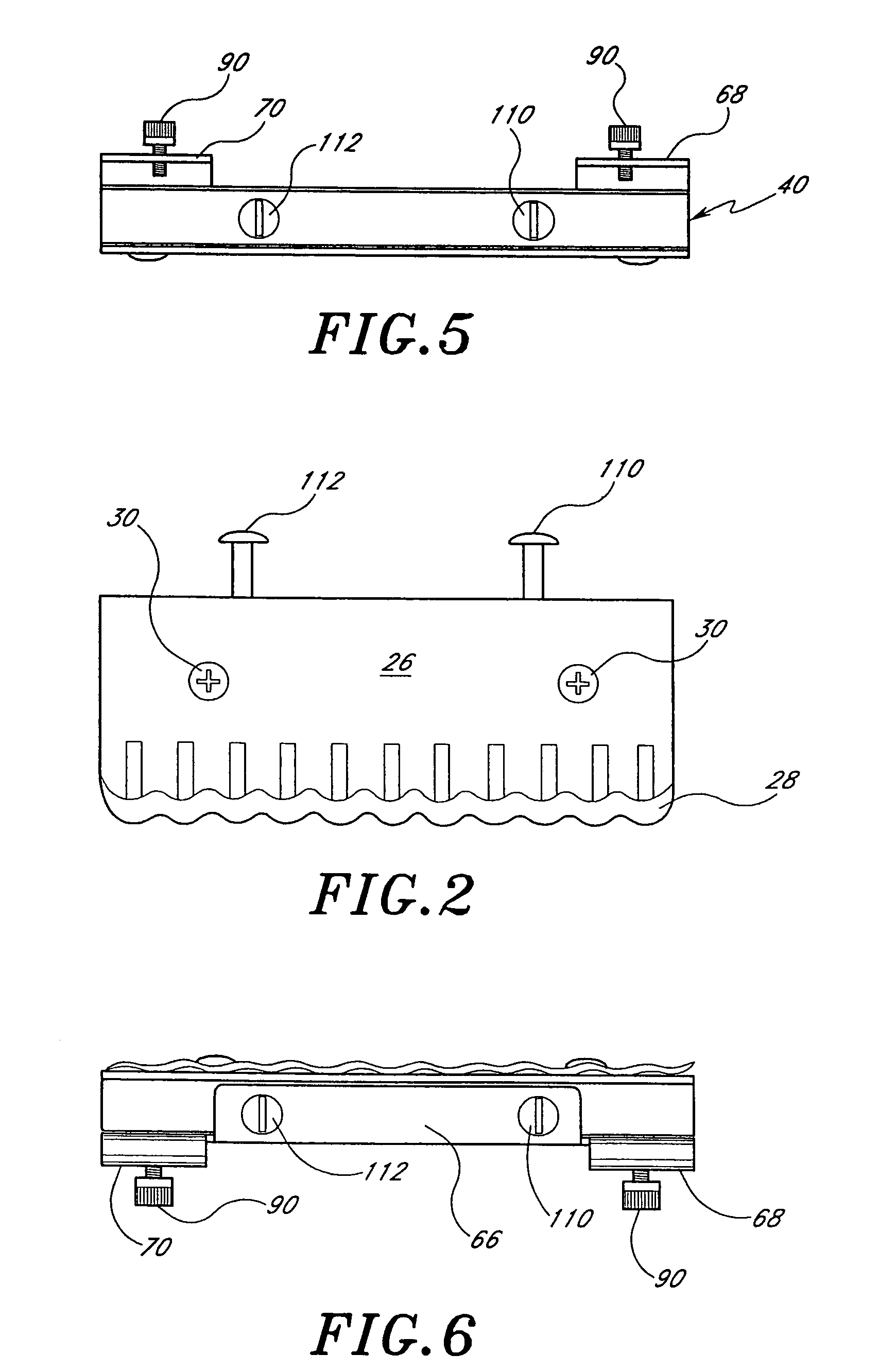

Weeder tool attachment

An attachment device detachably connects a gardening or cultivating tool to the blade of a garden hoe. This attachment device enables a tool such as weed cutters, rakes, pronged tools, and scythes to be detachably mounted to a hoe. The attachment device includes a sheet of metal wherein one or more U-shaped slots are formed along one edge. Tool retaining bolts are threaded into threaded holes in one side of the U-shaped slot(s) to tightly engage the hoe blade within the slot. A cutting tool having this attachment device maintains a spring loaded cutting blade which floats with respect to the hoe attachment device so that compression of the springs during use stores energy when the cutting blade hits an object for enhancing the cutting cycle and for reducing operator fatigue.

