Patents

Literature

79results about How to "Reduces the possibility of loosening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

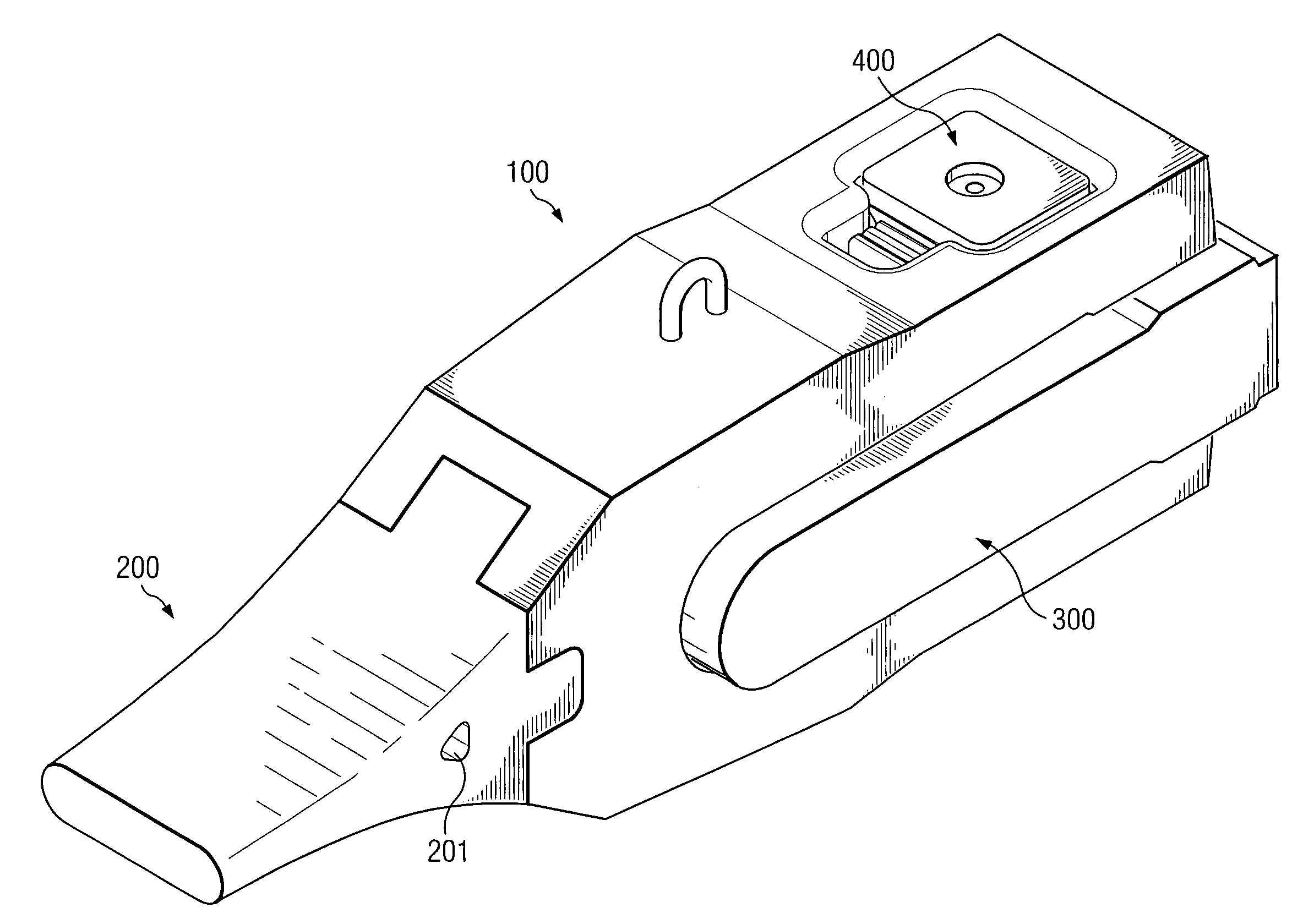

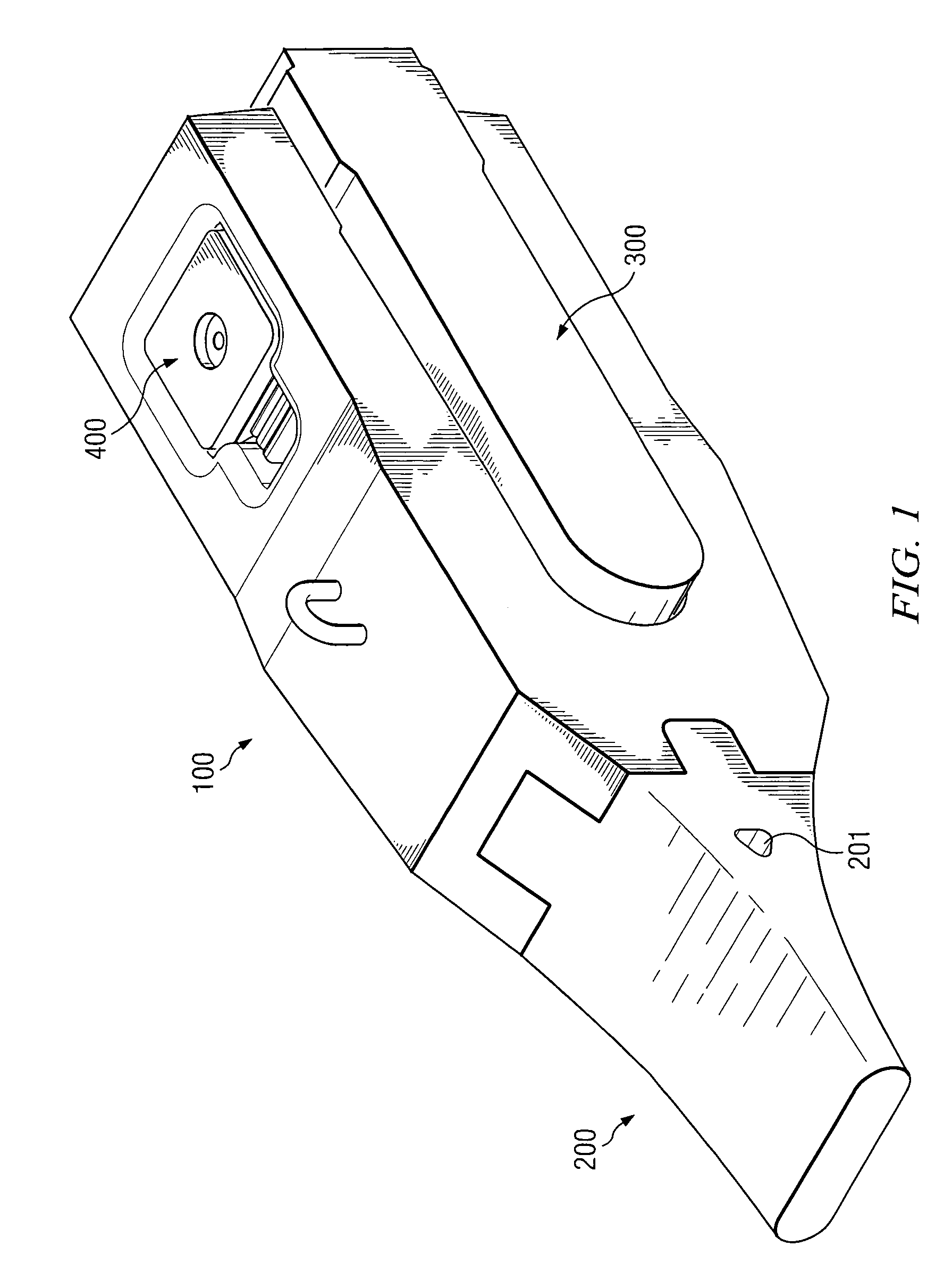

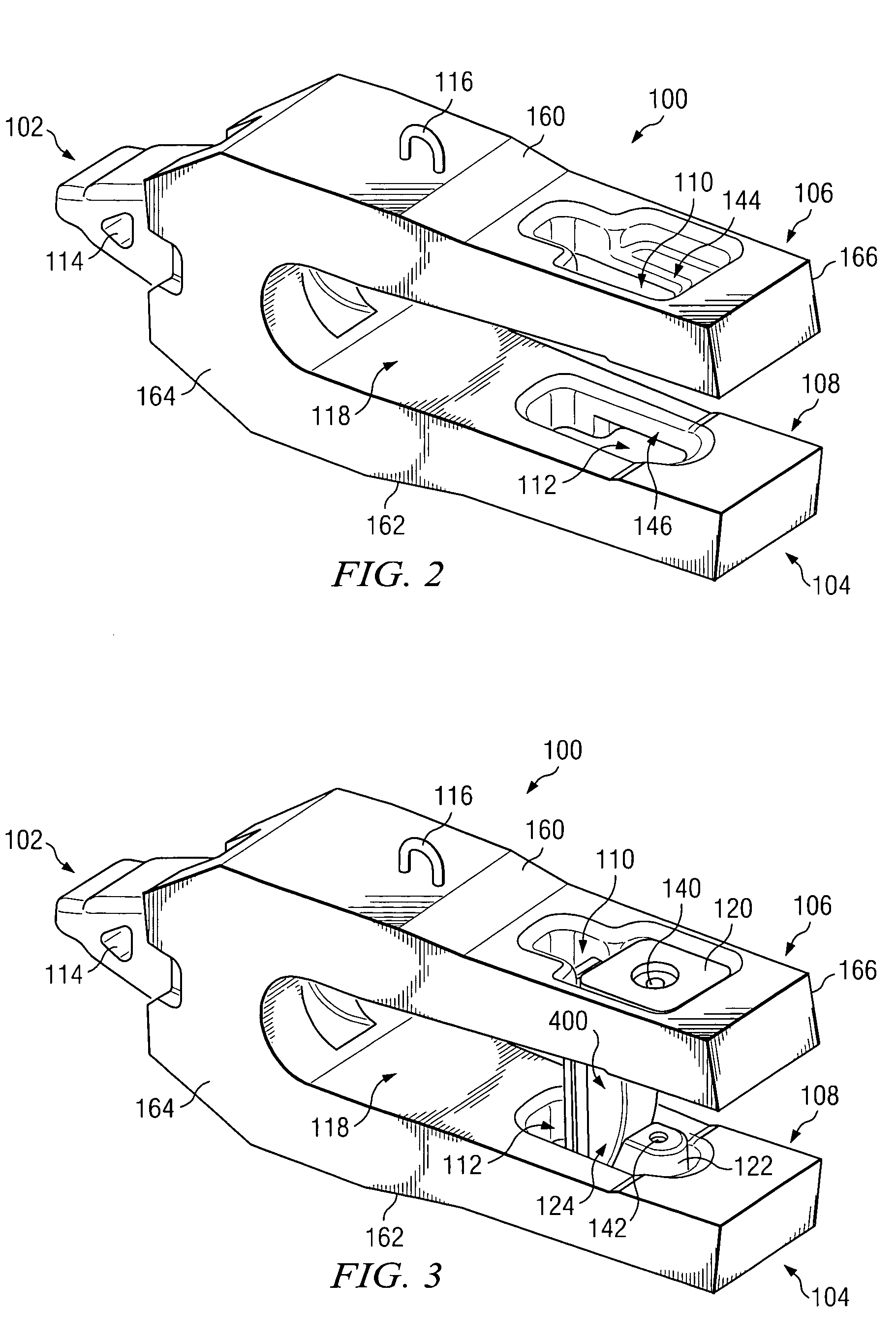

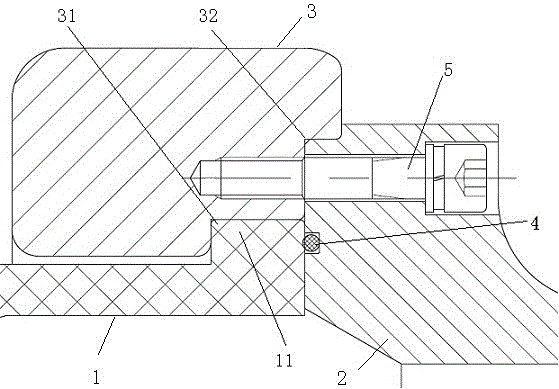

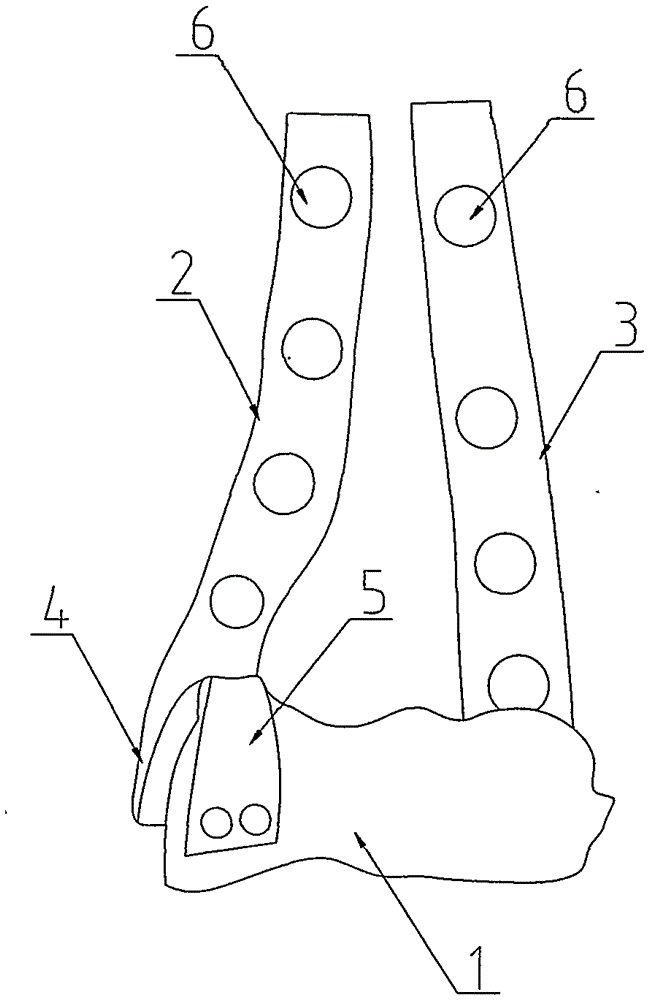

Tooth adapter having an elastomeric clamp assembly and method for using same

InactiveUS7036249B2Less susceptible to looseningReduces the possibility of looseningSoil-shifting machines/dredgersFastenerEngineering

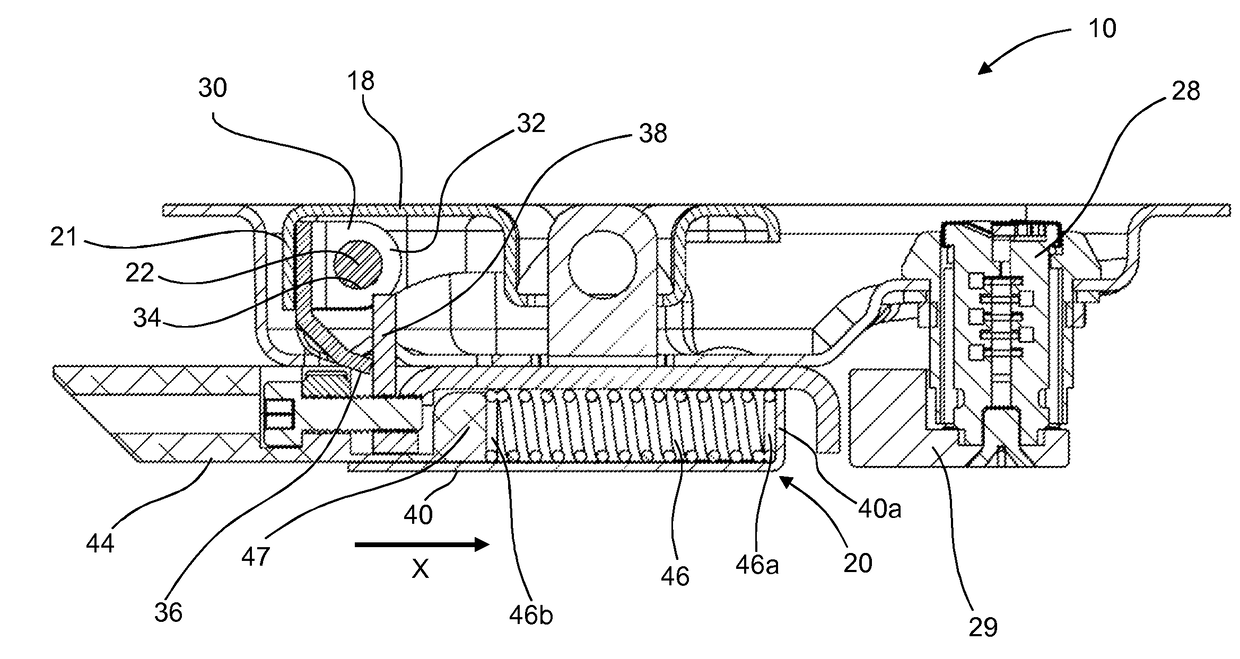

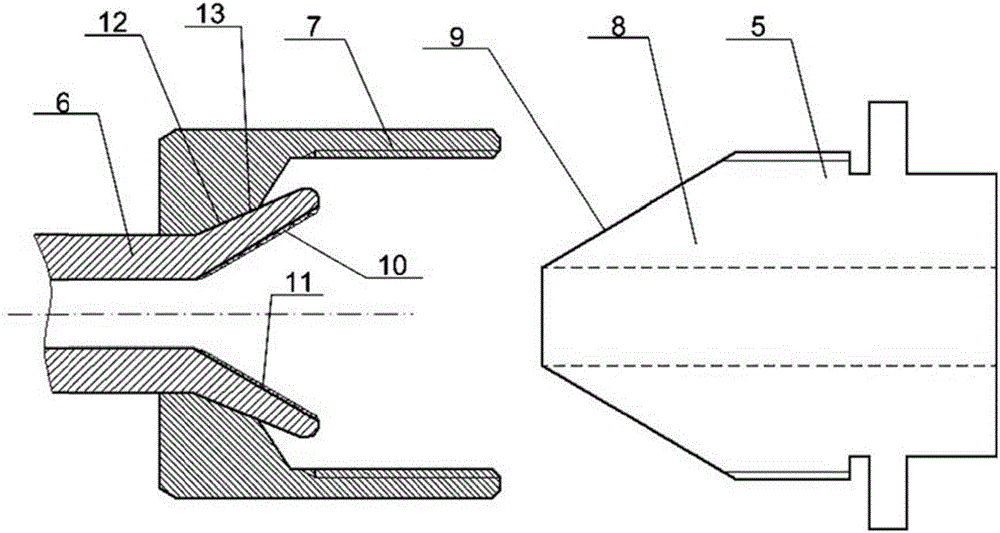

A tooth adapter having an elastomeric clamp assembly and a method for using the same are provided. The system includes a tooth adapter having a first end operable to receive a removable tooth point and a second end having an upper blade and a lower blade, the upper and lower blades at least partially defining a cavity configured to receive a tooth horn. An upper insert is configured to be disposed at least partially within an orifice in the upper blade, and a lower insert is configured to be disposed at least partially within an orifice in the lower blade. A wedge member having an elastomeric portion disposed between its first and second faces is positioned at least partially within the cavity, through a slot in the tooth horn, such that when a fastener is used to couple the upper and lower inserts through the slot in the tooth horn, the first face of the wedge member engages the tooth horn and the second face of the wedge member engages the upper and lower inserts, forming a rigid coupling between the tooth adapter and the tooth horn.

