Patents

Literature

76results about How to "Act as tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

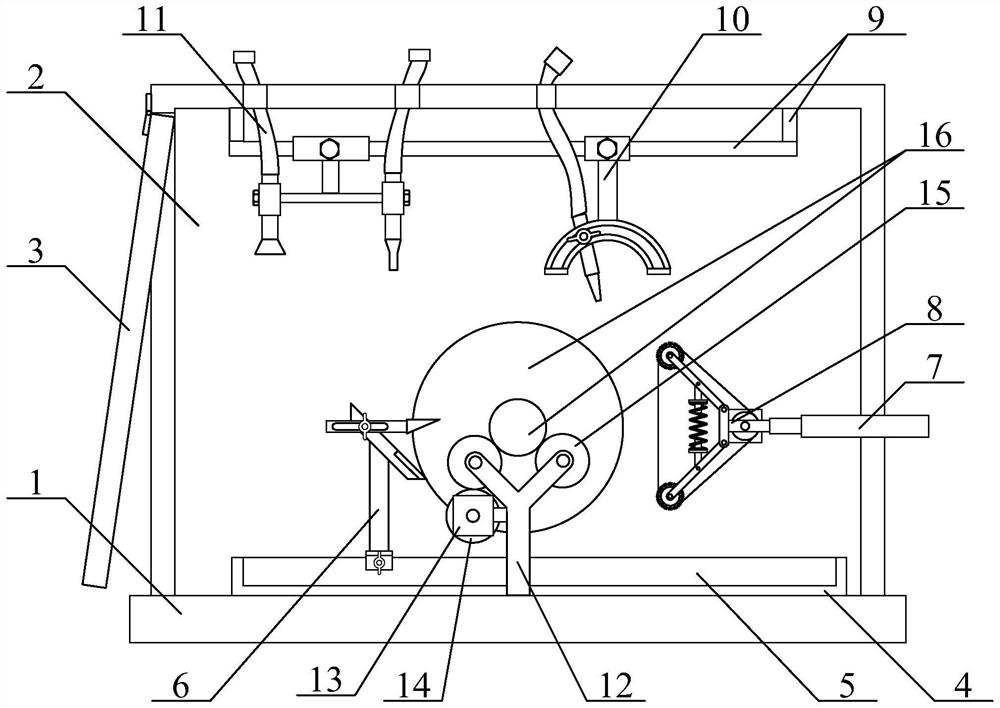

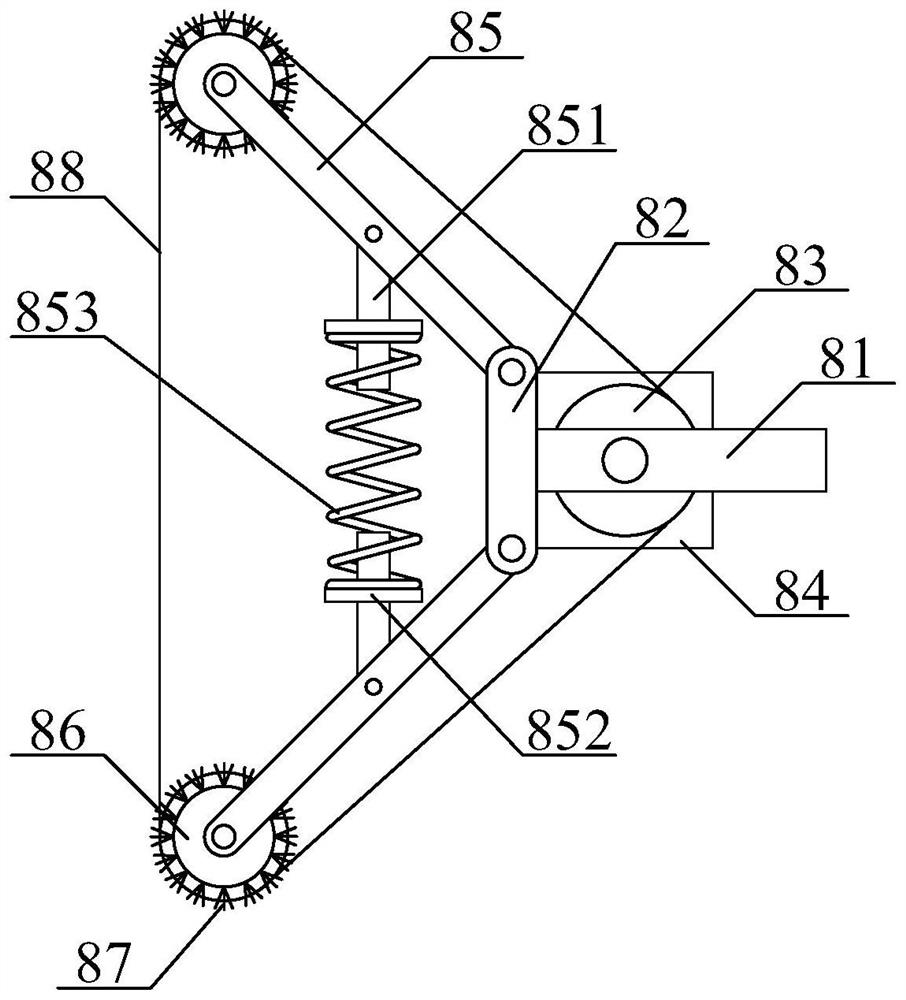

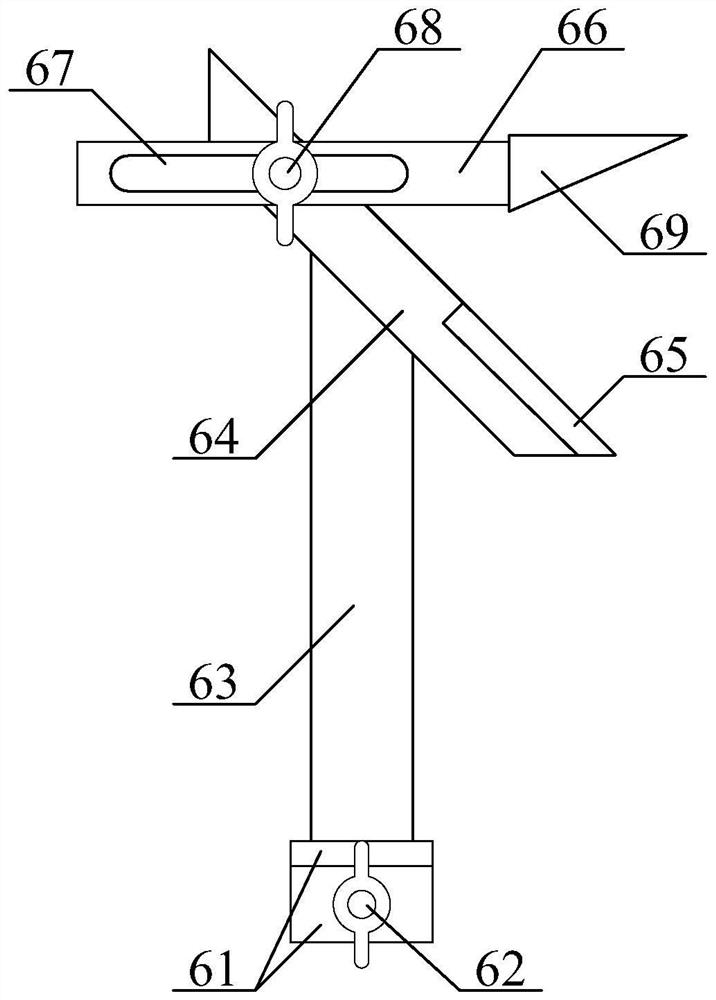

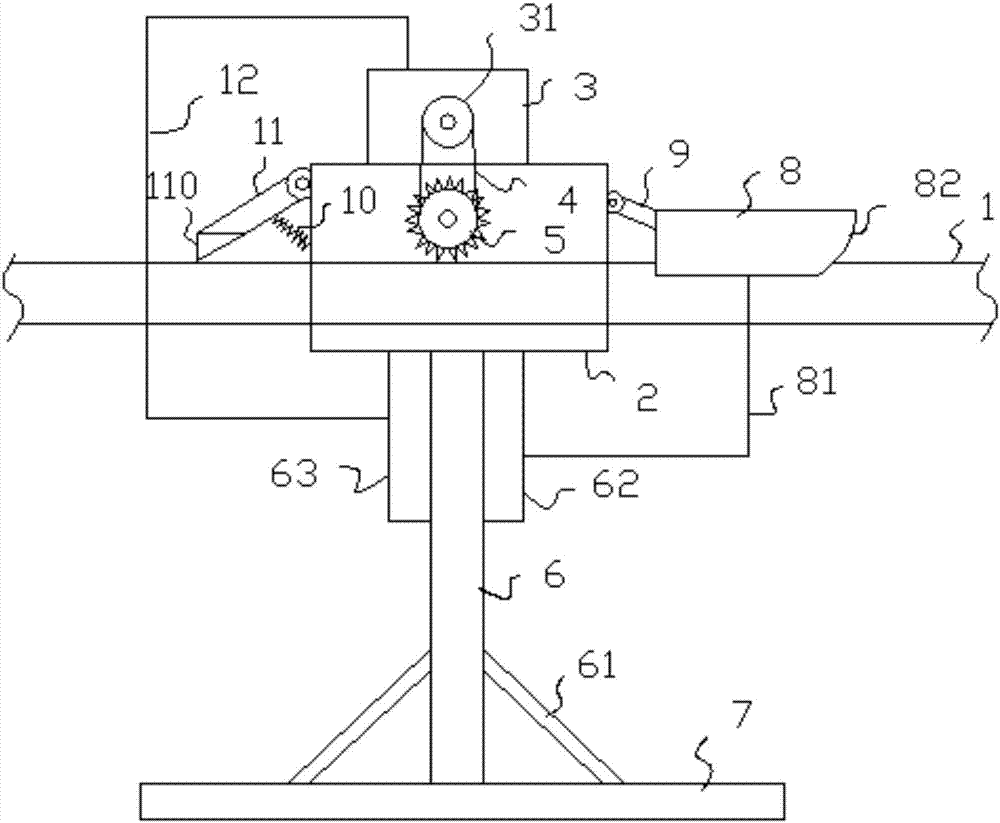

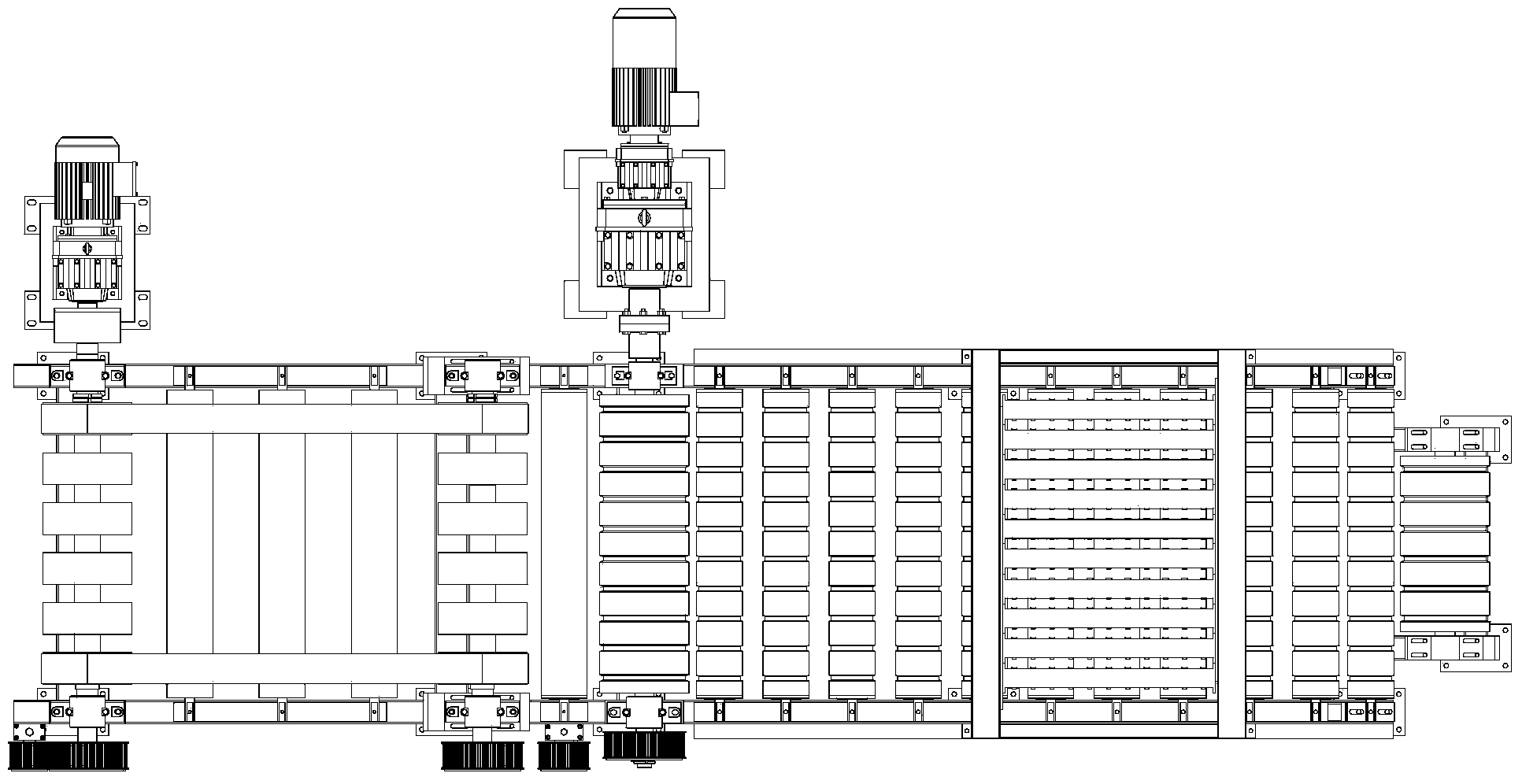

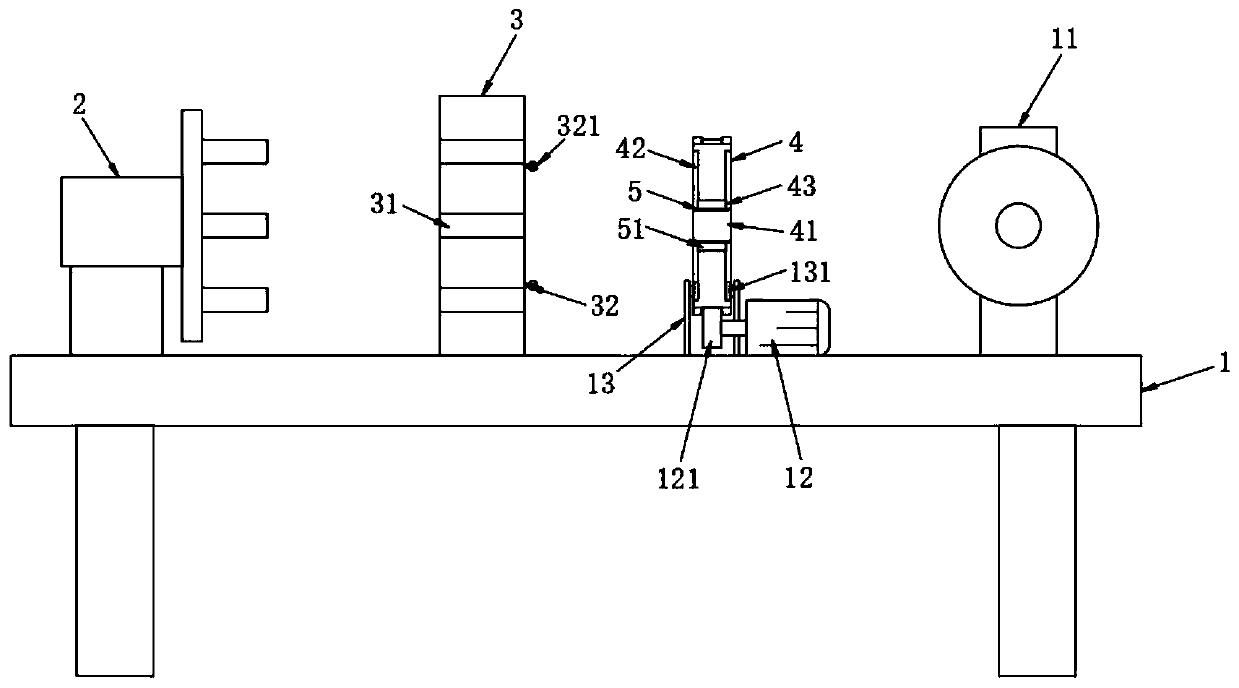

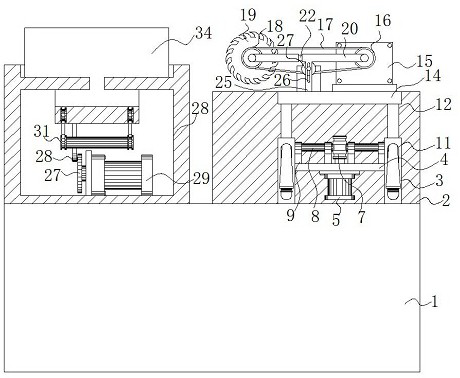

Tungsten carbide spraying equipment with both grinding and surface defect repair functions

ActiveCN111962003AImprove processing effectImprove flattening effectMolten spray coatingGrinding drivesGrindingDrive motor