Owner:COPPOCK CHRISTOPHER C

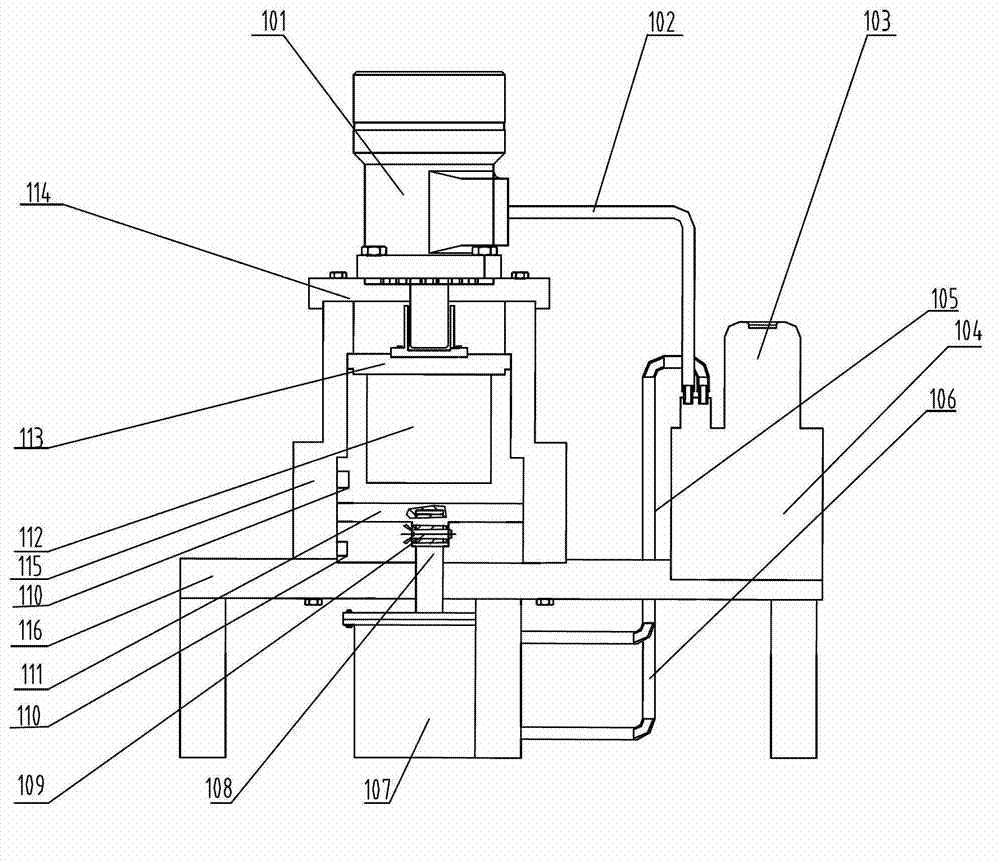

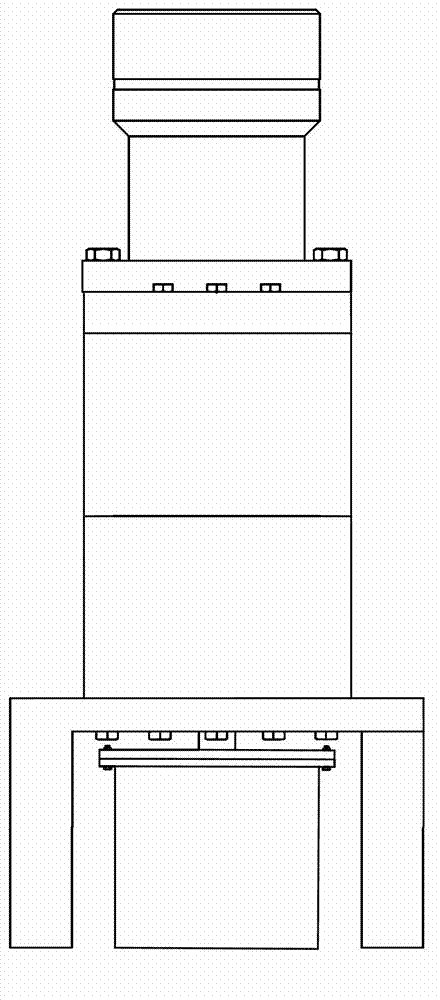

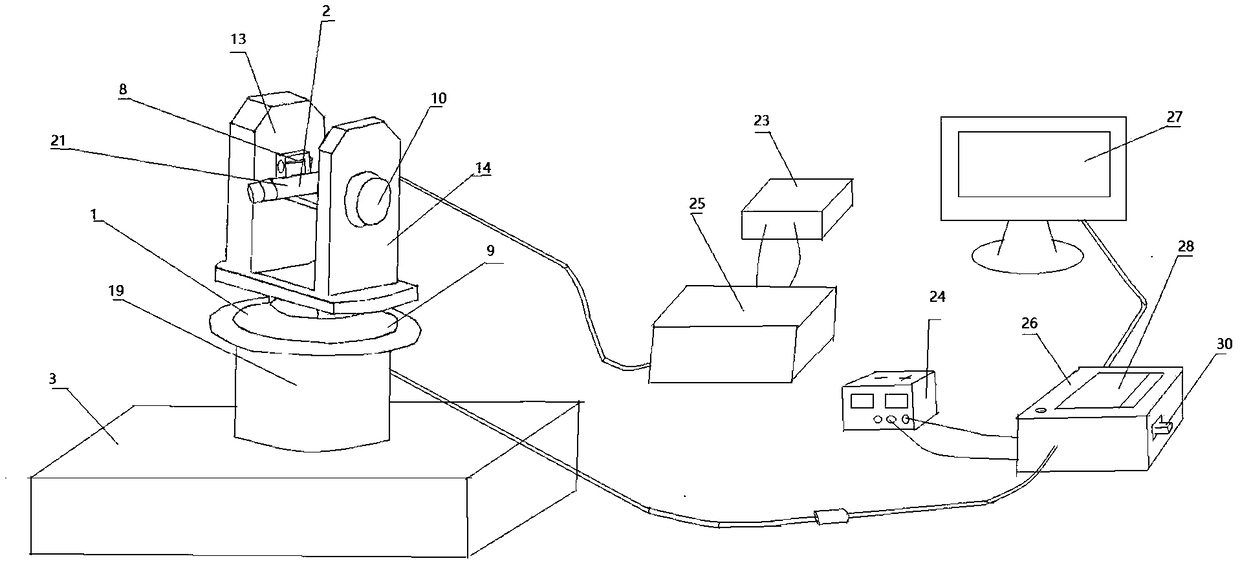

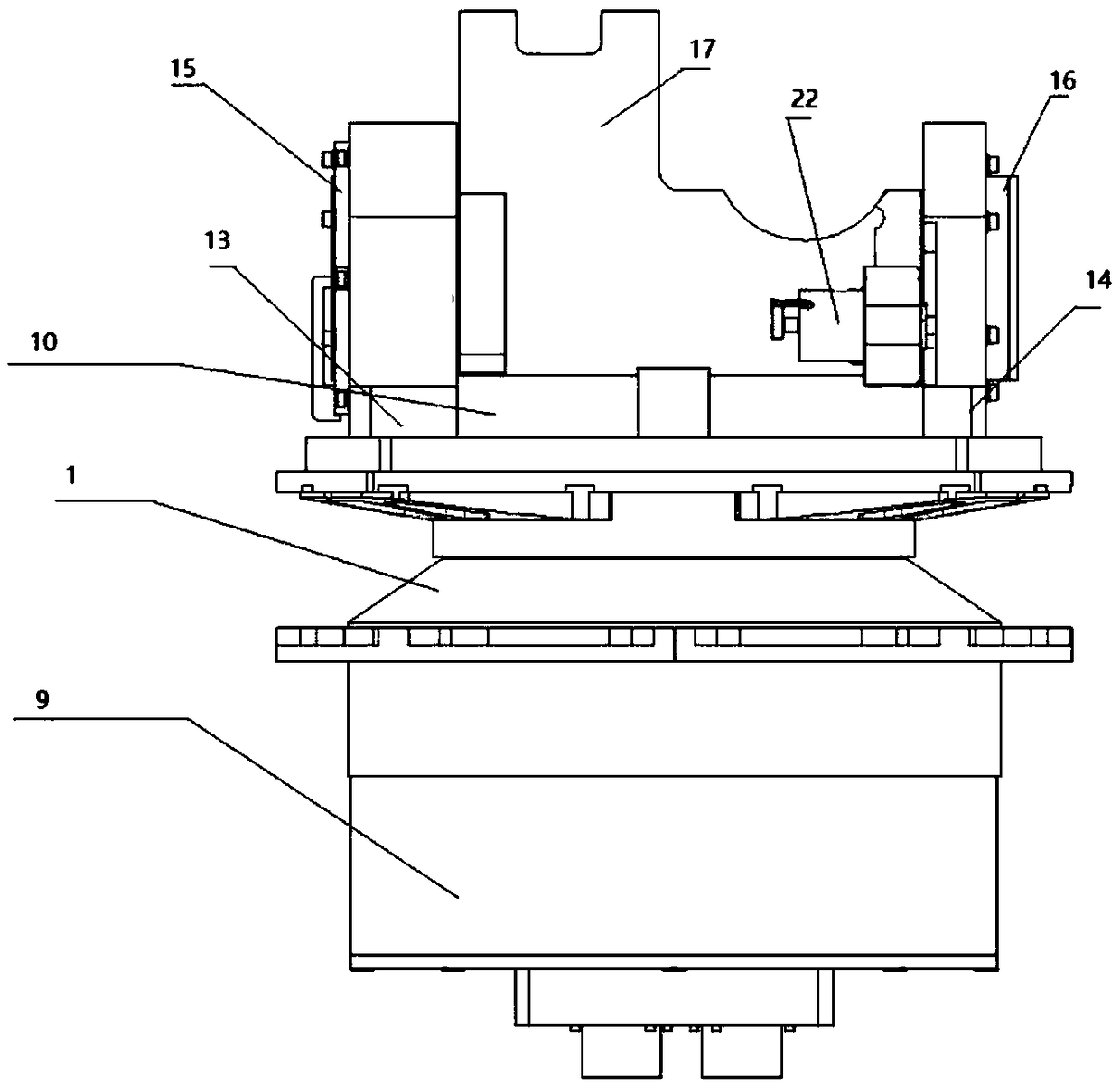

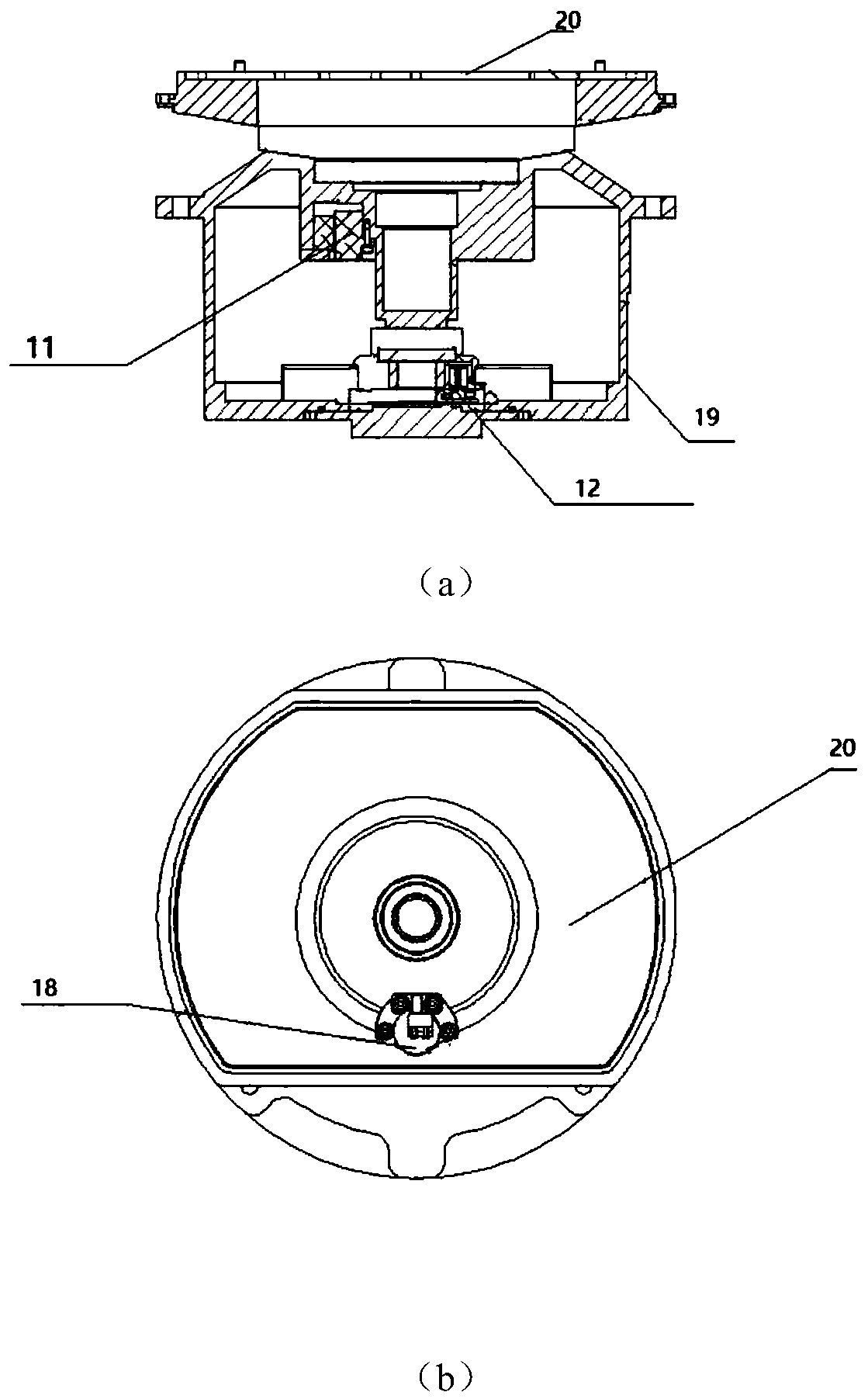

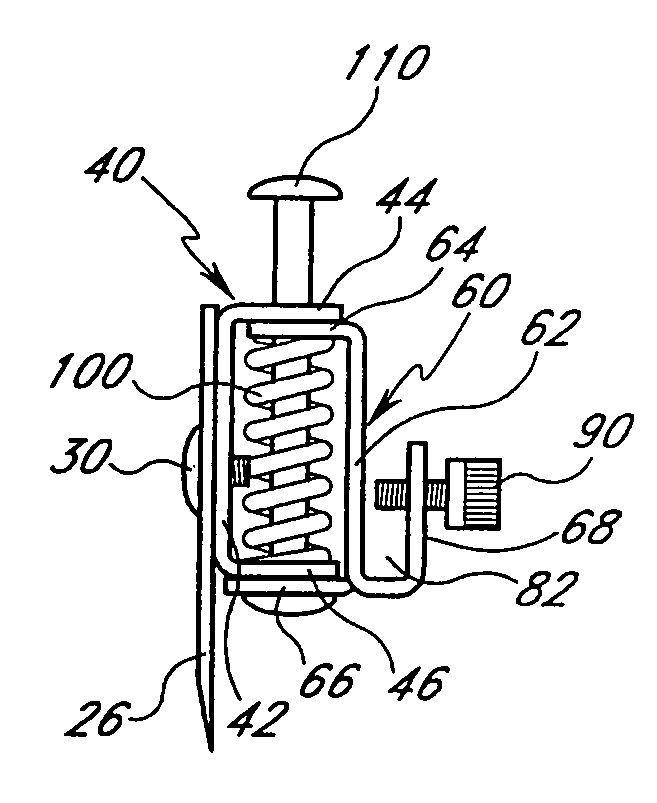

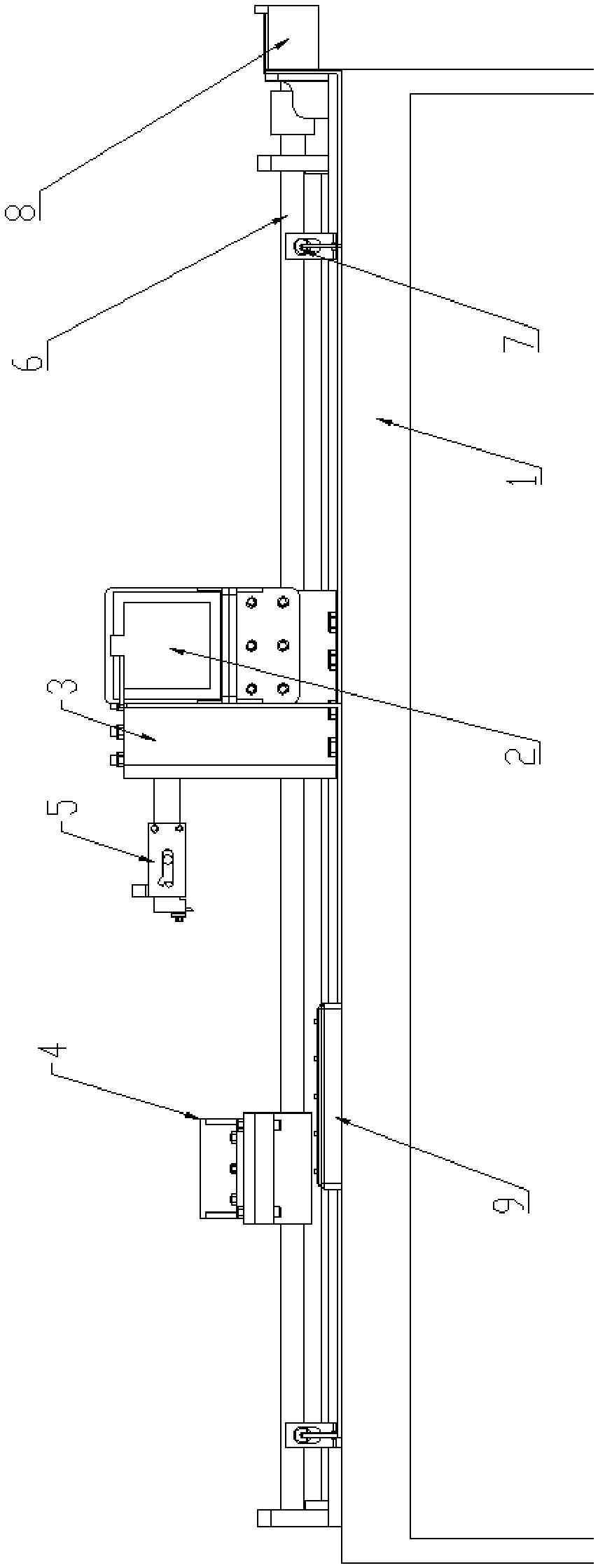

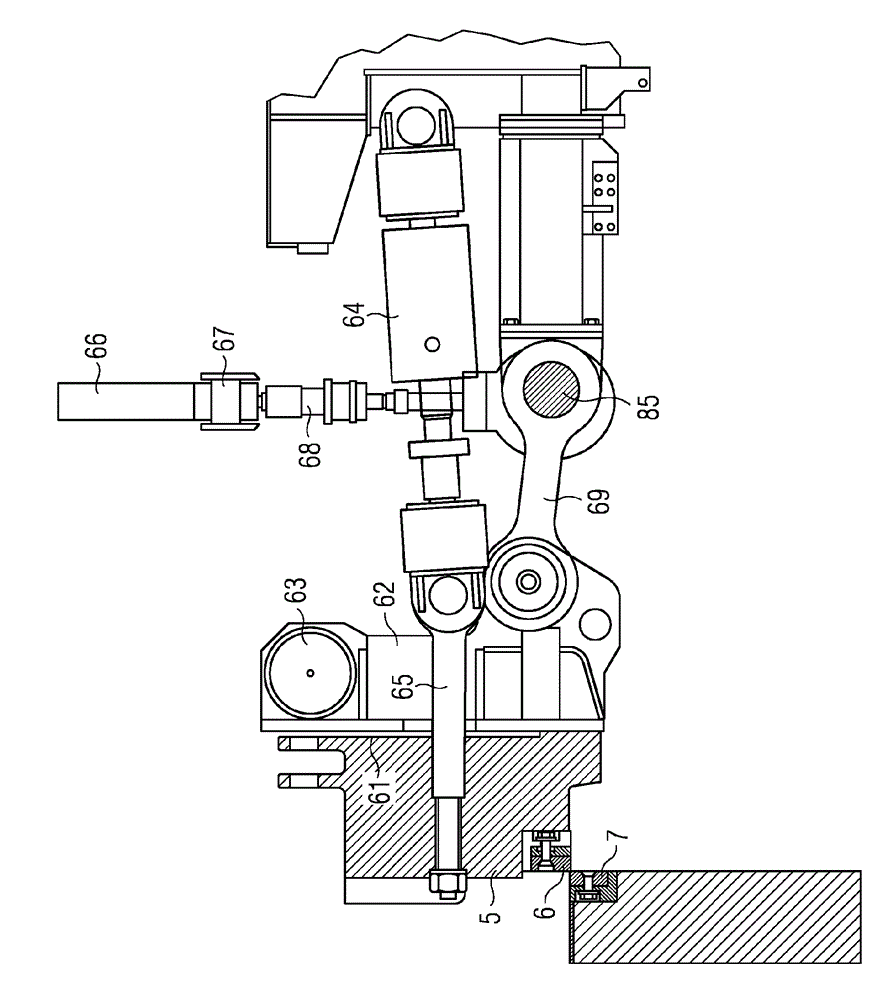

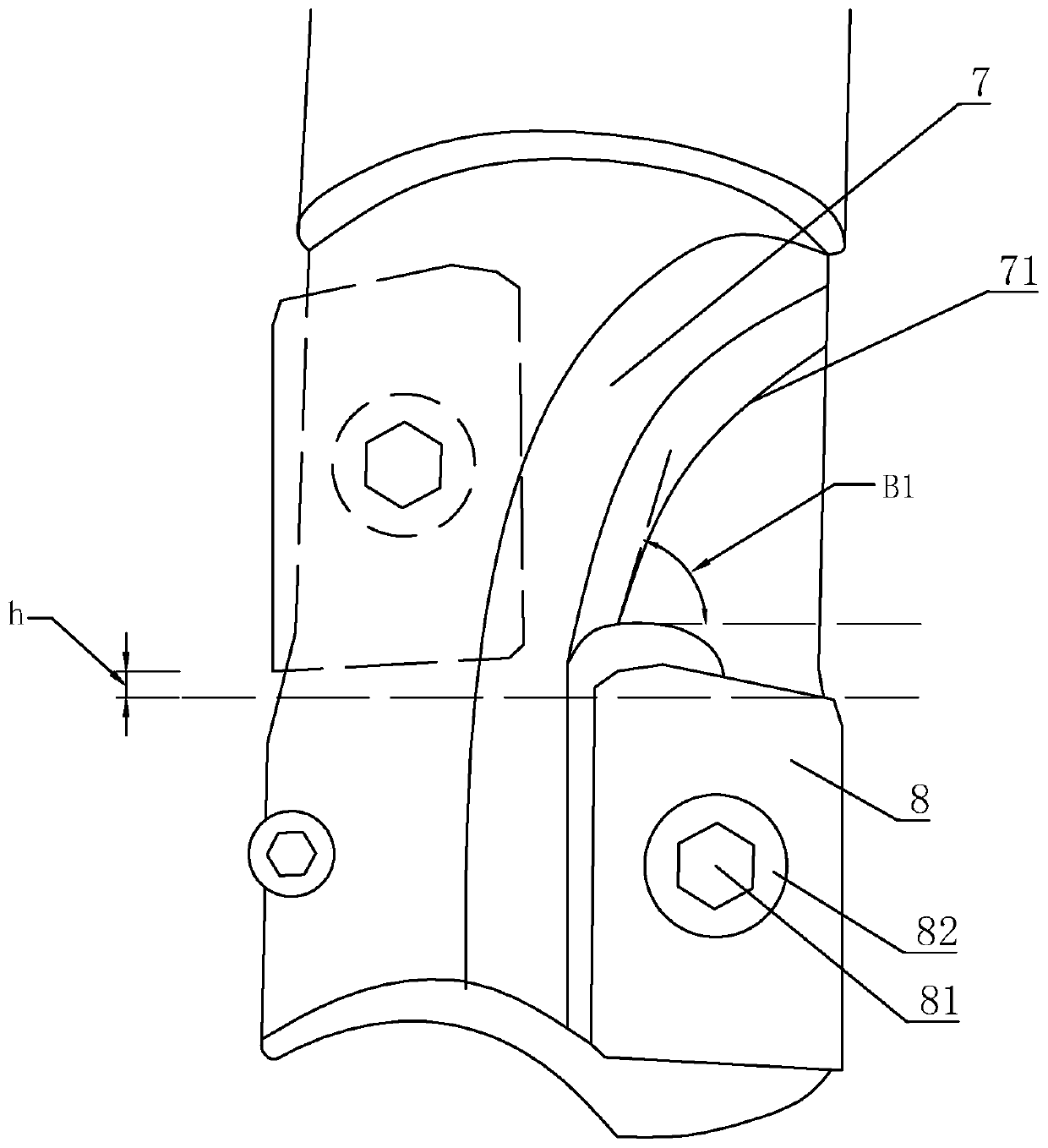

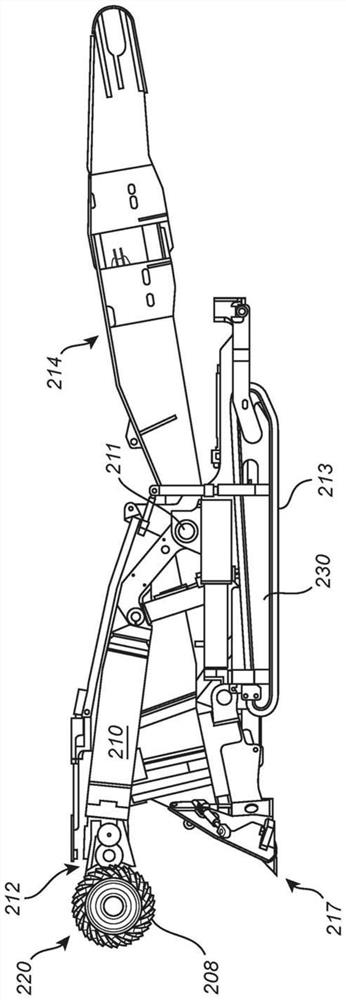

Simulated vibration cutting impact cutter falling experimental device and a working method thereof

ActiveCN108287067AComplete simulation of the vibration cutting processEasy to modifyMachine part testingCutting cycleAutomation

The invention discloses a simulated vibration cutting impact cutter falling experimental device and a working method thereof. The device comprises a worktable, a clamp, a vibration cutting device anda control device. The vibration cutting device comprises a cutter falling module and a vibration generating module. The cutter falling module comprises a cutter, a cutter pressing piece, a cutter falling slide bar, a cutter falling shell, a spring bracket and a spring. The vibration generating module comprises a slide block, a slide block supporting plate, a slide block pin straight-side self-lubricating bearing, a connecting rod, a flanged-side self-lubricating bearing, a short shaft turntable, a long shaft turntable and a vertical bearing seat. The simulated vibration cutting impact cutter falling experimental device is provided with the vibration generating module and the cutter falling module, can simulate a complete vibration cutting process, and can achieve a complete vibration cutting cycle at a time, can set different cutting parameters that can be input by a program and can be modified conveniently, and improves the level of automation by means of the control device .

Owner:DALIAN JIAOTONG UNIVERSITY

Method and apparatus for operating shear