Owner:TRINITY IND INC

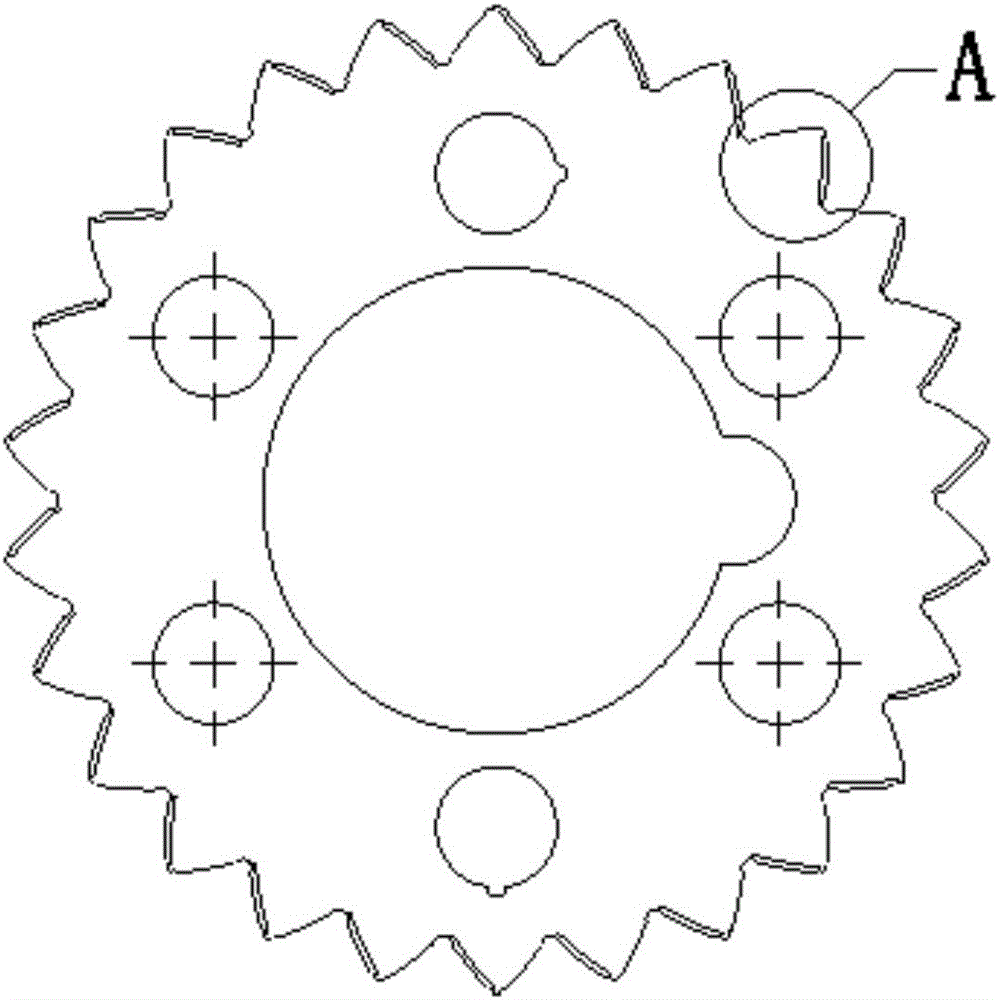

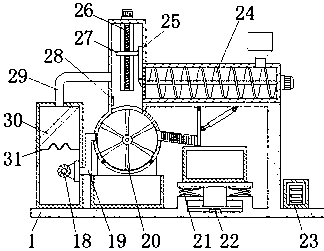

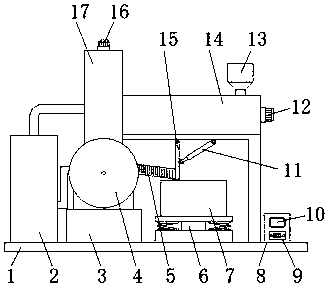

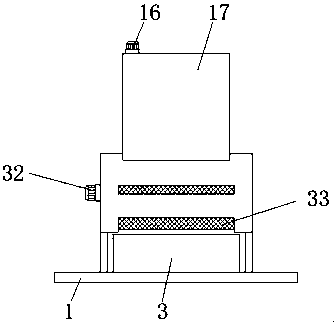

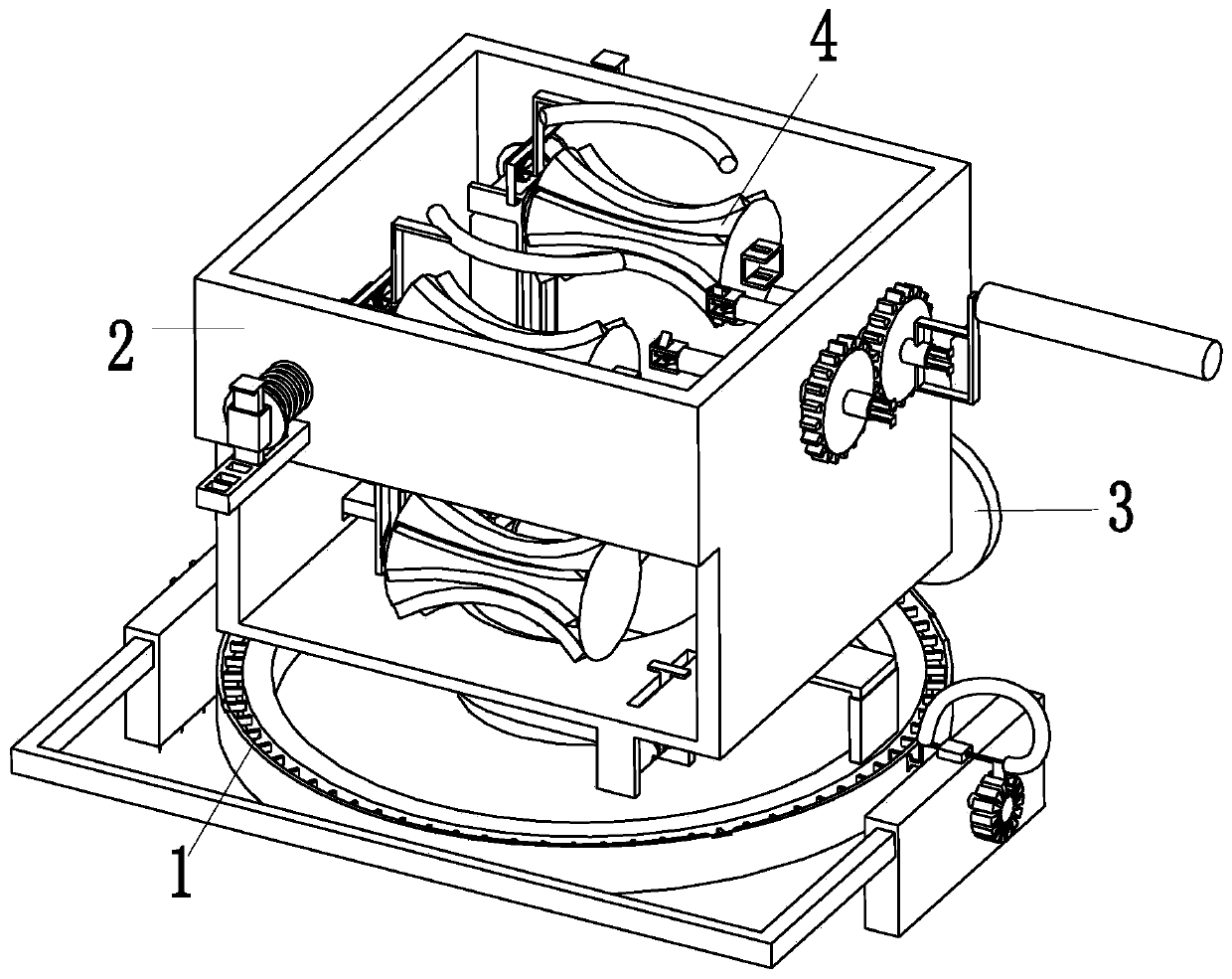

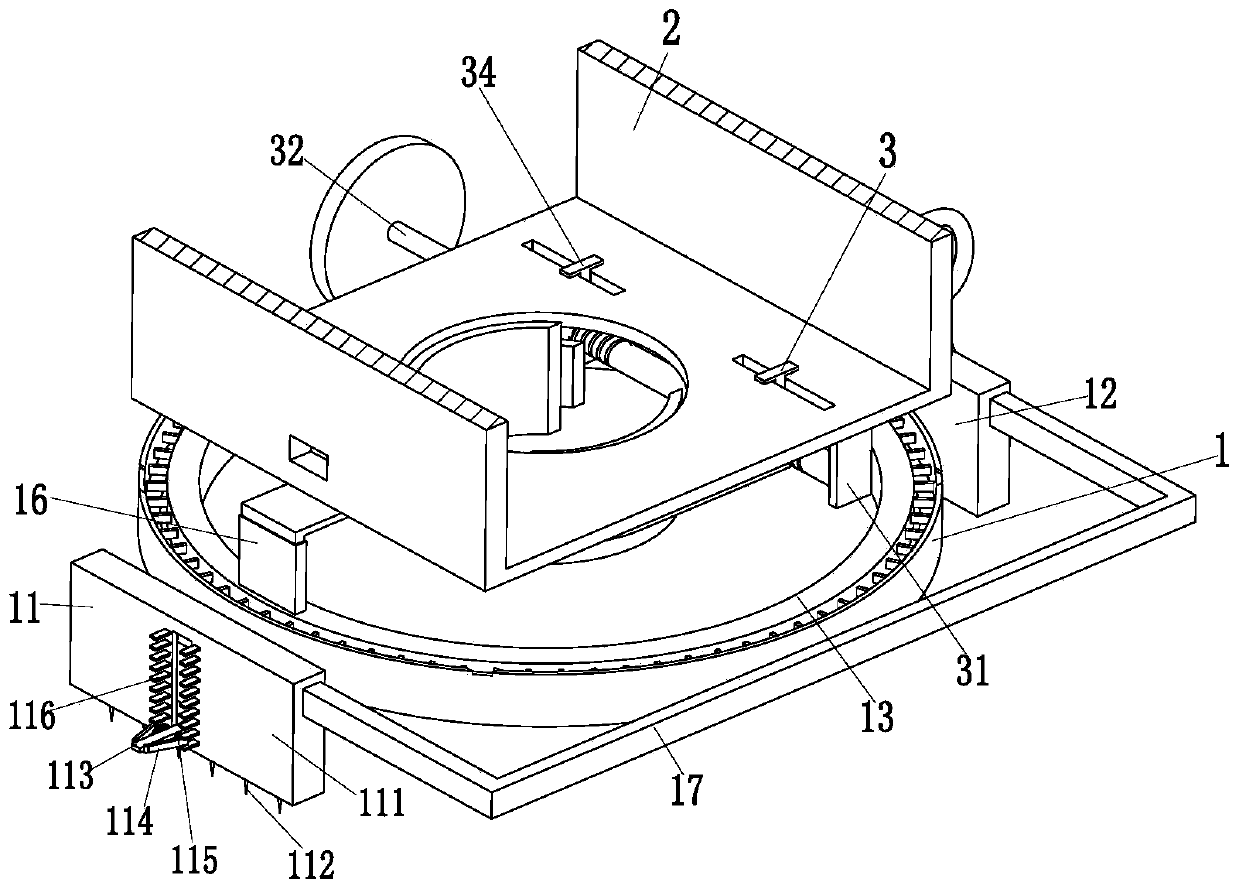

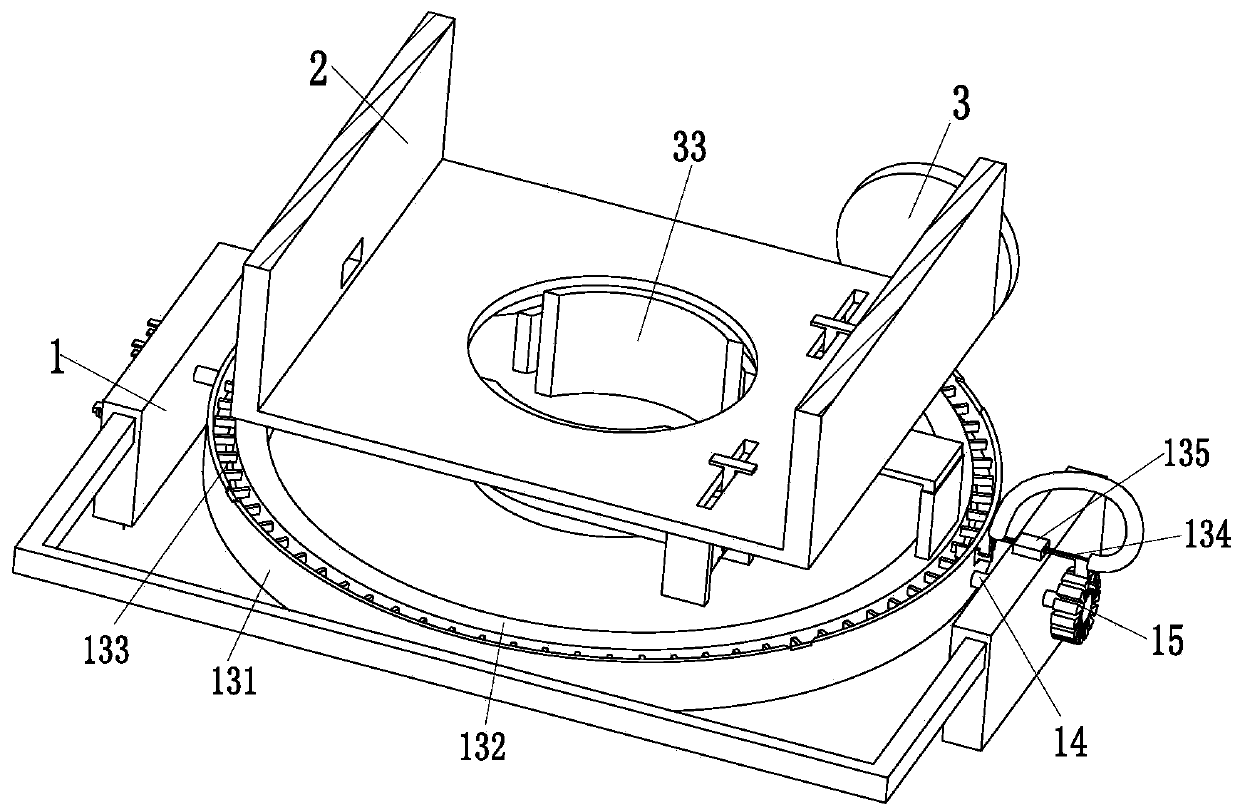

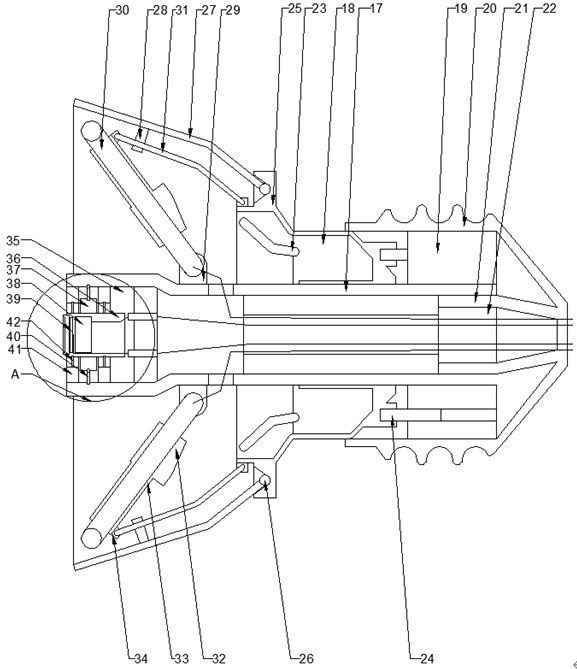