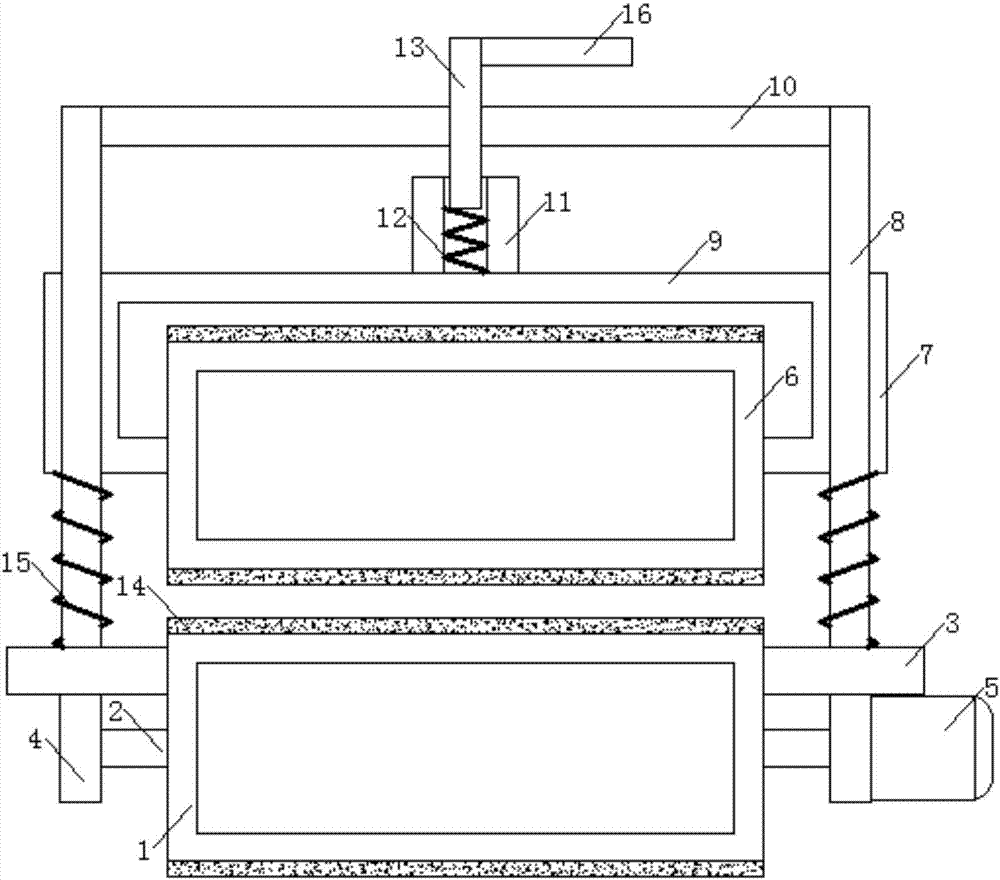

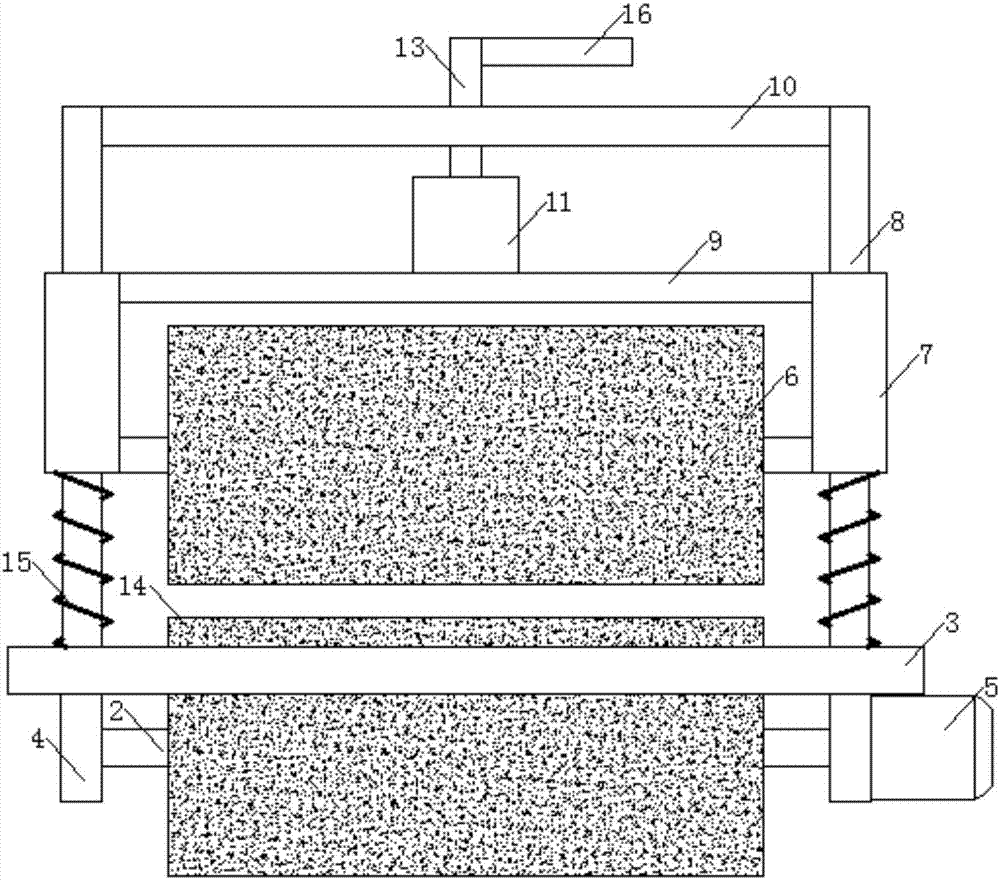

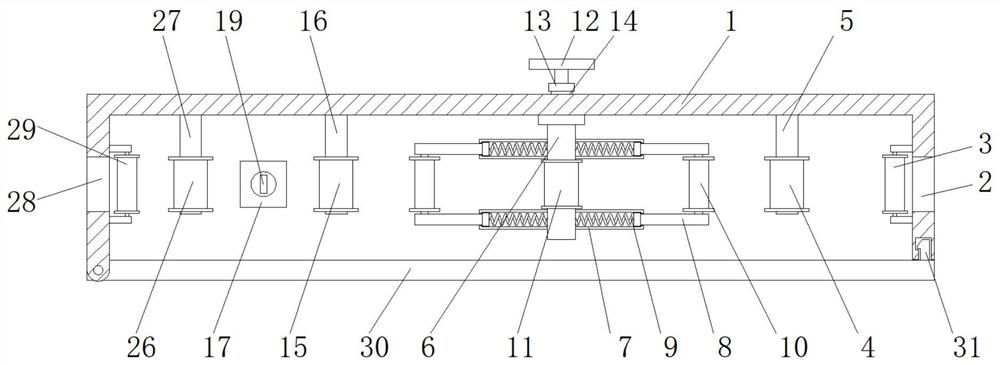

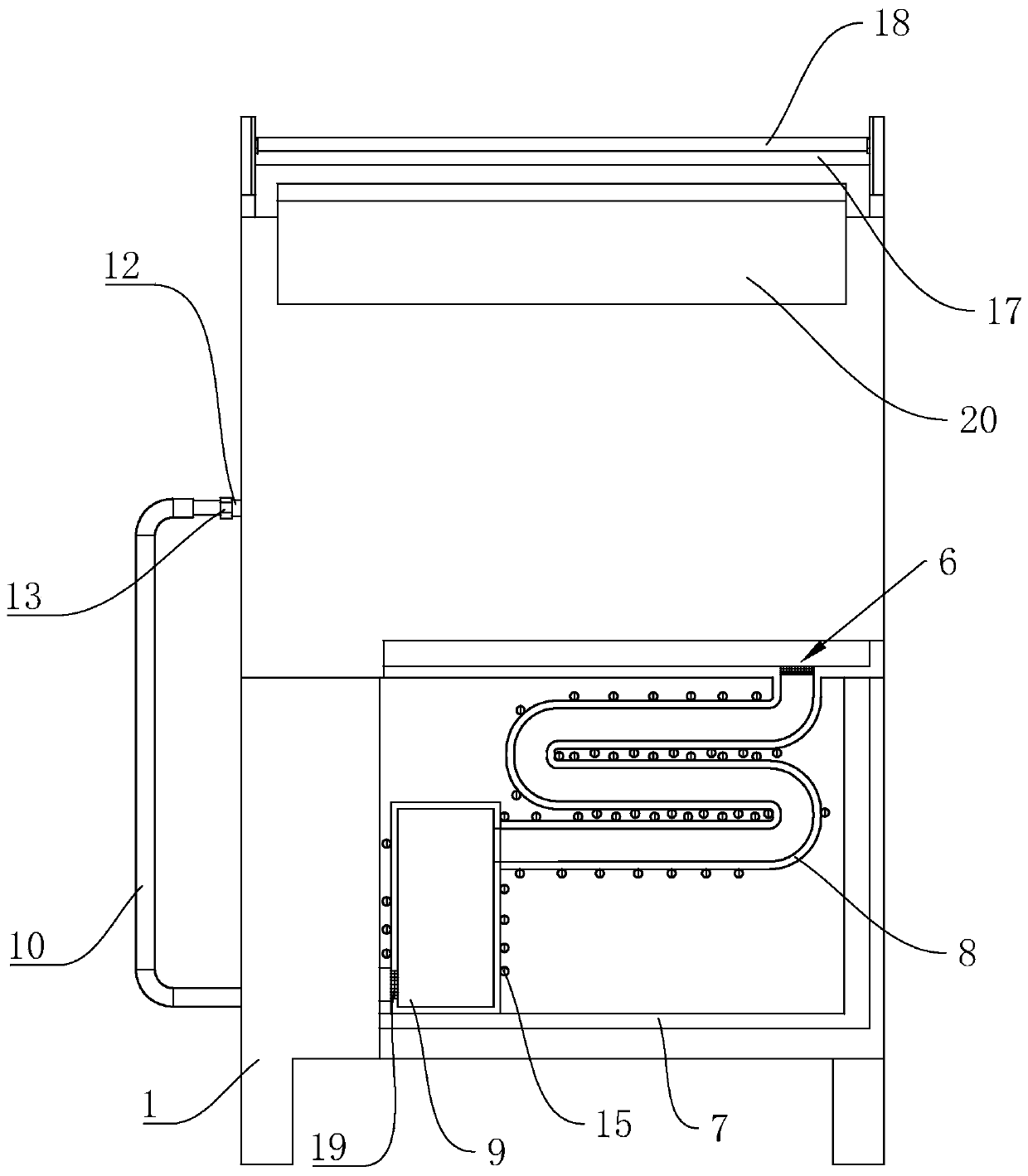

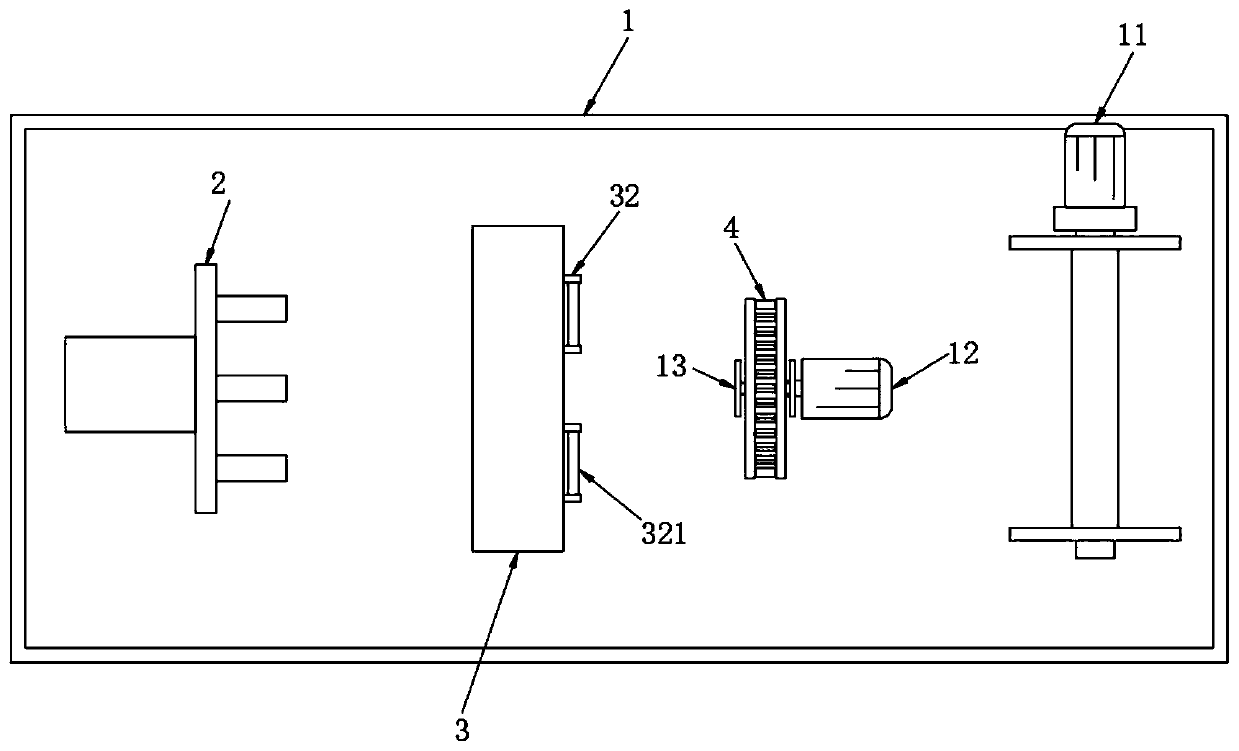

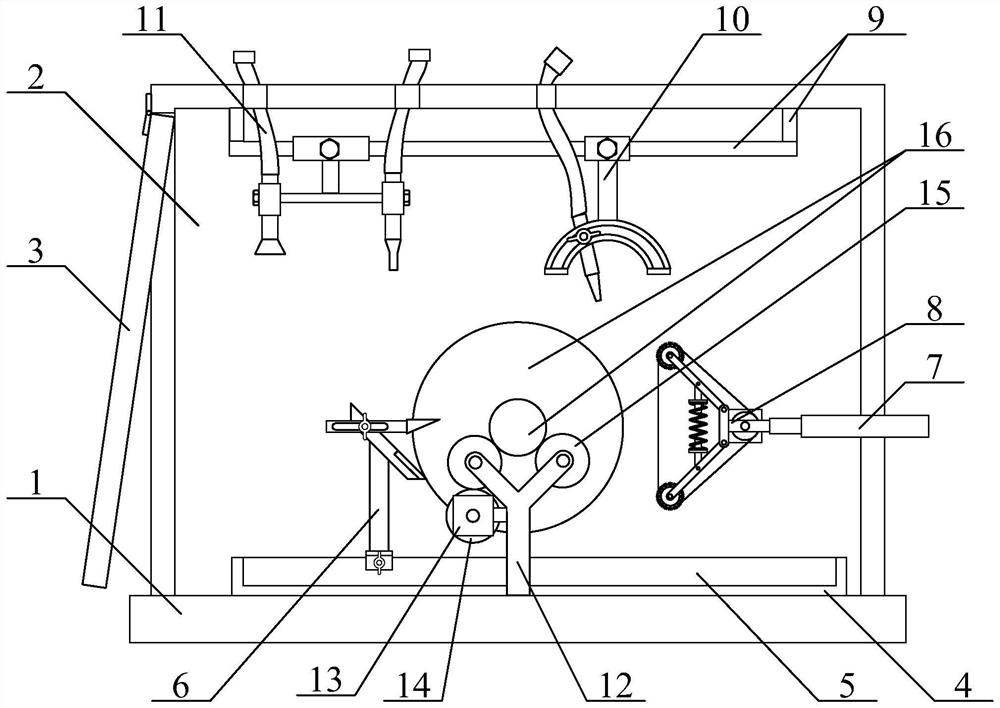

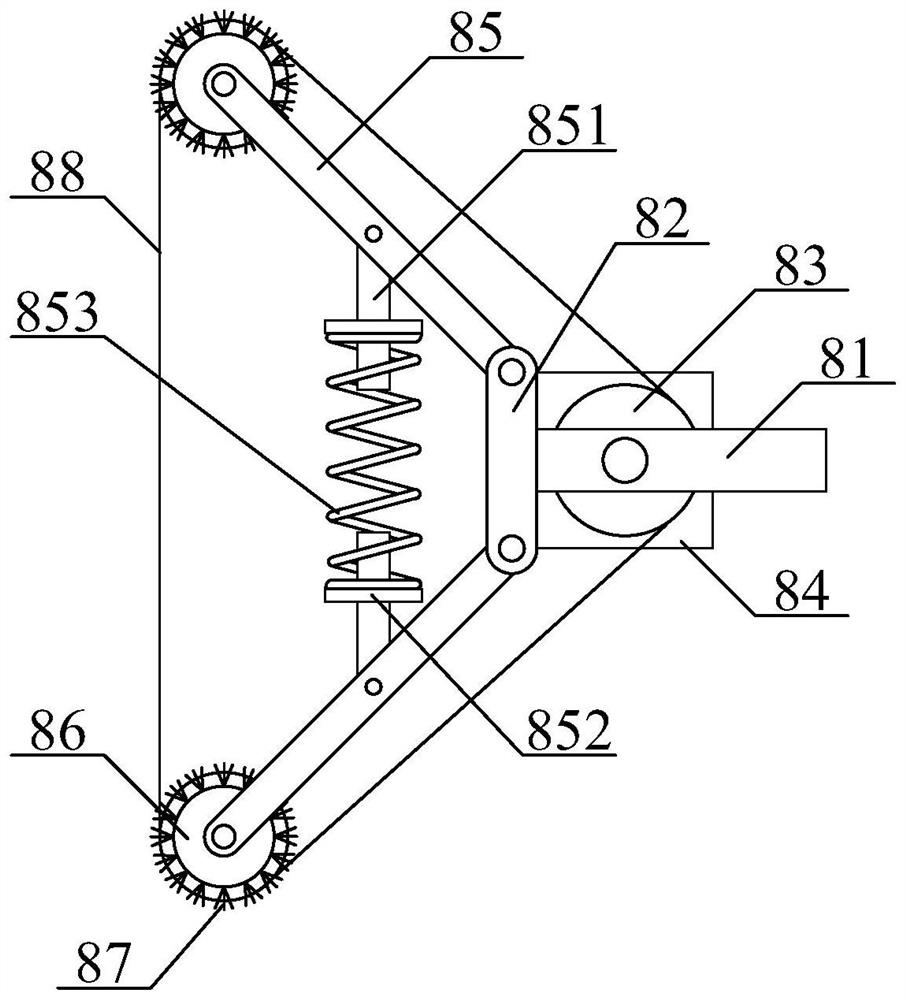

The invention provides tungsten carbide spraying equipment with both grinding and surface defect repair functions. The equipment comprises a base, a shell, a protective cover, a collecting frame, a collecting groove, a roller shaping frame structure, a cylinder, an arc surface polishing frame structure, a guide rail, an adjustable spraying fun fixing frame structure, a machining cleaning frame structure, a Y-shaped frame, a drive motor, a driving wheel, a driven wheel and a to-be-machined roller. The shell is in bolt connection with the upper portion of the base. The protective cover is in hinged connection with the left side inside the shell. The collecting frame is in bolt connection with the middle of the upper portion of the base. The equipment has the beneficial effects that by arranging the roller, a polishing motor, a rotating roller, a brush and a polishing belt, the surface of the to-be-machined roller is polished and ground conveniently, the polishing motor drives the rollerto rotate, the surface of the to-be-machined roller is ground through the grinding belt, and meanwhile unmolten tungsten carbide powder remaining at the corners of the front and back ends of the to-be-machined roller is cleaned thoroughly through the brush.

Owner:合力(天津)能源科技股份有限公司

High-altitude cable de-icing device

InactiveCN107123962AReduce loadPlay the role of heating and meltingOverhead installationHigh tension lineReducer

A high-altitude cable deicing device, mainly including a sleeve placed on the high-voltage line. When in use, the deicing gear can be driven by the motor reducer, so that the ice on the high-voltage line can be removed, which is beneficial to reduce the overall pressure of the high-voltage line. load; when the bushing slides to the right, the heating seat can heat and melt the icing on the high-voltage line at the front first, and prepare for the treatment of the deicing gear at the back; after the treatment of the heating and deicing gear , the scraper can finally scrape off the ice slag remaining on the high-voltage line; the solar cells are used to absorb solar power to generate electricity, and store the electric energy in the first battery and the second battery, making a good job for subsequent heating and deicing Preparation; the tension spring can play a role in tensioning the second support rod, which is beneficial to scrape off the ice on the surface of the high-voltage line by the scraper.

Owner:ZHONGSHAN FENGSHEN ELECTRICAL APPLIANCE CO LTD

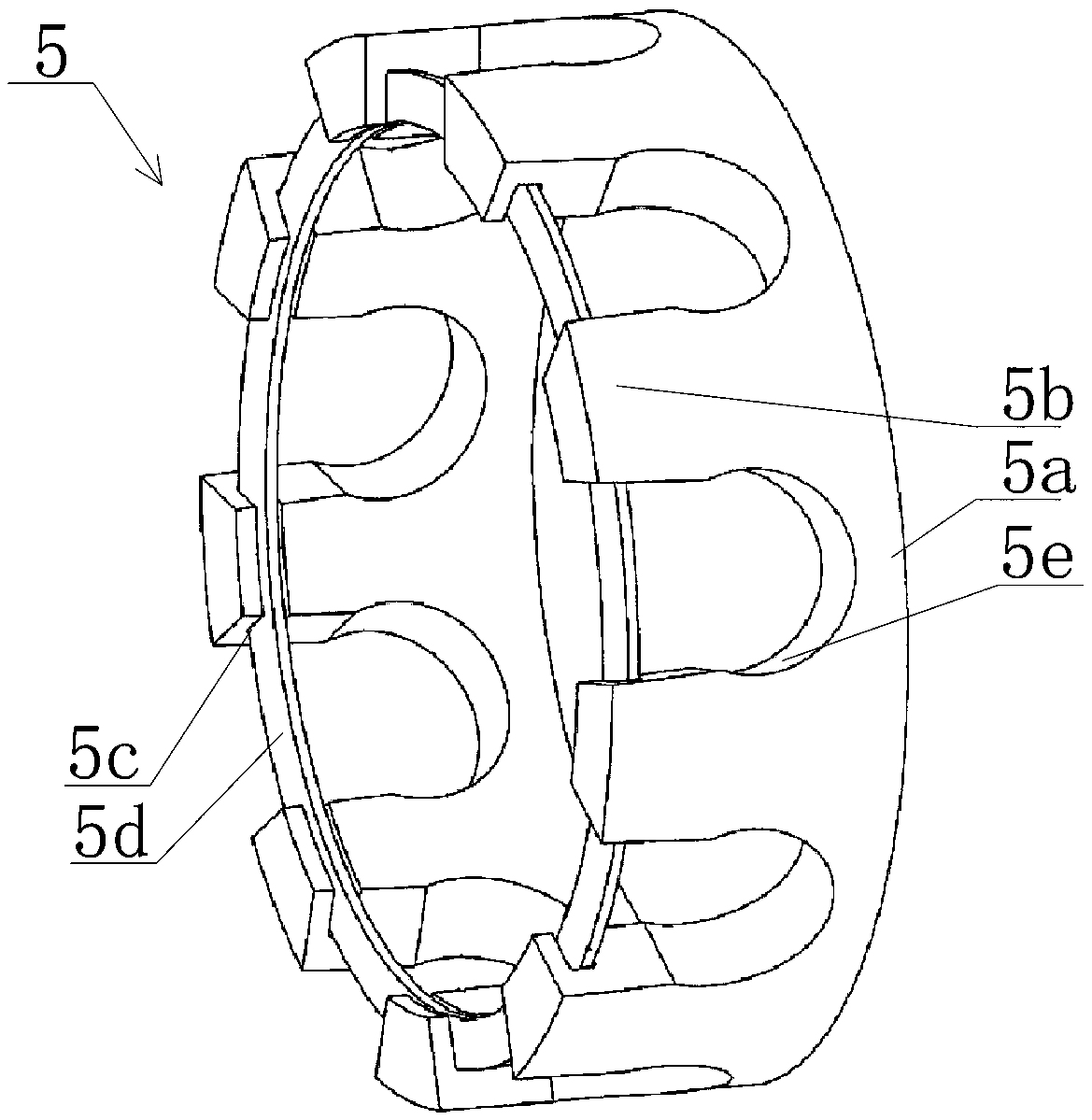

Winding mechanism used for accommodating cables with different cable diameters

The invention discloses a winding mechanism used for accommodating cables with different cable diameters. The winding mechanism comprises a mounting bottom plate, a rotary motor, winding support plates, a linear screw rod module, cycloid blocks, press line blocks, first compression springs, feeding support plates, guide columns, adjusting blocks, adjusting shaft mounting blocks, second compressionsprings, adjusting handles, locking wedge blocks and third compression springs, wherein the rotary motor is fixed to one side of the top of the mounting bottom plate, and the two winding support plates are oppositely arranged on one side of the end part of an output shaft of the rotary motor and are both fixedly connected to the top of the mounting bottom plate. By arrangement of the cycloid blocks and floating design of the press line blocks arranged at equal angles, a cable is enabled to uniformly and tightly wind around a cylindrical surface of a bobbin in the axial direction automatically, and through fine adjustment for the floating setting of the adjusting shaft mounting blocks, the winding mechanism is suitable for winding the cables with different cable diameters, is simple and compact in structure and greatly reduces cost.

Owner:黄健

Elastic extrusion-type tightening mechanism for special paper coater

InactiveCN107142788AAvoid excessive frictionGuaranteed transmission qualityPulp material addition processesMotor driveEngineering

The invention discloses an elastic extrusion tensioning mechanism of a special paper coating machine. The upper ends of two guide rods are connected by a horizontal plate, and the horizontal plate is located on the upper side of the connecting rod. The middle part of the upper end of the connecting rod is A guide cylinder with an upward opening is provided, and a spring is provided at the bottom of the inner cavity of the guide cylinder. A threaded rod is inserted into the position corresponding to the upper end of the horizontal plate and the guide cylinder, and the lower end of the thread rod goes deep into the guide cylinder. The lower end of the threaded rod is against the spring. The process is: S1 installation, S2 debugging efforts, S3 experiment and S4 re-debugging. The motor drives the driving roller to rotate, and the linear speed of the driving roller is greater than the transmission speed of the special paper, so that there will be slippage between the special paper and the stretching and tensioning effect. By rotating the rotating rod, the spring below is squeezed. The extrusion force of the driven roller can be adjusted to prevent excessive friction. At the same time, the flannelette layer on the top protects the paper from damage and ensures the transmission quality of special paper.

Owner:ANHUI JINYIHE SPECIALTY PAPER CO LTD

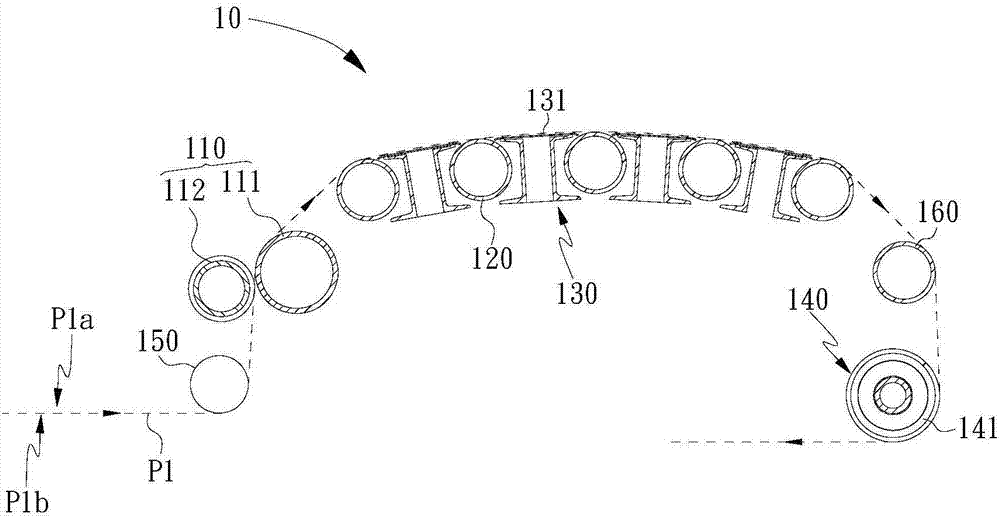

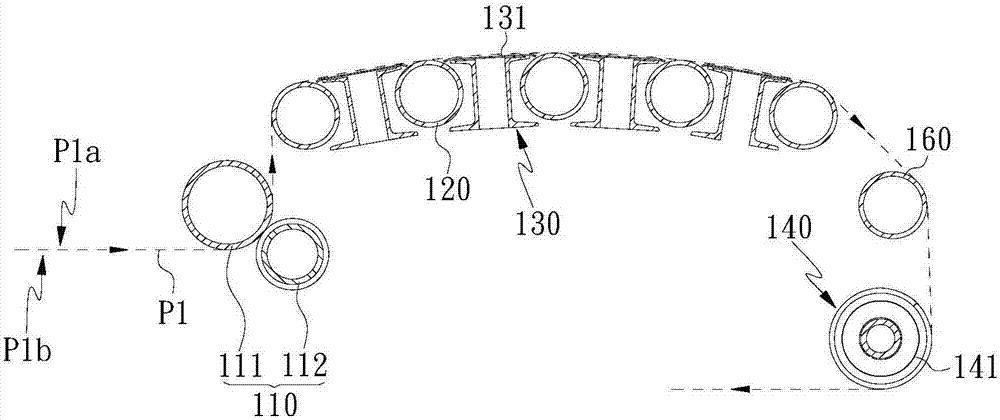

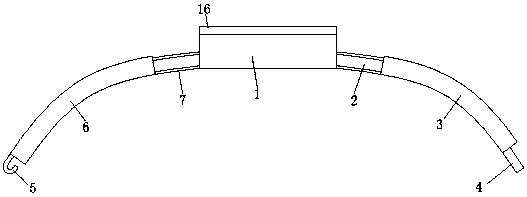

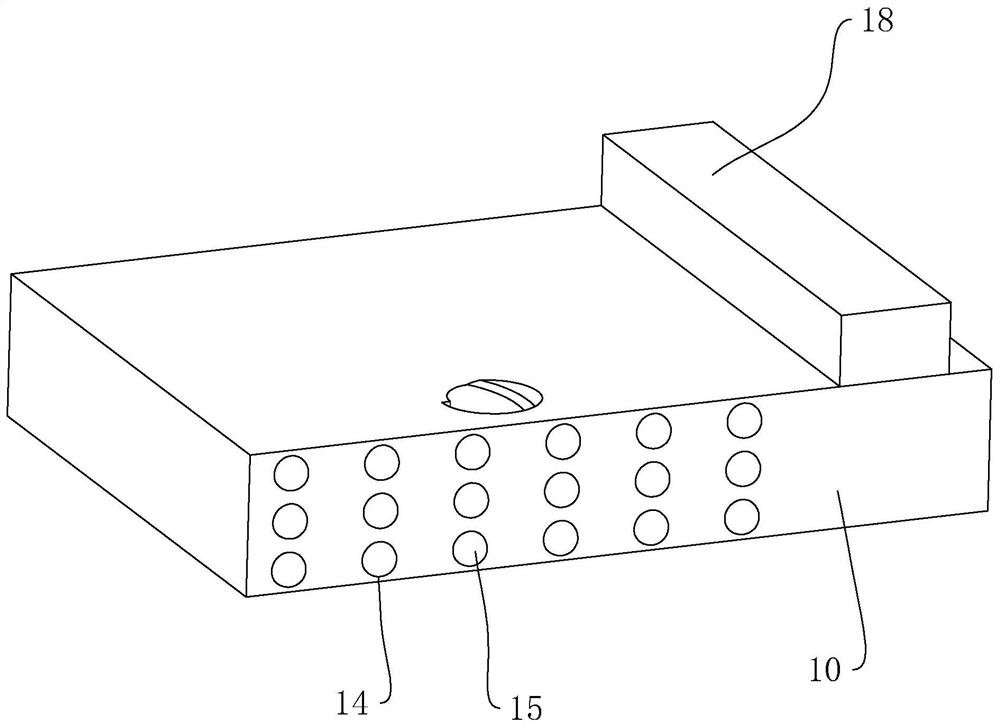

Jet printing platform device

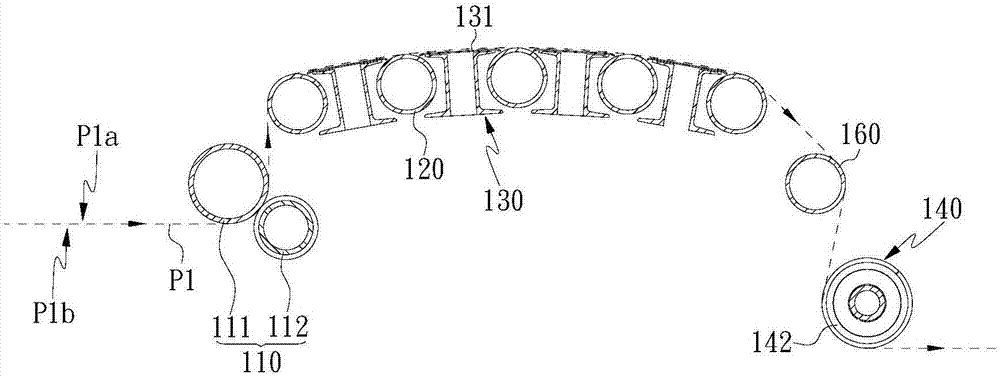

PendingCN106956518AAvoid wrinklingFacilitate printing operationsOther printing apparatusSpray nozzleProcess engineering

The embodiment of the invention discloses a jet printing platform device applied to the technical field of jet printing. Jet printing paper to be printed is conveyed to at least three parallel carrier rollers and jet printing platform mechanisms between two corresponding and adjacent carrier rollers through a preposition driving mechanism, printed jet printing paper is conveyed through a postposition driving mechanism, the at least three carrier rollers are arranged in an arc shape, and therefore the jet printing paper conveyed on the carrier rollers are bent in an arc shape, the jet printing paper is tightened, and the jet printing paper is prevented from being folded; and in addition, the jet printing paper is attracted to a jet printing platform through air suction holes formed in the jet printing platform, and therefore the jet printing paper and the jet printing platform are tightly attached, printing operation is facilitated, and physical damage caused by the fact that the jet printing paper collides a spraying nozzle of a printing machine can be prevented; and meanwhile, the production cost is reduced, and the production process is simplified.

