A high-efficiency machining system for deep holes in the oil pump housing

A processing system and oil pump technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult material removal efficiency, low cutting efficiency, weak tool rigidity, etc., to improve processing stability and workpiece surface quality, improve the surface quality of the workpiece, and reduce the effect of burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

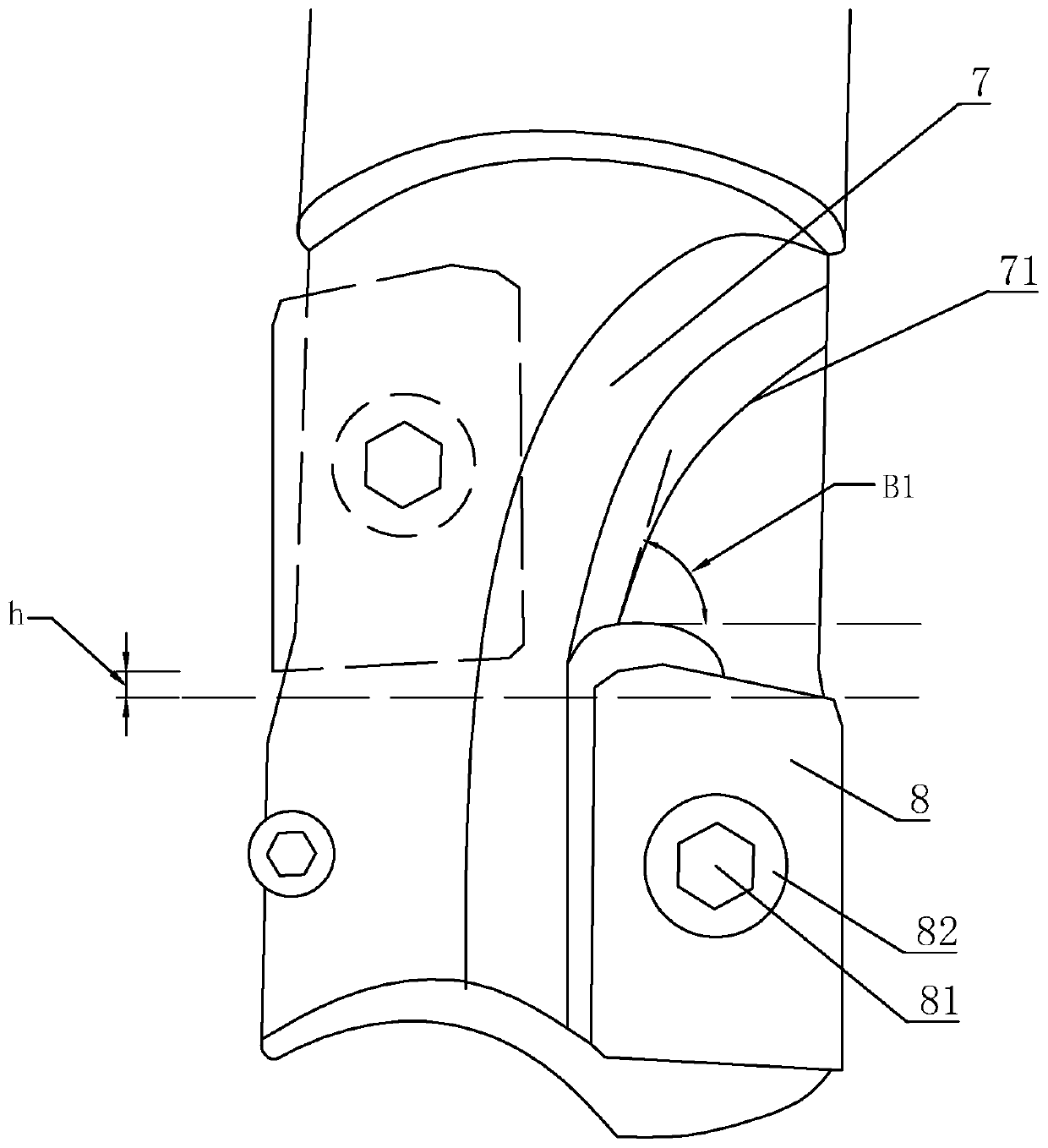