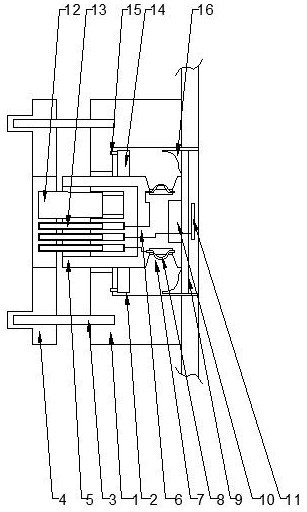

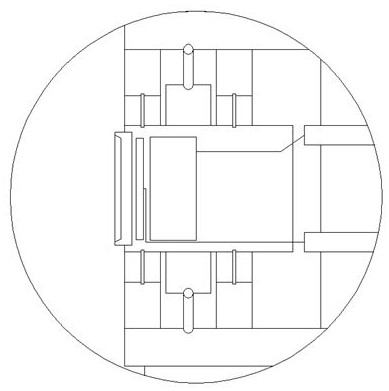

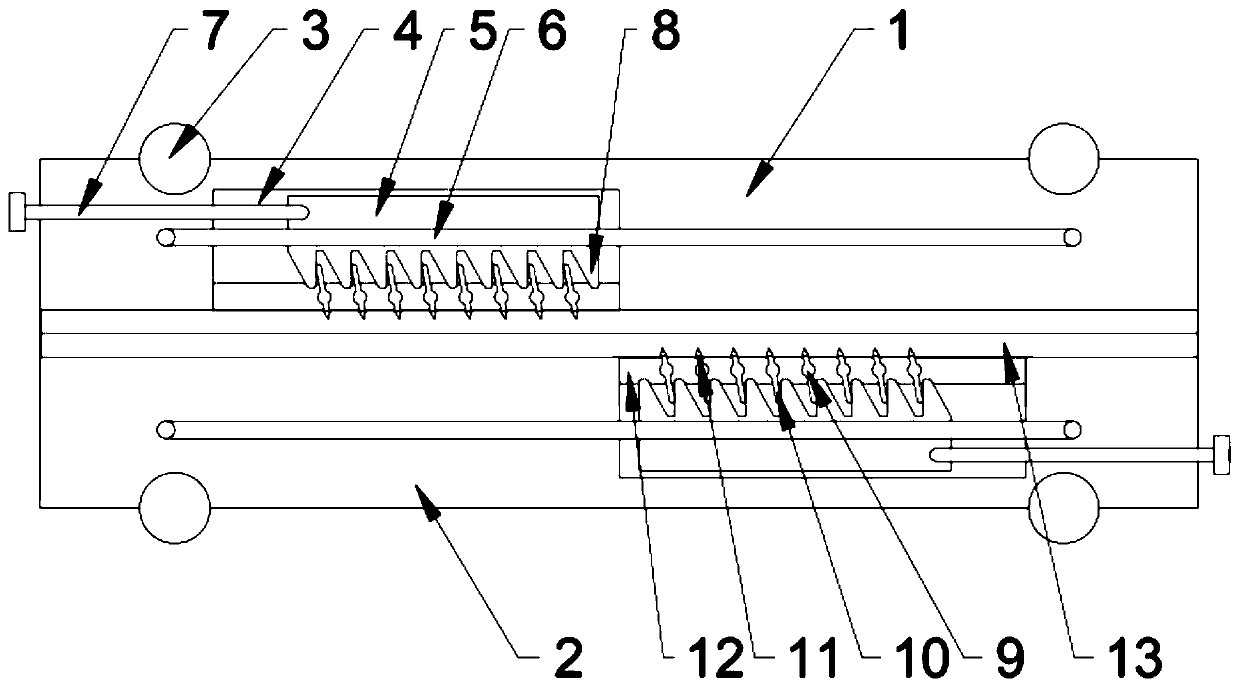

Round-tooth cutter numerical control grinding machine and grinding method thereof

ActiveCN106181605ASolve the problem that it is impossible to process the edge of the scalloped knifeImprove grinding accuracyGrinding carriagesGrinding drivesNumerical controlGrinding wheel