Owner:SHENZHEN HANDWAY IND DIGITAL EQUIP CO LTD

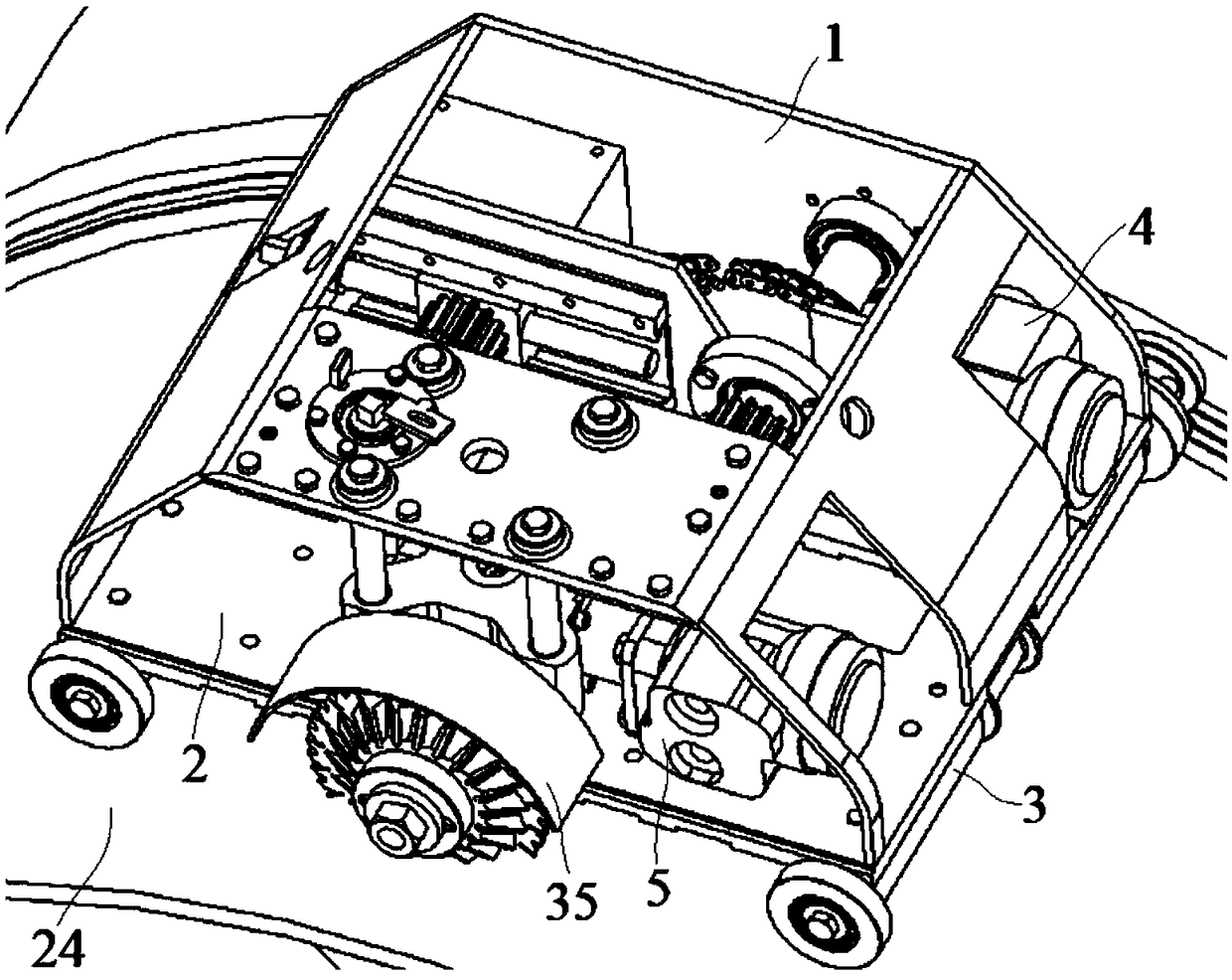

Pipe-climbing type cutting electric beveling machine

PendingCN109396526AAvoid harmEasy to replaceTube shearing machinesShearing machine accessoriesReduction driveGear wheel

The invention discloses a pipe-climbing type cutting electric beveling machine. The pipe-climbing type cutting electric beveling machine comprises a machine frame, a climbing wheel assembly arranged on a base plate of the machine frame, driving mechanisms and cutting mechanisms, the driving mechanisms and the cutting mechanisms are all installed on the machine frame, and the driving mechanisms comprise driving motors, reducers and driving gears connected with output shafts of the reducers; and a plurality of pin holes are formed in cutter containing discs, cutters and cutter pressing gaskets correspondingly, one driving pins are embedded into pin holes of the cutter containing discs, the cutters and the cutter pressing gaskets, a first installing plate, a second installing plate and a third installing plate which are parallel to each other are vertically arranged on the base plate of the machine frame, a second chain wheel is installed on the second installing plate of the machine frame through a sliding block, and the climbing wheel assembly comprises a guiding wheel, two connecting rods, climbing wheels and a side rail wheel. According to the pipe-climbing type cutting electric beveling machine, automatic pipe-climbing cutting is realized, the degree of automation and the cutting efficiency are improved, the cutting precision is higher, personnel is prevented from harm, and the whole working efficiency is improved.

Owner:苏州博合雅工程材料科技有限公司

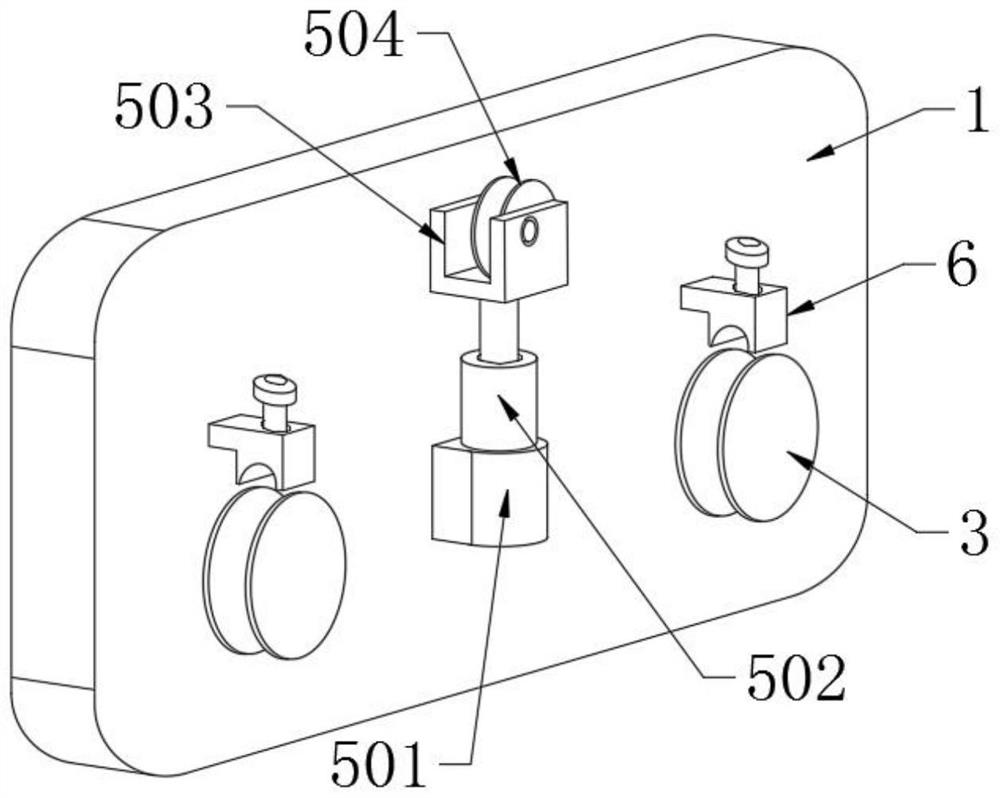

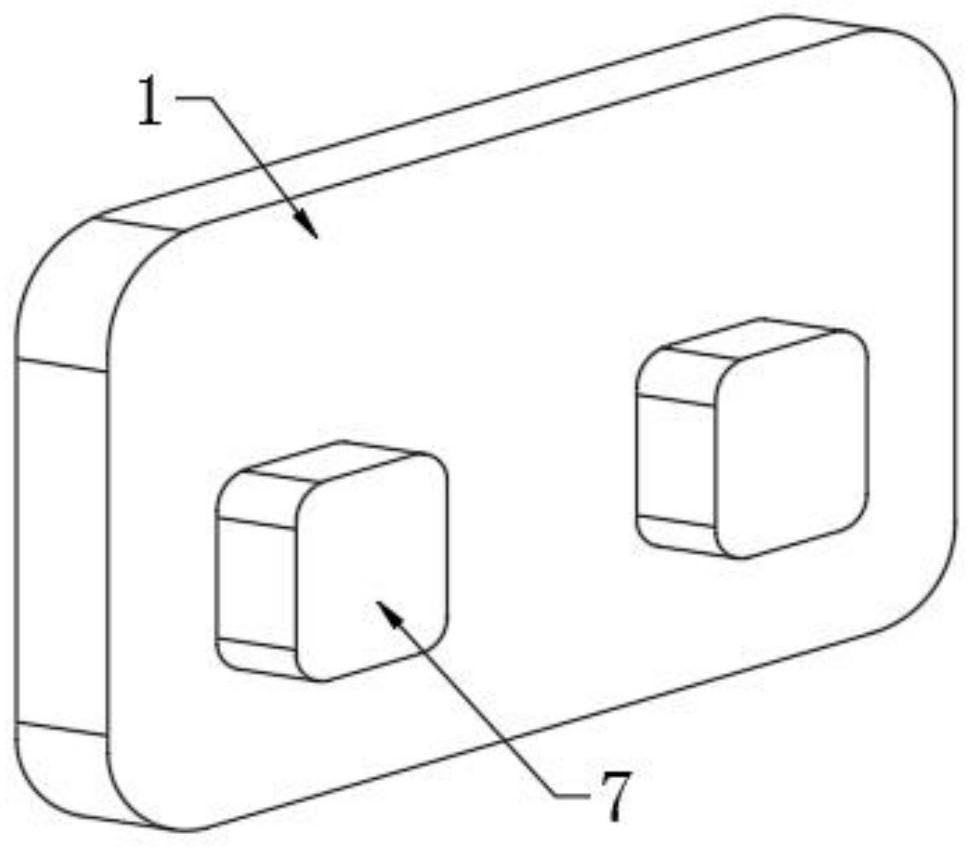

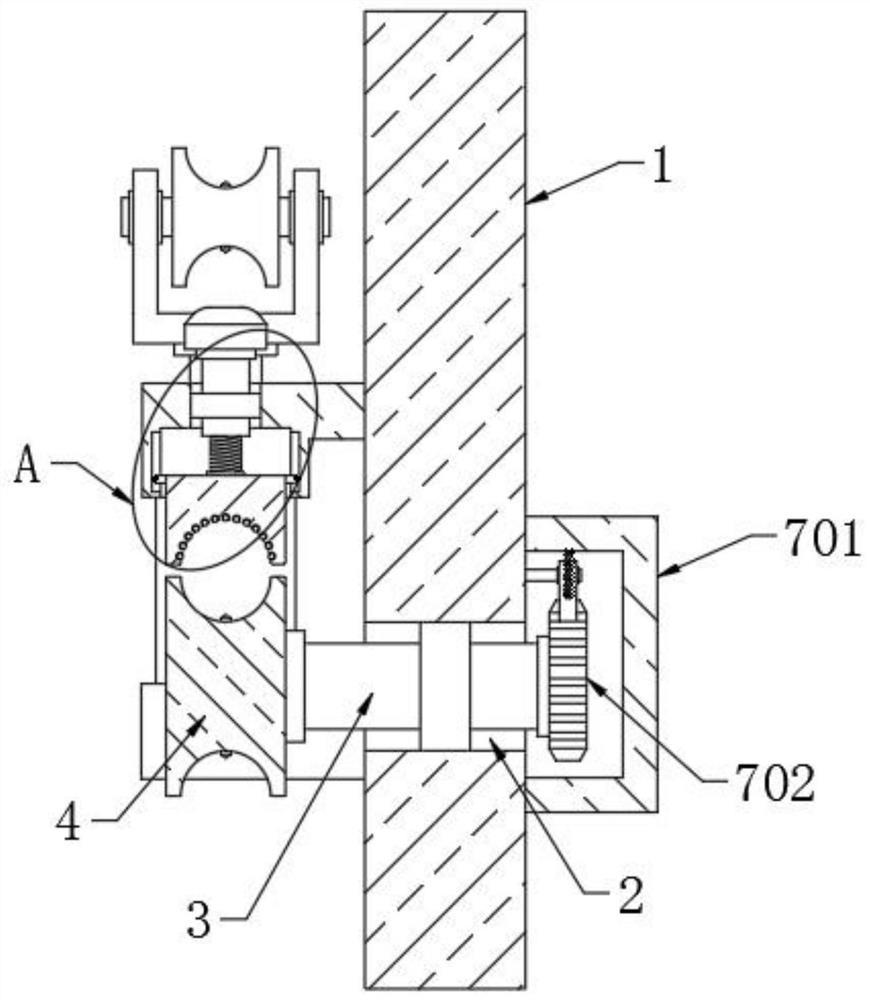

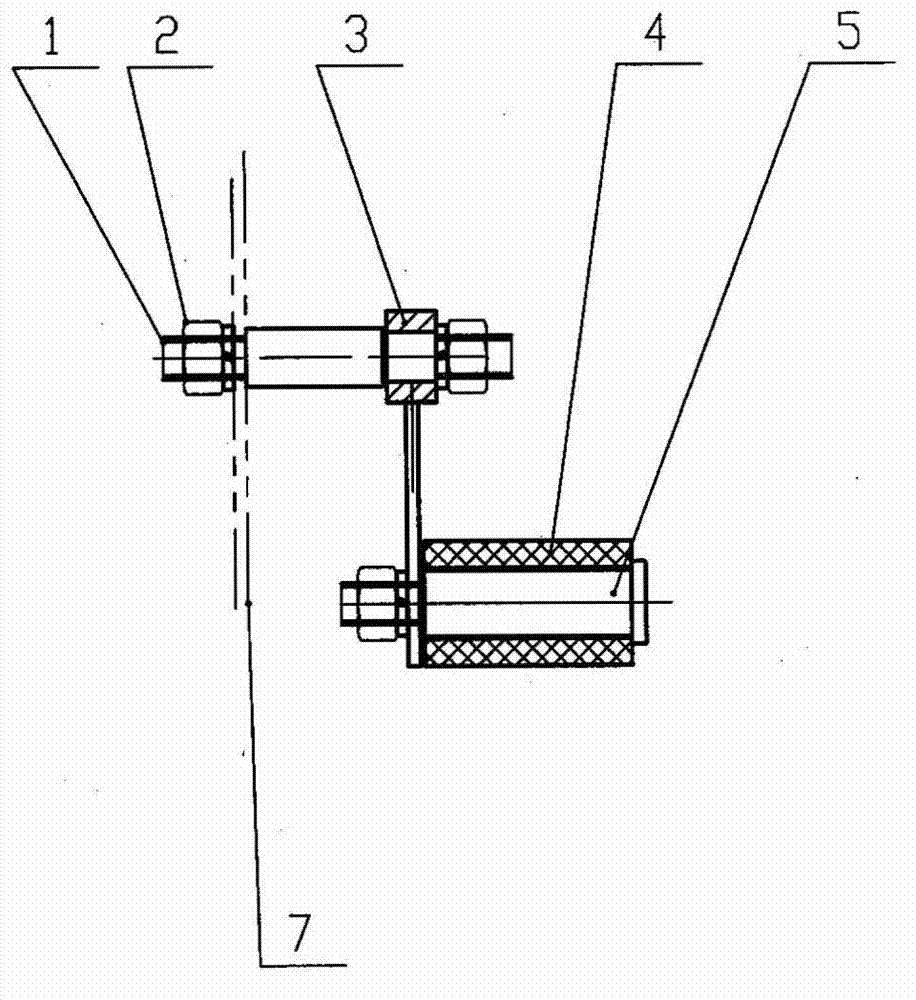

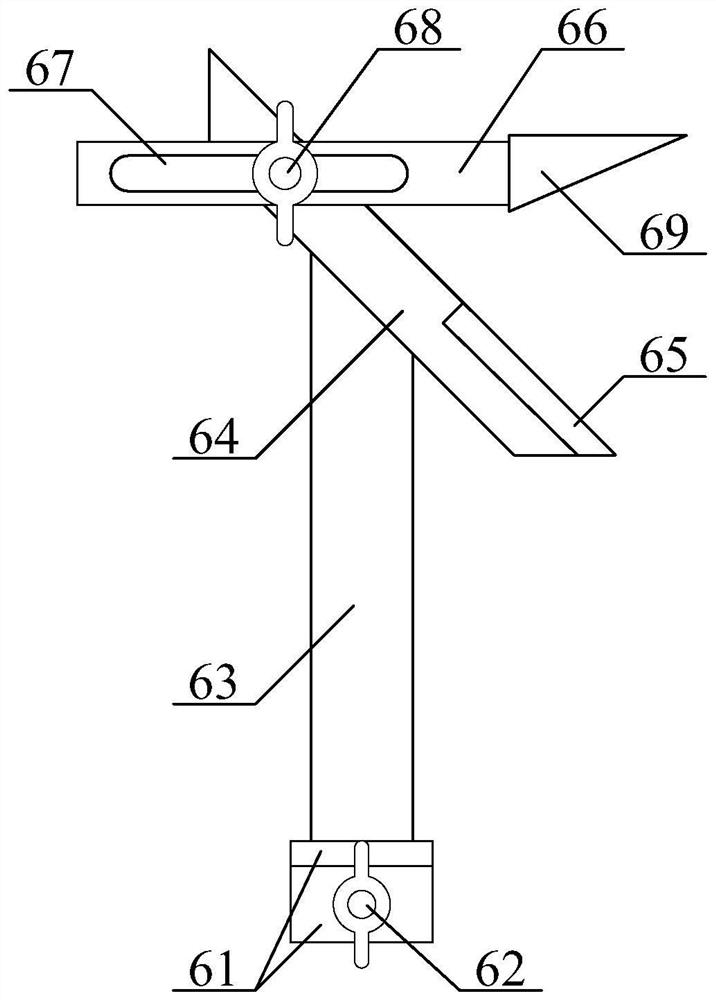

Extra-high voltage power transmission tower stringing mechanism

InactiveCN111817207AAct as tensionReduce vibrationApparatus for overhead lines/cablesStructural engineeringElectric power

The invention belongs to the technical field of wire erection, in particular to an extra-high voltage power transmission tower stringing mechanism. The mechanism comprises a mounting plate, two rotating holes are formed in the mounting plate; rotating shafts are rotationally mounted in the two rotating holes; the two rotating shafts respectively penetrate through the corresponding rotating holes;first guide wheels are fixedly mounted at the ends, located in the same side, of the two rotating shafts correspondingly, a tensioning mechanism is arranged at the side, close to the first guide wheels, of the mounting plate, the tensioning mechanism comprises a fixing block, the fixing block is fixedly connected with the mounting plate, a telescopic column is fixedly mounted at the top of the fixing block, and a mounting frame is fixedly mounted at the top end of the telescopic column. The extra-high voltage power transmission tower stringing mechanism is high in practicability, abrasion caused by friction in the electric wire erecting process can be reduced, an electric wire can be well protected, meanwhile, the electric wire can be limited, the electric wire is not prone to falling offfrom the device, and it is guaranteed that electric wire erecting is normally conducted.

Owner:许同

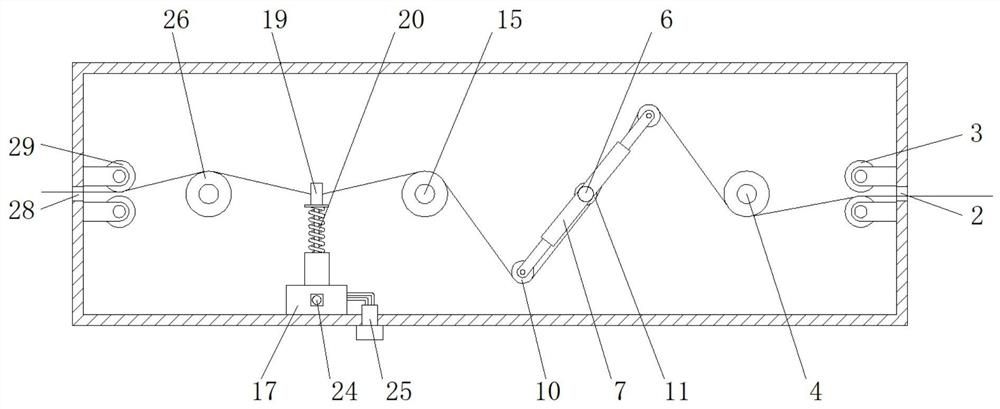

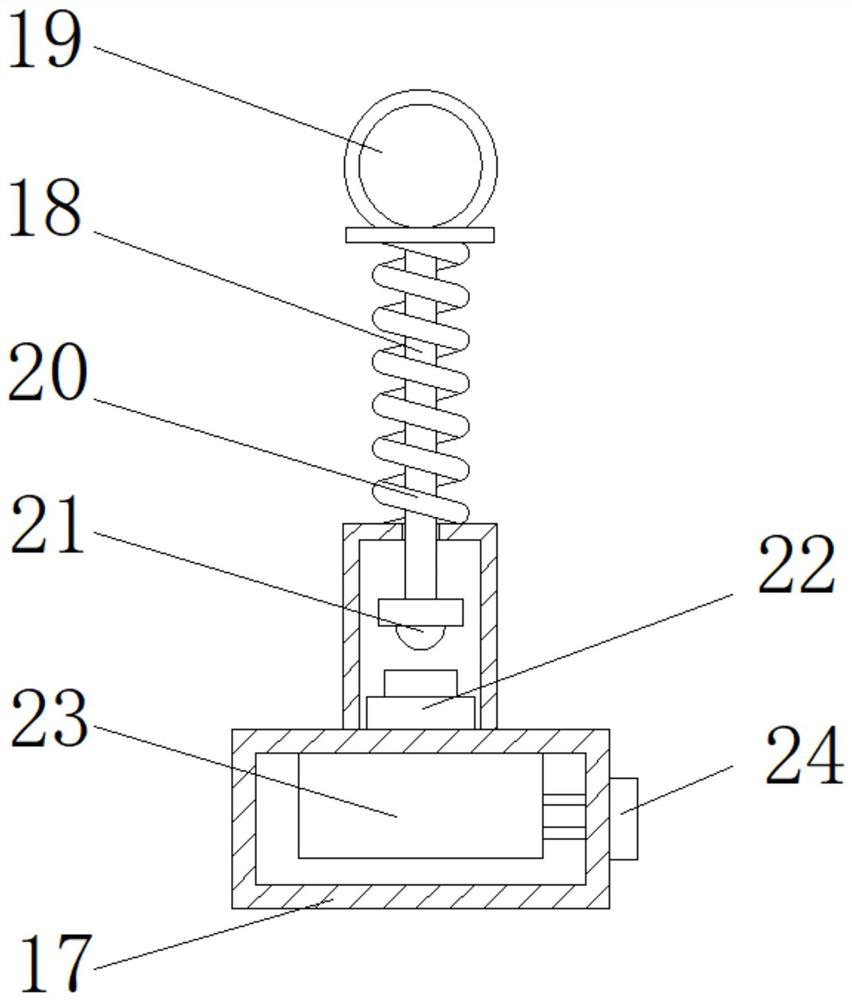

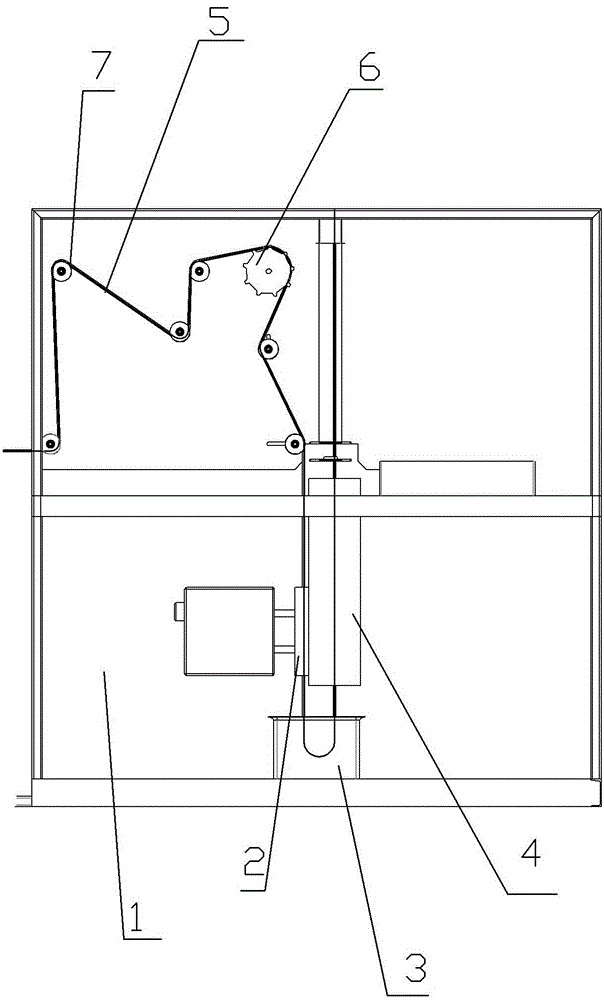

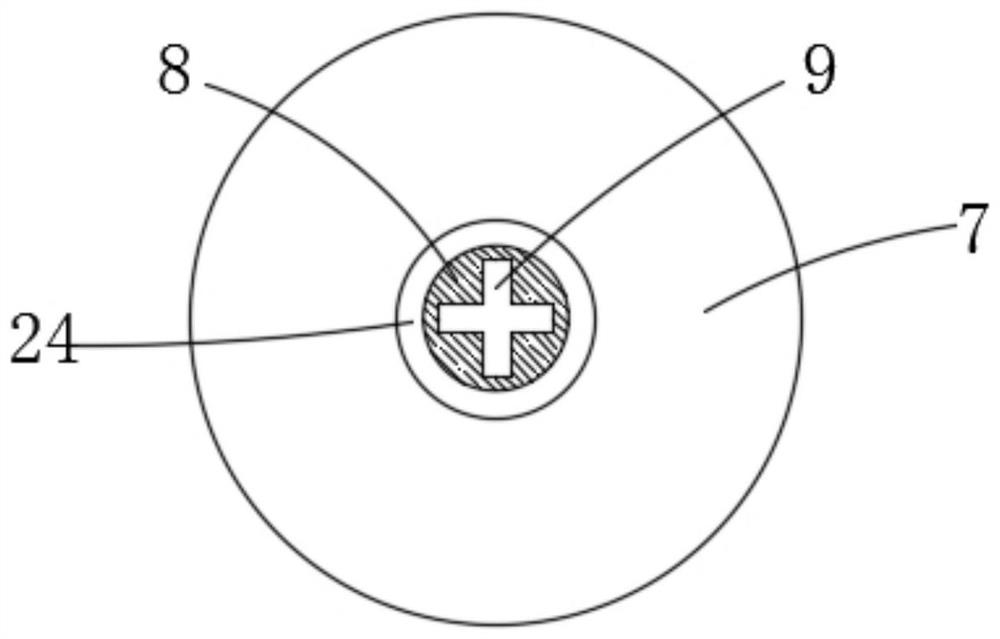

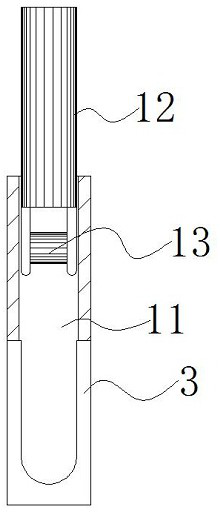

Groove drum type winder silk tensioning device for silk processing

InactiveCN111747223AAct as tensionTension manual adjustmentFilament handlingPolymer scienceEngineering

The invention relates to the technical field of the winders, in particular to a groove drum type winder silk tensioning device for silk processing. The device comprises a shell, wherein the right sideof the shell is a silk inlet hole, the left side of the silk inlet hole is provided with a silk inlet clamping wheel, the middle of the shell is in movable sleeve connection with a center rod, the right side of the center rod is fixedly connected with a stretchable rod, the right side of the stretchable rod is in movable sleeve connection with inner sleeve rods, the interior of the stretchable rod is provided with a supporting spring, and the right ends of the inner sleeve rods are in movable sleeve connection with winding wheels. By arranging the stretchable rod, a silk is wound around the winding wheels at the two ends of the stretchable rod in an S shape, the silk drives the inner sleeve rods to inwards compress the supporting spring, the supporting spring is used for giving outward elastic force to the inner sleeve rods and the winding wheels, the winding wheels can tension the silk, and automatic adjusting can be conveniently conducted according to strength of different silks.

