Hedge trimmer

A hedge trimmer and hedge trimming technology, which can be used in agricultural machinery and implements, gardening, agriculture, etc., and can solve the problem that the hedge trimmer is not suitable for use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

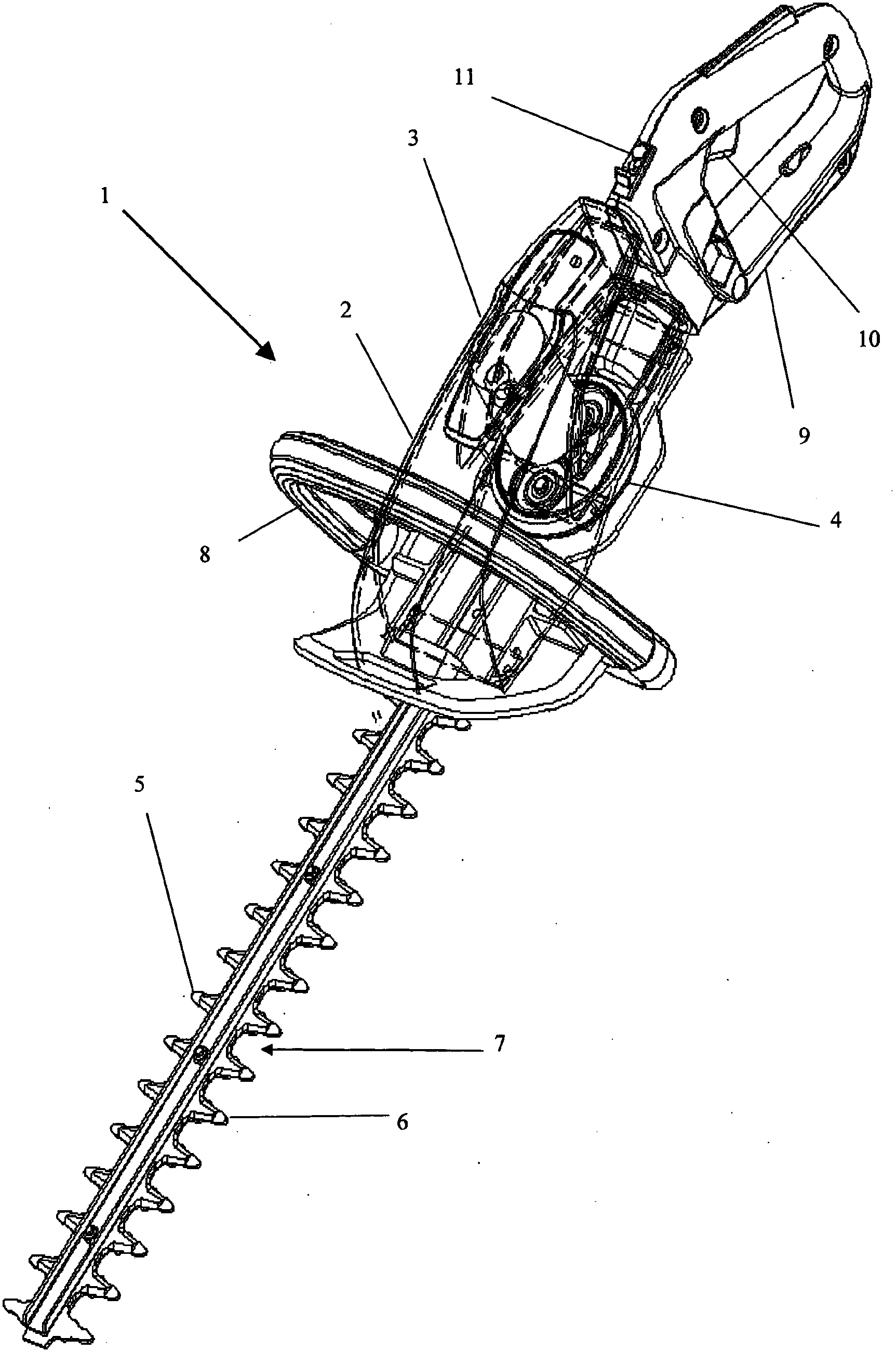

[0027] The hedge trimmer 1 includes a main body housing 2 that houses a motor 3 and a gear box 4. The gearbox 4 includes an input shaft fixed to the output shaft of the engine, and the output shaft of the engine is fixed to or forms a part of the engine rotor. The output end of the gearbox is connected to a linkage. This arrangement is such that as the engine rotates, the linkage device moves forward toward one end of the housing and moves back to its starting position. As the engine continues to rotate, this movement is continuously performed so that the linkage device performs reciprocating motion.

[0028] The gearbox includes a two-speed planetary gear, which allows two different gear ratios to be selected between the input shaft and the output shaft of the gearbox. One gear ratio is approximately 30 times higher than the other gear ratio.

[0029] Two cutting blades 5, 6 are provided, one above the other. Each edge of each blade has a row of teeth, and the teeth of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com