A method of operating a side trim or slitting shear to shear a full length of a material (10) to be sheared is described. The full length comprises a plurality of cutting lengths and the shear comprises a first blade (6) and a second blade (7). The methodcomprises determining parameters of a material to be sheared and storing the determined parameters. In one cutting cycle, the method comprises cutting a single cutting length (14) of the material; carrying out a series of cutting cycles to cut the full length of the material; and in a control system at least once in the series of cutting cycles using the determined parameters to control adjustment of the gap (H) between the first and second blades in a cutting phase in a cutting cycle. The angle between the blades may also be adjustedÂ

Owner:PRIMETALS TECH

Method and apparatus for sawing lineal material to length

ActiveUS8453549B2Reduce and eliminates disadvantage and shortcomingSafe distanceTemperatue controlStatic/dynamic balance measurementMachine controlTime limit

An enhancement for use with automatically cycled saw systems that provides an operator access to two-hand anti-tie down buttons and other machine control functions while manually crowding the material to be cut against the saw's fence. The enhancement includes anti-tie down buttons to prevent a cutting cycle unless both buttons are depressed within preset time limit of each other.

Owner:TECHNOLOGY SERVICE CORPORATION

Cutting seedling method of osmanthus fragrans

InactiveCN106818383AHigh rooting rateImprove survival rateBiocidePlant growth regulatorsDiseaseCutting cycle

The invention discloses a cutting seedling method of osmanthus fragrans. The method comprises operation steps as follows: (1) an excellent plant which grows vigorously and is not damaged by diseases or insects is taken as a mother tree for cutting, and one-year-old half-lignified twigs at the upper part of the periphery of a tree crown of the excellent plant are sheared to serve as cuttings; (2) the base parts of the cuttings are cut into planes