Owner:任宏雅

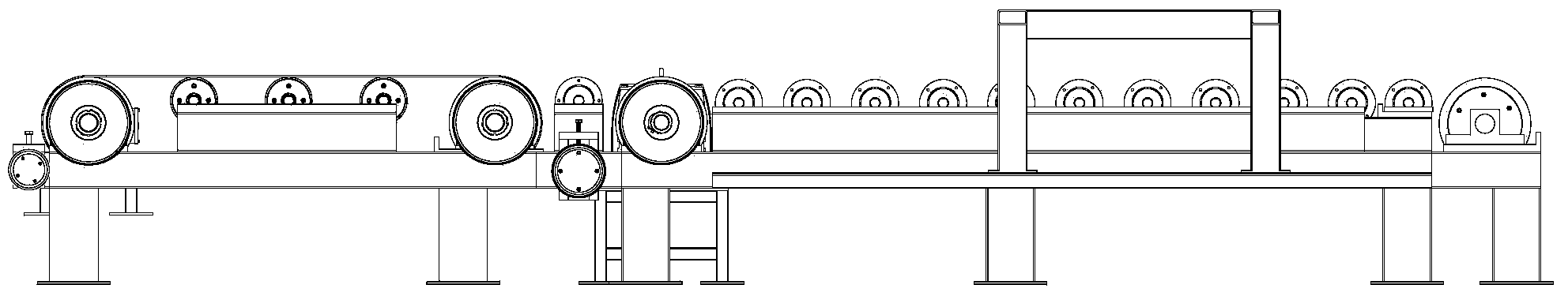

Plastic dipping structure of super-long chain

The invention discloses a plastic dipping structure of a super-long chain, and belongs to the field of chain manufacture. The plastic dipping structure comprises a rack and a motor, and further comprises a guiding device, a preheating device, a plastic dipping device and a heating device, wherein the guiding device comprises a plurality of guiding wheels; the motor is connected with the guiding wheels; the preheating device is arranged below the guiding device; the plastic dipping device is arranged below the preheating device, and comprises a plastic dipping tank; the plastic dipping tank is filled with a cooling liquid; the heating device is arranged above the plastic dipping device and positioned at one side of the preheating device. Through adoption of the plastic dipping structure, the surface of each chain link can be coated with a plastic dipping liquid, and thus the quality of the super-long chain can be guaranteed.

Owner:CHONGQING YONGGANG RUBBER & PLASTIC

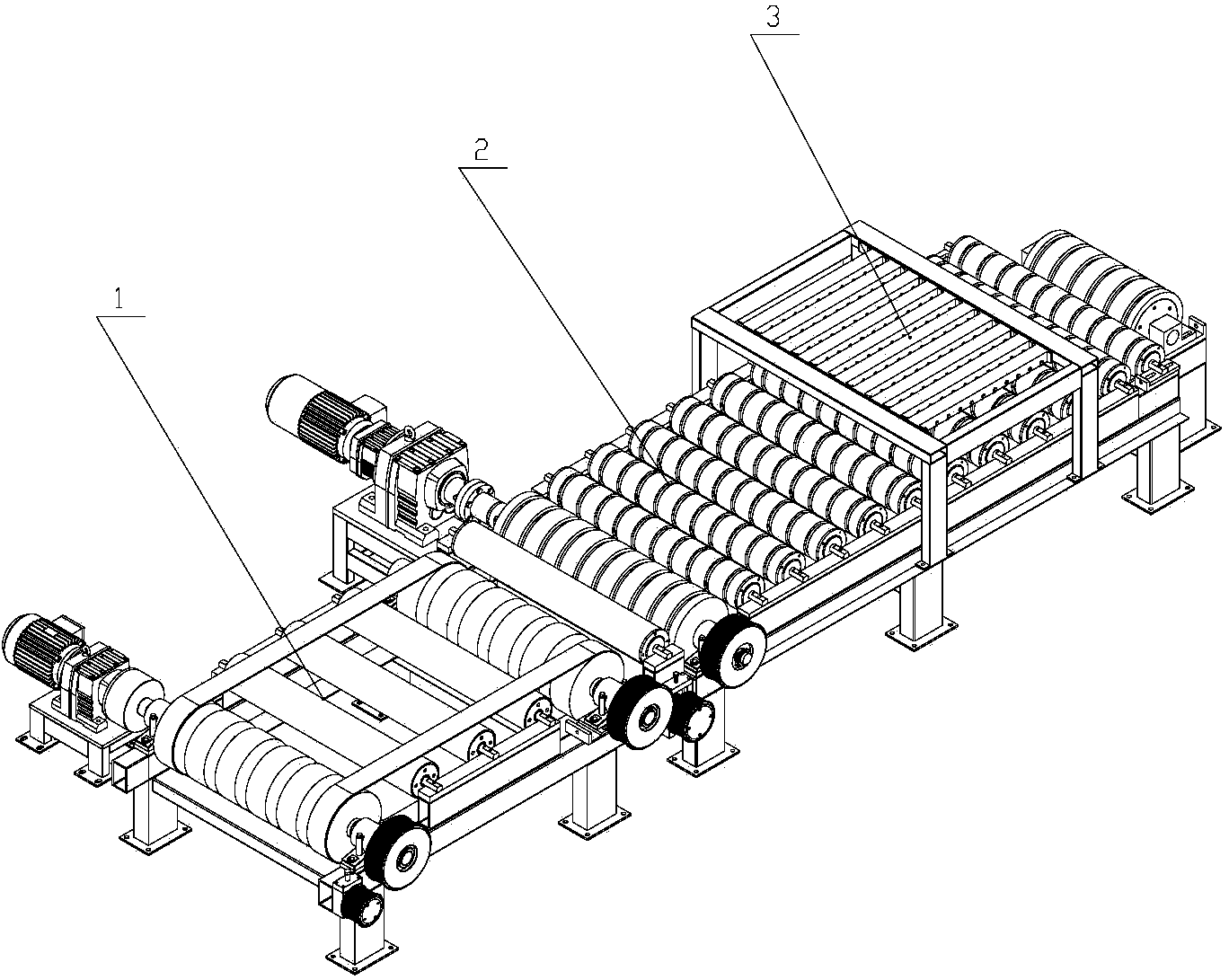

Building block cutting, feeding and conveying mechanism

ActiveCN103878873AGuaranteed to liftExpand the scope of useCeramic shaping apparatusRoller-waysFixed frameEngineering

The invention discloses a building block cutting, feeding and conveying mechanism which comprises a conveying mechanism, a feeding mechanism and a first compressing mechanism. The tail end of the conveying mechanism is fixed to the front end of the feeding mechanism; the first compressing mechanism is mounted above the feeding mechanism; the conveying mechanism comprises a conveying mechanism frame, a conveying motor fixing frame, a gear motor, a first roller and a first synchronous belt pulley, the feeding mechanism comprises a motor fixing frame, a motor, a transitional roller, a driving roller, a second compressing mechanism, a feeding mechanism frame, a first tension roller and a second tension roller, the second tension roller is arranged at the tail end of the feeding mechanism frame, the first compressing mechanism comprises compressing wheel fixing plates, compressing wheel frames and compressing wheels, and the bottoms of the compressing wheel frames are mounted on supporting steel angles of the feeding mechanism frame; the compressing wheels are connected onto the compressing wheel fixing plates by shafts, and rolling surfaces of the compressing wheels are positioned above first supporting rollers. The building block cutting, feeding and conveying mechanism has the advantages that by the aid of the building block cutting, feeding and conveying mechanism, building blocks can be continuously and stably cut, can be assuredly thoroughly cut and can be quickly conveyed after being cut, accordingly, the efficiency can be improved, and the labor intensity of staffs can be relieved.

Owner:湖州优研知识产权服务有限公司

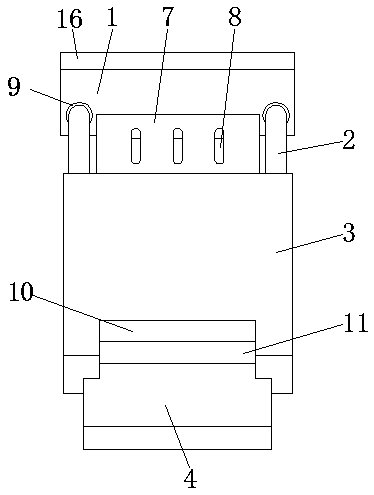

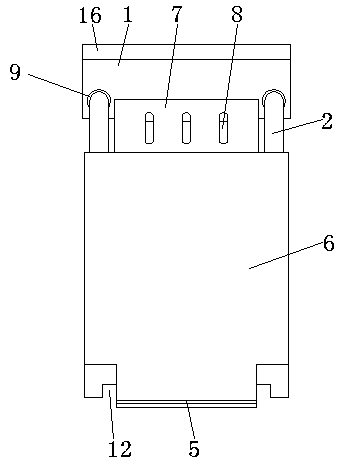

Intelligent wearable bracelet

PendingCN107772667AImprove breathabilityAct as tensionBraceletsWrist-watch strapsLeft wristPhysical medicine and rehabilitation

The invention discloses an intelligent wearable bracelet which comprises a watch face base, wherein the upper surface of the watch face base is connected with a cover plate through a screw; a containing groove is formed in the middle of the upper surface of the watch face base; spring grooves are formed in the front of the upper surface and two sides of the rear of the watch face base; reset springs are fixedly connected to one ends, which are far away from the outer side of the watch face, of the spring grooves; and through holes communicated with the spring grooves are formed in the left side face and the right side face of the watch face base. According to the intelligent wearable bracelet, by utilizing overlap fit of hooks and cross columns, the watch face base is fixed on the wrist, the fixed overlap mode is simple, the bracelet is convenient to wear, and due to clamping fit between an insertion block and a slot, connection at the joint of a left wrist strap and a right wrist strap can be firm, and contact between the bracelet and the wrist is uniform. The intelligent wearable bracelet is comfortable to use, and due to an elastic effect of a rubber band, the intelligent bracelet can be fixed on wrists of different sizes.

Owner:河南华赫电子科技有限公司

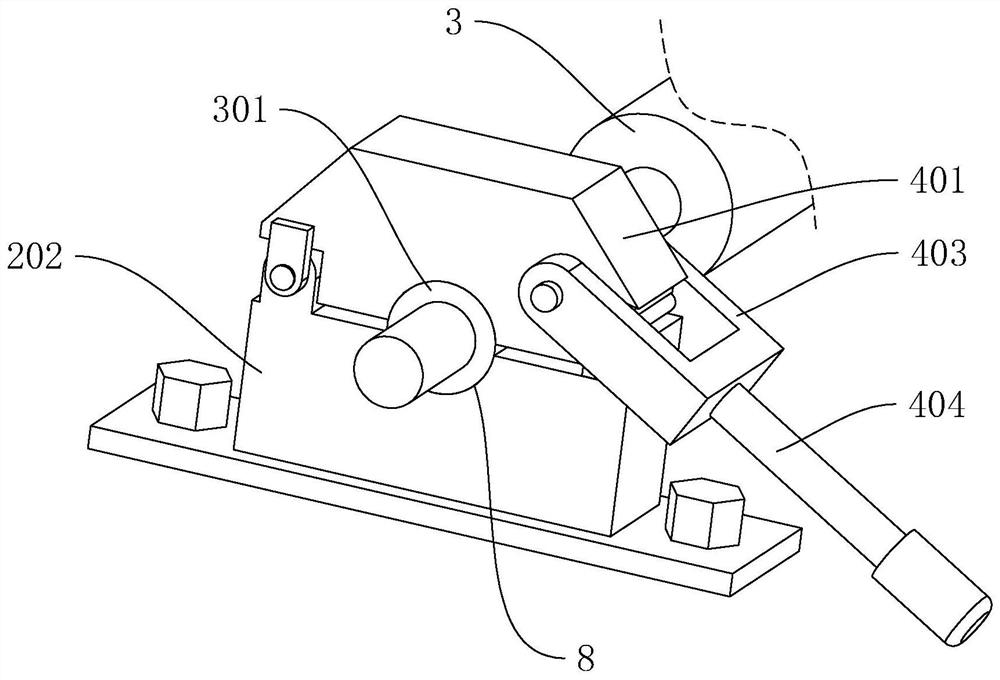

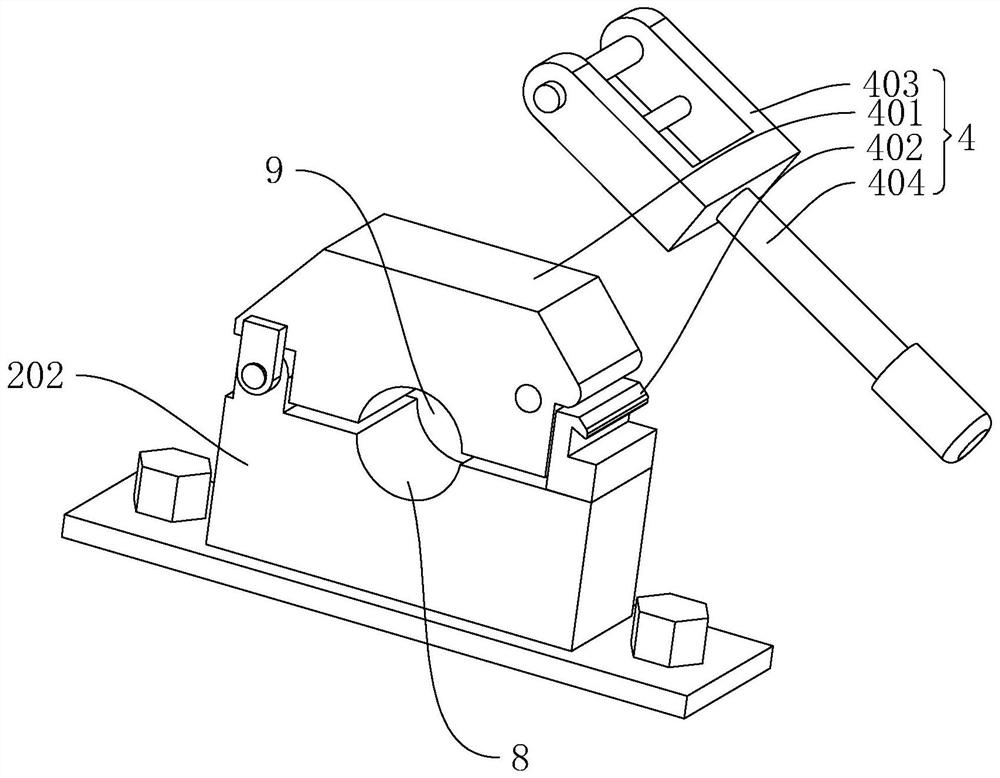

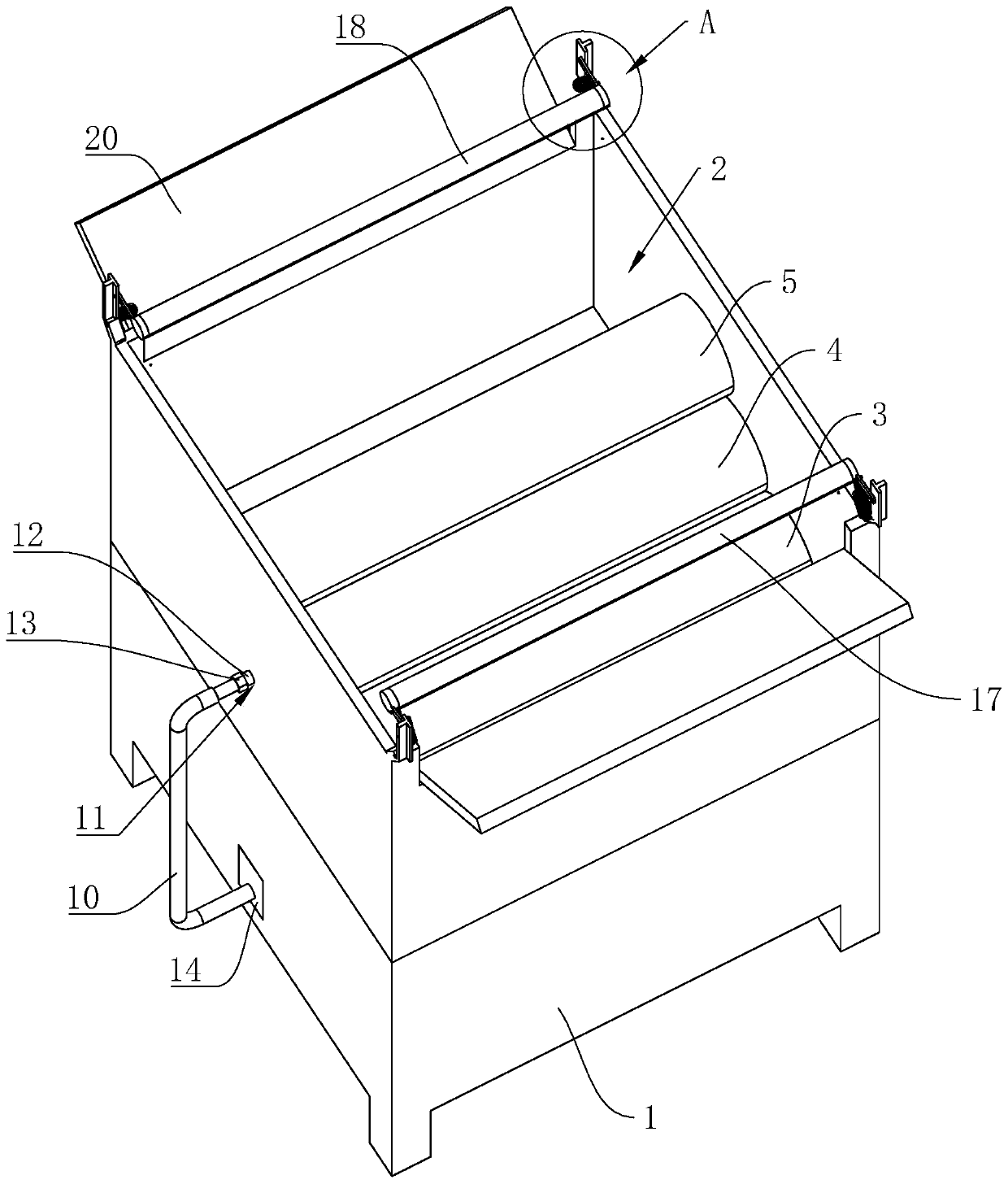

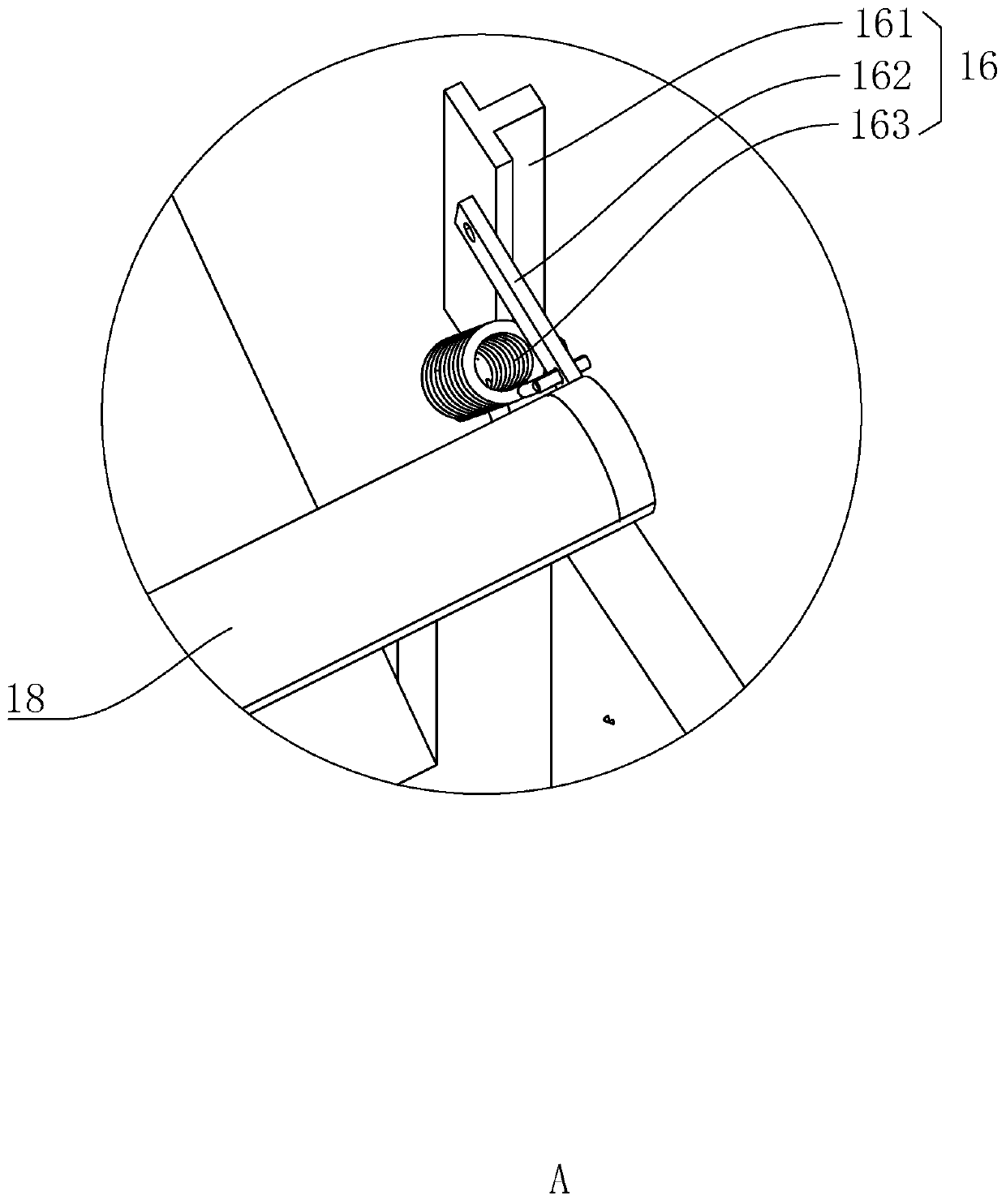

Film laminating device and film laminating process for plastic sheet machine

InactiveCN112677441AVersatileImprove product qualityLamination ancillary operationsLaminationThin membraneEngineering

The invention relates to a film laminating device and a film laminating process for a plastic sheet machine, and relates to the field of sheet compounding equipment. The film laminating device comprises a rack, a support, an unwinding shaft, a limiting assembly, a driving assembly, a guiding assembly and a flattening assembly. The limiting assembly is used for positioning the unwinding shaft, the driving assembly is used for driving the unwinding shaft to rotate, the guiding assembly is used for guiding a thin film, and the flattening assembly is used for flattening the thin film. The support comprises a bottom frame and two vertical plates. One ends of the vertical plates are connected with the bottom frame, the two vertical plates are parallel and arranged in a spaced mode, lower grooves for containing the unwinding shaft are formed in the top ends of the vertical plates, the unwinding shaft is placed in the lower grooves, and each limiting assembly comprises a limiting block, a spring bolt, a locking ring and a handle. One ends of the limiting blocks are hinged to the top ends of the vertical plates, and the other ends of the limiting blocks are hinged to the corresponding locking rings. The lock rings are connected with the handles, upper grooves are formed in the sides, close to the lower grooves, of the limiting blocks, and the spring bolts are connected to one sides of the vertical plates and further matched with the locking rings. The film laminating device and the film laminating process for the plastic sheet machine have the effect of enriching the functions of the plastic sheet machine.

