All-day laser semi-automatic de-icing method based on infrared

A semi-automatic, laser technology, used in cable installation, overhead installation, electrical components, etc., can solve problems such as low work efficiency, poor deicing effect, and poor real-time feedback, and achieve high cutting efficiency, light equipment, and high flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

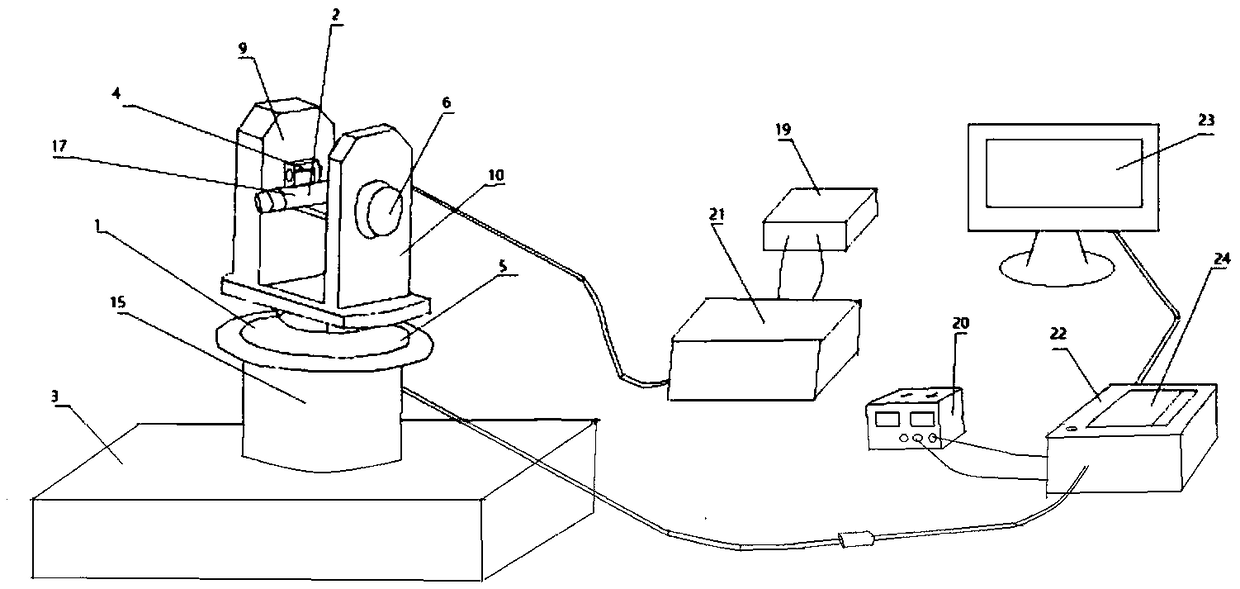

[0032] An infrared-based all-day laser semi-automatic deicing method, which is realized based on a laser deicing device, such as figure 1 As shown, the laser deicing device includes a turntable 1, a laser component 2, a base 3, a power supply system, an input device, a display screen, a control system and a visual sensor module 4; the turntable 1 includes an azimuth component 5 and a pitch component 6, The azimuth component 5 is installed above the base 3, the pitch component 6 is installed above the azimuth component 5, and the laser component 2 and the visual sensor module 4 are installed on the coupling component 13 of the pitch component 6;

[0033] Described control system comprises industrial computer 22 and control driving part, and described industrial computer 22 is connected with visual sensor module 4, is used for controlling visual sensor module 4 to adjust parameter, and the image that visual sensor module 4 collects is recognized, and recognition result Transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com