and uniformly coated with a yellow gelatin nutritional solution; (3) the cuttings coated with the yellow gelatin nutritional solution are put in a greenhouse at the temperature of 23-27 DEG C and irritated by purple light, and the cuttings are taken out after 4-5 days; (4) the nutritional solution at the base parts of the cuttings are washed clean and a rooting liquid is uniformly sprayed to the base parts of the cuttings; (5) the cuttings with the rooting liquid sprayed are perpendicularly inserted into a seedling bed and watered thoroughly, and other seedling bed management work is done. By means of the cutting seedling method of osmanthus fragrans, the rooting rate of the cuttings of the osmanthus fragrans and the survival rate of seedlings can be effectively increased, the rooting speed of the cuttings is increased, the cutting cycle is shortened, damage of diseases and insects to the cuttings can be reduced, and the quality of the seedlings of the osmanthus fragrans is improved.

Owner:焦杰彪

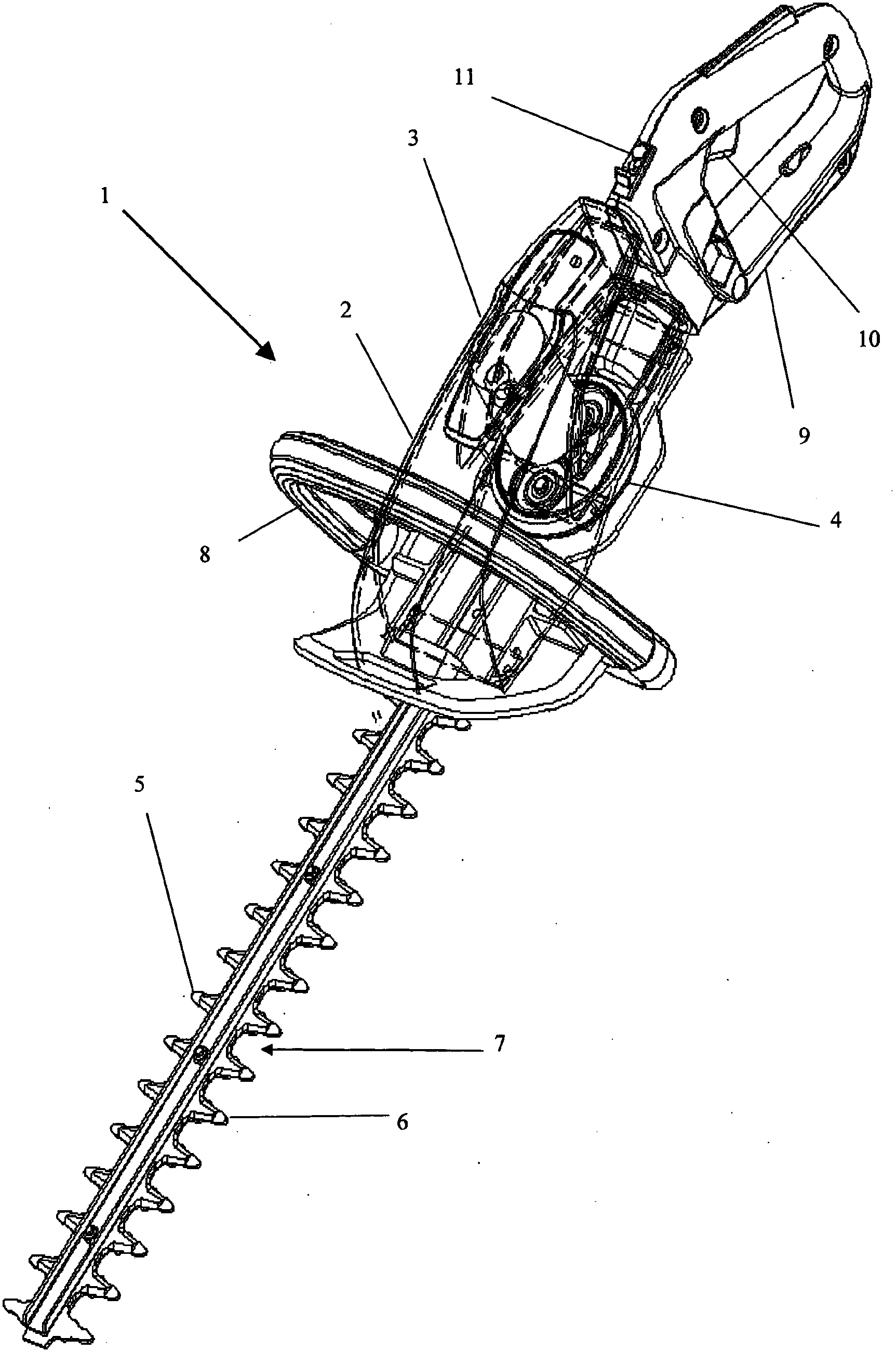

Hedge trimmer

A hedge trimmer (1) comprises an electric motor (3) and at least two cutting blades (5,6), each blade comprising at least one row of teeth with the motor being connected to at least one of the blades so that rotation of the motor (4) produces a movement of at least one of the blades relative to the other, a first user operable switch (10) for operation of the hedge trimmer blades and a second user operable switch (11) which enables a user to select between at least two operating modes of the hedge trimmer, the two modes comprising a hedge trimming mode in which operation of the first user operable switch causes a reciprocal motion of the at least one blade, and a secateur mode in which operation of the switch causes a single cutting cycle to be performed. A two ratio gearbox may be provided to enable the blades to move at a lower speed and with higher torque when in the secateur mode compared with the hedge trimming mode.