Owner:黄冈双健包装有限公司

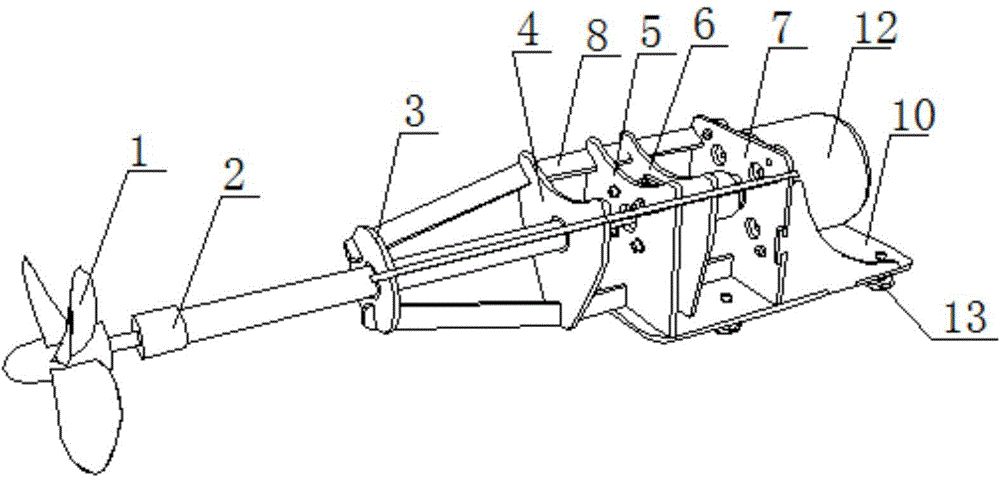

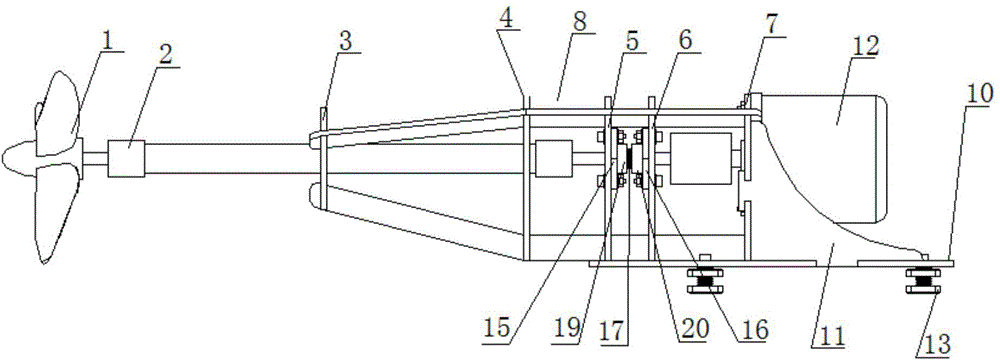

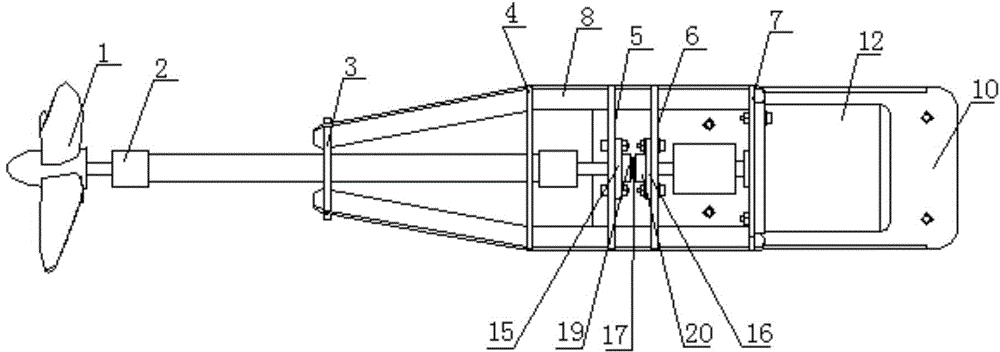

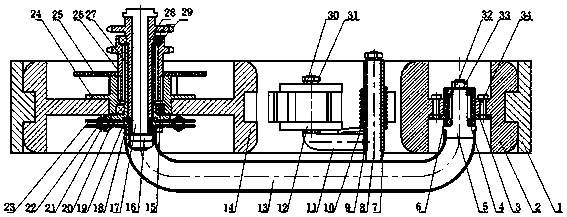

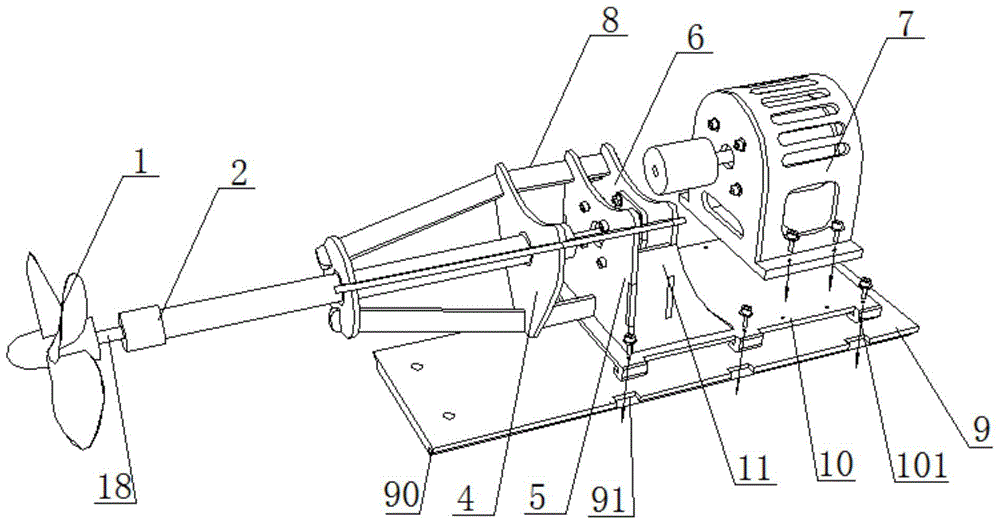

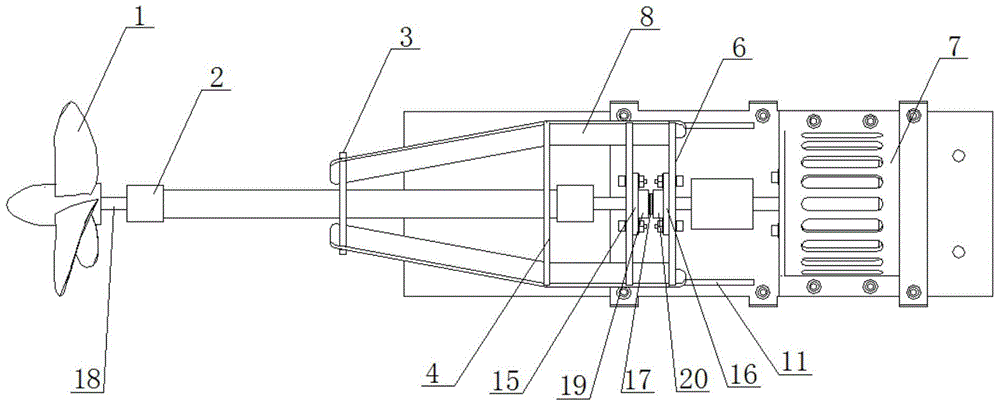

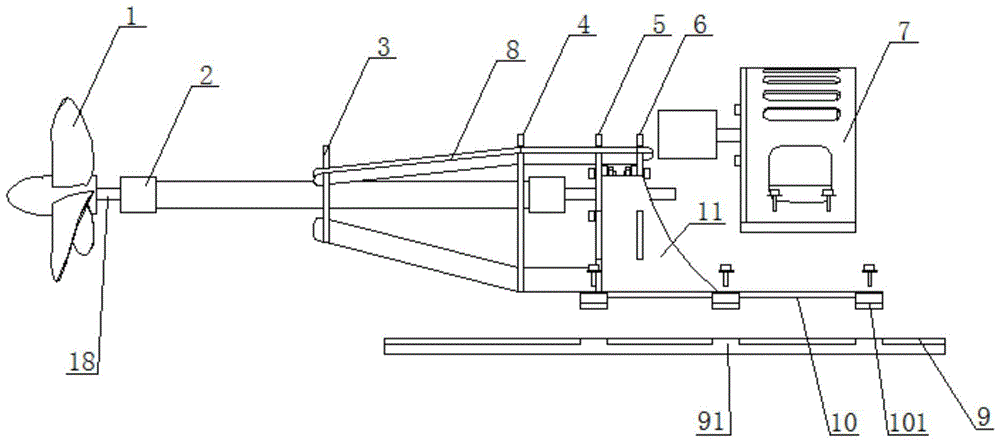

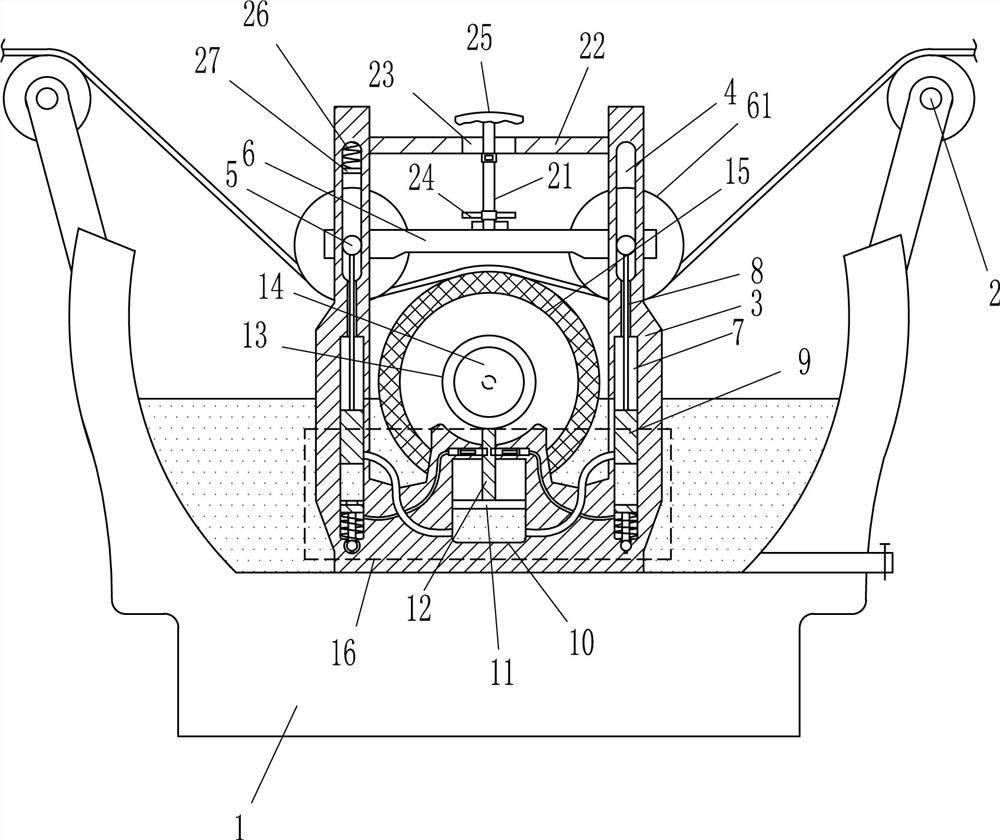

Novel electric propulsion device

ActiveCN104443338ASimple structureReasonable designPropulsion power plantsPropulsive elementsPropellerMotor shaft

The invention discloses a novel electric propulsion device. On the basis of an original simple motor support which is only composed of a motor installation plate and an installation base, a transmission shaft installation plate and a tensioning connecting piece are additionally arranged, and the characteristics that the structure is simple and the design is reasonable are still kept. Thus, when a linkage part (such as a propeller) runs at high speed, the transmission shaft installation plate and the connecting piece will support a transmission shaft and share a part of force, so that the situation that propulsion force generated by the linkage part is completely and directly transmitted to a motor shaft through the transmission shaft is avoided; moreover, the connecting piece can tension the transmission shaft and a motor through the motor installation plate and the transmission shaft; a buffering assembly is additionally arranged, vibration generated by the linkage part and vibration generated by work of the motor itself can both be buffered through the buffering assembly, and the probability that the motor shaft and the transmission shaft become loose is reduced.

Owner:ZHEJIANG OCEAN UNIV

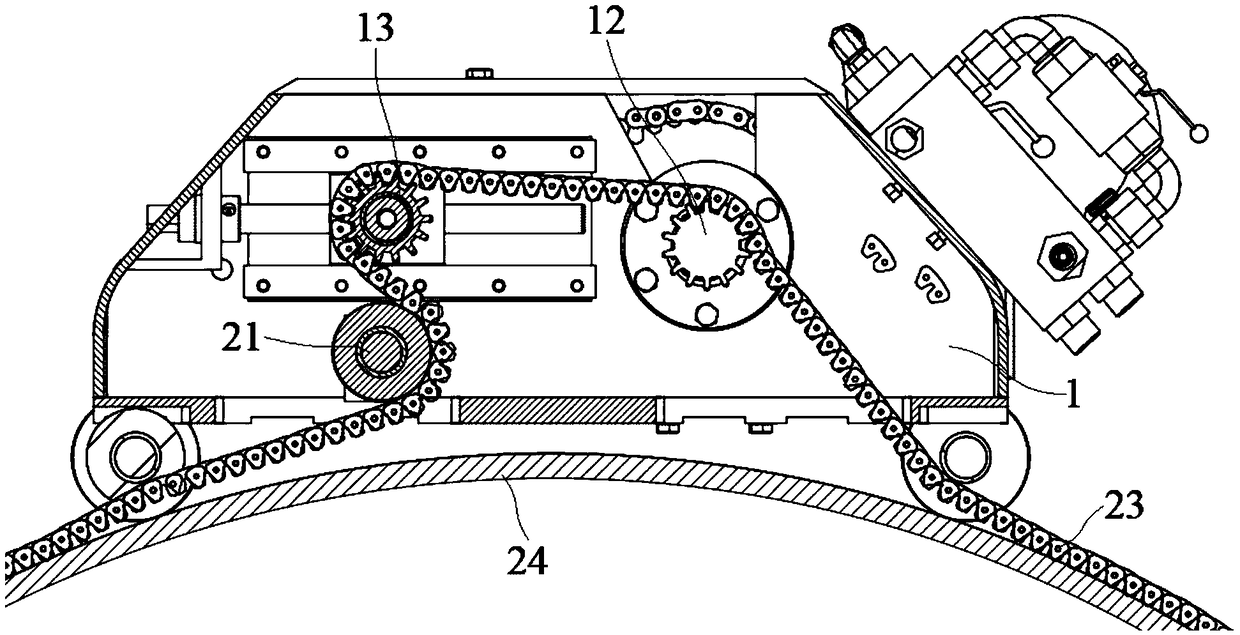

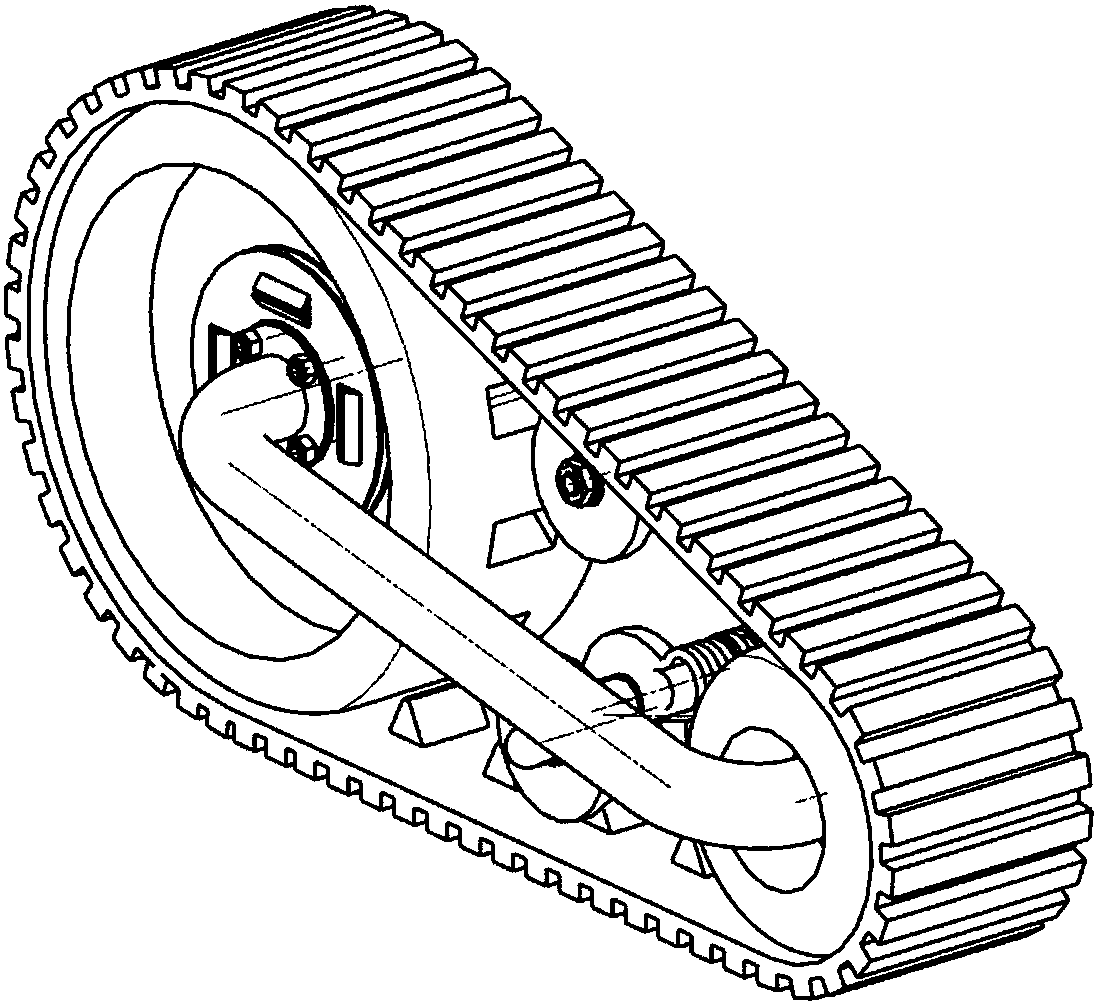

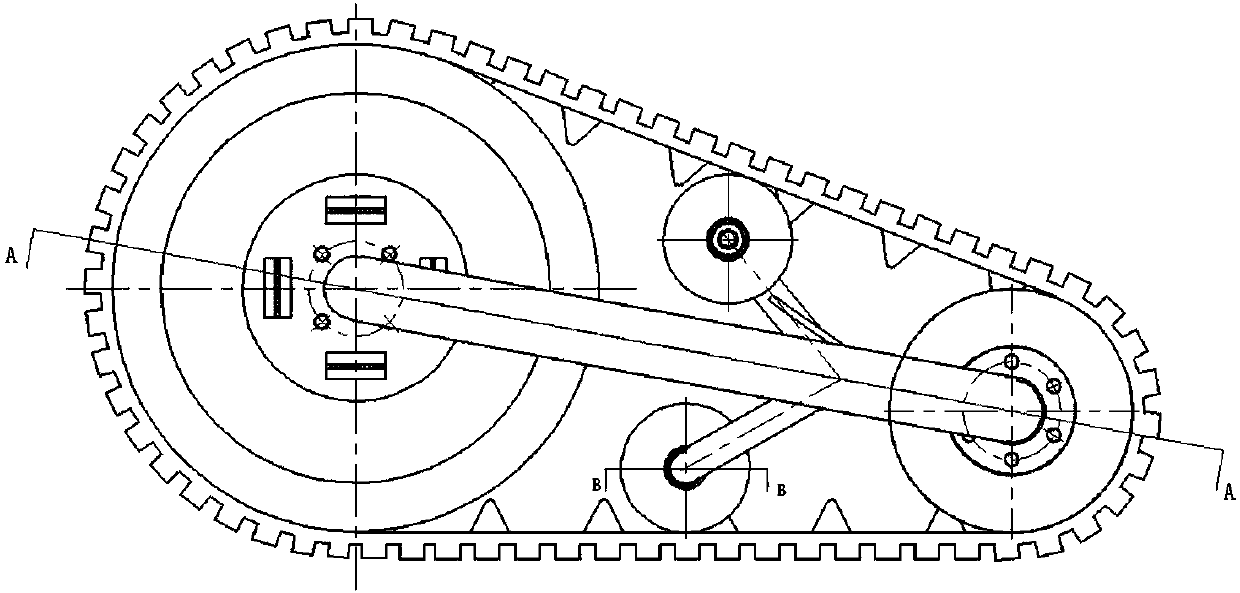

Joint track with posture adjusting mechanism

PendingCN107826171AWith ground angle adjustment functionImprove adhesionEndless track vehiclesTerrainDrive shaft

The invention relates to a moving mechanism of a tracked vehicle or a crawler type mobile robot, in particular to a joint track with a posture adjusting mechanism. A posture adjusting hollow shaft (28) with a chain disk on one side is sleeved on the position between a large wheel rotating shaft (17) and a driving hollow shaft (26), and the three shafts are of a same coaxial line and can be mutually rotated; the inserting end of the posture adjusting hollow shaft (28) is connected to a rod-shape swing arm (13) through a torque damping mechanism, and the other end of the swing arm (13) is rotatably connected with a small wheel (2); and the length direction of the swing arm (13) is consistent with a connecting line of the axial lines of a large wheel (14) and the small wheel (2). A crawler assembly has a grounding angle adjusting function, obstacles can be overcame to adapt to a complex road environment, the active adjustment of a track grounding angle can be realized, the ability of imitating terrain is relatively good, the adhesion of tracked ground is improved, the torsional vibration of the front of a track is decreased, the impact is cushioned and the noise is reduced; and the structure is simple and compact, the parts are under reasonable stress, the manipulation posture is easy to adjust, and the manipulation effect and efficiency are good.

Owner:北京履坦科技有限公司

Back coating device and compound machine using same

ActiveCN111304963AIncrease heatAvoid condensationPaper/cardboardPulp material addition processesCoatingElectric heating

The invention relates to a back coating device. The back coating device comprises a box body, and a back coating groove is formed in the box body. A hydrophilic roller in contact with back coating liquid, a coating roller propped against the hydrophilic roller and an auxiliary roller playing a propping role are mounted in the back coating groove. A back coating tank is mounted in the box body. A water outlet communicated with the back coating tank is formed in the bottom of the back coating groove. A water inlet is formed in the side wall of the back coating tank. A feeding pipe is installed at the water inlet, and the feeding pipe is communicated with the back coating groove. A water pump used for pumping back coating liquid is installed on the feeding pipe. A coiled pipe is installed inthe back coating tank, one end of the coiled pipe is communicated with the water outlet, the other end of the coiled pipe is communicated with the water inlet, and an electric heating wire used for heating the coiled pipe is wound on the peripheral side wall of the coiled pipe. The back coating device can be prevented from being condensed when used at a low temperature.

Owner:上海鼎韧包装科技有限公司

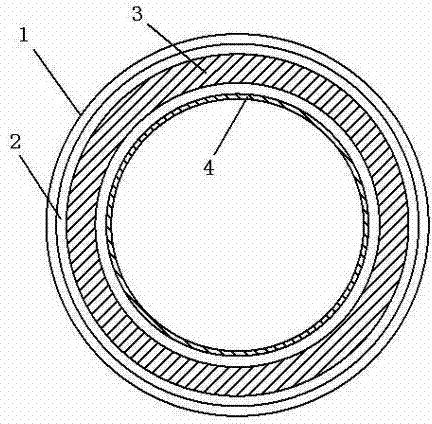

Heat preservation PPR water pipe

InactiveCN103486351APrevent looseningAvoid getting lostThermal insulationPipe heating/coolingWater pipeEngineering

The invention discloses a heat preservation PPR water pipe which structurally comprises a pipe body. A double-layer heat preservation shell is arranged in the pipe body, a vacuum layer is arranged in the middle of the double-layer heat preservation shell, a metal reflecting layer is arranged on the inner wall of the double-layer heat preservation shell, vacuum spacing pieces are evenly arranged in the vacuum layer and divide the vacuum layer into a plurality of independent areas, the thickness of the vacuum spacing pieces is 0.5mm, and the distance between adjacent vacuum spacing pieces is 100mm-500mm. The heat preservation PPR water pipe is capable of overcoming the defects in the prior art, simple in structure and good in heat preservation effect.

Owner:张人益

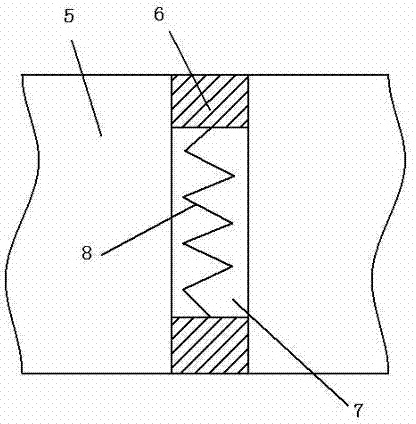

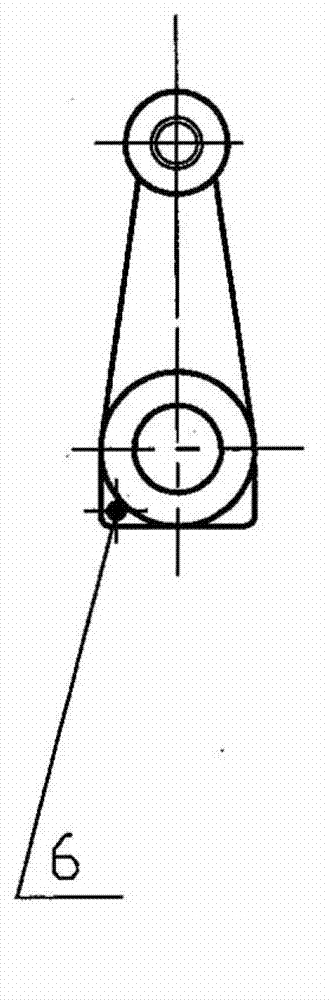

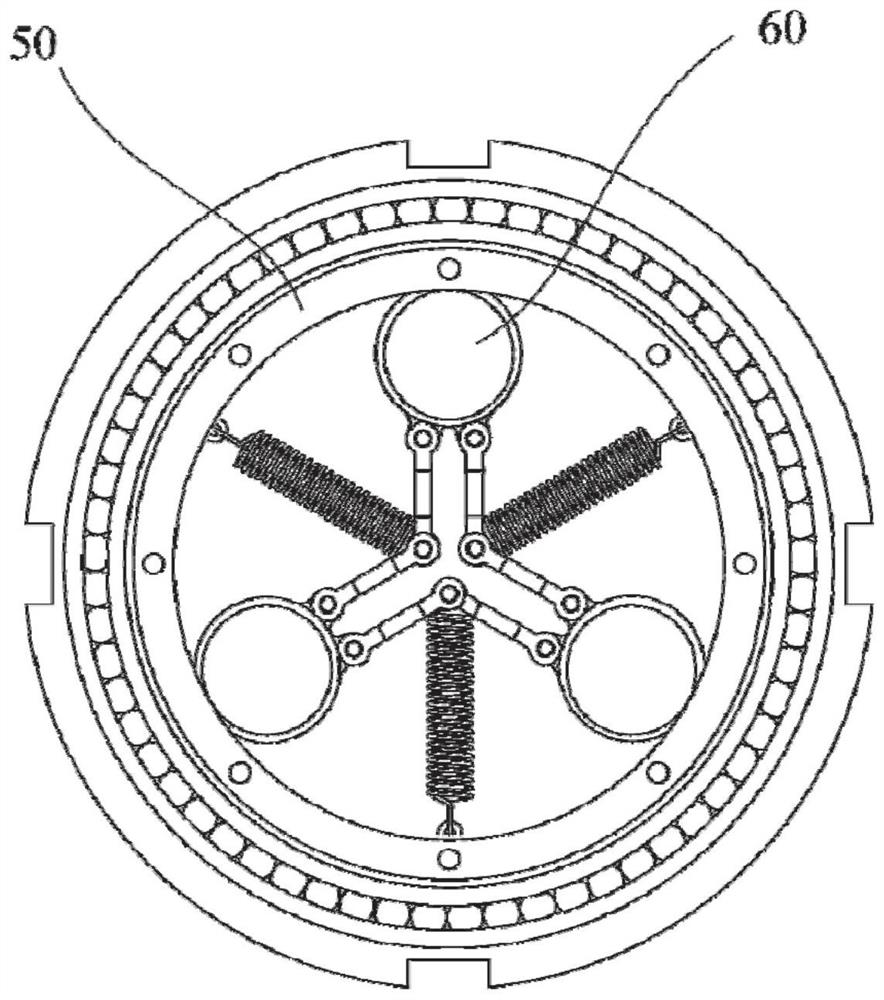

Caterpillar band tensioning device

The invention provides a caterpillar band tensioning device which is characterized in that bosses (6) are symmetrically arranged on opposite faces of two opposite support seats (1), a guide bolt (5) is arranged between the two bosses (6), a steel spring (4) is sleeved on the guide bolt (5), the end portions of the steel spring (4) are connected with the bosses (6), the inner surface of an outer ring spring (2) and the outer surfaces of inner ring springs (3) are matched to form an annular spring, the inner ring springs (3) at two ends of the annular spring are tightly attached on the support seats (1) and are fixed on the bosses (6) of the support seats (1). The caterpillar band tensioning device can tension a caterpillar band anytime, the caterpillar band is in a certain tensioning state all the time, and damage to a caterpillar band chain caused by sudden impact force can be effectively lowered. The caterpillar band tensioning device is mainly used in walking parts of an excavator, a bulldozer, a crane and the like which are provided with a caterpillar band structure.

