Plastic dipping structure of super-long chain

A dipping and chain technology, applied in the field of chain manufacturing, can solve problems such as large contact area, inability to coat chain links with dipping liquid, adverse effects of chain dipping effect, etc., to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

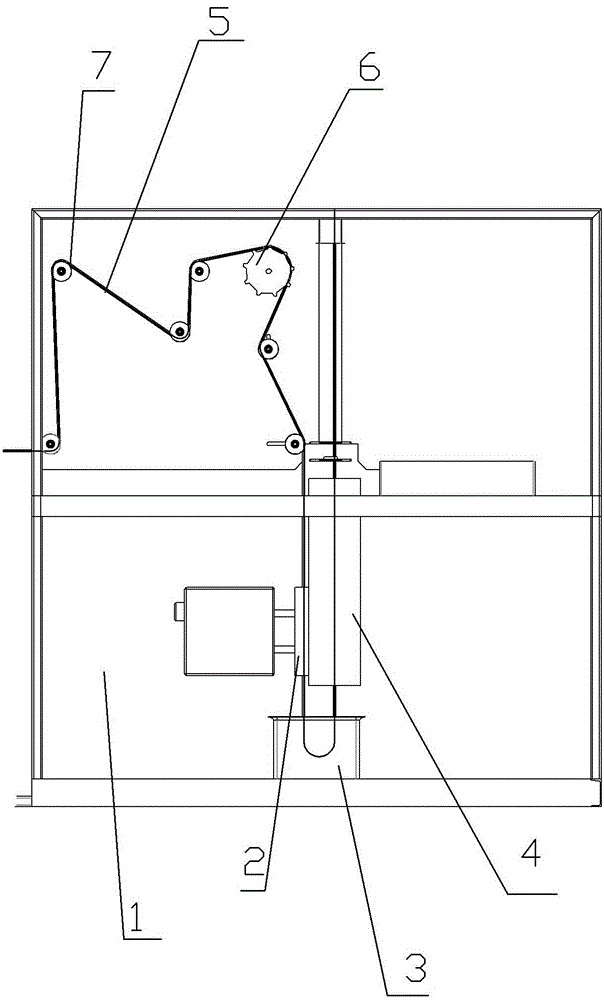

[0012] The reference signs in the accompanying drawings of the specification include: 1-frame; 2-electric heater; 3-dipping tank; 4-high-frequency heater; 5-super long chain; 6-guiding wheel; 7-driven wheel.

[0013] The embodiment is basically as attached figure 1 Shown: a super-long chain impregnation structure, including a frame 1, a guide device, a preheating device, a dipping device and a heating device; the guide device includes a guide wheel 6 and five driven wheels 7, and the super-long chain bypasses the guide When the wheel 5 and the driven wheel 7 wrap angle is not less than 120 °, it can ensure that the super long chain 5 is tensioned and the super long chain 5 is in a vertical state. The guide wheel 6 is rotatably connected with the frame 1; the preheating device is an electric heater 2, and the electric heater 3 is barrel-shaped, fixedly arranged below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com