Coal cutting method with multiple demonstration knifes

A technology for memorizing coal cutting and demonstration knives, applied in cutting machinery, earth-moving drilling, etc., can solve problems such as affecting the continuous mining of coal seams and affecting the effect of coal cutting, so as to improve the effect of coal cutting, improve stability and reduce cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

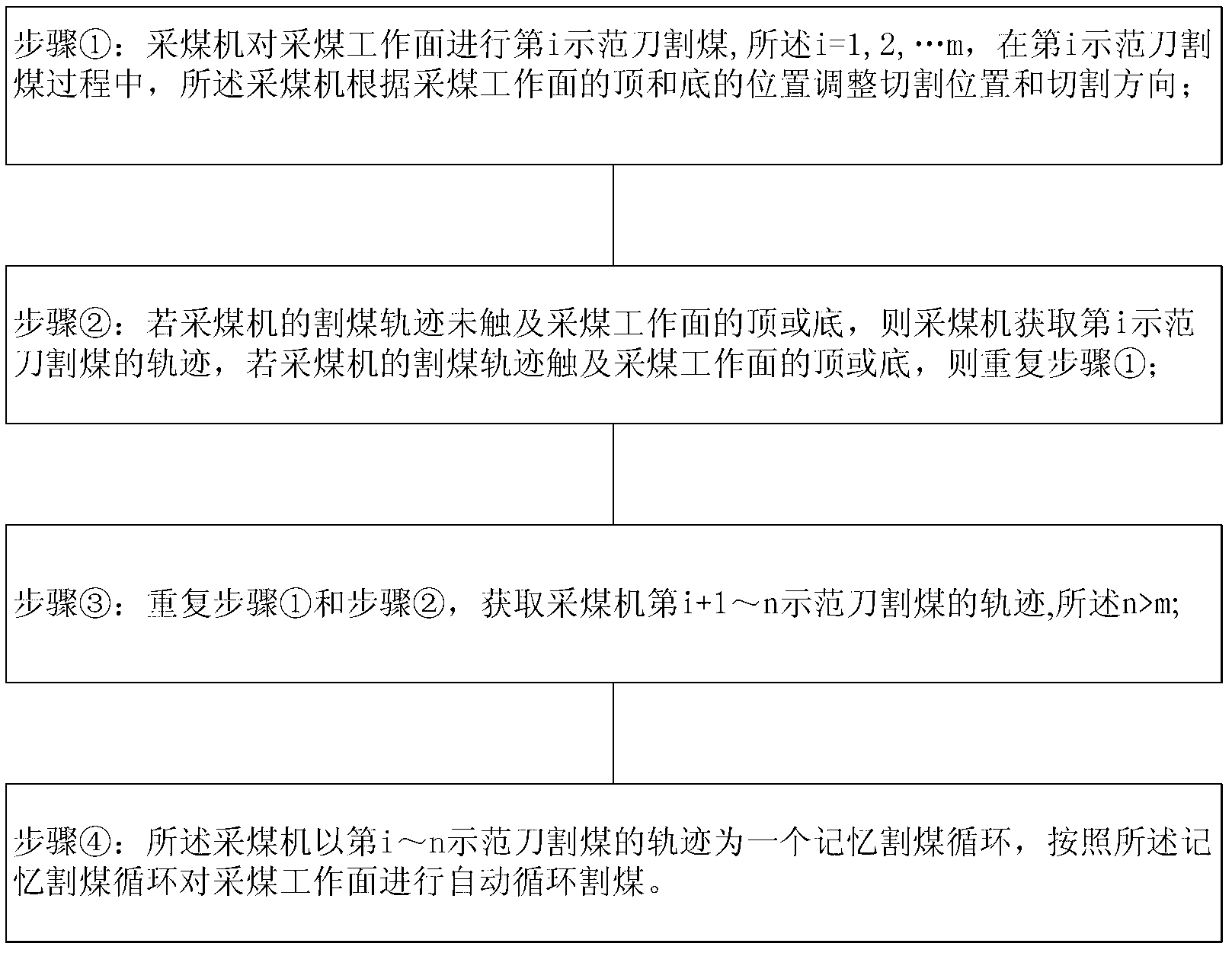

[0022] Such as figure 1 Shown, the present invention provides a kind of multi-demonstration knife memory coal cutting method, and this method comprises the steps:

[0023] Step ①: The coal shearer performs the i-th demonstration knife cutting coal on the coal mining face, and the i=1, 2,...m, during the i-th demonstration knife cutting coal process, the coal shearer performs Adjust the cutting position and cutting direction according to the position of the top and bottom;

[0024] Step ②: If the coal cutting trajectory of the shearer does not touch the top or bottom of the coal mining face, the shearer obtains the coal cutting trajectory of the i-th demonstration knife; if the coal cutting trajectory of the shearer touches the top or bottom of the coal mining face top or bottom, repeat step ①;

[0025] When the shearer walks from one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com