Owner:SOUTHWEST JIAOTONG UNIV

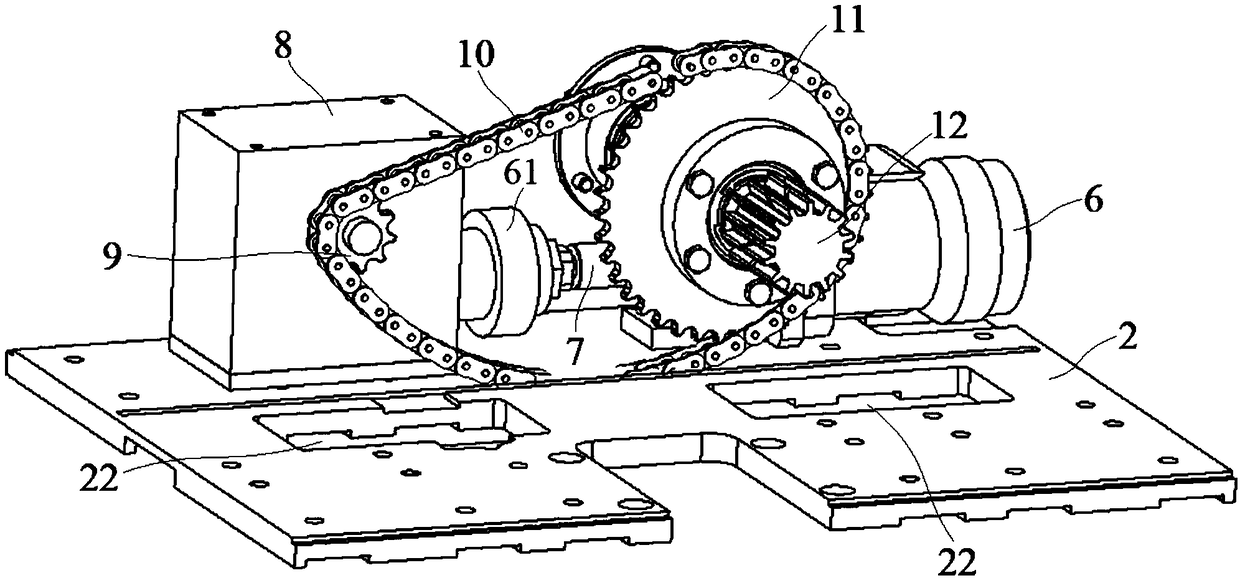

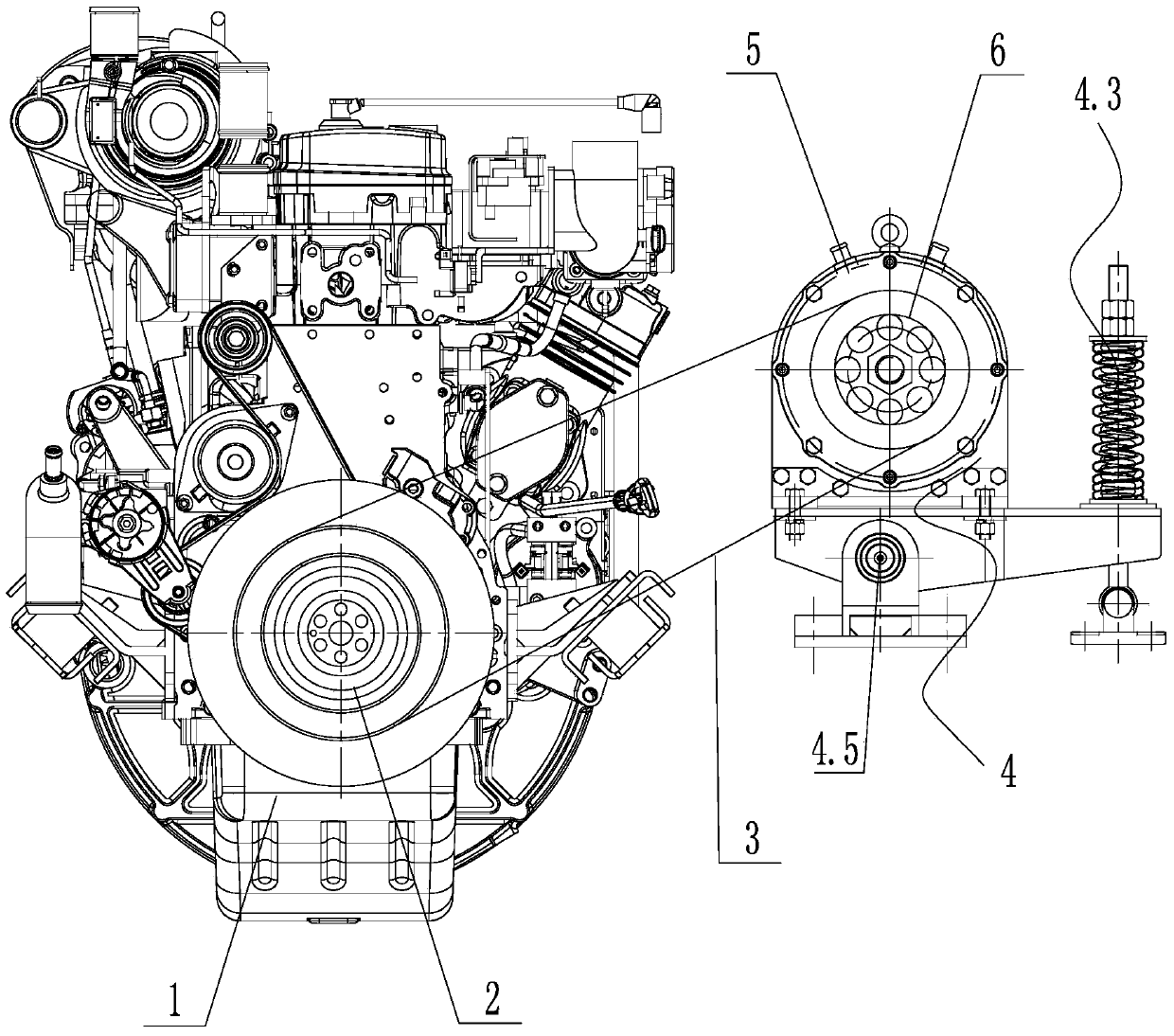

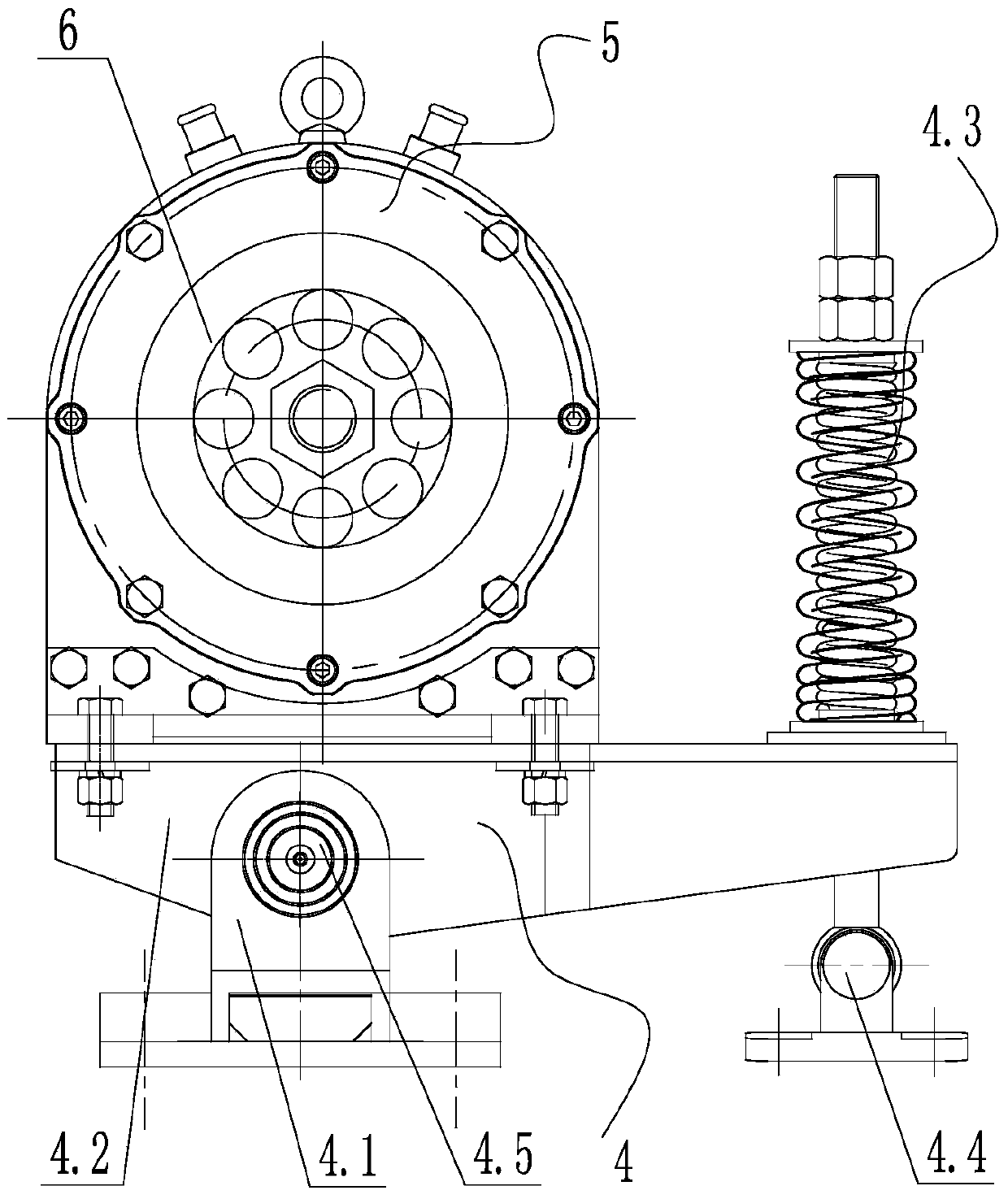

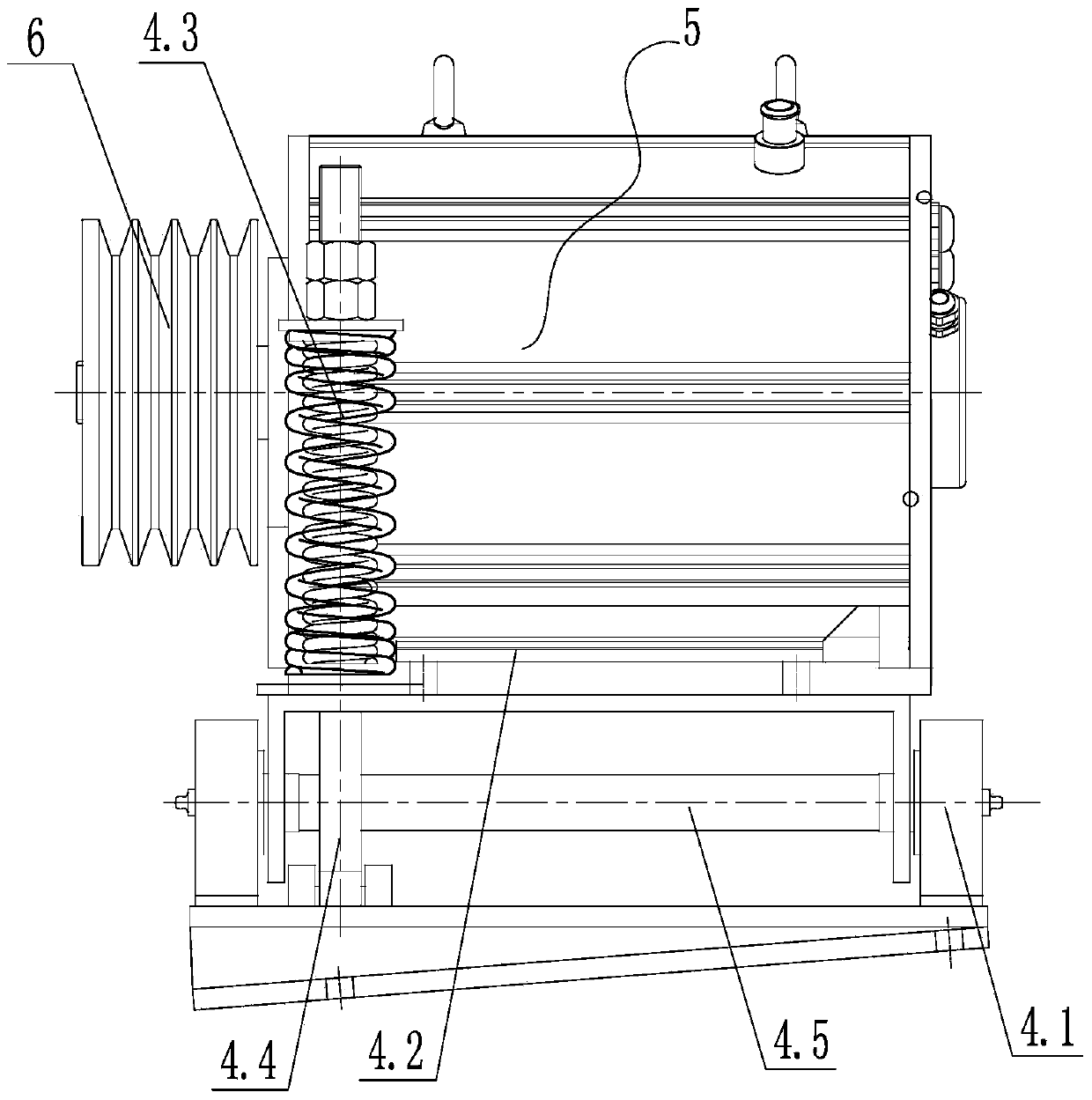

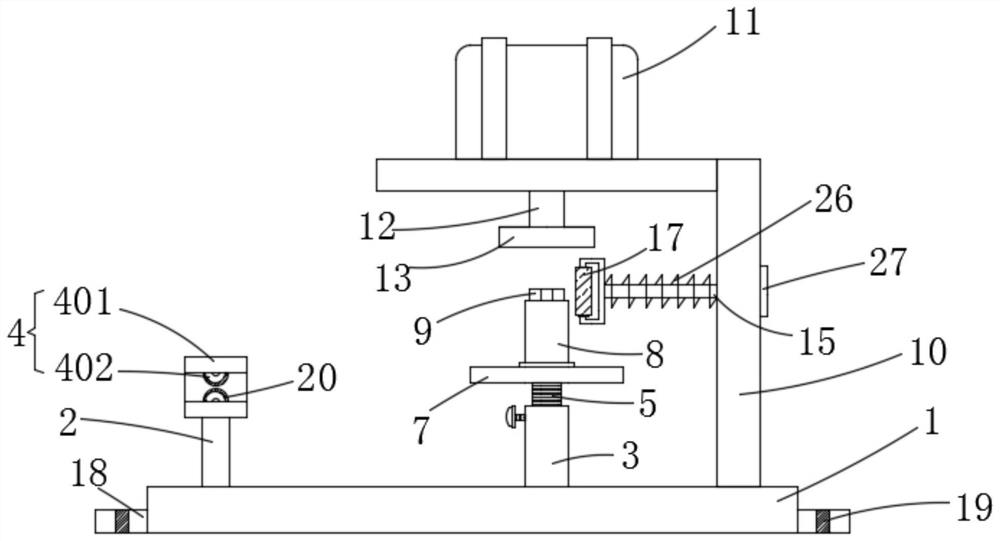

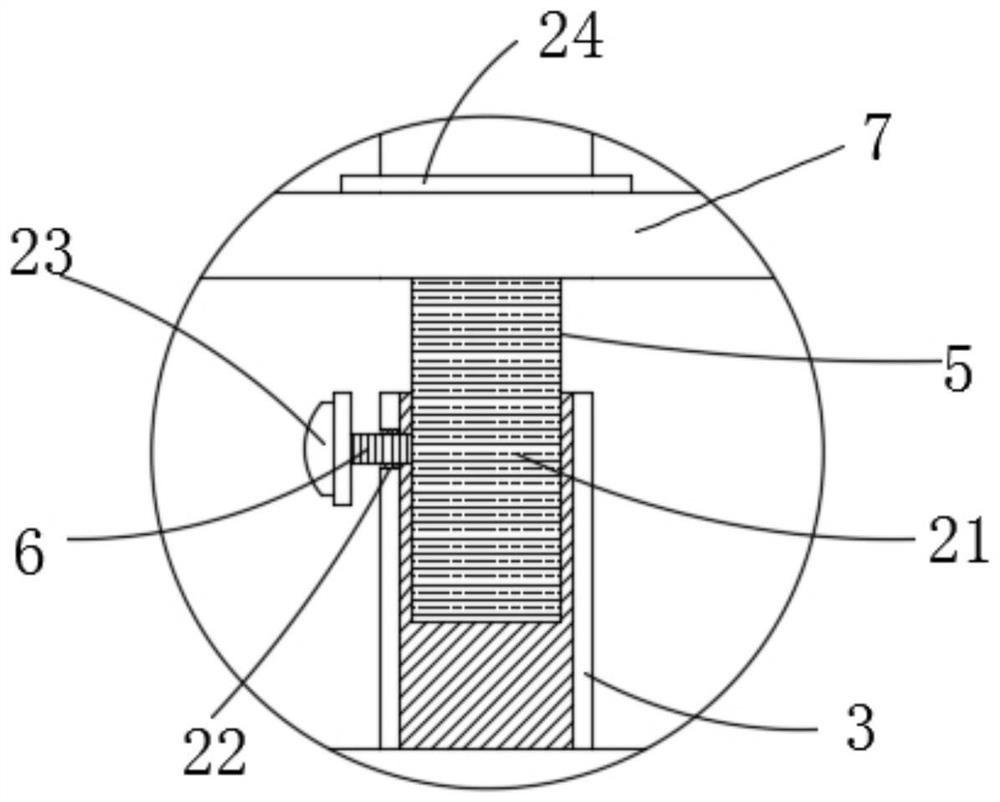

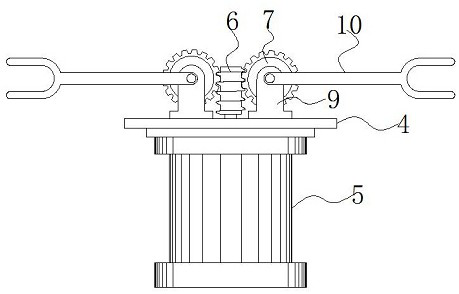

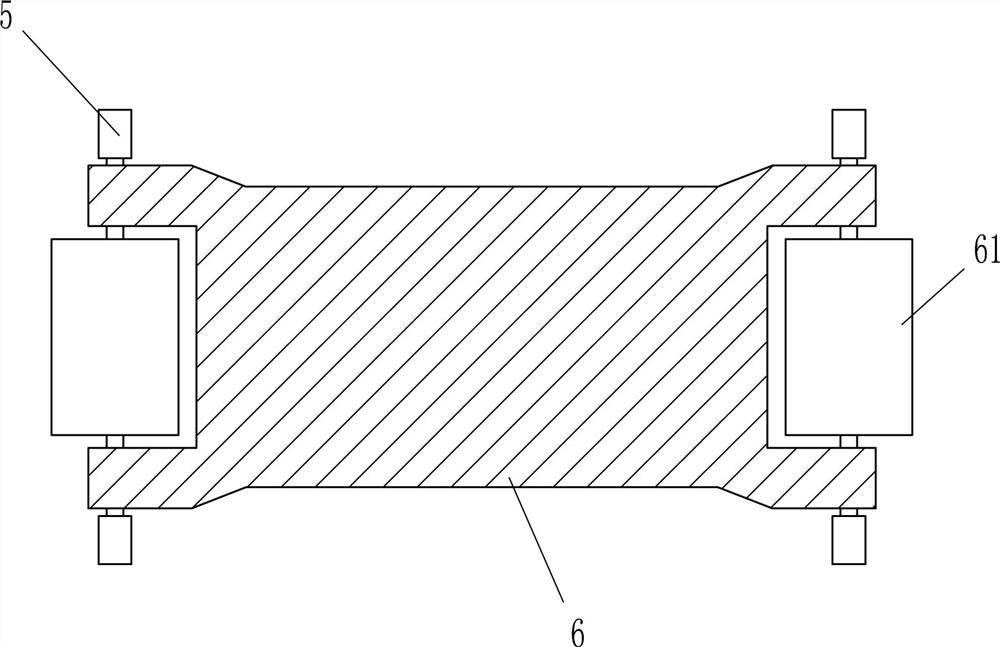

Mounting device used for power mechanism of hybrid electric bus

InactiveCN103465767AAdjust the forceEven by forceGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectric machineEngineering

The invention discloses a mounting device used for a power mechanism of a hybrid electric bus. The mounting device comprises a motor (5), a motor-end belt wheel (6) connected with the motor (5), an engine (1) connected on the bus, an engine-end belt wheel (2) connected with the engine (1), a transmission belt (3) used for connecting the motor-end belt wheel (6) with the engine-end belt wheel (2), and a swinging and tensioning mechanism (4) connected on the bus, both the motor (5) and motor-end belt wheel (6) are arranged on the swinging and tensioning mechanism (4), and stressing and tensioning of the transmission belt (3) are adjusted through the swinging and tensioning mechanism (4). By the mounting device, stress between the two belt wheels can be more balanced, and wear of the transmission belt can be reduced.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

