Coal cutter memory cutting and memory positioning combination learning method

A learning method, the technology of coal mining machine, applied in the direction of cutting machinery, earth square drilling and mining, etc., to achieve the effect of improving accuracy and increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

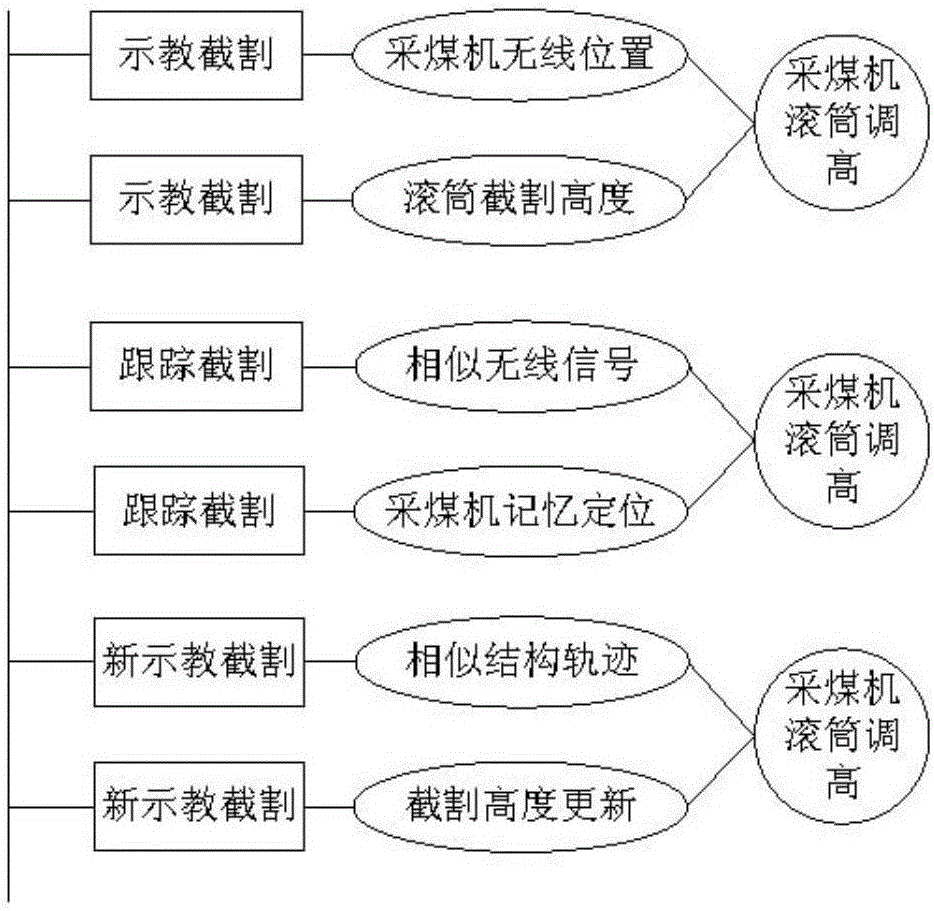

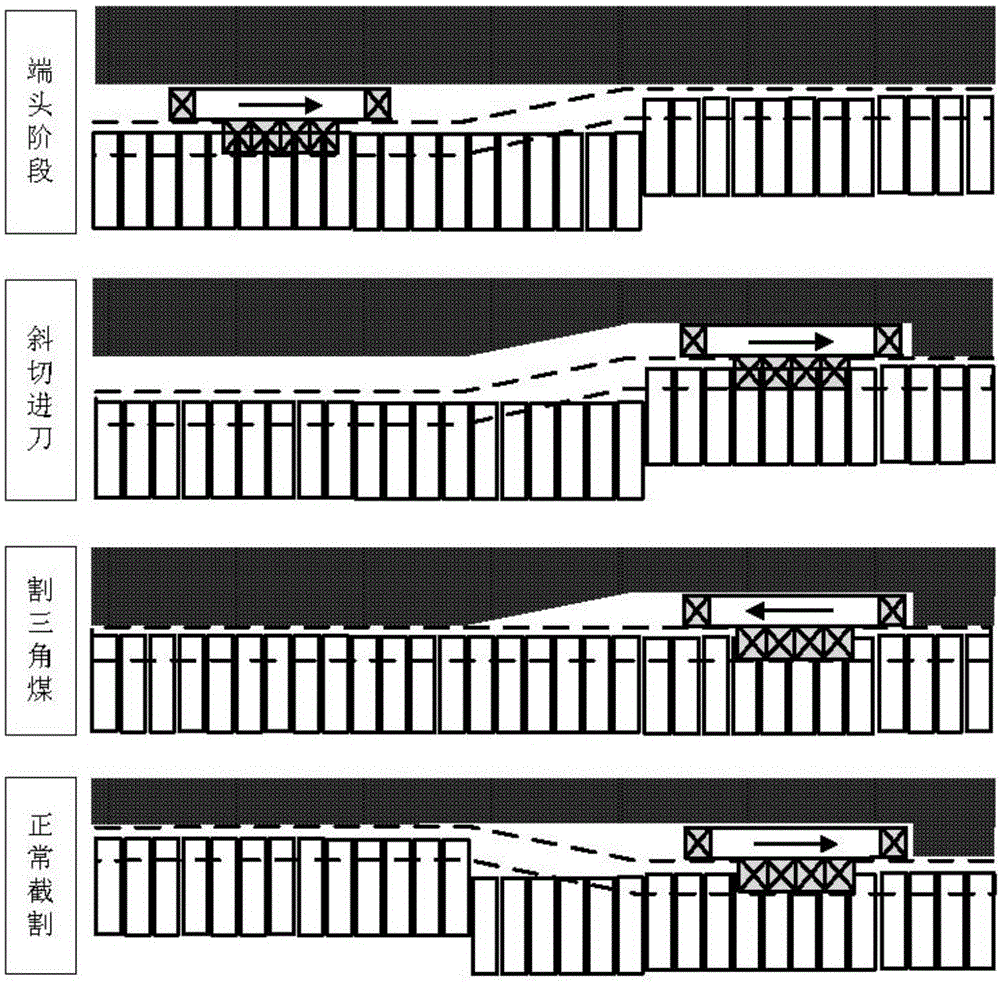

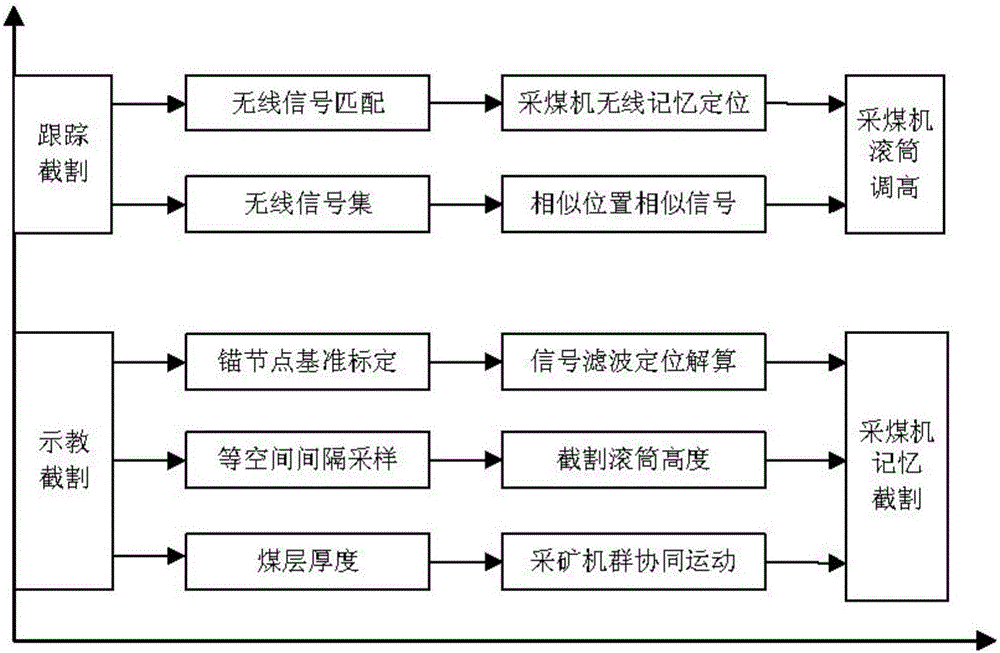

[0032]This embodiment is used for the self-adaptive height adjustment technology of the shearer, which is mainly composed of the shearer memory cutting technology, the tracking cutting memory positioning and the new teaching drum cutting height update technology.

[0033] The concrete steps of the inventive method are as follows:

[0034] A joint learning method of shearer memory cutting and memory positioning. It records the cutting height of the drum under the current position of the shearer at equal intervals along the traction direction of the working face. The coordinates of the wireless anchor nodes are calibrated by equipment constraints, and the location and height mapping is established in the teaching and cutting stage to realize the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com