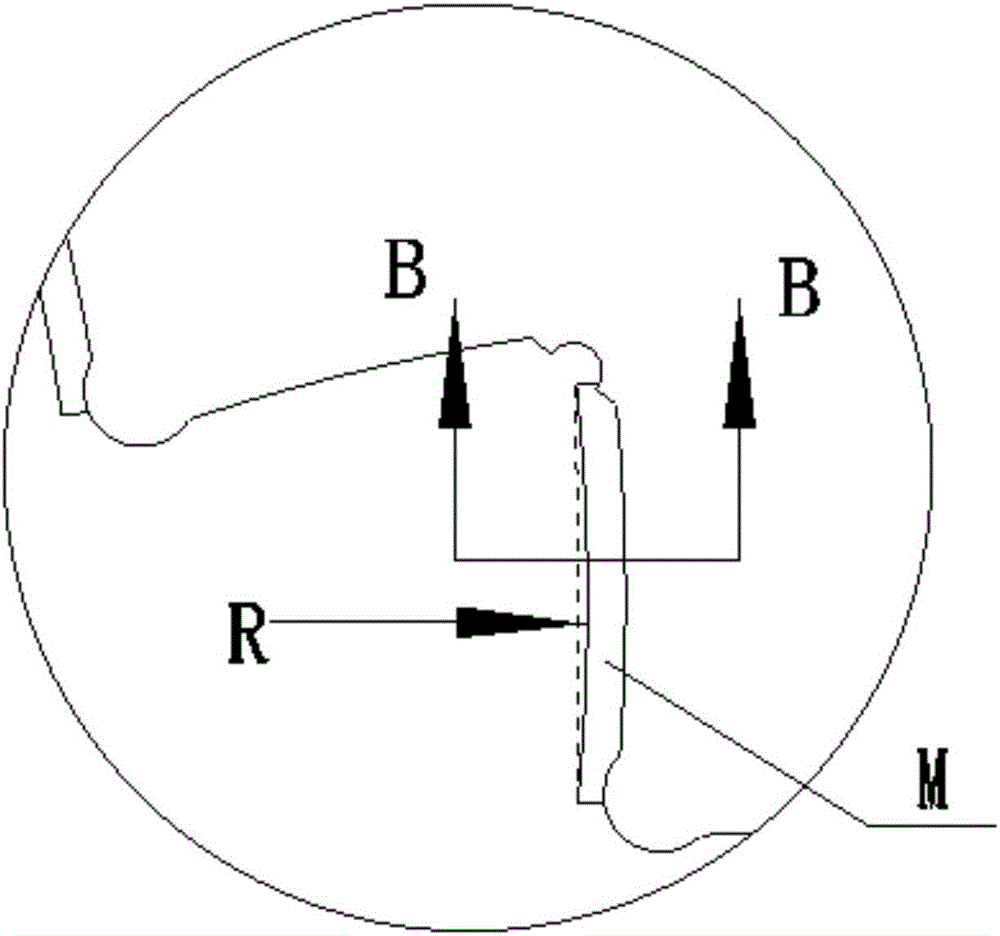

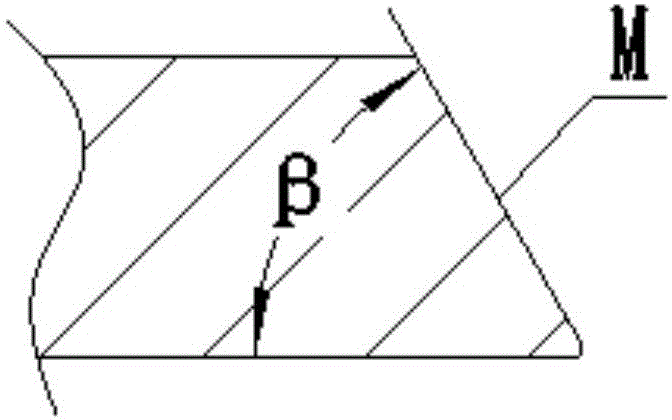

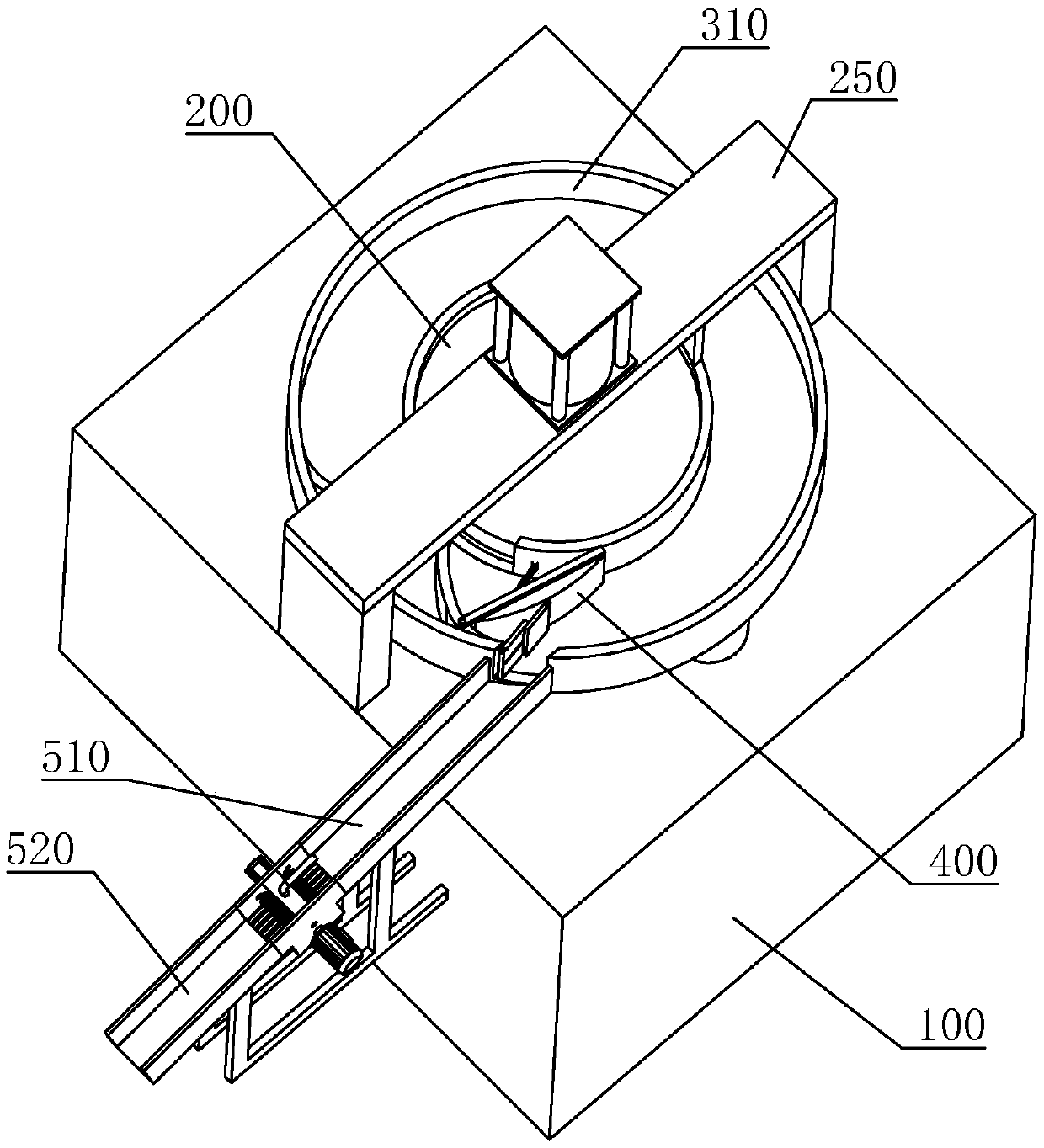

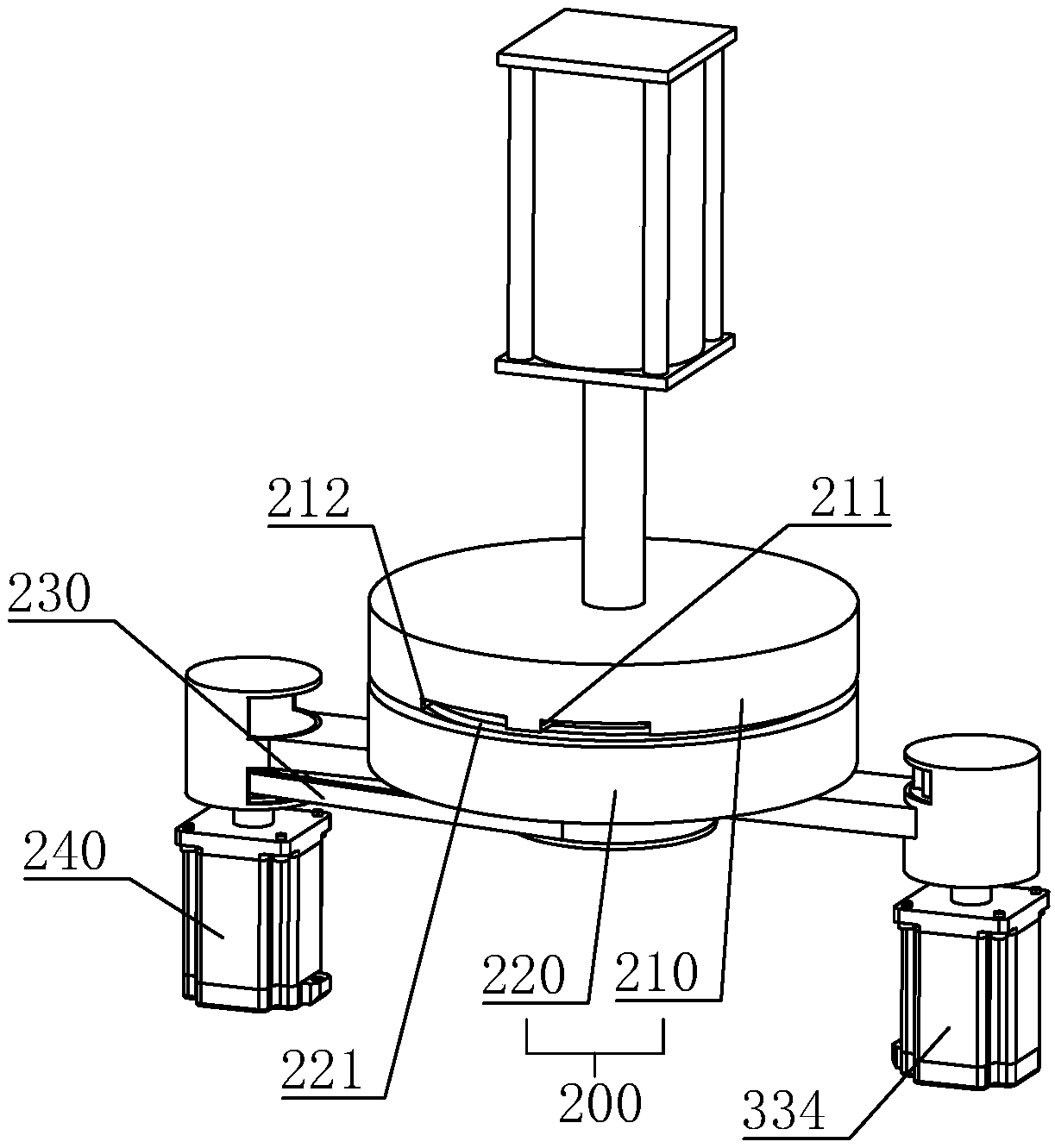

The invention discloses a round-tooth cutter numerical control grinding machine and a grinding method thereof, and belongs to the field of grinding machines. The grinding machine comprises an X-axis part, a Y-axis part, a Z-axis part and a grinding wheel dressing device. The X-axis part comprises a grinding wheel drive device, and the grinding wheel drive device is used for driving a grinding wheel to rotate in the XZ plane to grind a blade and can move in the X-axis direction so as to adjust the X-axis coordinate of the grinding wheel. The Y-axis part is provided with the Z-axis part. The Z-axis part comprises a workpiece drive device, and the workpiece drive device is used for clamping and driving the blade to rotate and can adjust the Y-axis coordinate and the Z-axis coordinate of the blade. The grinding wheel dressing device is used for driving a dressing wheel to rotate in the XY plane. According to the method, the peripheral face of the grinding wheel is firstly dressed through the dressing wheel, then the vertical height of a round-tooth cutter is adjusted, and finally a cutting edge of the round-tooth cutter is ground. According to the round-tooth cutter numerical control grinding machine and the grinding method, the cutting edge of the round-tooth cutter can be automatically ground, grinding operation can be completed through one-time clamping, and the beneficial effects of being high in machining precision, production efficiency and yield and low in cost are achieved.

Owner:马鞍山俊强精密机械设备有限公司

Lapping machine

ActiveCN109551334AEasy to take outEasy to operateSpherical surface grinding machinesGrinding feedersSteel ballMachining