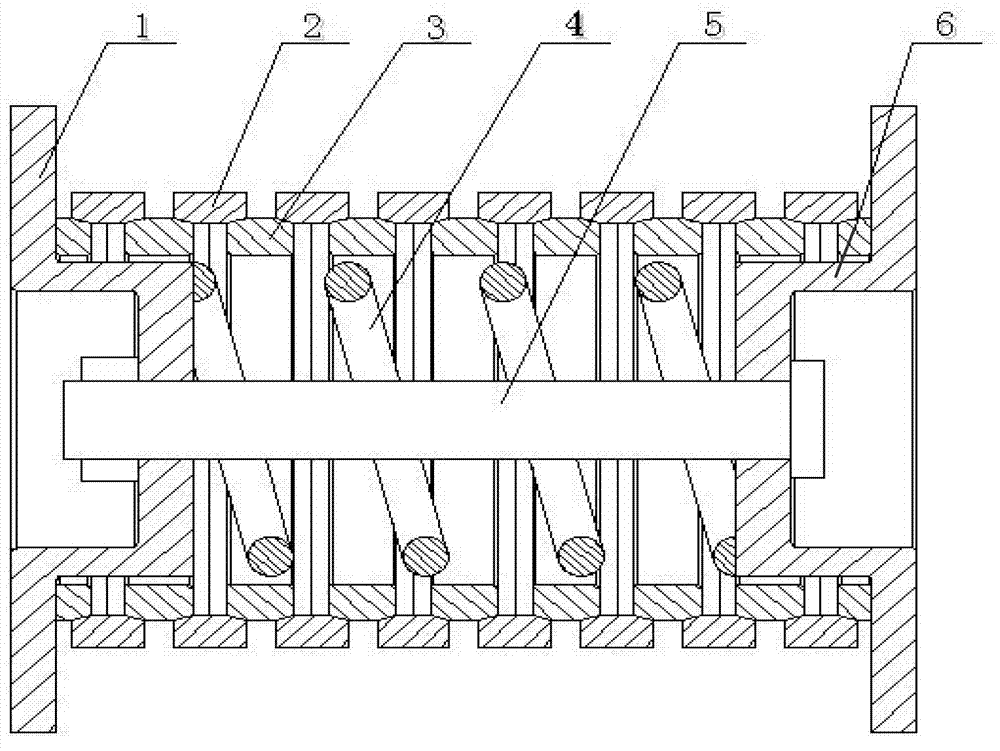

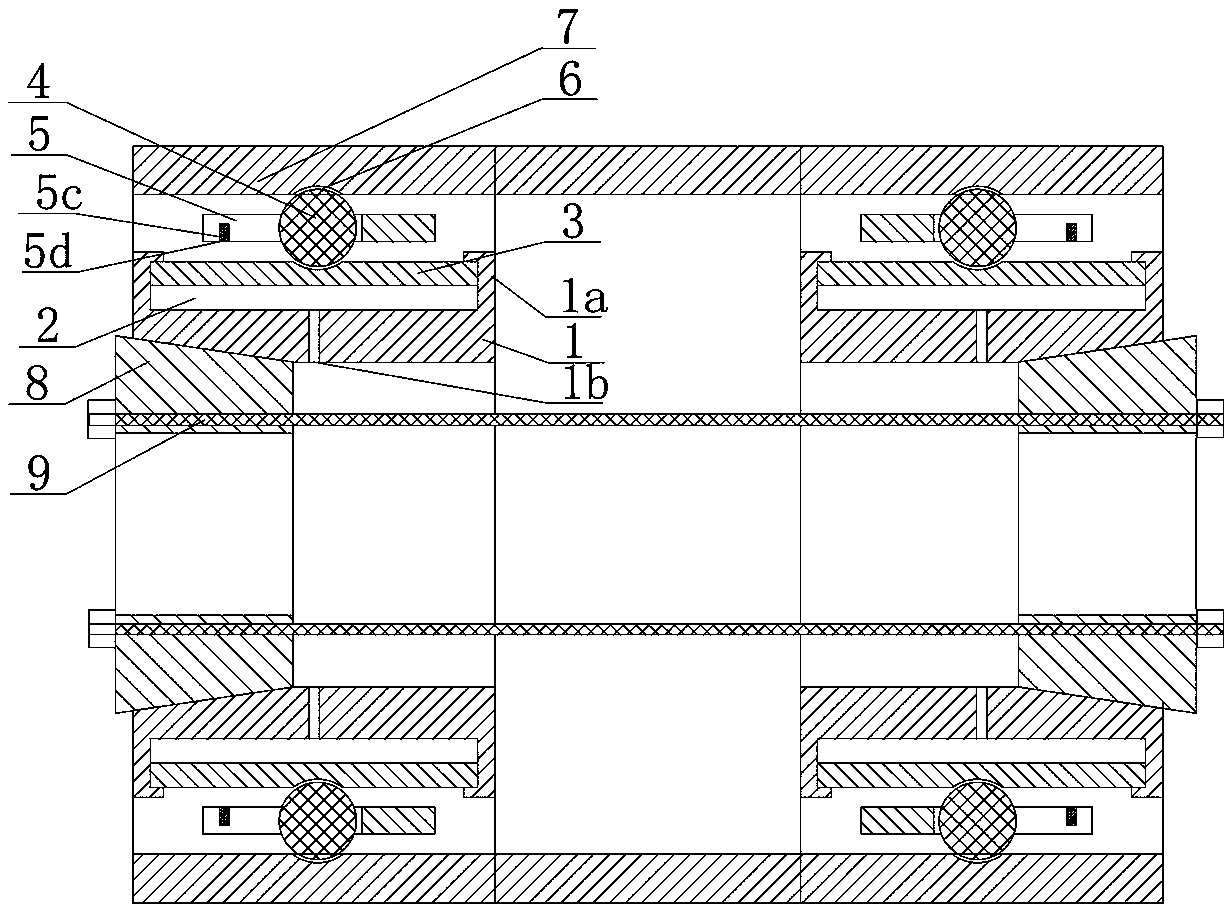

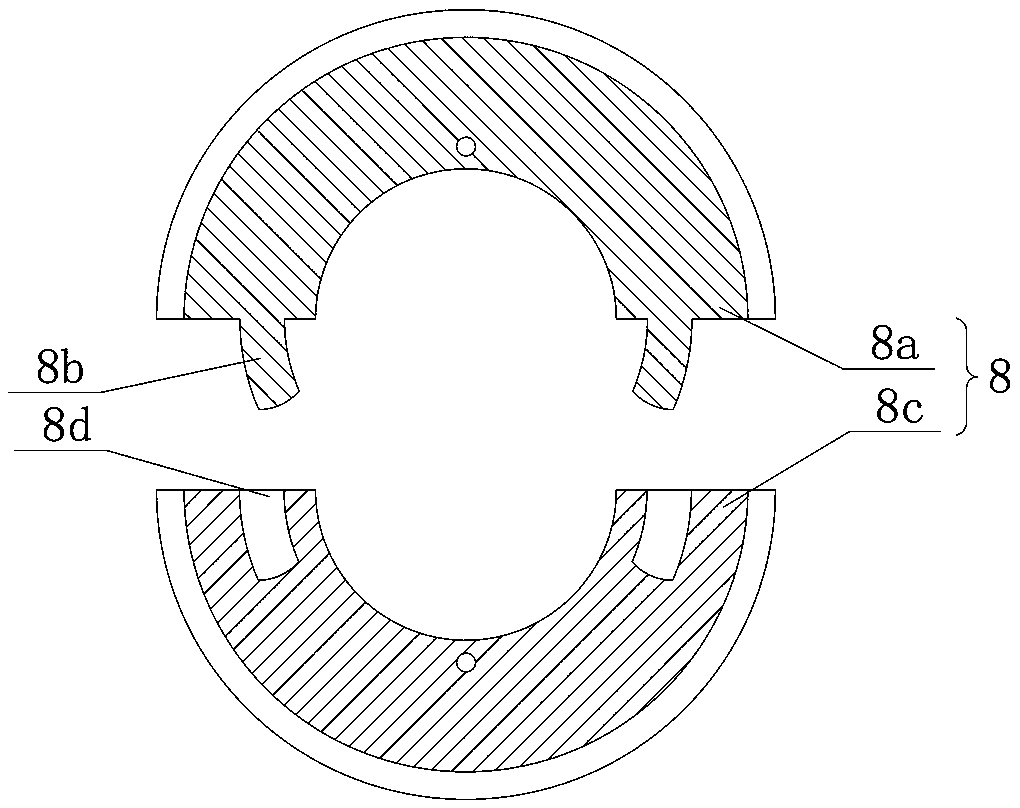

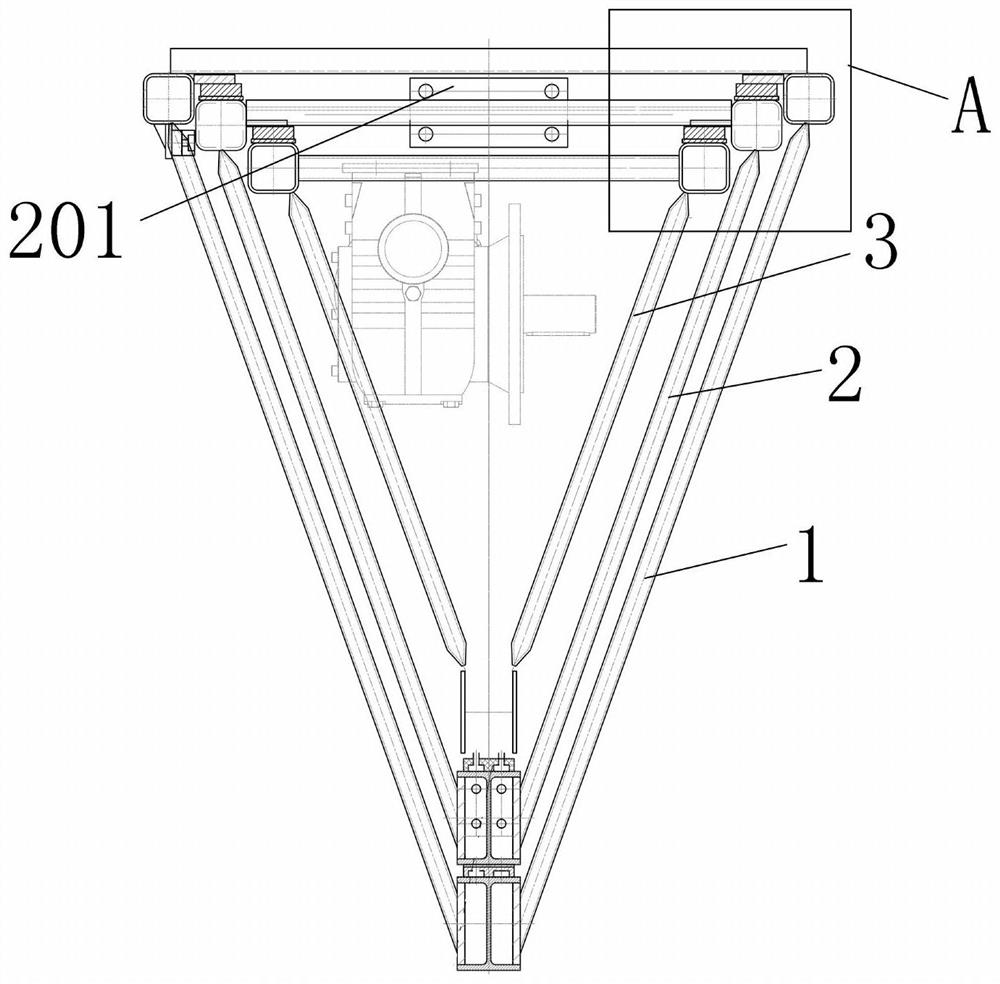

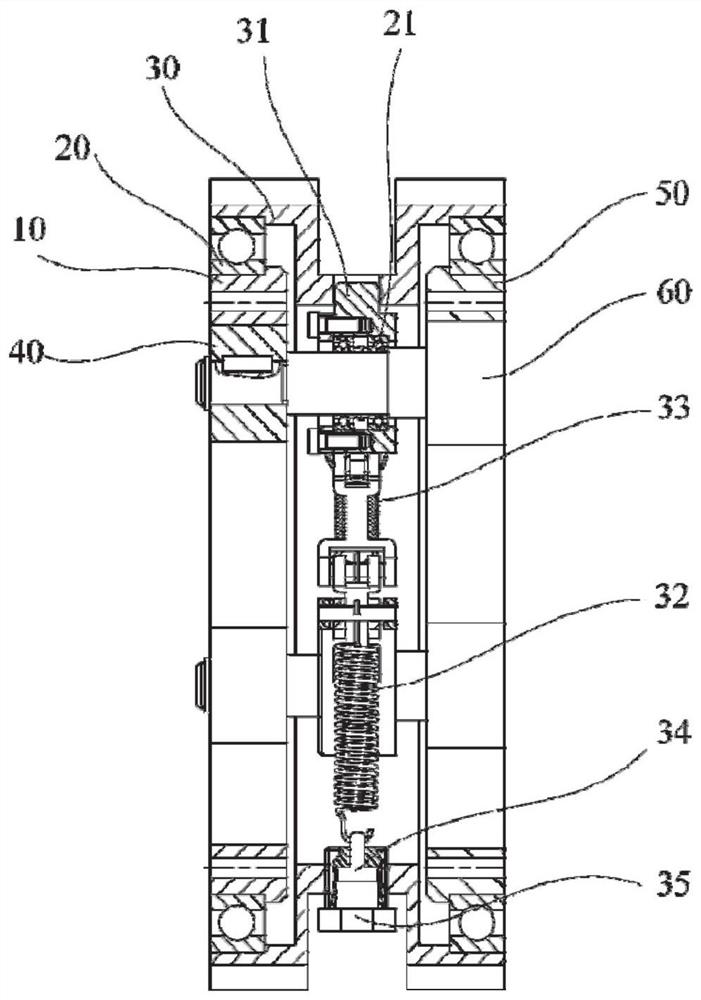

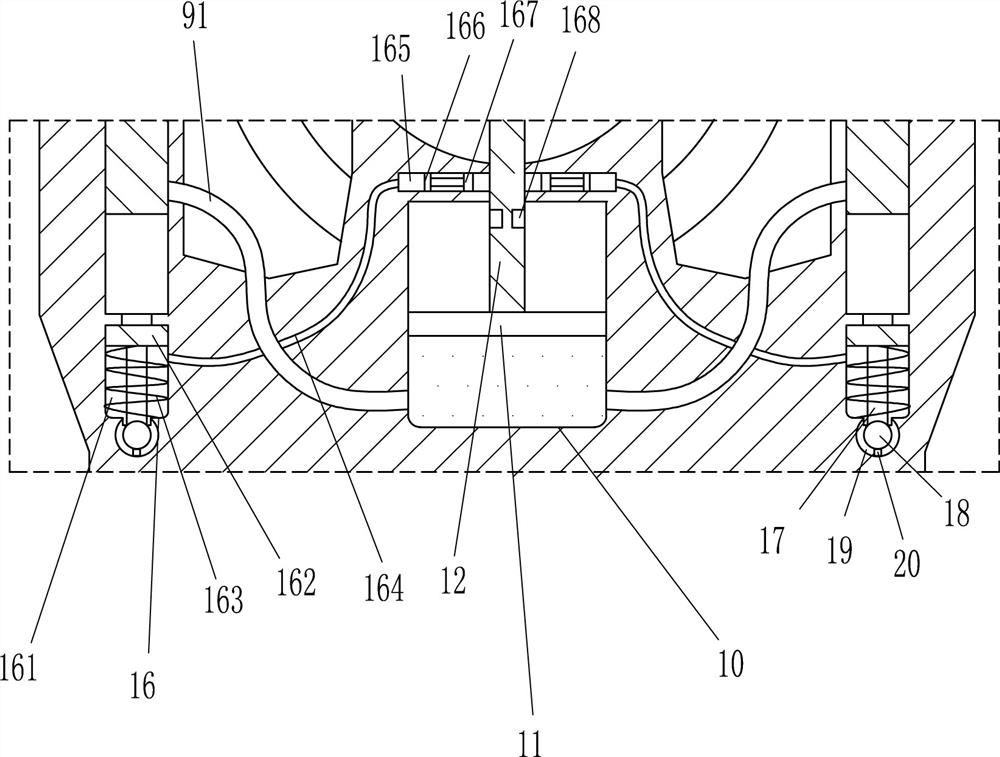

Tension bearing

The invention discloses a tension bearing, and belongs to the technical field of bearings. The tension bearing comprises first inner rings, second inner rings, balls, retainers, an outer ring, tensionblocks and bolts, wherein two first inner rings, two second inner rings, two balls and two retainers are provided, and are symmetrically arranged on two sides of the outer ring in an axial direction;the first inner rings, the second inner rings and the outer ring are coaxially arranged; the second inner rings are arranged outside the first inner rings in a sleeving manner; the first inner ringsand the second inner rings are in clearance arrangement to form inner oil storage cavities; the tension blocks are mounted on the outer sides of the first inner rings; the tension blocks are in hollowround table shapes; horn-shaped openings are formed in the outer sides of the first inner rings, and the inner walls of the first inner rings are attached to the outer walls of the tension blocks; the tension blocks comprise upper tension half blocks and lower tension half blocks which are inserted mutually. The two tension blocks clamp the first inner rings, so that the bearing is fixedly mounted on rotating shafts with different diameters to achieve a tension effect.

Owner:新昌沛斯轴承配件有限公司

Winding mechanism of T2 ring-shaped winding machine

InactiveCN113044663AAct as tensionAvoid peeling paintFilament handlingCoils manufactureWinding machineElectric machinery

The invention discloses a winding mechanism of a T2 ring-shaped winding machine. The winding mechanism comprises a baseplate, wherein a supporting column and a sleeve are fixedly welded onto the top surface of the baseplate in sequence; a cleaning and tensioning assembly is arranged at the upper end of the supporting column; a limiting column is slidably connected into the sleeve in a sleeving manner; a limiting screw rod is mounted on the side wall of the sleeve; a supporting plate is fixedly welded to the top of the limiting column; a fixing column used for fixing a coil core is arranged at the top of the supporting plate; a clamping block is arranged at the upper end of the fixing column in an integral-forming manner; a bracket is fixedly welded to one end of the surface of the baseplate; a driving motor is mounted at the top of the bracket; one end of the rotating shaft penetrates through the top of the bracket and is fixedly connected with a connecting block; a clamping groove is formed in the bottom of the connecting block; a connecting rod is slidably connected onto the side wall of the bracket in an inserting manner; a fixing frame is fixedly welded to one end of the connecting rod; and a pressing wheel is mounted on the fixing frame. The winding mechanism is high in winding efficiency and precision; the labor intensity is greatly reduced; and human resources are saved.

Owner:杭州正昇安全科技有限公司

Chain tensioning device

The invention discloses a chain tensioning device. The chain tensioning device is characterized in that one end of a fixed shaft is fixed to a bottom cover of a transmission box through a lock nut, a rotary sleeve is mounted at the other end of the fixed shaft through a lock nut, one threaded end of a pin penetrates through a tensioning nylon wheel to be mounted on the rotary sleeve through a lock nut, and a tension spring hole is drilled at the tail end of the rotary sleeve. The chain tensioning device can be used with a chain to play a role in tensioning, the tensioning nylon wheel is simple in processing and manufacturing and low in cost, the tensioning device is convenient to mount, production process is simplified, production cost is reduced, and production efficiency is improved.

Owner:SHANDONG HENGIN AGRI & ANIMAL HUSBANDRY MACHINERY

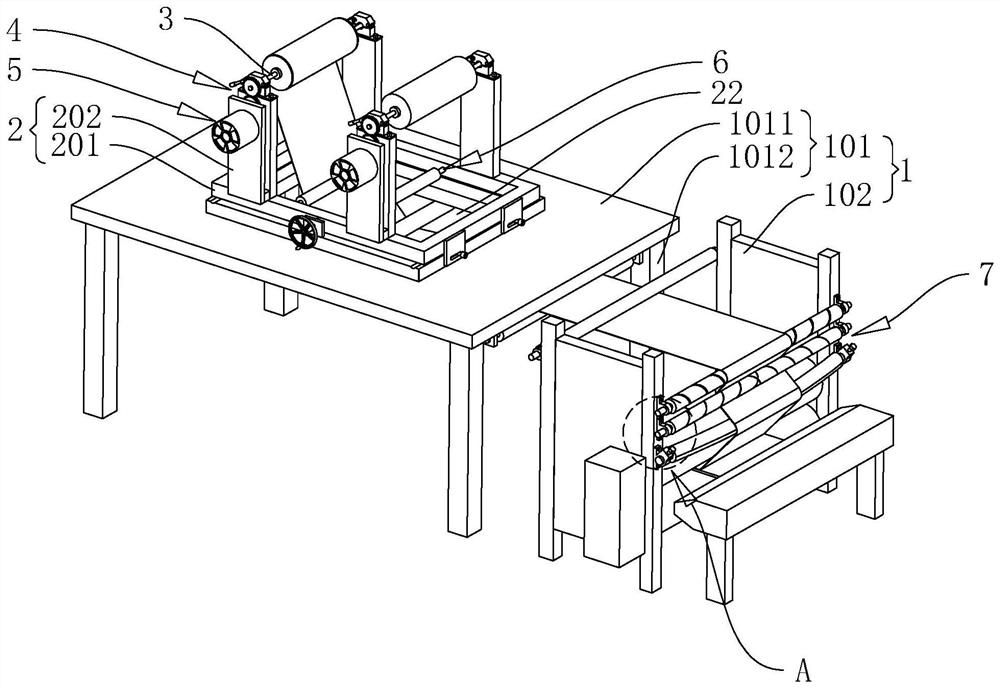

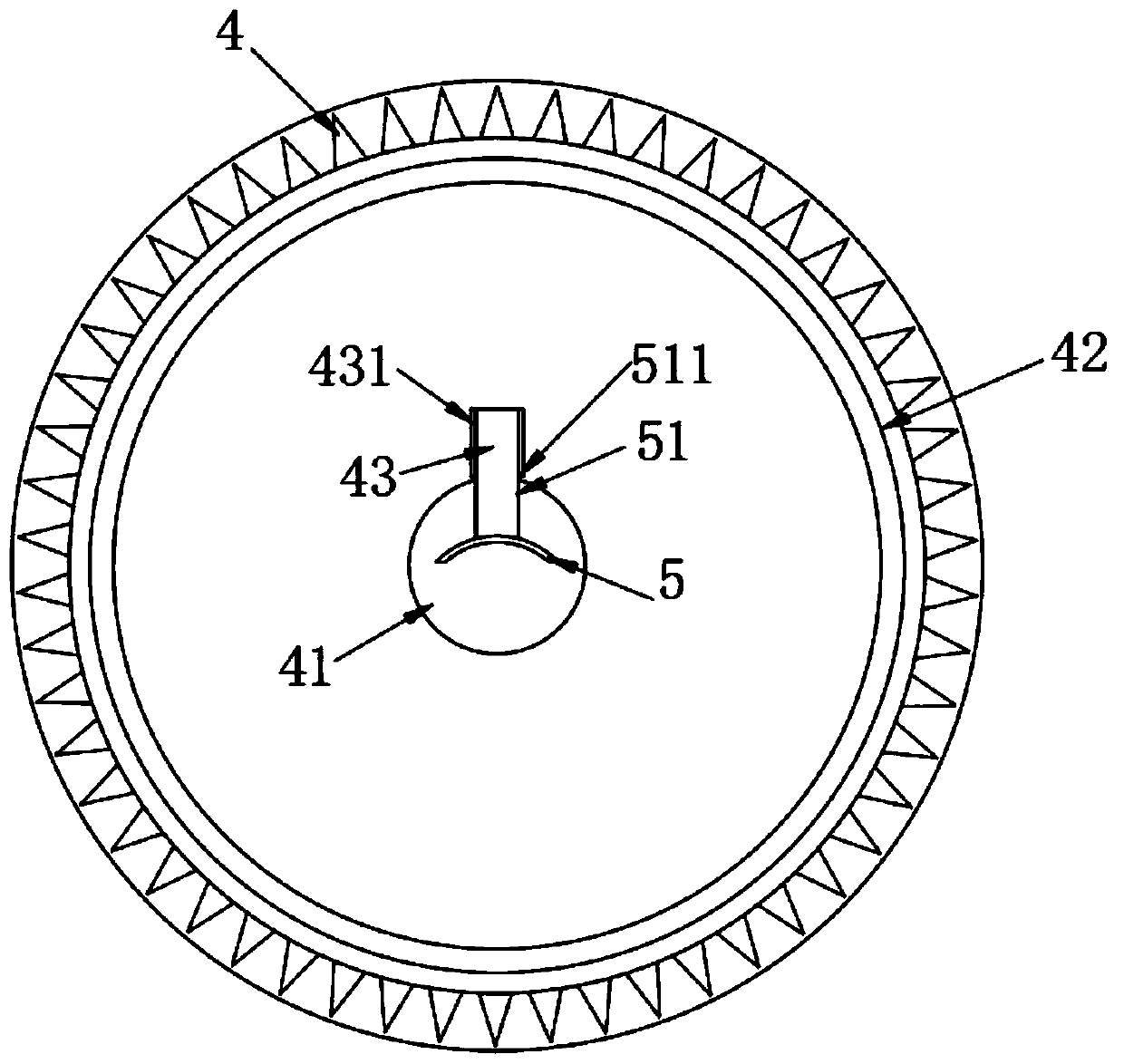

Ground wire and core wire automatic wire placing and stranding device for cable processing

ActiveCN111564260AImprove stabilityEasy to reinforceCable/conductor manufactureElectric machineStructural engineering

The invention belongs to the technical field of cable processing, and particularly relates to a ground wire and core wire automatic wire placing and stranding device for cable processing. The device comprises a workbench, wherein the left side of the top of the workbench is fixedly connected with a wire placing plate, the top of the workbench is fixedly connected with a wire distribution block, the wire distribution block is positioned on the right side of the wire placing plate, five through holes are formed in the wire distribution block, the top of the workbench is fixedly connected with amotor, and the motor is electrically connected with an external power supply. According to the invention, the wire placing plate and the winding roller are arranged at the top of the workbench, the wire distribution block internally provided with the through holes and the gear ring internally provided with the through groove are sequentially arranged between the wire placing plate and the windingroller from left to right, the gear ring is meshed with the gear at the output end of the motor at the top of the workbench, the ground wire and the core wire penetrate through the through holes and the through groove to be fixed to the winding roller before machining, the pressing plate is arranged in the through groove and can press the ground wire and the core wire, and the stability of the ground wire and the core wire during stranding can be improved.

