A motor mounting bracket

A technology for mounting brackets and motor support, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve the problems of adhesion, affecting the operation of the motor, and poor reliability, and achieves lower operating costs and stable installation. Reliable, Convenience-enhancing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order for those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above objects, features and advantages of the present invention more clearly understood, the technical solutions in the present invention are further detailed below with reference to the accompanying drawings. illustrate.

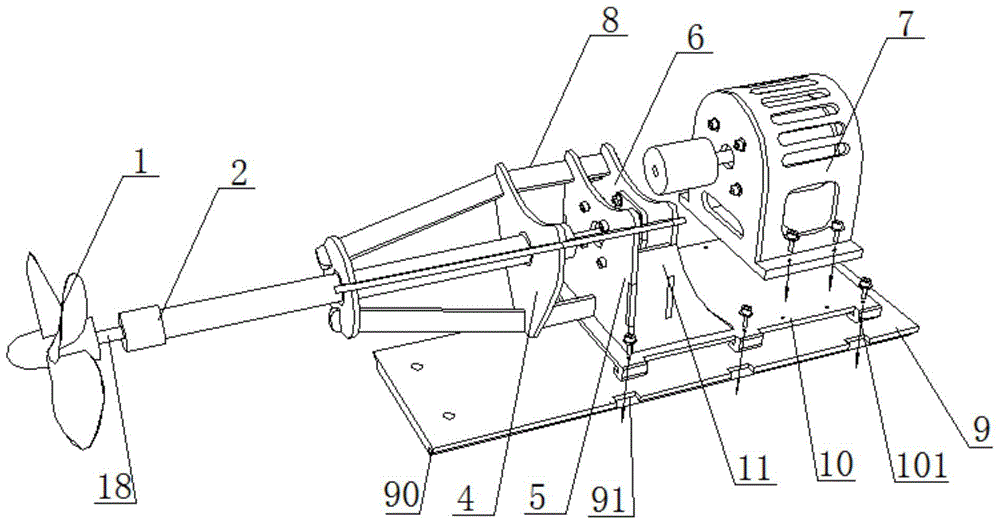

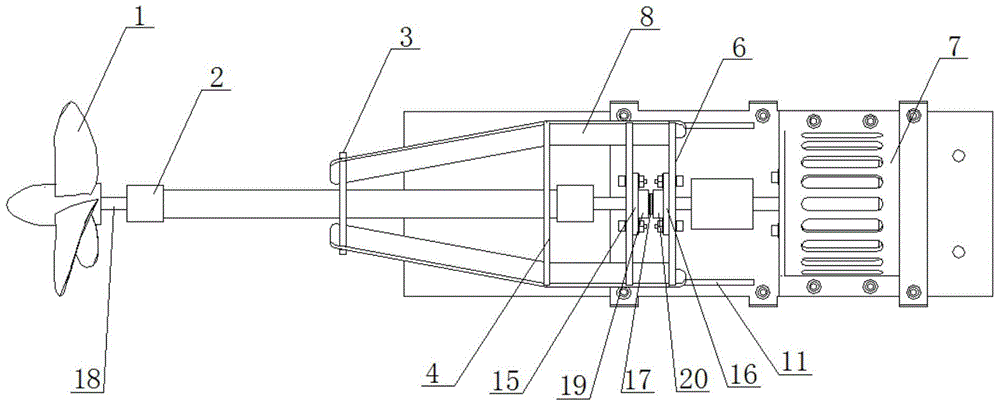

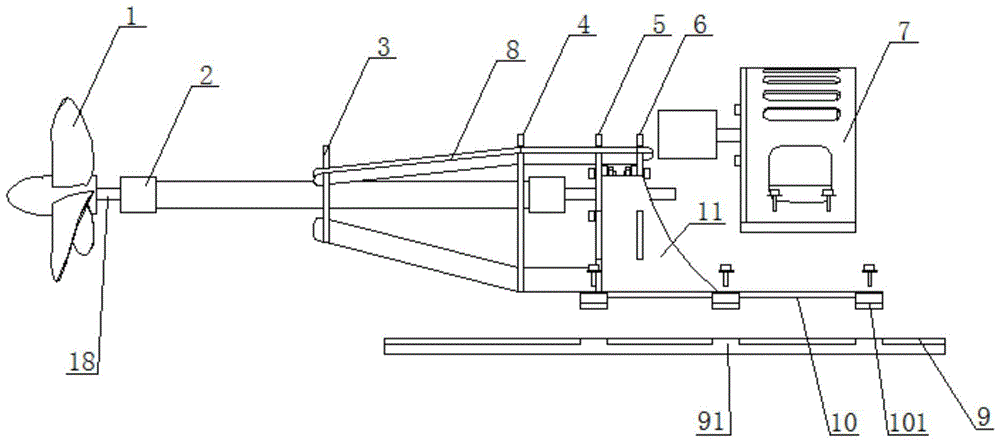

[0029] A motor mounting bracket, comprising a mounting base 10 and a support 7;

[0030] The mounting base 10 is slidably connected to the other side of the support member 7 with a guide rail plate 9, and a position adjustment structure is provided between the mounting base 10 and the guide rail plate 9. The mounting base 10 slides relative to the other side of the motor support member A guide rail plate 9 is connected, and a position adjustment structure is arranged between the installation base 10 and the guide rail plate 9. The position adjustment structure includes a guide rail 90, a detachable and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com