Owner:HUSQVARNA AB

A coal caving method with segmental staggered cutting and circular coal caving in top coal caving working face

ActiveCN109025997BImprove work surface efficiencyRealize the parallel operation of picking and releasingUnderground miningSurface miningSpelunkingEngineering

Owner:TAIYUAN UNIV OF TECH

All-day laser semi-automatic de-icing method based on infrared

InactiveCN108988267AIncrease flexibilityHigh control precisionOverhead installationInfraredControl system

The invention discloses an all-day laser semi-automatic deicing method based on infrared. The control system calculates the corresponding rotary table instruction according to the received cutting cycle times and cutting speed instruction; the control system calculates the rotary table instruction according to the received cutting cycle times and cutting speed instruction. The control system calculates the angle information according to the pixel information of the selected starting point and ending point, and calculates the corresponding turntable instruction at each time. The laser componentsends laser light, and the control system sends corresponding angle command to the turntable, and the turntable is controlled to drive the laser component to rotate. At this time, the display displays the planned path, and the equipment starts to cut along the path; After cutting, the control system recognizes the image, if there is still ice, the turntable will continue to track; If there is noice in the image, the control system does not send a command to the turntable and waits for the end. The invention collects and displays the target position through the visual sensor module, and on the basis of automatic tracking, controls the start point and the end point of the cutting path through the user end, thereby improving the cutting efficiency.

Owner:NANJING UNIV OF SCI & TECH

A high-efficiency machining system for deep holes in the oil pump housing

ActiveCN109332766BImprove surface qualityImprove processing stabilityTransportation and packagingMetal working apparatusPiezoelectric actuatorsEngineering

The invention discloses a high-efficiency deep hole machining tool in an oil pump housing, which comprises a tool bar and a blade fixedly installed on the tool bar. Both sides of the blade have cutting edges, and the cutting edges are provided with micro-cutting edges. A deep hole high-efficiency machining system with the machining tool includes a vibrating horn and a piezoelectric actuator, and the vibrating horn transmits vibration to the tool. The present invention improves the processing stability of the cutting process and the surface quality of the workpiece through the micro-cutting edges on both sides of the blade, and reduces the burrs on the inner surface of the deep hole and the fillet; It is transmitted to the blade, so that a stable ultrasonic vibration cutting cycle is generated during the cutting process, and the surface quality of the workpiece is further improved.