Owner:嘉兴旭耀电缆科技有限公司

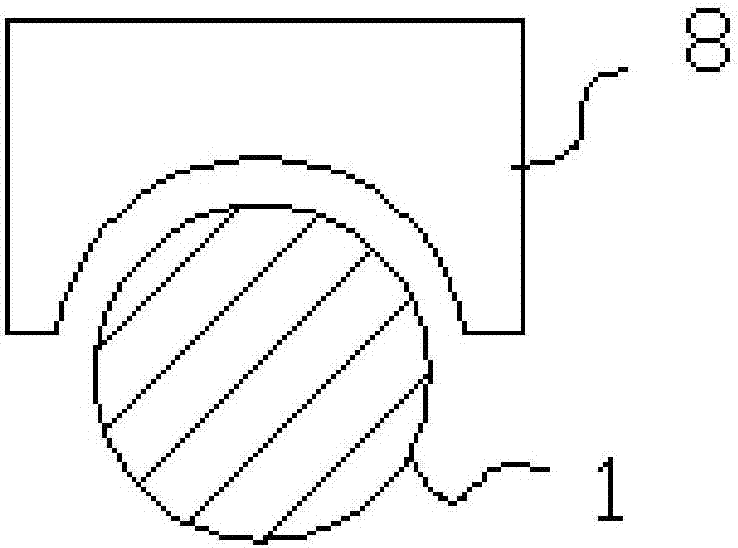

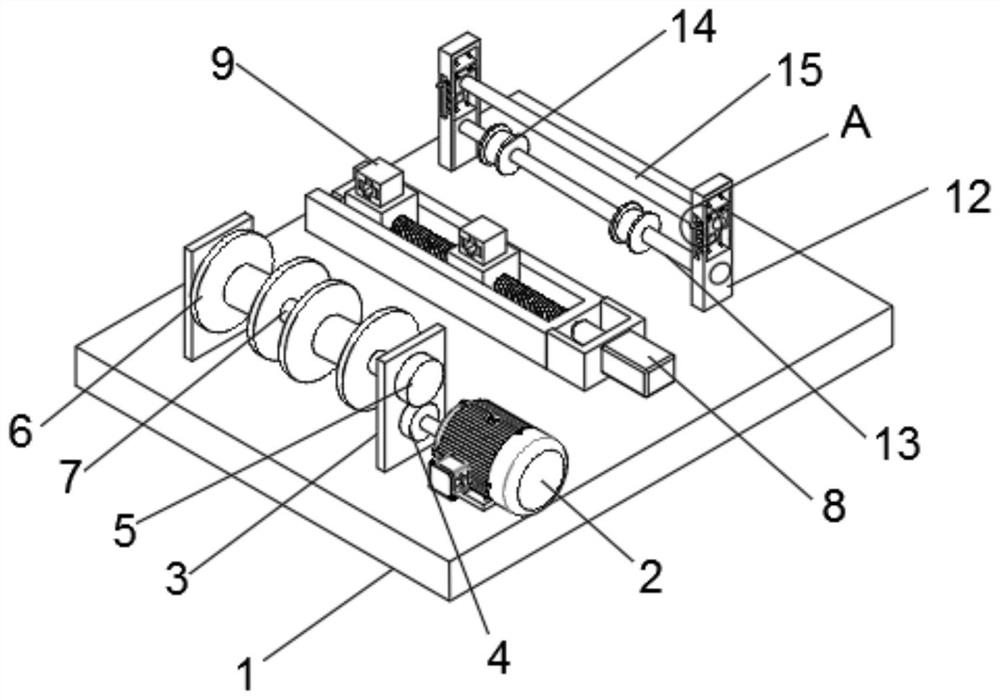

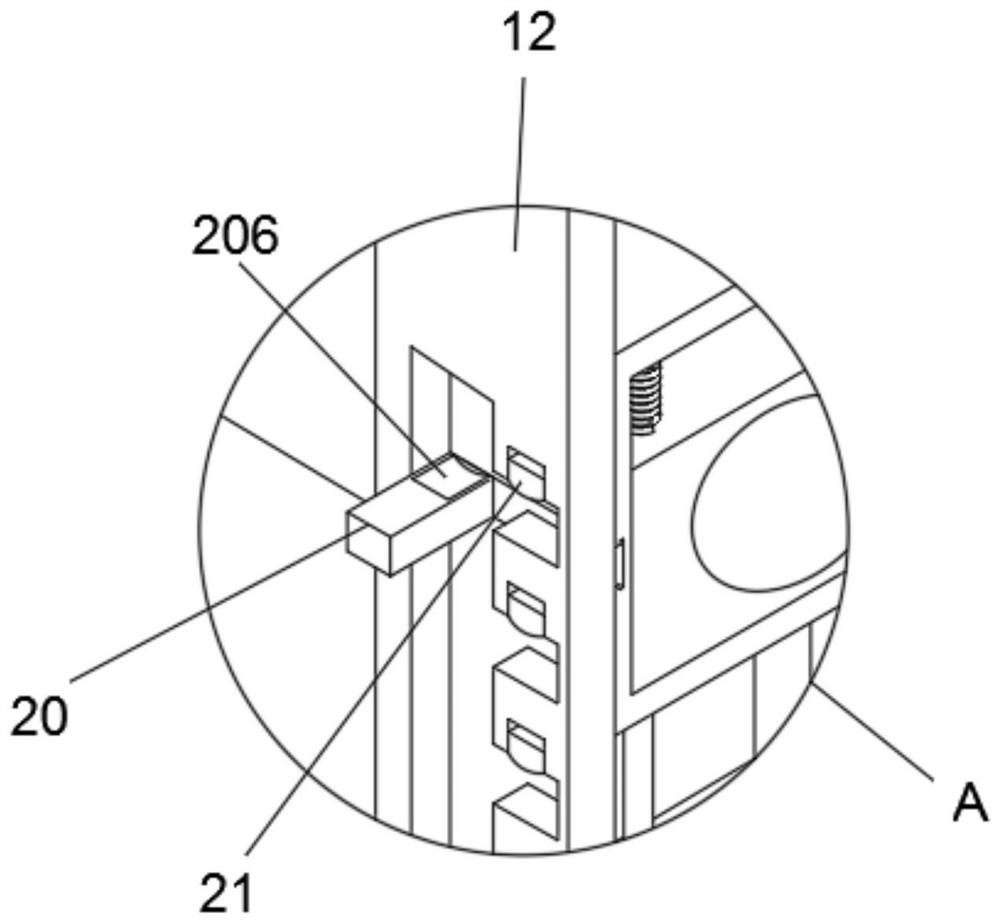

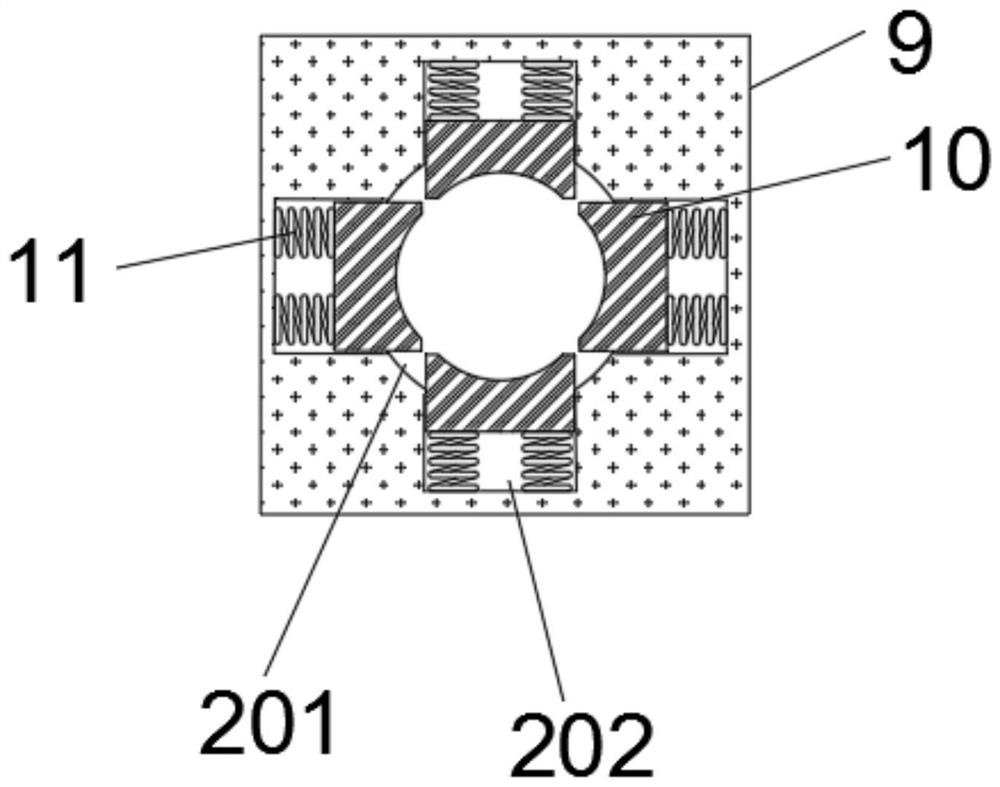

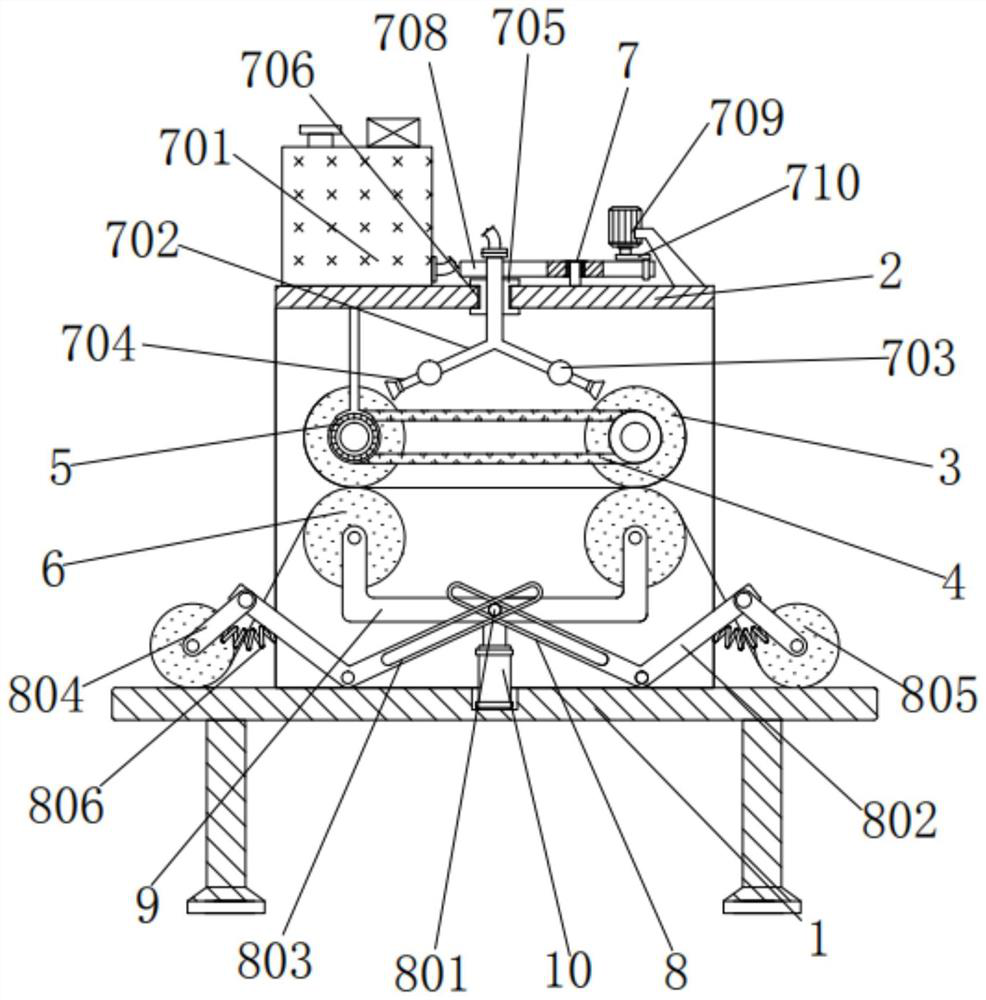

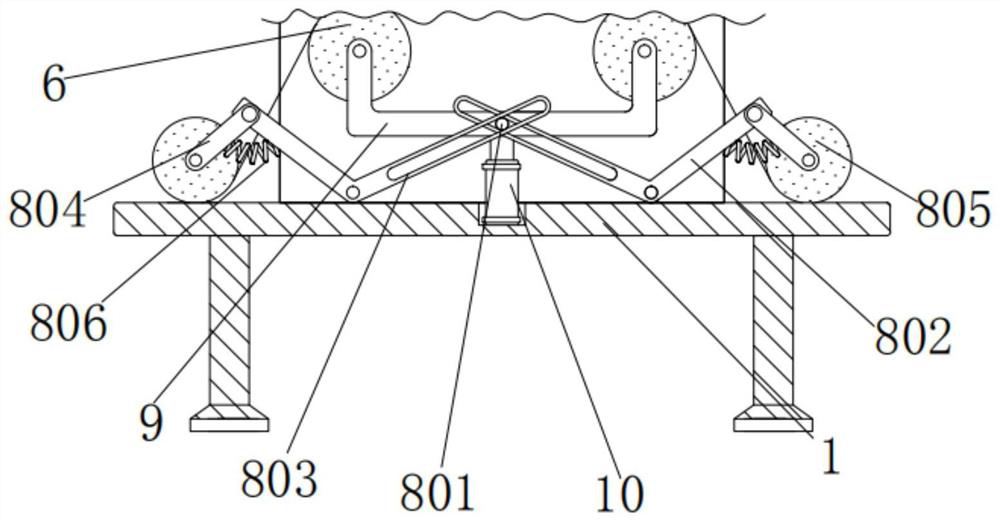

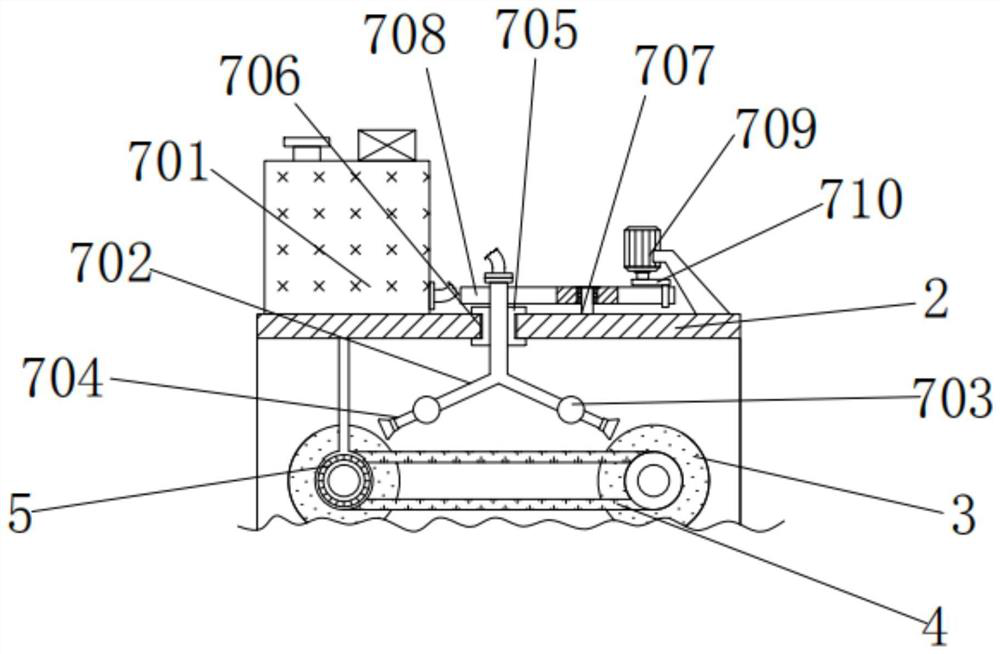

A tungsten carbide spraying equipment with both grinding and surface defect repairing functions

ActiveCN111962003BEasy to cleanAct as tensionMolten spray coatingGrinding drivesDrive wheelDefect repair

The invention provides a tungsten carbide spraying equipment with both grinding and surface defect repairing functions, including a base, a casing, a protective cover, a collecting frame, a collecting tank, a roll shaping frame structure, a cylinder, an arc surface polishing frame structure, and guide rails. Adjust the structure of the spray gun fixing frame, the structure of the processing and cleaning frame, the Y-shaped frame, the driving motor, the driving wheel, the driven wheel and the roll to be processed. The shell bolts are connected to the upper part of the base; the protective cover hinge is connected to the shell Inside left; the collection shelf described is bolted to the upper middle of the base. The beneficial effects of the present invention are as follows: through the arrangement of the cylinder, the polishing motor, the rotating roller, the brush and the grinding belt, it is beneficial to grind and polish the surface of the roll to be processed, and the polishing motor drives the cylinder to rotate, so that the grinding belt can polish the surface of the roll to be processed Grinding, and at the same time, the brush cleans the unmelted tungsten carbide powder remaining at the corners of the front and rear ends of the roll to be processed.

Owner:HELI TECH ENERGY CO LTD

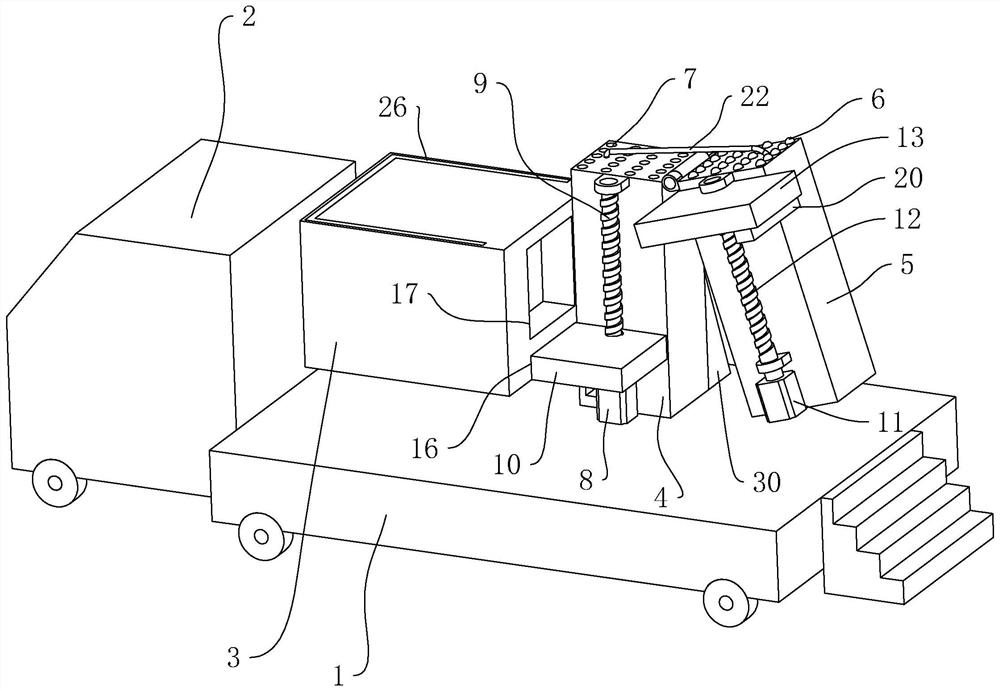

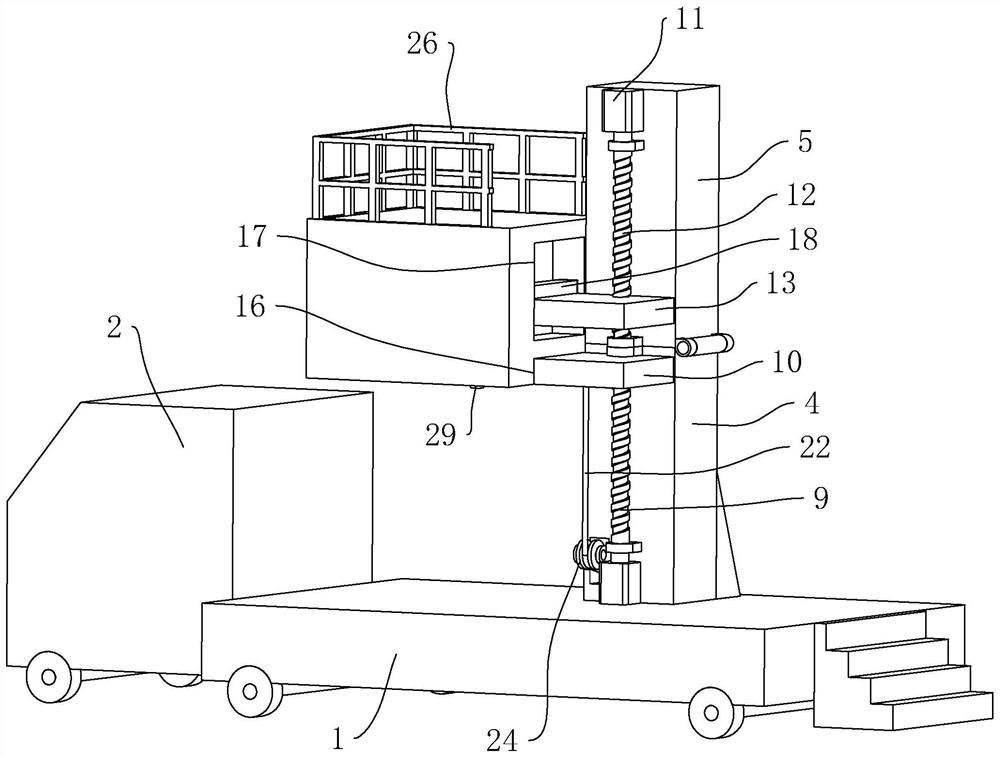

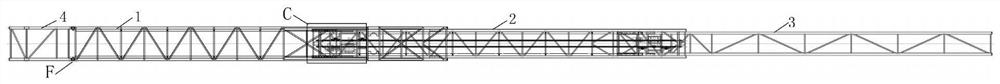

Bridge cast-in-place box girder in-span non-bearing convenient construction support

ActiveCN113620216ALower vertical heightReduce the overall heightLifting devicesBridge erection/assemblyArchitectural engineeringStructural engineering

The invention relates to a bridge cast-in-place box girder in-span non-bearing convenient construction support which comprises a trolley body and a trolley head, the trolley head is arranged on one side of the trolley body, a folding lifting mechanism is arranged on the trolley body and comprises a lifting platform, a first lifting supporting column and a second lifting supporting column, and the first lifting supporting column is vertically arranged on the trolley body. One end of the second lifting supporting column is hinged to one end of the first lifting supporting column, a linkage locking assembly is arranged between the first lifting supporting column and the second lifting supporting column, and a lifting assembly for driving the lifting table to slide on the first lifting supporting column and the second lifting supporting column is arranged on the trolley body. An operator can conveniently move the bridge cast-in-place box girder in-span non-bearing convenient construction support.

Owner:无锡大诚建设有限公司

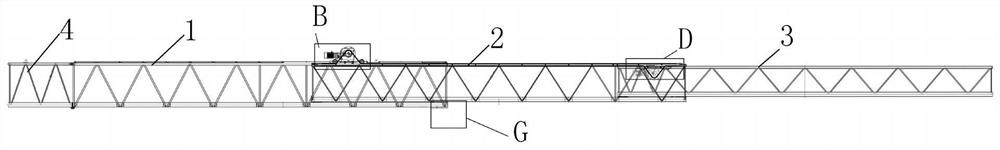

Crossing frame telescopic main arm and double-arm telescopic push type crossing frame

PendingCN111969483AAvoid tooth skippingBlocking time is controllableApparatus for overhead lines/cablesEngineeringComputer hardware

Owner:浙江省建设工程机械集团有限公司

Double-row planetary reducer based on friction transmission

ActiveCN112984065ALarge transmission ratioHigh torque outputGearing detailsFriction gearingsReduction driveReducer

The invention discloses a double-row planetary reducer based on friction transmission. The double-row planetary reducer comprises a planetary carrier, a first friction wheel ring, a second friction wheel ring, a plurality of first planetary friction wheel shafts and a plurality of second planetary friction wheels, the planetary carrier comprises a lantern ring and a plurality of planetary wheel bearing seats arranged on the lantern ring, the lantern ring is arranged outside the first friction wheel ring and the second friction wheel ring in a sleeving mode and rotationally connected with the first friction wheel ring and the second friction wheel ring, the second planetary friction wheel is located in the second friction wheel ring, the first planetary friction wheel shafts are located in the first friction wheel ring and penetrates through the second planetary friction wheels, each planet wheel bearing seat is rotationally connected with the corresponding first planet friction wheel shafts, each first planet friction wheel shaft is fixedly connected with the corresponding second planet friction wheels, the first friction wheel ring is fixed, the lantern ring is connected with a power source, and power of the speed reducer is input through the lantern ring and output through the second friction wheel ring. The double-row planetary reducer has the advantages of compact structure, reliable work, large transmission ratio, adjustable positive pressure and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Processing equipment for helical gear pair keyway

InactiveCN111958027AExtended production timeIncrease productivityMilling equipment detailsDriving apparatusElectric machineryDrive wheel

The invention discloses processing equipment for a helical gear pair keyway. The processing equipment comprises a bottom rack; a lifting chassis is installed on the right side of the upper surface ofthe bottom rack; a workbench is installed on the right side of the lifting chassis, and a second control motor is arranged inside the workbench; an output end of the second control motor is equipped with a turntable, and the surface of the turntable is provided with a fixed pin; a push rod is connected to the outer side of the fixed pin, and the right side of the push rod is equipped with a firstdriven rod; and the right side of the first driven rod and the left side of a second driven rod are connected with a clamp plate, and the bottom of the clamp plate is provided with a sliding chute. According to the processing equipment for the helical gear pair keyway provided by the invention, a driven wheel and a synchronous wheel are connected through a telescopic rod, and through the arrangement of a stepping motor and a rack, a cutter can conveniently extend to operate a helical gear tooth hole, so that a working operation of an operator is facilitated to be changed into a mechanical operation, thus the production time is accelerated, and the production efficiency is improved.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

Printing and dyeing device for textiles

InactiveCN112210919AIncreased persistenceTo achieve continuous operationLiquid/gas/vapor textile treatmentMechanical engineeringIndustrial engineering

The invention discloses a printing and dyeing device for textiles. The printing and dyeing device comprises a bottom frame; a square frame is fixedly connected to the top of the bottom frame; a telescopic rod of an air cylinder is fixedly connected with the bottom of a support; and a material spraying assembly is arranged above the square frame. According to the printing and dyeing device for thetextiles, through the arrangement of a charging barrel and the communication of a three-way pipe, circular pipes and spray heads, the spray heads can continuously spray on printing and dyeing rollers,so that the printing and dyeing continuity is greatly improved, the continuous operation is realized, the printing and dyeing efficiency is improved, the spray heads can swing back and forth along with the printing and dyeing device, and the spray uniformity of the spray head is improved, and the printing and dyeing quality is ensured; through clearance fit of round rods and through grooves and arrangement of pressing rollers, the textile fabric can be tensioned, the fabric is smooth during printing and dyeing, and the printing and dyeing effect is further improved; and the round rollers canabut against or be separated from the printing and dyeing rollers at the same time, the pressing rollers can abut against or be separated from the bottom frame at the same time, and then the textile fabric can be conveniently filled, thereby improving use practicality.

Owner:SHAOXING DAWEI KNITTING MACHINERY

A motor mounting bracket

InactiveCN104393707BAdd position adjustment structureImprove convenienceSupports/enclosures/casingsControl theoryEngineering

Owner:ZHEJIANG OCEAN UNIV

An underwater dedusting and grinding machine

ActiveCN110714100BAvoid stickingAvoid accumulationSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentBristleDust control

The invention belongs to the technical field of leather processing, and in particular relates to an underwater dust-removing leather grinding machine. The technical problem to be solved is how to provide an underwater dust-removing leather grinding machine that can avoid dander from adhering to leather. An underwater dust removal and leather grinding machine, including a liquid storage platform, a guide roller, a mounting frame, a sliding shaft, a mounting plate, a pressure roller, a first cylinder, a connecting rod, a first piston, a connecting pipe, a second cylinder, The second piston, etc.; guide rollers are arranged symmetrically on the left and right sides of the liquid storage platform, and mounting brackets are arranged symmetrically on the front and back of the liquid storage platform, and there are chutes on the mounting brackets, and sliding shafts are movable in the chute. A mounting plate is arranged between them, and pressure rollers are arranged symmetrically on the mounting plate. The invention achieves the effects of being able to avoid dander from adhering to the leather and from accumulating wear debris in the bristles.

Owner:平邑县经发企业服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com