Method for machining soft aluminum part threads through turning

A thread and soft aluminum technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of poor plastic deformation resistance, thread rotten teeth, and easy occurrence of knife sticking, so as to ensure product quality and solve problems. The effect of thread rot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] The present invention is a method for turning and processing the threads of soft aluminum parts, comprising the following steps:

[0027] The first step: choose the coolant: choose a coolant with strong viscosity;

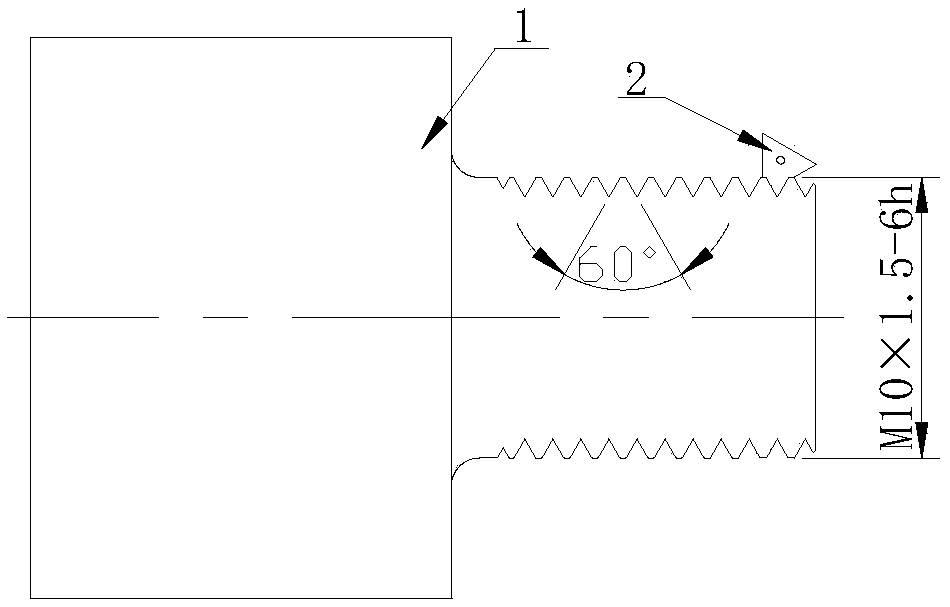

[0028] The second step: select the blade: select the threaded blade 2 with a larger pitch to replace the threaded blade 2 that needs to be processed normally;

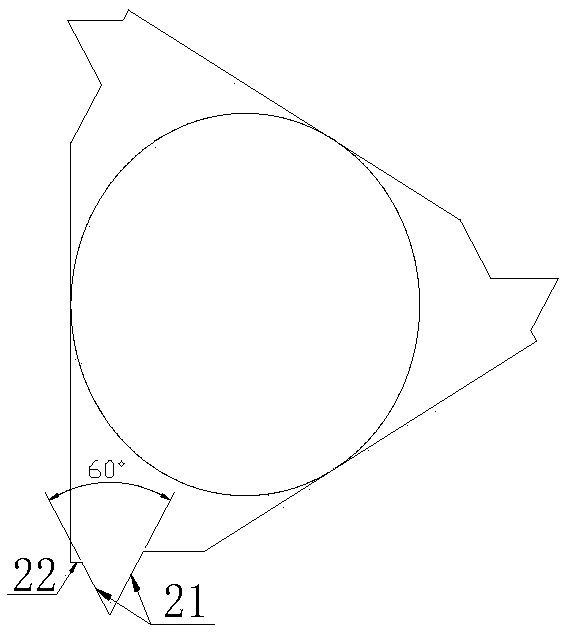

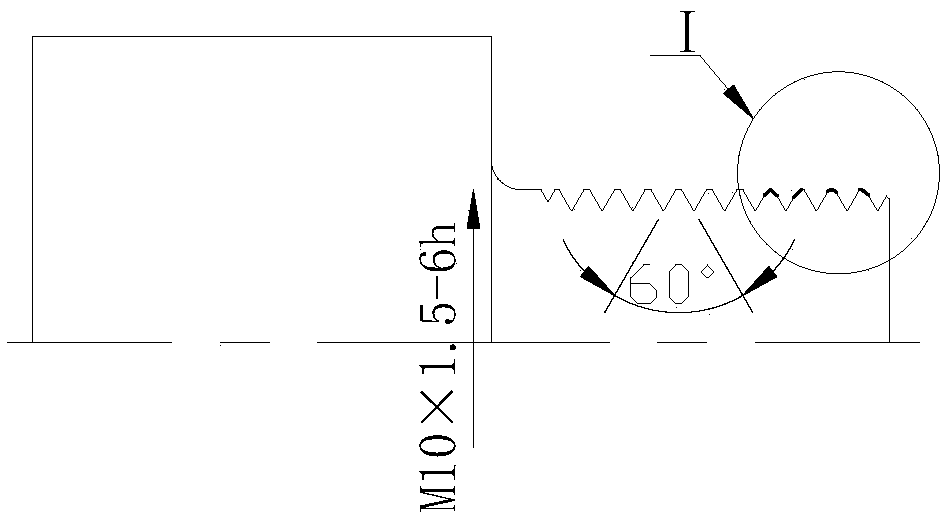

[0029] Step 3: Select the thread cutting programming method: use G76 (multiple thread cutting cycle command) to process threads, and use the side feed method programmed by G76, such as Figure 5 As shown, the insert is fed at a profile angle smaller than the relief angle

[0030] Step 4: Select the cutting parameters: thread single cycle back cutting amount ap = 0.05mm ~ 0.07mm, line speed Vc = 55 ~ 60rpm.

[0031] Take the thread processing of part M10×1.5-6h as an example:

[0032] Step 1: R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com