Owner:HUNAN INST OF TECH

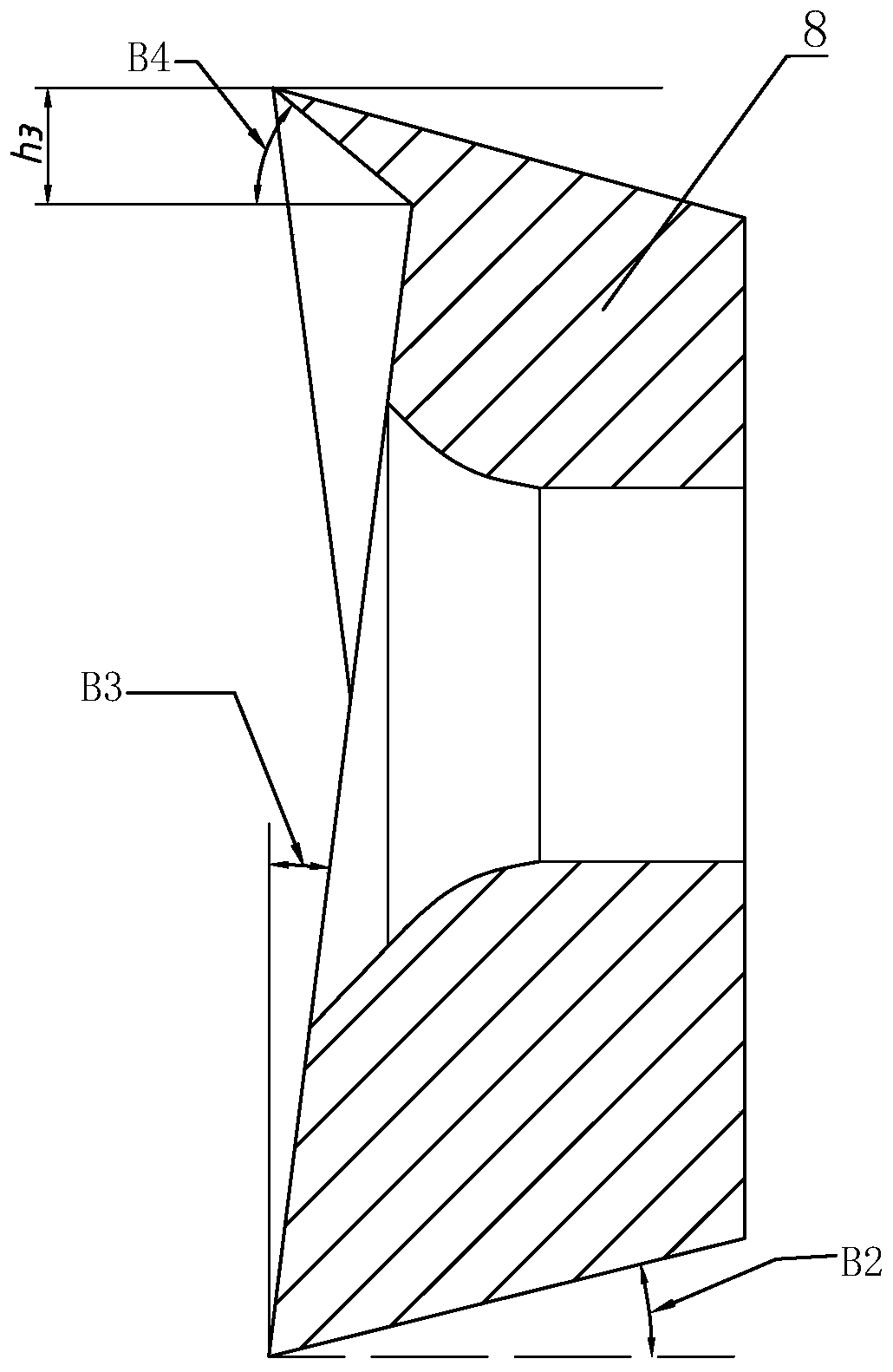

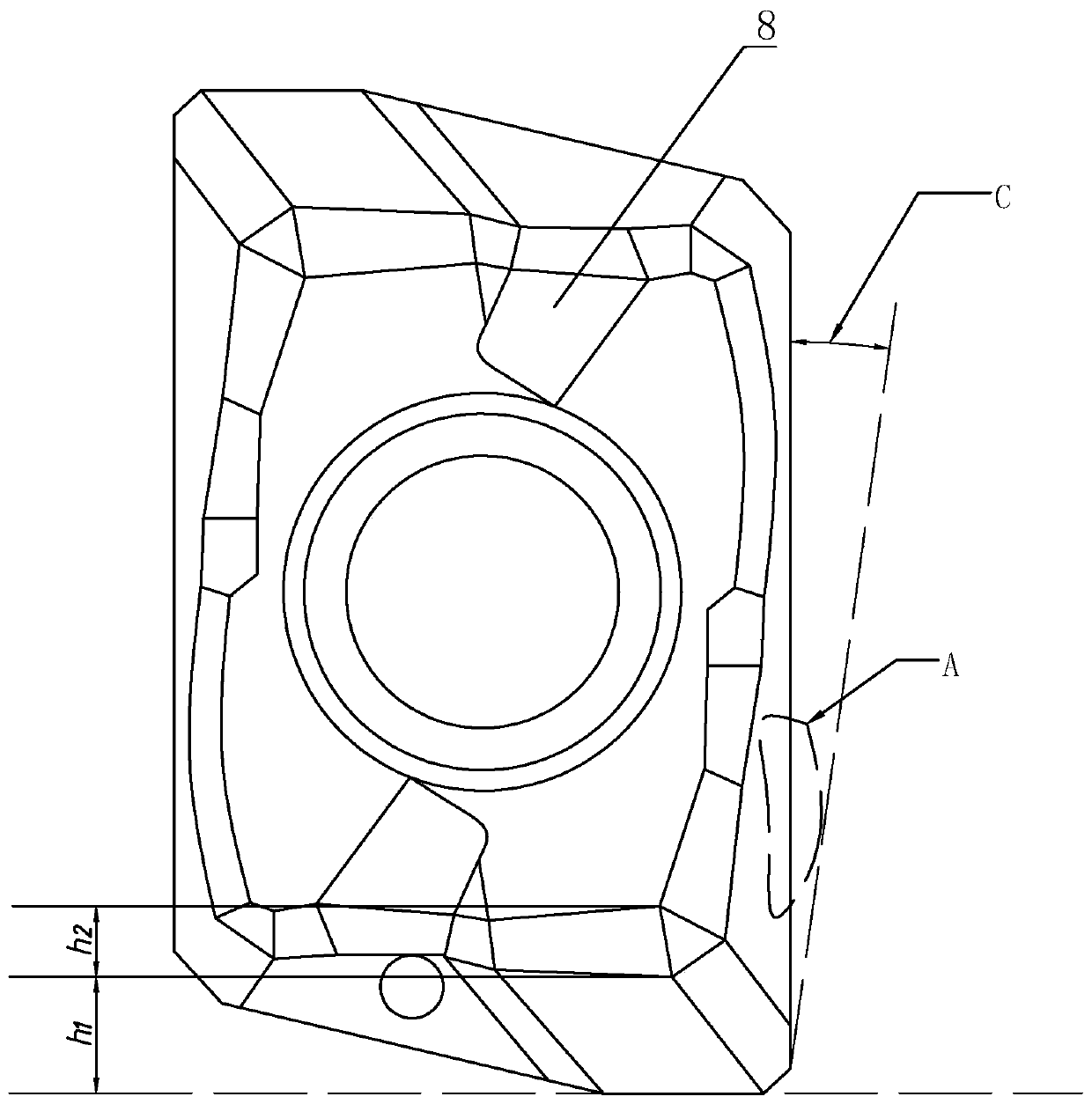

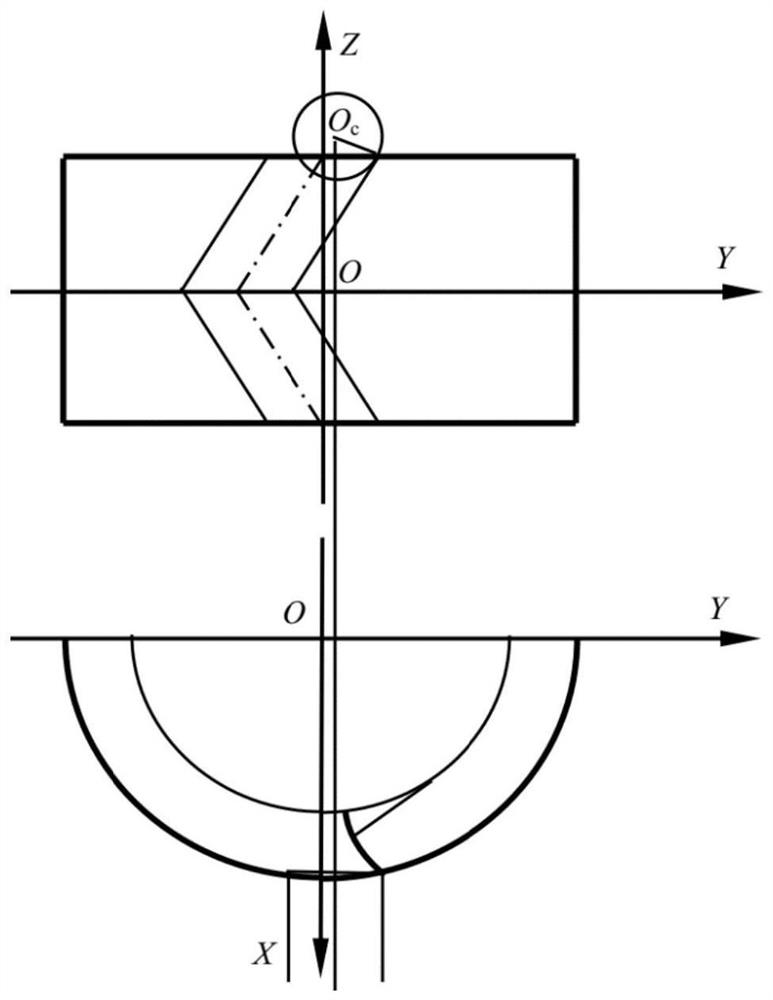

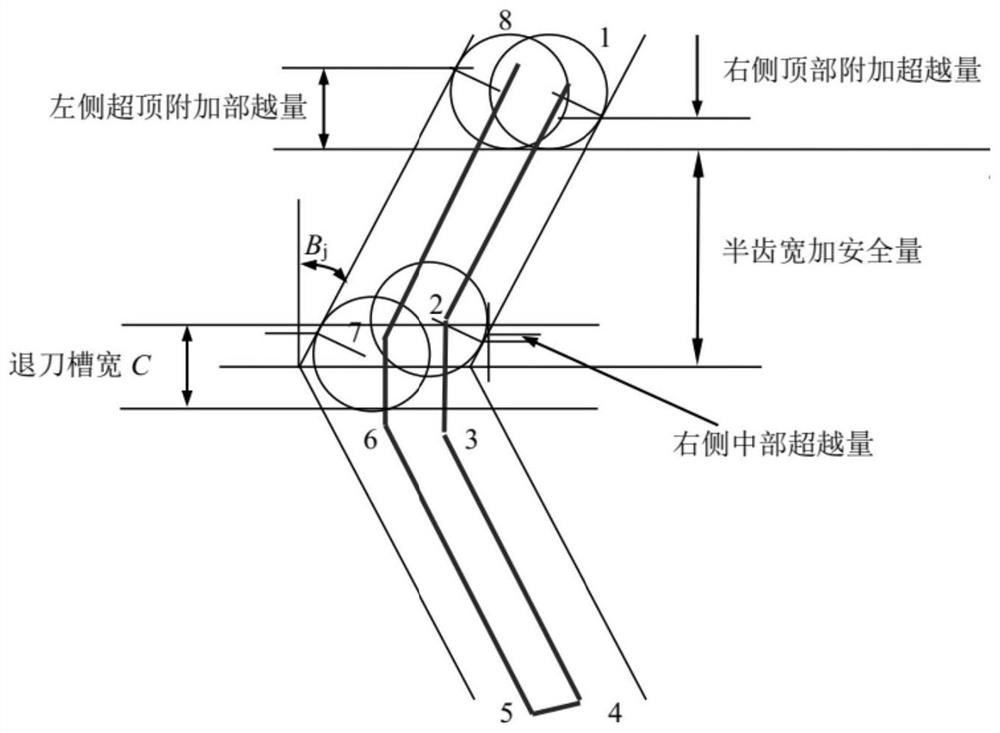

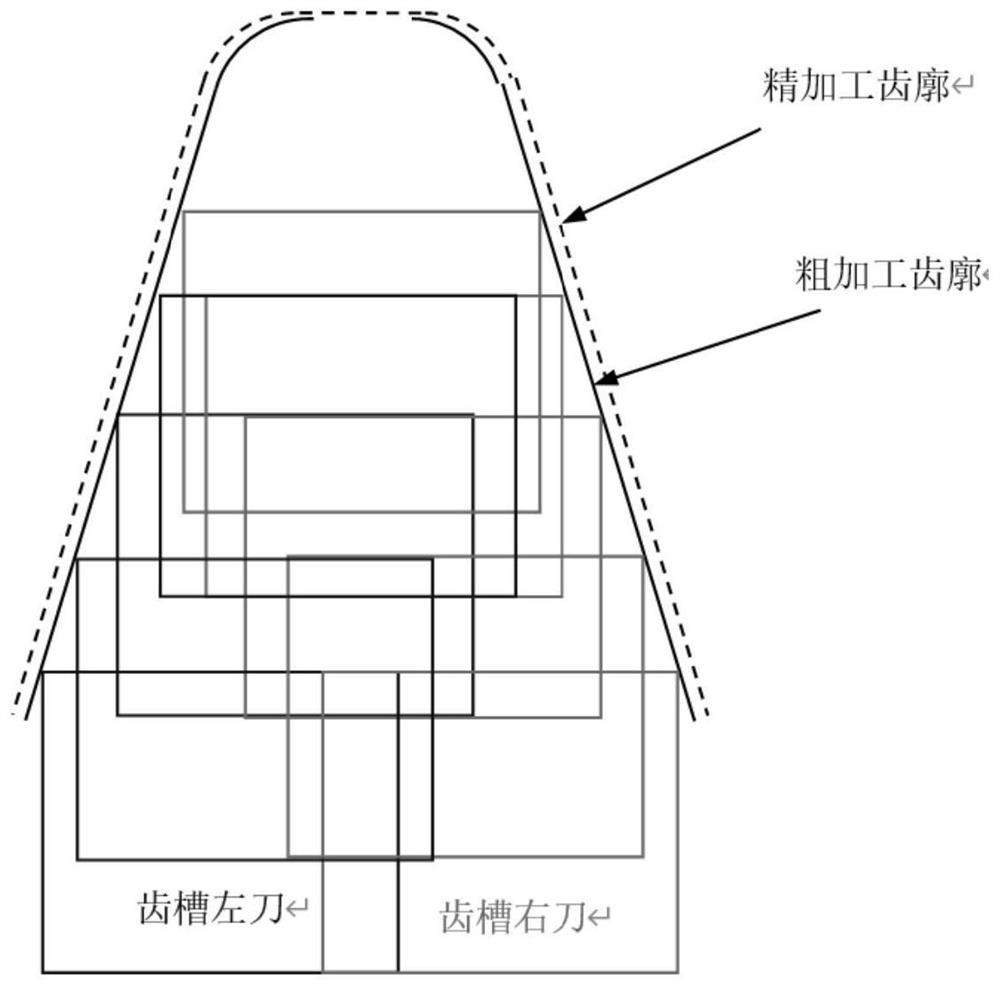

A method for rough cutting with step feed of herringbone gear with narrow empty sipes

ActiveCN111687495BImprove processing efficiencyReduce manufacturing costGear teethGroove widthRooted tooth

The invention discloses a step-feed rough cutting method of a herringbone gear with narrow empty sipes, belonging to the field of herringbone gear processing. A step-feed rough cutting method for a narrow empty sipe herringbone gear, comprising: 1) calculating the half-angle σ of the base circular tooth groove based on the parameters of the herringbone gear b ; 2) Based on σ b Calculate the normal slot width S of the tooth top of the herringbone gear rdna ′, and the normal slot width S of the starting point of the involute line of the herringbone gear rdnf '; 3) based on S rdna ' and S rdnf ’, select the rough cutting cylindrical end mill tool; 4) The tool is stepped into the tool along the radial direction of the gear, and the tool cuts along one side of the tooth groove in the tooth width direction and then returns along the other side of the tooth groove to complete a cutting cycle, that is, complete Single-layer cutting; repeat the step feed until the width of the rough cutting groove is smaller than the diameter of the tool, and complete the maximum cutting depth of the tool; use the tool for tooth division processing until all the tooth grooves are cut to the maximum cutting depth of the tool; replace the next tool Carry out cutting, the cutting method is the same as that of the last tool, until all the tools are cut and the rough cutting is completed.

