Pipe-climbing type cutting electric beveling machine

A technology for cutting bevels and cutting mechanisms, which is applied in the field of beveling machines, can solve the problems of poor surface quality, bulky size, and low efficiency, and achieve the effects of high cutting precision, improved versatility, and liberated manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

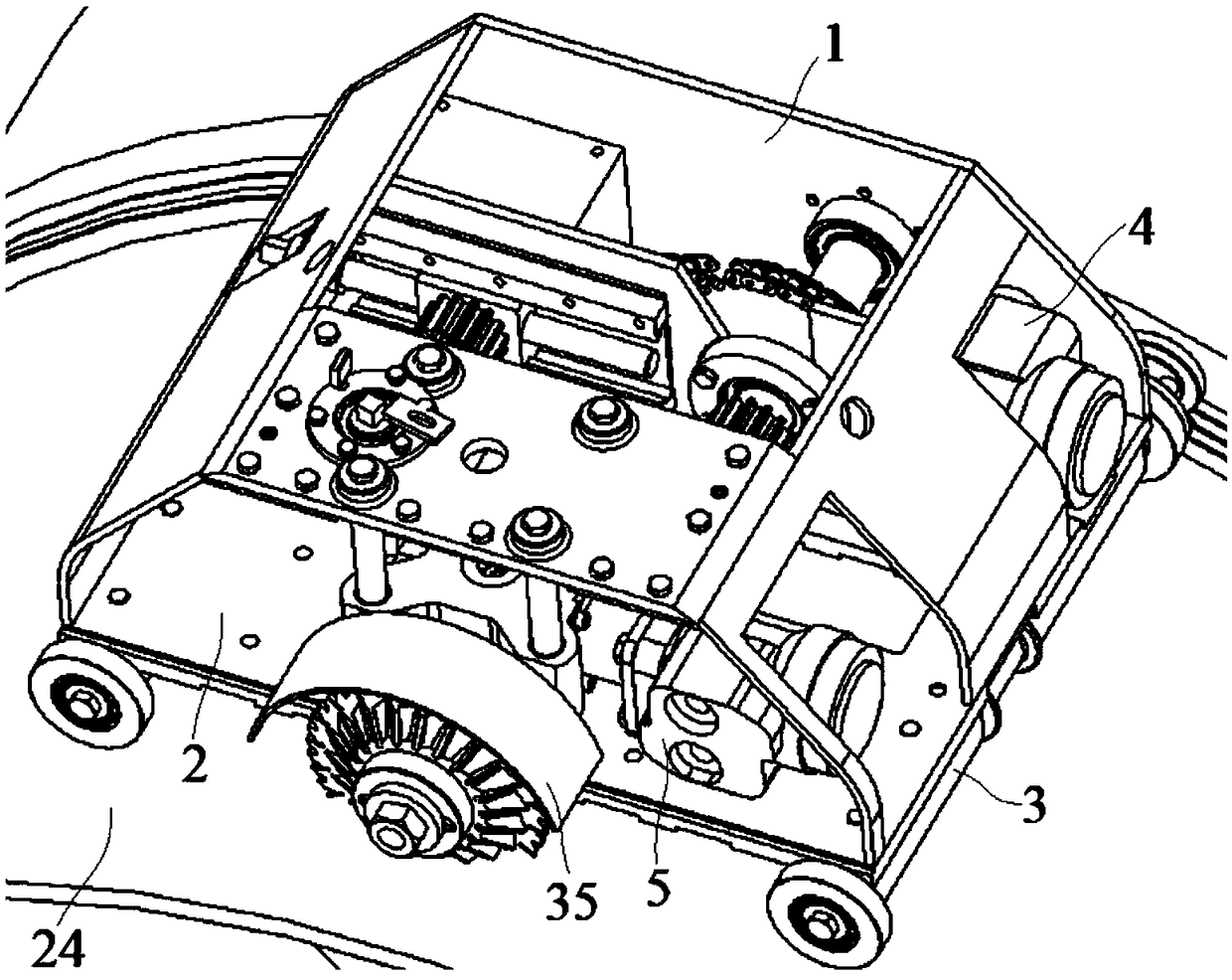

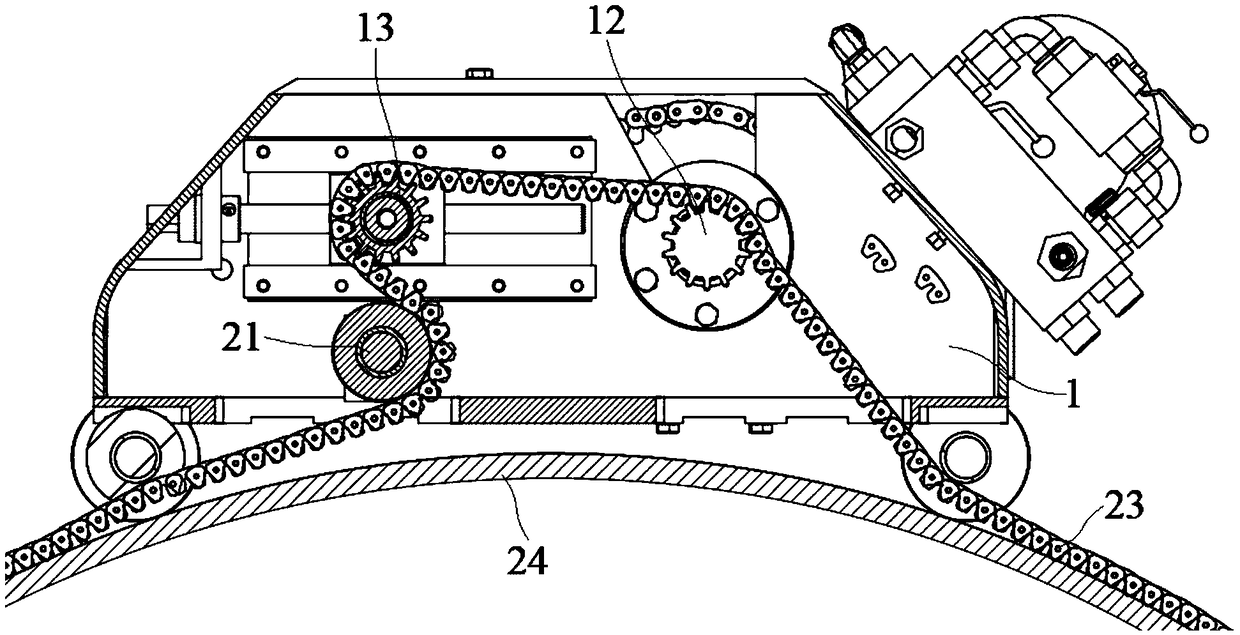

[0038] Embodiment 1: A pipe climbing type cutting beveling machine, comprising a frame 1, a crawling wheel set 3 installed on the bottom plate 2 of the frame 1, a driving mechanism 4 and a cutting mechanism 5, the driving mechanism 4 and the cutting mechanism 5 Both are installed on rack 1;

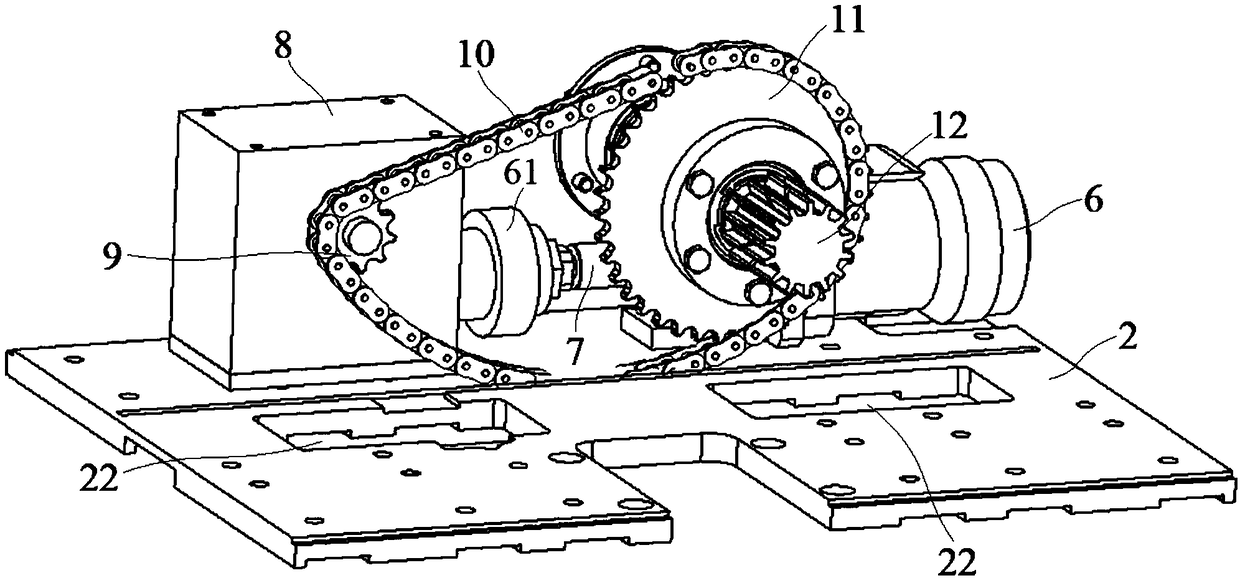

[0039] The drive mechanism 4 includes a drive motor 6, a speed reducer 8, a drive gear 9 connected to the output shaft of the speed reducer 8, a main gear 11 connected to the drive gear 9 through a transmission chain 10, a first sprocket 12 and a second chain wheel 13, the drive motor 6 and the speed reducer 8 are connected by a connecting shaft 7, the main gear 11 and the first sprocket 12 are both sleeved on a rotating shaft 39, and the rotating shaft 39 is installed on the shaft through at least two bearing seats On the frame 1, the second sprocket 13 is rotatably mounted on the frame 1, and a through hole 22 is respectively opened on the bottom plate 2 of the frame 1 below the first s...

Embodiment 2

[0047] Embodiment 2: A pipe climbing type cutting beveling machine, comprising a frame 1, a crawling wheel set 3 installed on the bottom plate 2 of the frame 1, a driving mechanism 4 and a cutting mechanism 5, the driving mechanism 4 and the cutting mechanism 5 Both are installed on rack 1;

[0048] The drive mechanism 4 includes a drive motor 6, a speed reducer 8, a drive gear 9 connected to the output shaft of the speed reducer 8, a main gear 11 connected to the drive gear 9 through a transmission chain 10, a first sprocket 12 and a second chain wheel 13, the drive motor 6 and the speed reducer 8 are connected by a connecting shaft 7, the main gear 11 and the first sprocket 12 are both sleeved on a rotating shaft 39, and the rotating shaft 39 is installed on the shaft through at least two bearing seats On the frame 1, the second sprocket 13 is rotatably mounted on the frame 1, and a through hole 22 is respectively opened on the bottom plate 2 of the frame 1 below the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com