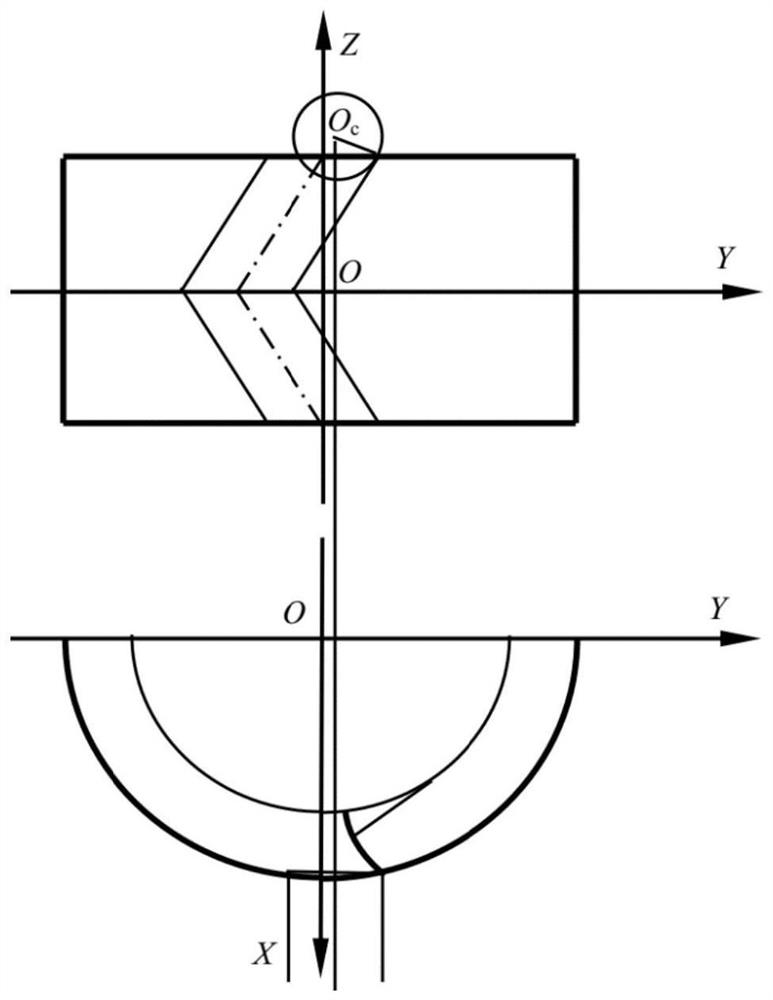

A method for rough cutting with step feed of herringbone gear with narrow empty sipes

A technology of herringbone gears and empty knife grooves, which is applied in the directions of belts/chains/gears, gear teeth, components with teeth, etc., can solve the problems of poor tooth surface accuracy and low processing efficiency of herringbone gears, and achieves the scope of application. Wide, improve processing efficiency, reduce the effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