Owner:XI AN JIAOTONG UNIV

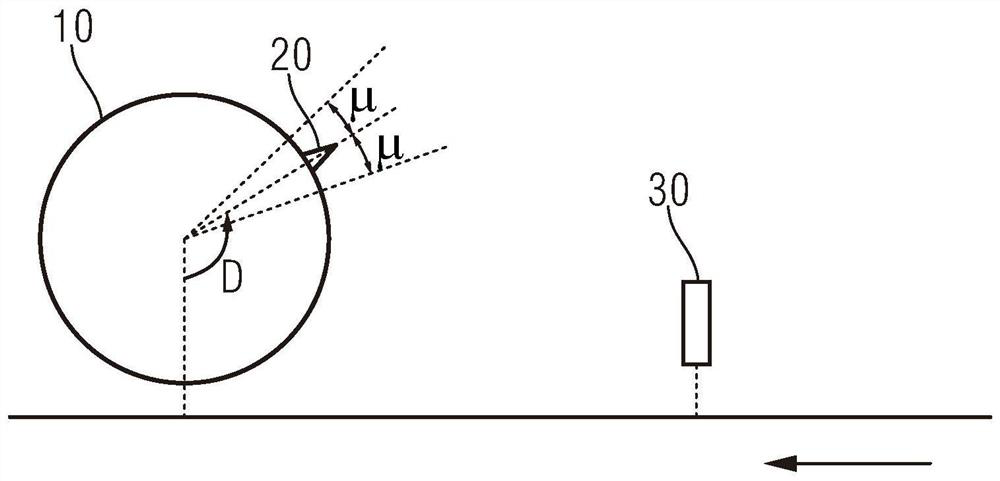

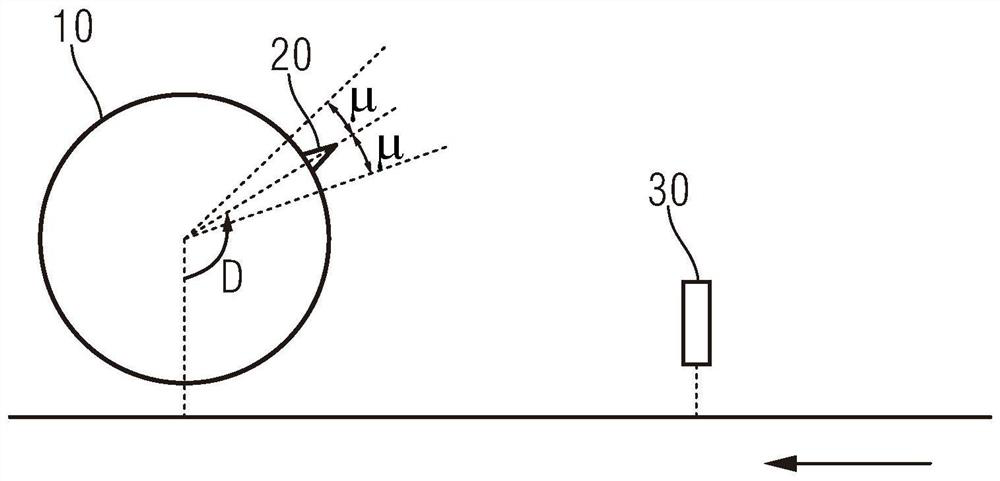

Method for automatically adjusting cutter angle of transverse cutting machine and transverse cutting machine

ActiveCN111731907AReduce production speedMetal working apparatusWebs handlingMaximum torqueElectric machinery

The invention provides a method for automatically adjusting the cutter angle of a transverse cutting machine and the transverse cutting machine. The method for automatically adjusting the cutter angleof the transverse cutting machine comprises the steps that when that the transverse cutting machine works normally by sensing color codes is determined, the cutter angle is adjusted, and normal cutting is achieved; when two adjacent color codes are sensed, a first angle Deg1 and a second angle Deg2 which are stored are not within the range of [ D - mu, D + mu ], and if the absolute value of Deg2-Deg1 is smaller than or equal to mu, the maximum angle adjustment amount which can be conducted by a cutter within a cutting period on the basis of position synchronization is adjusted according to the maximum rotating speed and the maximum torque of a motor; and if the absolute value of Deg2-Deg1 is smaller than mu, the value of Deg1 is modified, Deg1= Deg2, subsequent color codes continue to besensed, and the operation is repeated. According to the method for automatically adjusting the cutter angle of the transverse cutting machine and the transverse cutting machine, the cutter angle of the transverse cutting machine can be automatically adjusted according to the maximum adjustment capacity of the motor, the production speed does not need to be decreased, the production efficiency canbe improved, and meanwhile the workload of operators is relieved.

Owner:SIEMENS FACTORY AUTOMATION ENG

LED light bar aluminum substrate splitting equipment

InactiveCN112008138AImprove cutting efficiencyReduce idle timeShearing machinesShearing machine accessoriesIndustrial equipmentAir pump

The invention relates to the technical field of industrial equipment and discloses LED light bar aluminum substrate splitting equipment. The equipment comprises a box and an air pump, a fixed platformis fixedly installed at the top of an inner cavity of the box, a right conveying device is movably installed on the right side of the fixed platform, a left conveying device is movably installed on the left side of the fixed platform, the right conveying device is movably connected with the inner wall of the box, and the left conveying device is movably connected with the inner wall of the box. The right conveying device, the left conveying device and a cutting device are arranged; therefore, a cutting cycle of LED light bar aluminum substrates is formed; automatic cutting is achieved, manualintervention is reduced, manual use is reduced, the labor cost is reduced, the idling time of a front cutting knife wheel is shortened when the LED light bar aluminum substrates are returned manually, energy waste is reduced, the cutting cost is reduced, meanwhile, two aluminum substrates are cut at the same time, and the cutting efficiency of LED light bars is improved.

