Machining method of valve assembly made of dissimilar materials

A technology of dissimilar materials and valve assemblies, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of excessive roughness, lack of non-metal surface materials, etc., and achieve the effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A method for processing a shutter assembly made of different materials according to the present invention will be further described in detail below with reference to the accompanying drawings.

[0033] This example is to adopt the method of the present invention to carry out the processing of valve assembly, main steps are as follows:

[0034] Step 1: According to the distribution of dissimilar materials of the valve assembly, plan the processing strategy for different areas, including the following steps:

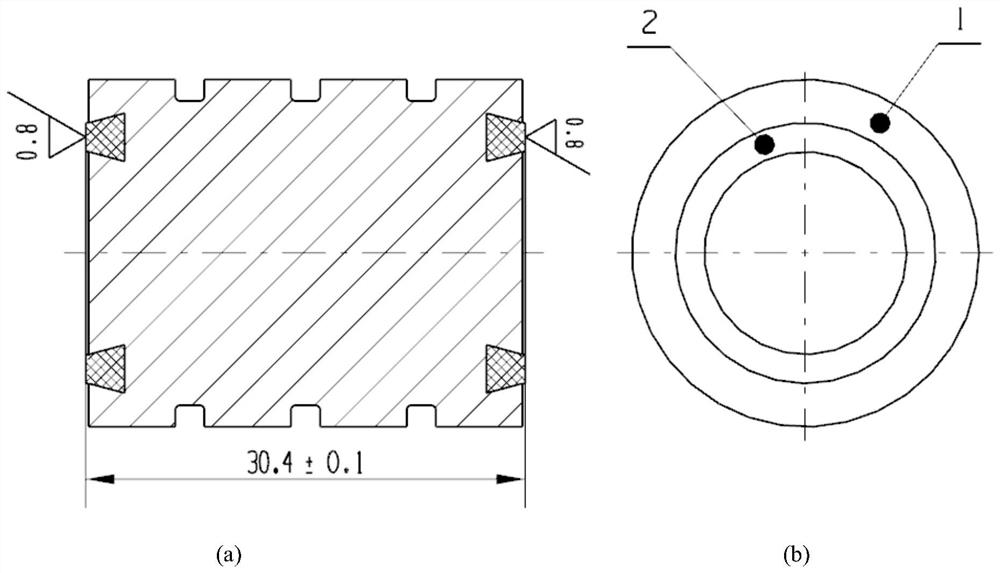

[0035] Step 11: The metal outer circle of the valve assembly is processed by turning. The machining strategy is to reserve 0.2mm margin for rough machining, and then finish the outer circle in place.