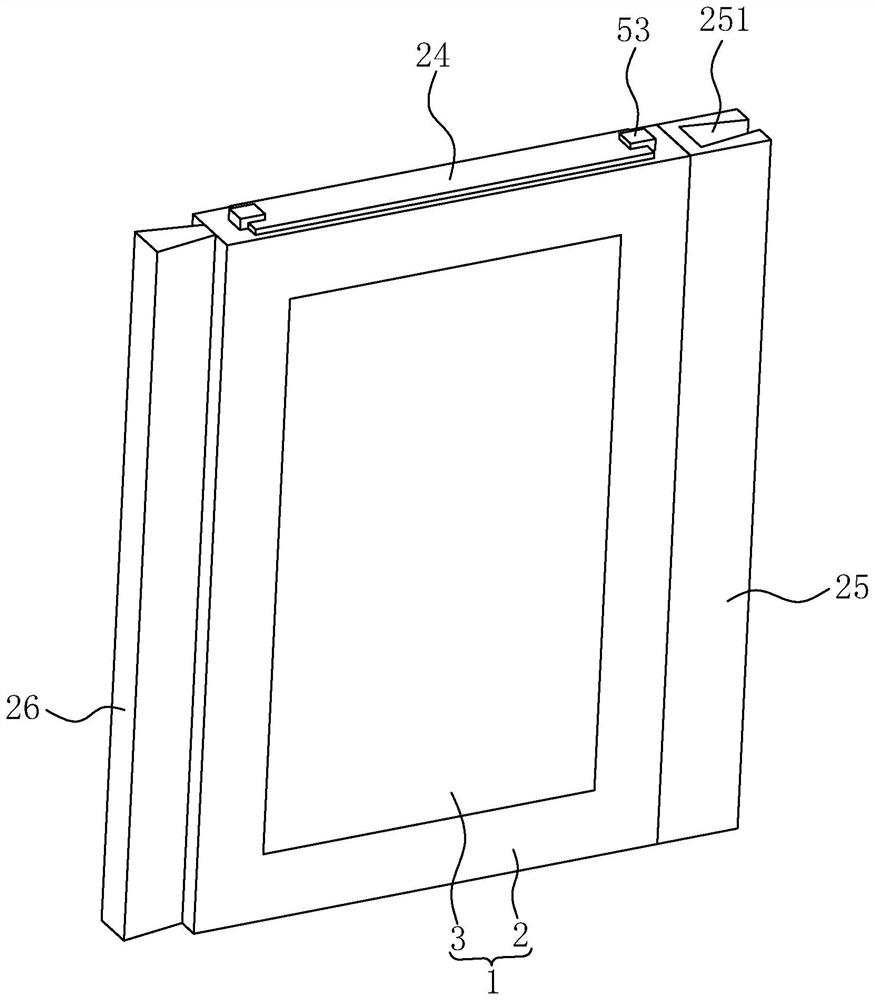

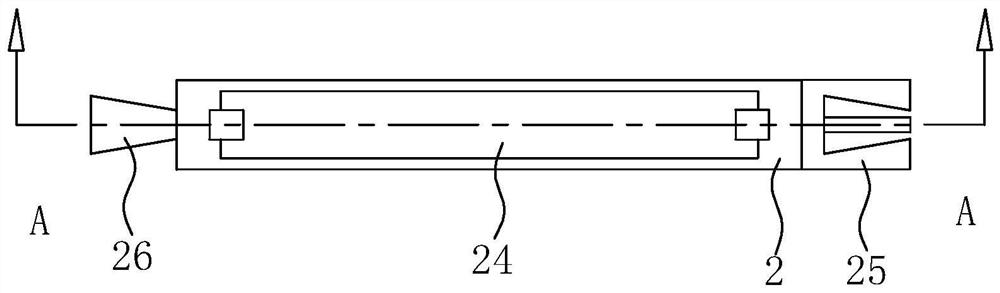

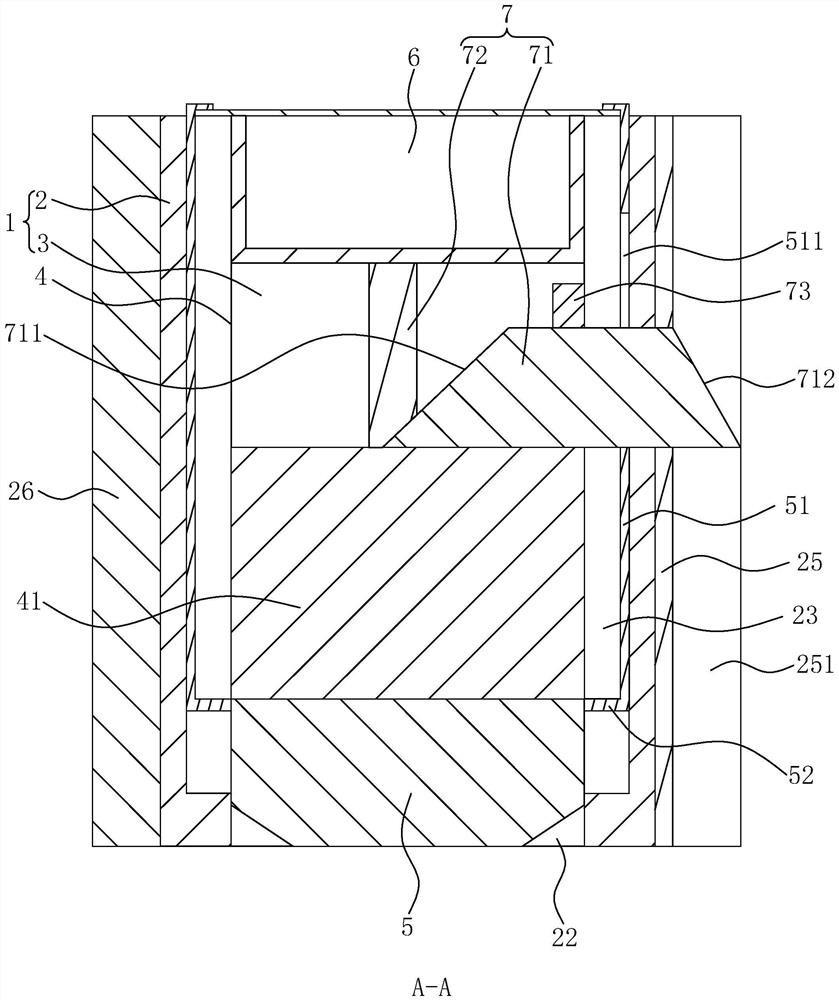

The invention relates to the technical field of steel ball machining equipment, in particular to a lapping machine. The lapping machine includes a rack, a ring feeding channel and a driving assembly,wherein the ring feeding channel is provided with a guiding block in a T shape, a feeding plate and a discharging plate are arranged at the two ends of the guiding block respectively, a splitter plateis arranged in the middle of the guiding block, and the splitter plate is positioned in an opening and divides the opening into a feeding opening and a discharging opening; and the end, away from thedischarging plate, of the feeding plate is connected with a direction changing plate in a hinged mode, the ring feeding channel is provided with an adjusting structure, position, on the side, away from the discharging plate, of the feeing