A coal caving method with segmental staggered cutting and circular coal caving in top coal caving working face

A working face and top coal caving technology, which is applied in ground mining, mine roof support, earthwork drilling and mining, etc., can solve the problem that the fully mechanized caving face cannot realize parallel operation of mining and caving, and it is difficult to meet the coal cutting output and working face efficiency of large mines. Low-level problems, to achieve the effect of reducing the waiting time for coal discharge, improving coal mining efficiency, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

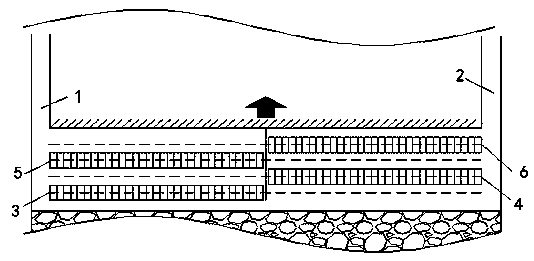

[0028] Such as figure 1 Shown:

[0029] Step 1: Divide the working face into the upper working face and the lower working face on average, the working face in the upper half is located in the conveyor lane 1, and the working face in the lower half is located in the auxiliary transport lane 2.

[0030] Step 2: The coal shearer enters the knife from the end of the upper half of the working face with an oblique cutting at the upper end, cuts the i-1th coal (i=4, 5, ..., n), and then moves the upper half of the working face to i -The top-coal caving hydraulic support at the 3rd position of the 1-knife coal mining position, the lower half of the working face does not move the frame, the front conveyor is moved, and the upper half of the i-1 and i-2 knives are placed, and the lower Hold halfway and pull the rear conveyor.

[0031] Step 3: After the shearer unidirectionally cuts coal and runs to the lower end of the lower half of the working face, the knife is cut from the lower en...

Embodiment 2

[0036] Based on the same inventive concept, Embodiment 2 of the present application changes the organization form of the working face in Embodiment 1 from two collections and one release to one collection and one release, and the others are the same as in Embodiment 1.

Embodiment 3

[0038] Based on the same inventive concept, Embodiment 3 of the present application changes the organization form of the working face in Embodiment 1 from two extractions and one release to three extractions and one release, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com