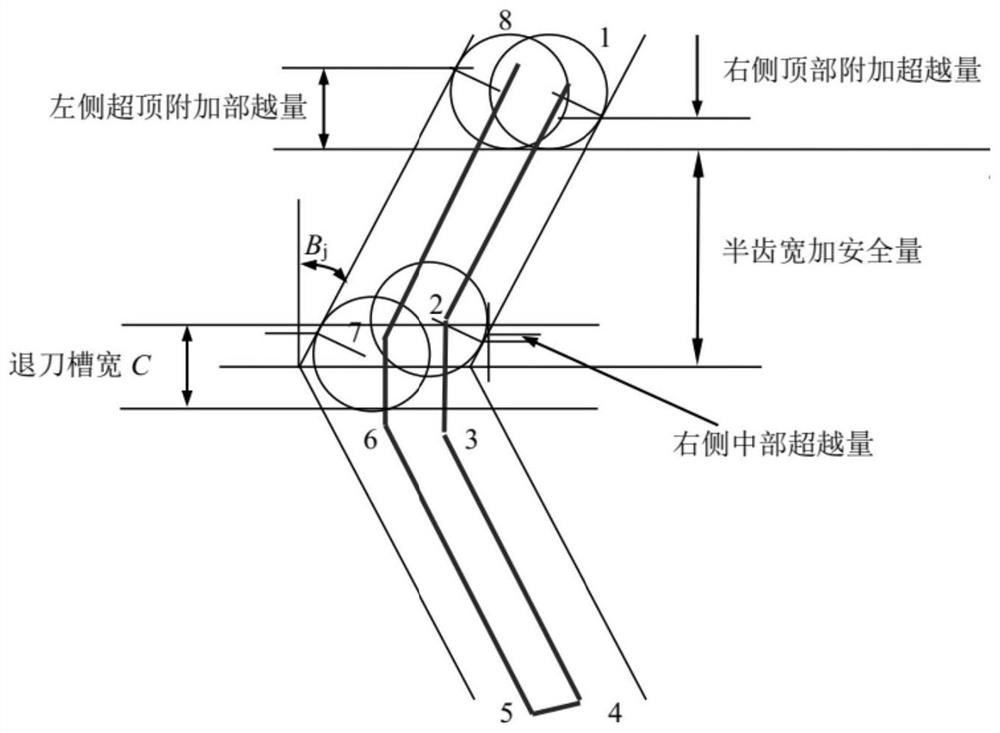

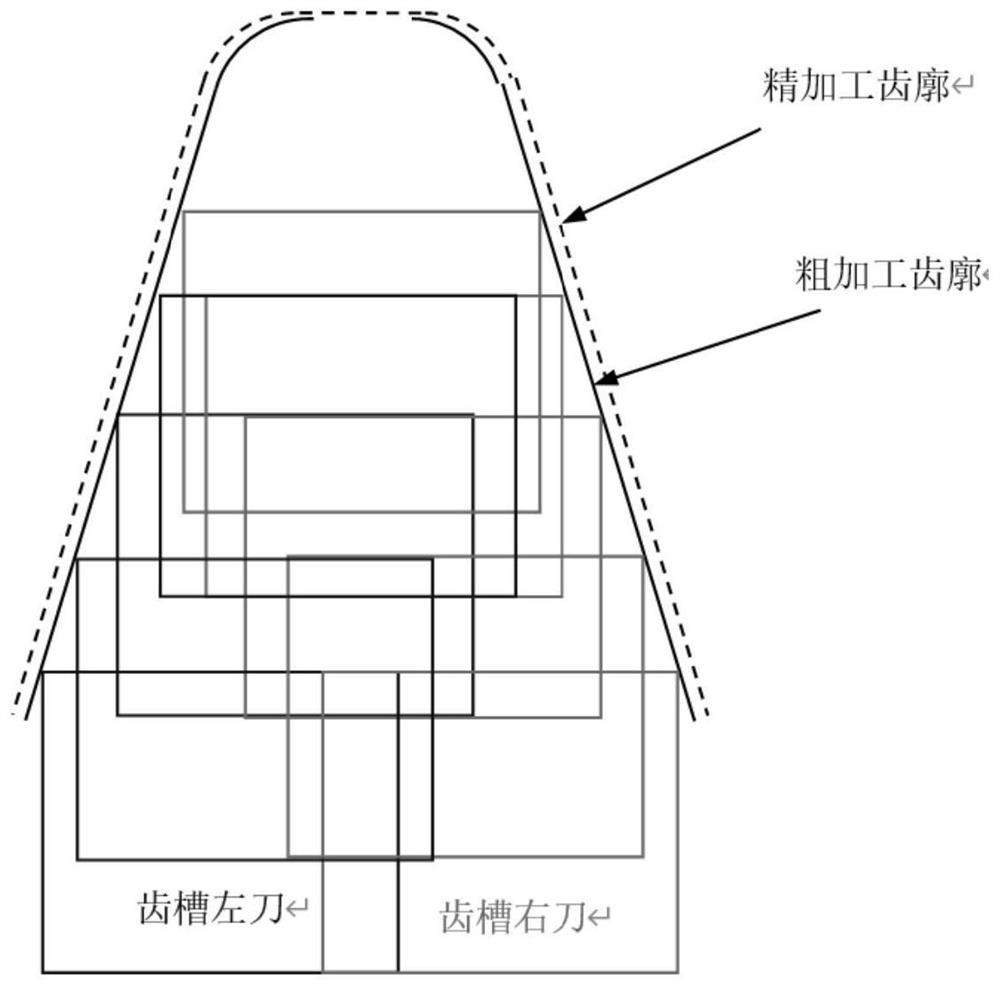

[0069] Gear parameters: number of teeth z=34, modulus m=10mm, pressure angle α=20°, helix angle β=34.5°, tooth width b=330mm, undercut width 30mm, normal tooth thickness S pn =14.08mm, graduation circle diameter d p =340mm, addendum circle diameter d a =360.122mm, involute starting diameter d f =328.067mm, rough machining allowance Δ f = 0.15 mm.

[0070] Determine the normal groove width of the rough cutting addendum of the herringbone gear:

[0071] 1) Alveolar half angle of base circle: σ b =1.561°

[0072] 2) Groove width in the normal direction of tooth top: S rdna '=19.612mm;

[0073] (2) Determine the rough cutting normal groove width of the starting point of the tooth root involute: S rdnf '=8.172mm

[0074] (3) Determine the number and diameter of rough cutting cylindrical end mill cutters:

[0075] Firstly, two benchmark values d max =9.806mm, d min =4.085mm:

[0076] 1) Determine RT1 tool diameter d RT1 = 10mm;

[0077] 2) Determine RT3 tool diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com