plate, on the outer side wall of the ring feeding channel is provided with a falling opening, and the direction changing plate can cover the falling opening after rotating. The lapping machine has the following effects that when a steel ball is made to move towards the feeding opening by the driving assembly, the steel ball abuts against the direction changing plate, the steel ball moves away from the ring feeding channel through the falling opening, an operation worker only needs to collect the steel ball from the falling opening and can take out the lapped steel ball conveniently, the operation process is simplified, and the machining efficiency is improved.

Owner:绍兴市上虞叶华实业有限公司

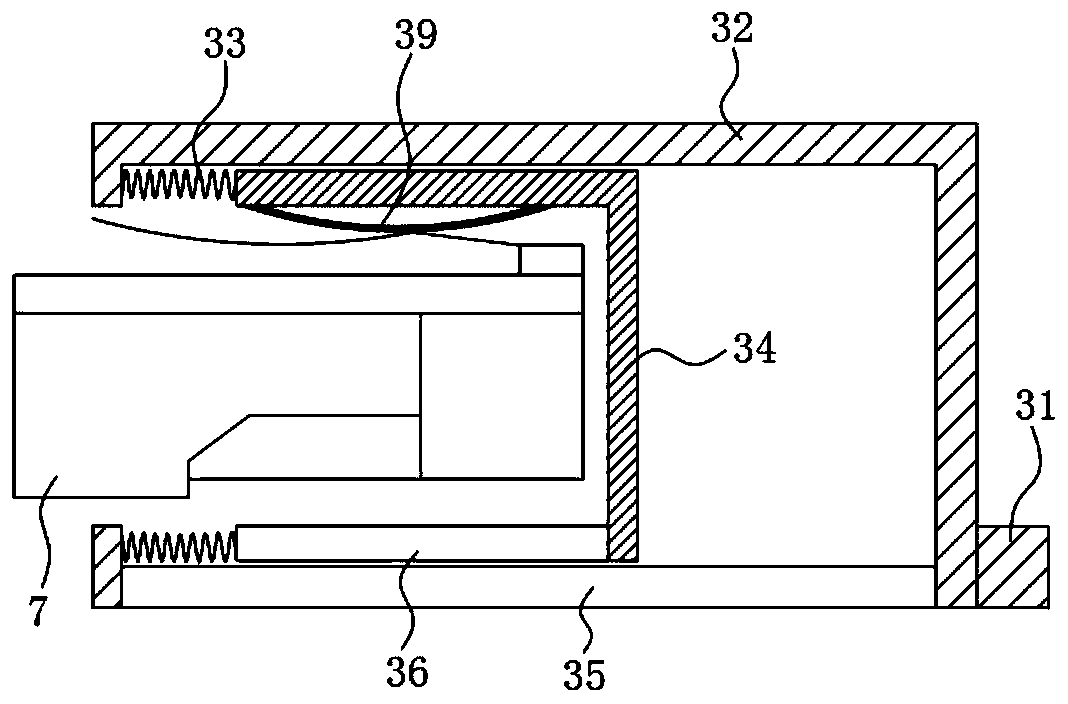

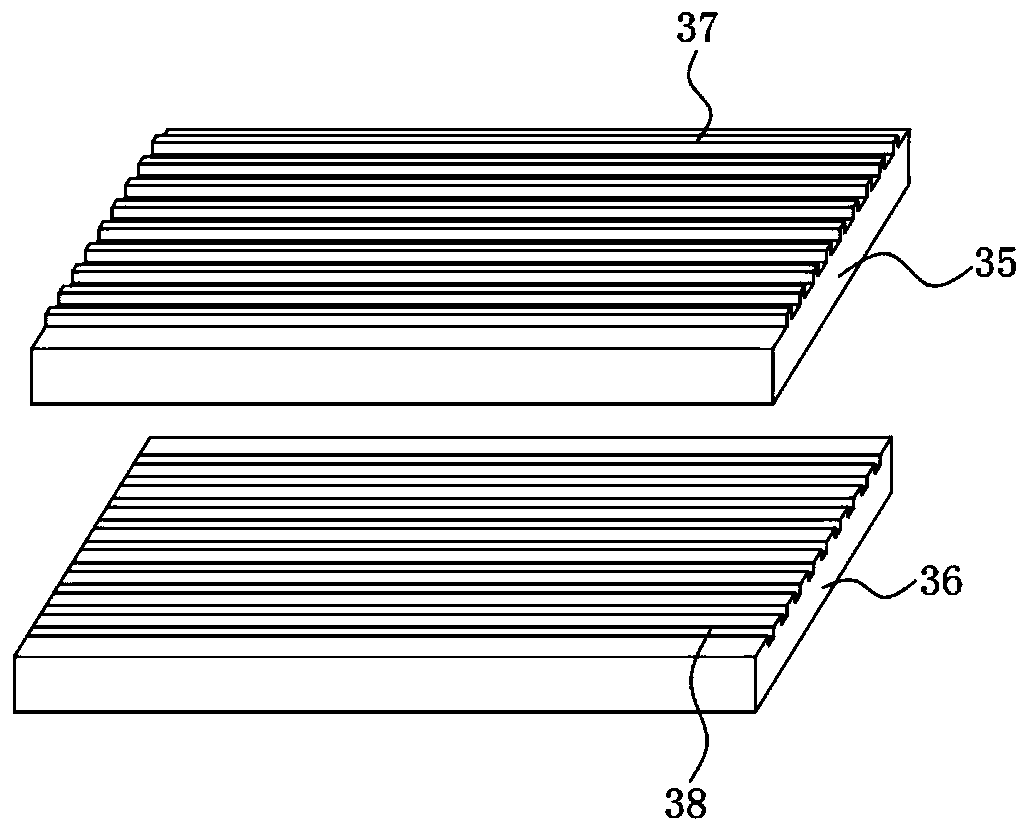

Feed granulation device with drying function for animal husbandry

InactiveCN109549238AIncrease squeezeReduces the possibility of looseningFeeding-stuffExtrusion mouldingFeed processing