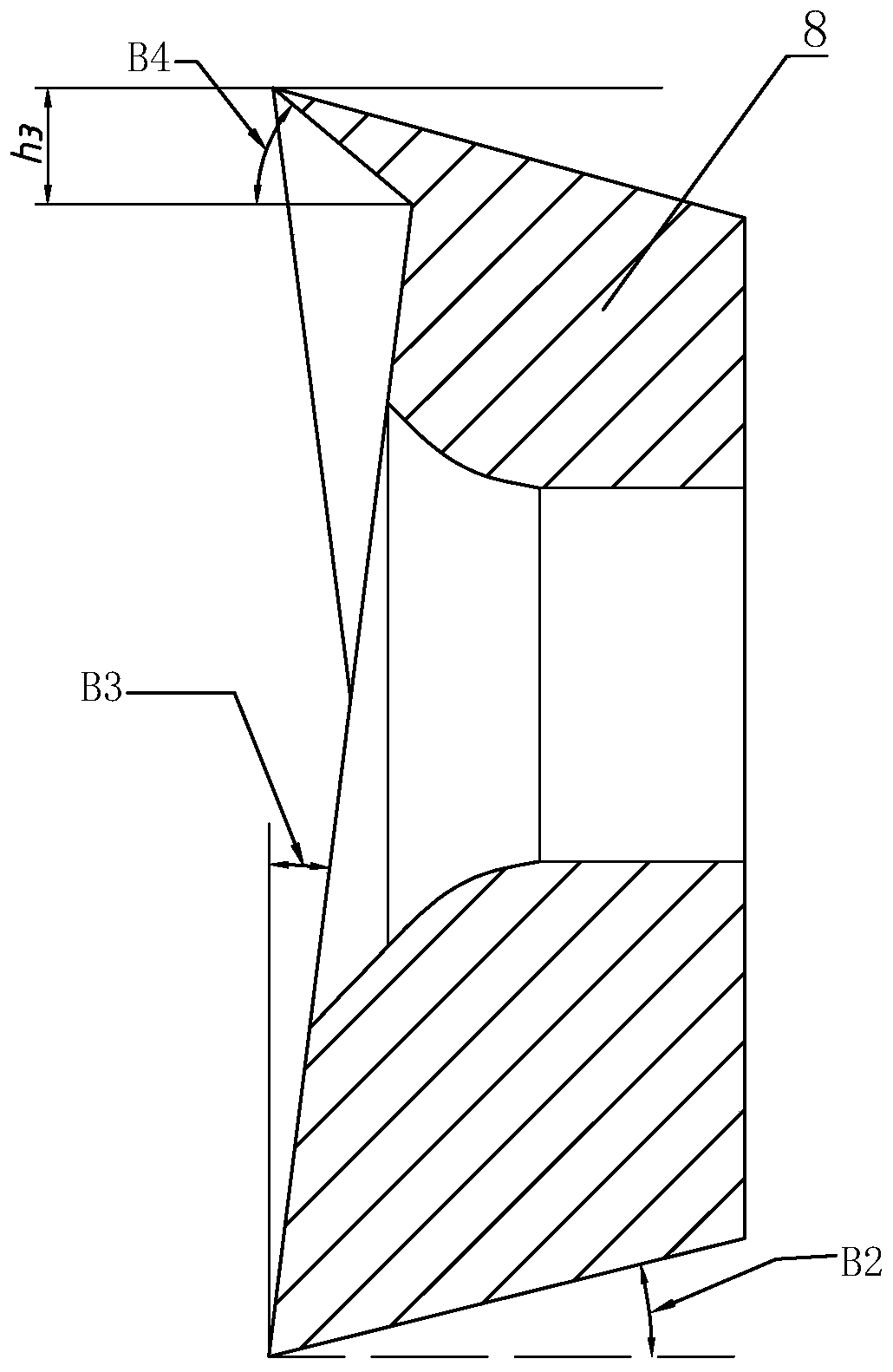

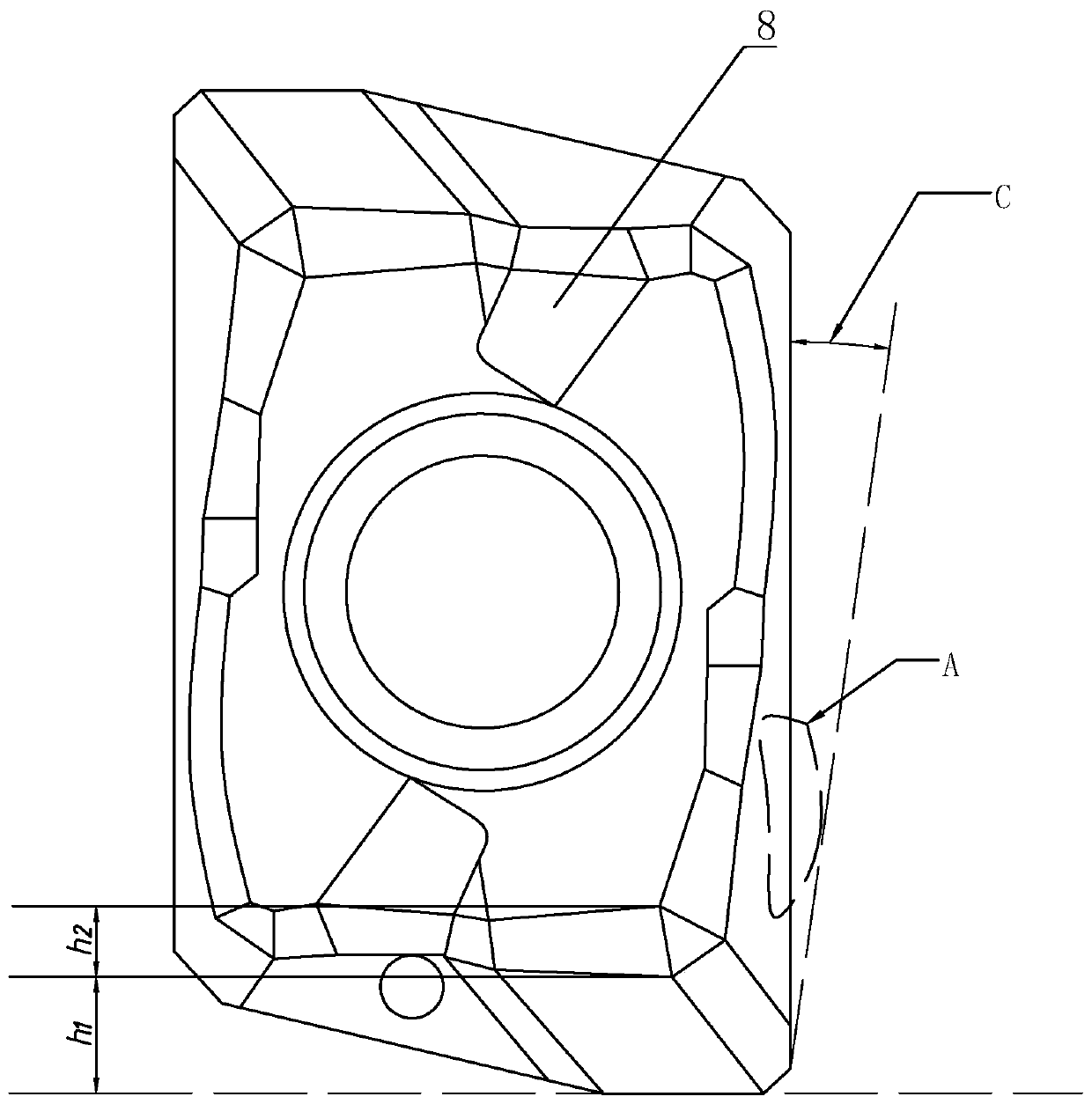

[0025] refer to Figure 1 to Figure 8 , a tool for high-efficiency machining of deep holes in the oil pump housing of the present invention, including a cutter bar 7 and a blade 8 fixedly mounted on the cutter bar 7, the blade 8 has cutting edges on both sides, and the cutting edge is provided with micro Cutting edge 83. A plurality of blades 8 are installed on the cutter bar 7, and the blades 8 are evenly and fixedly connected to the cutter bar 7 by bolts and gaskets. The blades 8 are arranged at intervals along the axial direction of the cutter bar 7, and the number of blades 8 installed on the cutter bar 7 is n, according to the depth h of the hole in the cutting process 4 And the length L of blade 8 decides, n is an integer. In this way the blade 8 can cover the entire depth of the hole. The distance h between adjacent blades 8 is 0.5-1um, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com