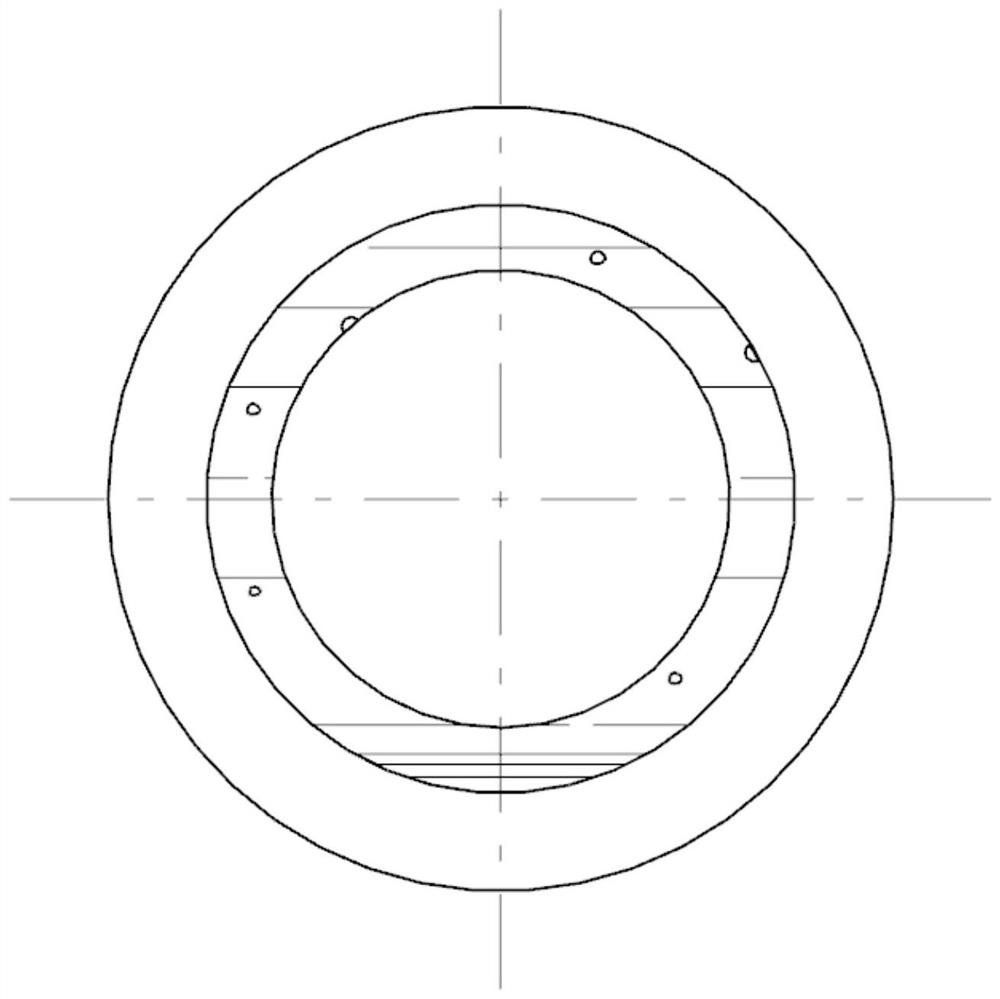

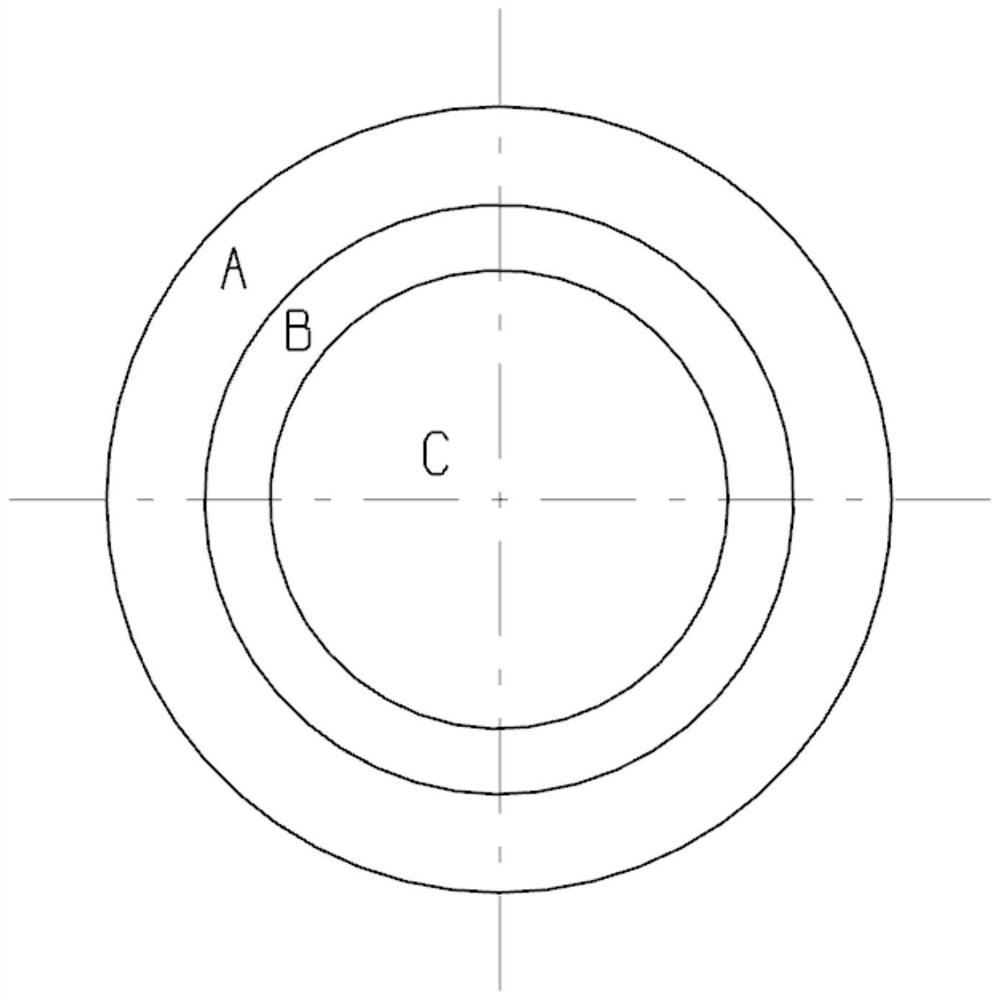

[0036] Step 12: Turning and milling are used for the end faces of dissimilar materials composed of metal and non-metal of the valve assembly, according to the distribution of metal and non-metal (such as image 3 As shown), the processing strategy is: first use a mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com