Owner:杨允炜

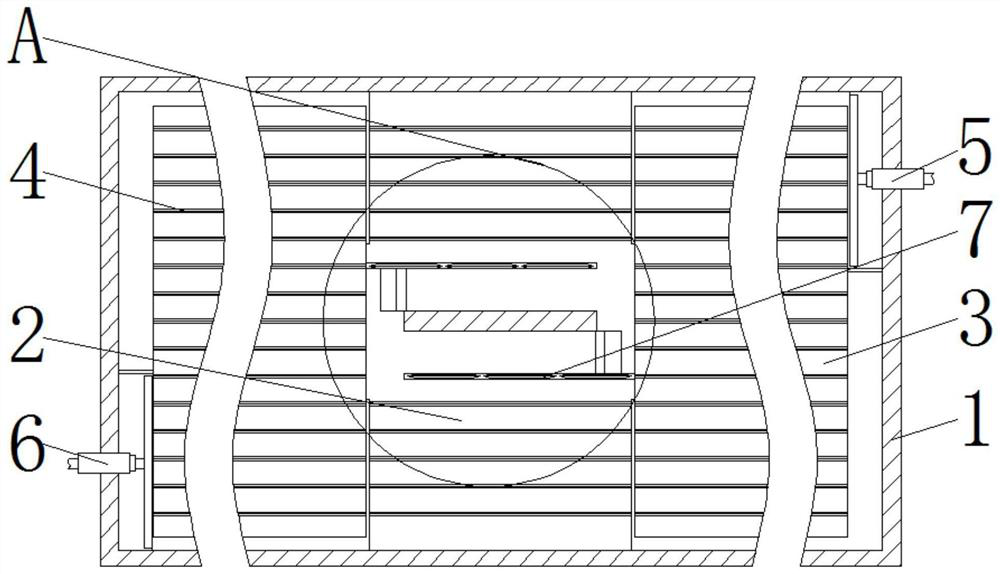

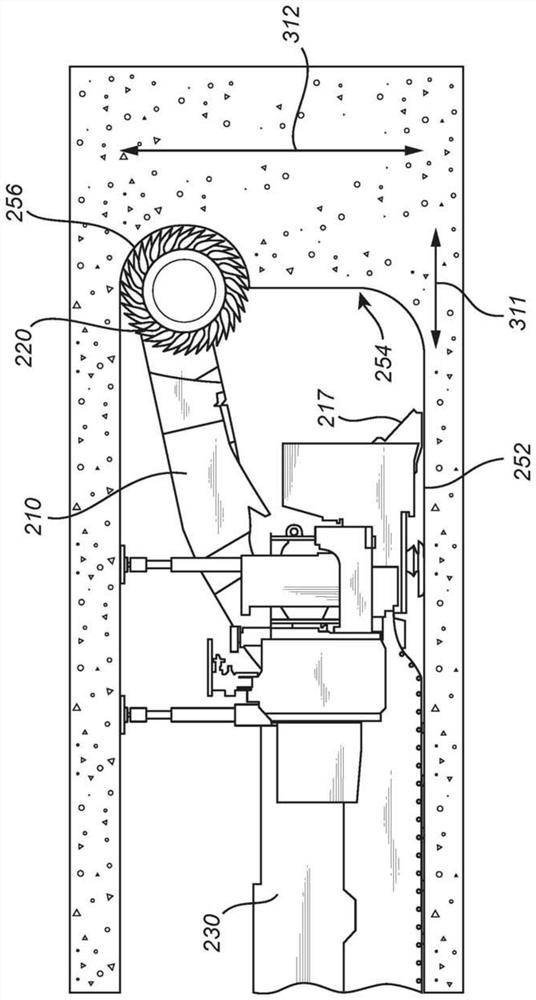

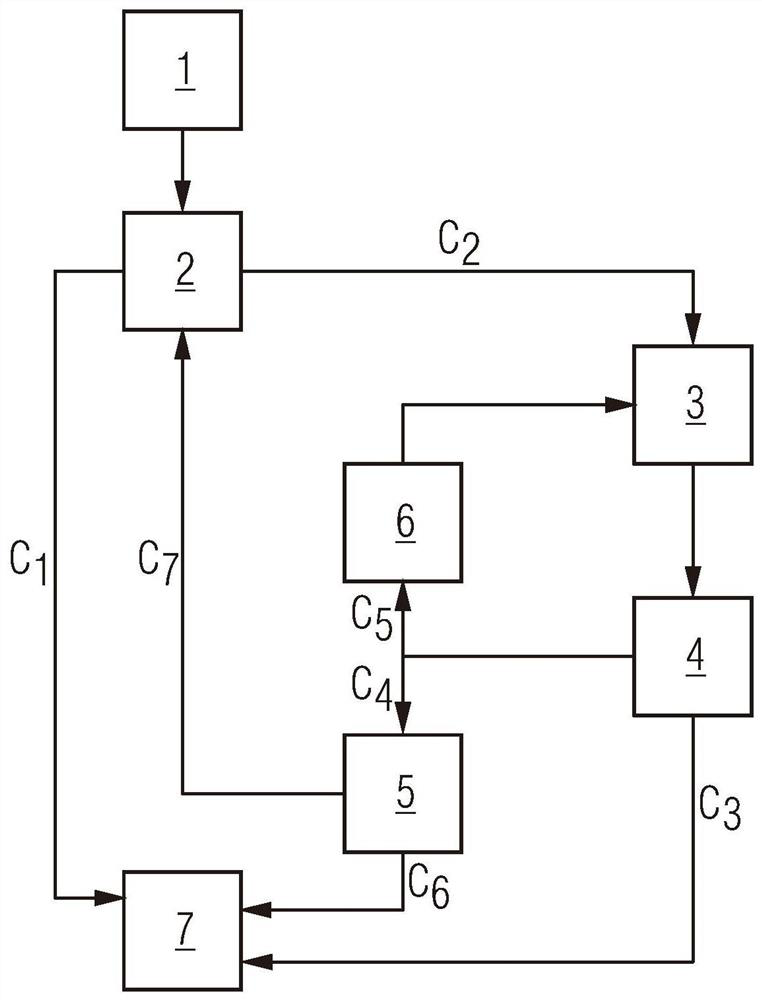

A mining machine adapted for extracting material from a deposit, and method for control thereof

PendingCN113330182AShorten the timeProgramme controlMechanical machines/dredgersExternal storageData file

The present disclosure relates to a mining machine (100) adapted for extraction of material from a deposit and a method for controlling operation of such a mining machine. According to an embodiment, the mining machine comprises a data handling unit (110) and a control unit (120). The data handling unit is adapted to receive, from an external storage medium (130), a data file (132) representative of a user-defined cutting path (114), and to send, to the control unit, data (112) corresponding to a cutting path selected among the user-defined cutting path and one or more machine-predefined cutting paths (118). The control unit is configured to control operation of the mining machine using an automatic cutting cycle in accordance with the selected cutting path corresponding to the data received from the data handling unit.

Owner:SANDVIK MINING & CONSTR OY

An intelligent cutting device for nonwoven production

ActiveCN111660360BRealize automatic feeding processAct as tensionSevering textilesMetal working apparatusProcess engineeringCutting cycle

The invention relates to the technical field of mechanical processing, in particular to an intelligent cutting device for non-woven fabric production, comprising a base, an upper end of the base is fixedly mounted with a lifting push rod, and an output end of the lifting push rod is fixed and mounted with a pair of bolts A lift table, and a pair of conveying devices are installed on the base at the front and rear ends of the lift table corresponding to the front side of the base. The beneficial effects are as follows: the cutting device designed by the present invention can realize automatic feeding through the conveying device, and during the feeding process, the position of the non-woven fabric can be guaranteed to be constant by the limit plate, and at the same time, a pair of feeding devices can be used to play the role of tension. , so as to effectively reduce the phenomenon of burrs in the cutting process. The device can also realize the precise control of different cutting sizes by changing the position of the slitting knife and the cutting cycle of the cross-cutting knife, so as to effectively replace the Manual cutting work can effectively reduce labor consumption and improve processing efficiency.

Owner:武汉叁木汽车部件有限公司

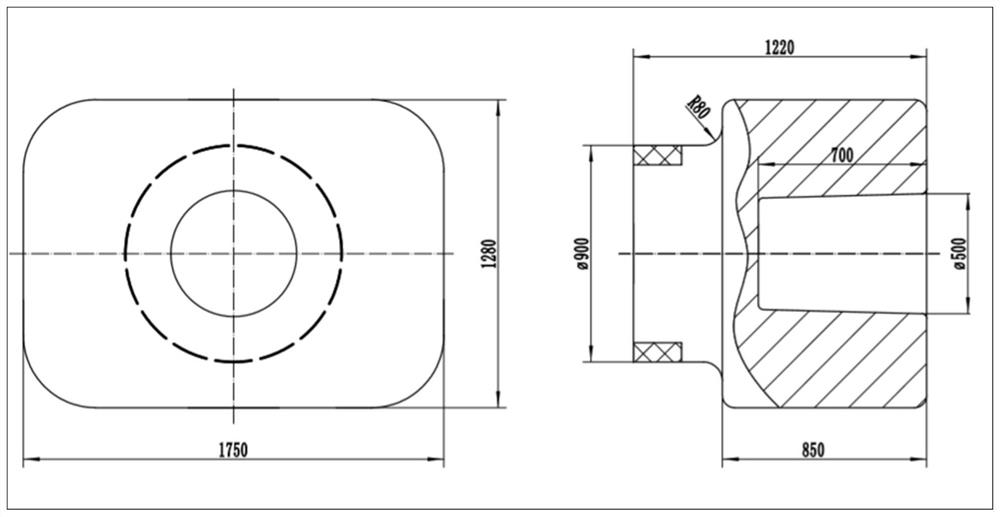

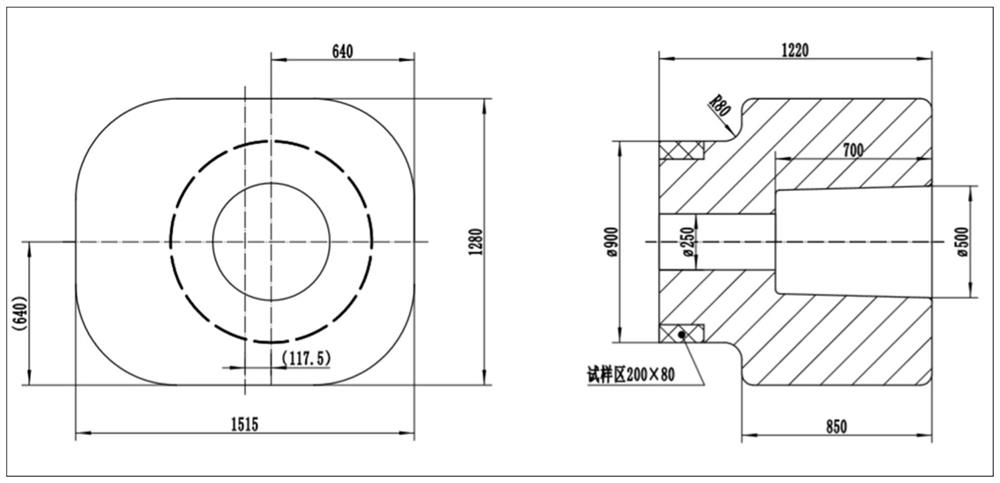

A stainless steel pump body forging forming process

ActiveCN113059103BLow costBlank weight is lightMetal-working apparatusEngineeringSS - Stainless steel

The invention provides a stainless steel pump body forging forming process, which makes the stainless steel material suitable for near forming technology, reduces the cost of raw materials, shortens the subsequent cutting and processing cycle, and reduces the overall cost of the entire stainless steel pump body. (1) Perform forming simulation with simulation software, select the best deformation conditions, design and make molds; (2) Select forgings with circular section asymmetric punching, the shape of the forging blank is close to the shape of the finished product; during the processing and forming of forgings, Control the deformation amount of 10-15% of each deformation part in the last fire during the final forming, control the grain size of the austenitic stainless steel structure, achieve the effect of deformation strengthening, the performance is qualified, and the flaw detection is qualified; (3) The near-formation after the flaw detection is qualified The forgings are subjected to solution treatment, and then the hardness test and inspection test are carried out, and then machining and cutting are carried out according to the drawings; (4) After the machining and cutting products pass the flaw detection, they are packaged and delivered.

Owner:WUXI HONGDA HEAVY IND

Method for automatically adjusting cutter angle of cross-cutting machine and cross-cutting machine

ActiveCN111731907BReduce production speedMetal working apparatusWebs handlingElectric machineryMachine

The invention provides a method for automatically adjusting the angle of a cutting knife for a cross-cutting machine and the cross-cutting machine. The method for automatically adjusting the angle of the cutting knife for the cross-cutting machine includes: when the cross-cutting machine is confirmed to be working normally by sensing the color mark, the angle of the cutting knife is adjusted to achieve normal cutting; when two adjacent Neither the stored first angle Deg1 nor the second angle Deg2 at the color scale is within the range of [D‑μ, D+μ]. If |Deg2‑Deg1| The torque-driven knife roller adjusts the maximum angle adjustment that the cutter can perform in one cutting cycle on the basis of position synchronization; if |Deg2-Deg1|>μ, modify the value of Deg1 so that Deg1=Deg2, And continue to sense subsequent color marks and repeat the above operations. The invention can automatically adjust the cutter angle of the cross-cutting machine according to the maximum adjustment capability of the motor, without reducing the production speed, can improve the production efficiency, and at the same time reduce the workload of the operator.

Owner:SIEMENS FACTORY AUTOMATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com