The invention belongs to the technical field of feed processing devices, in particular to a feed granulation device with a drying function for animal husbandry. In view of the problem that the existing feed granulation device cannot realize effective extrusion moulding, and the feed particles are easily loosened and bonded, a following scheme is proposed, the device further comprises a rack, wherein a filter box and a transport box are respectively fixed by screws on both sides of the top outer wall of the rack, one side outer wall of the transport box and the top outer wall of the filter boxare fixed with a fixed box by screws, a molding plate is fixed to one side of the bottom inner wall of the transport box by the screws, and the top outer wall of the transport box is fixed with a hopper by the screws. The feed granulation device helps to improve the extrusion molding effect, can reduce the possibility of looseness of the feed grains, facilitates the control of the size of the feedpellets, and facilitates the quantitative collection of the feed, is helpful for improvement of production efficiency, can dry the feed pellets inside the filter box, which helps to speed up the drying efficiency, can improve the filtration and screening effect of the feed, and is helpful for improvement of the product quality.

Owner:六安科创教育信息咨询有限公司

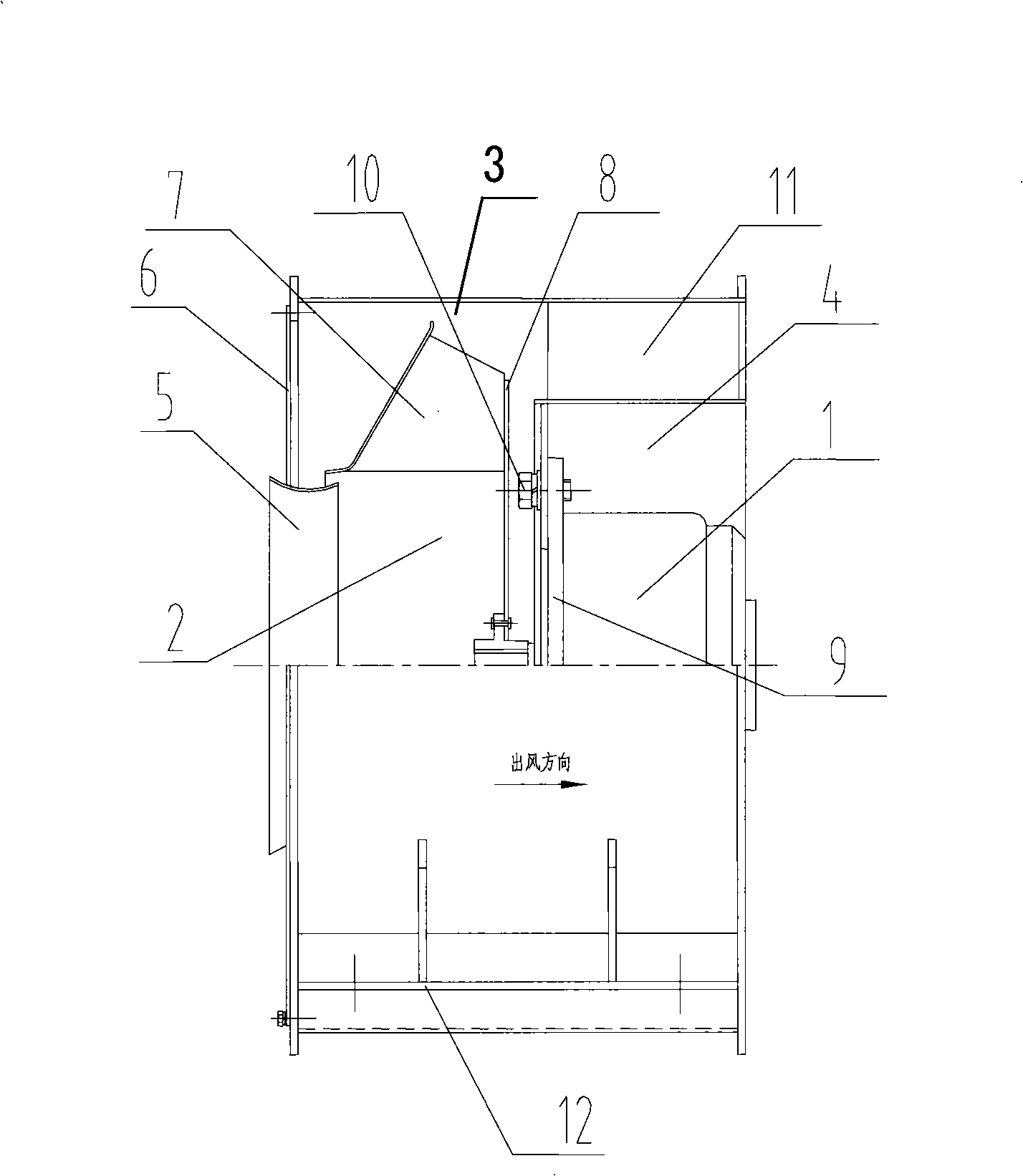

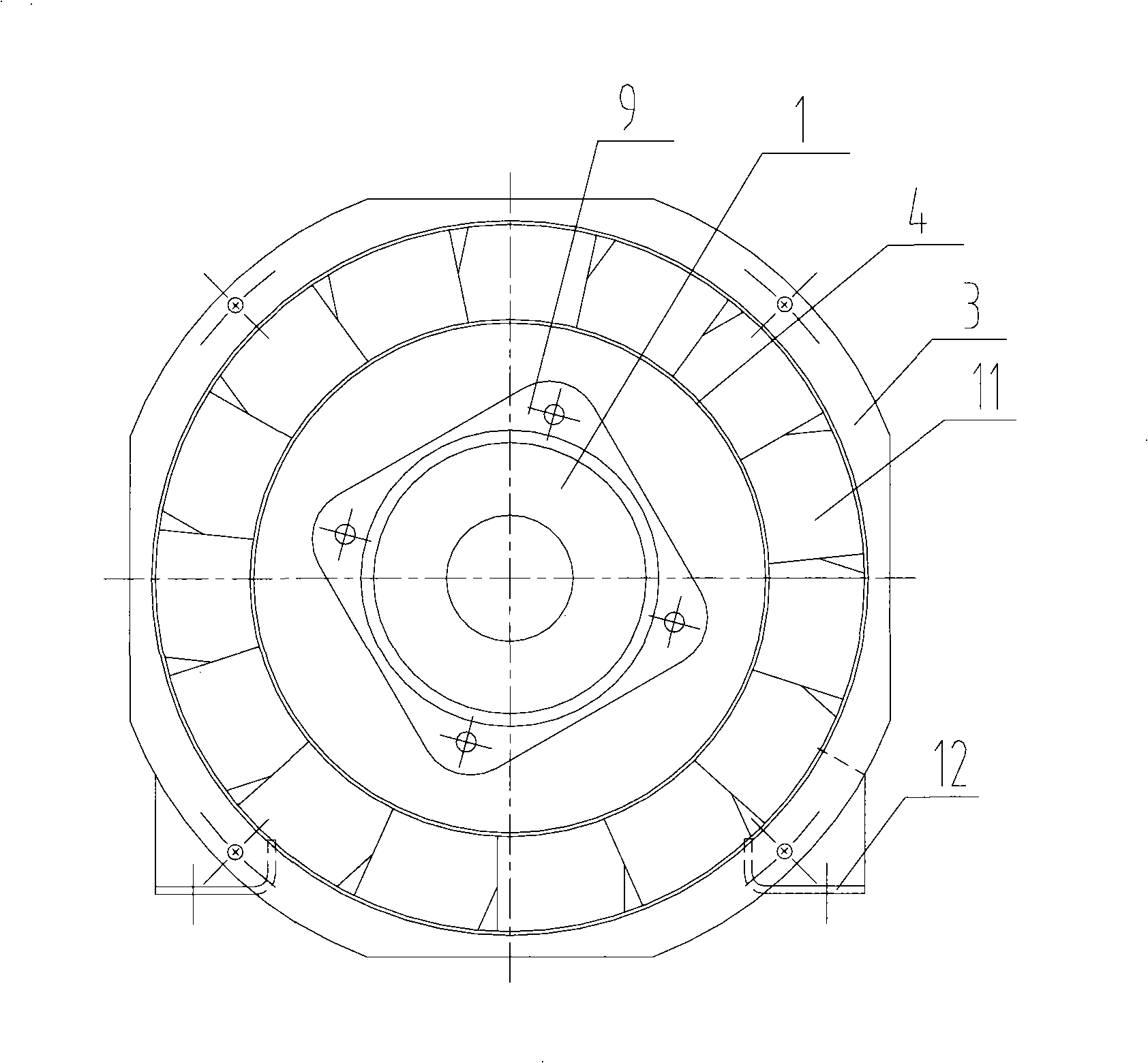

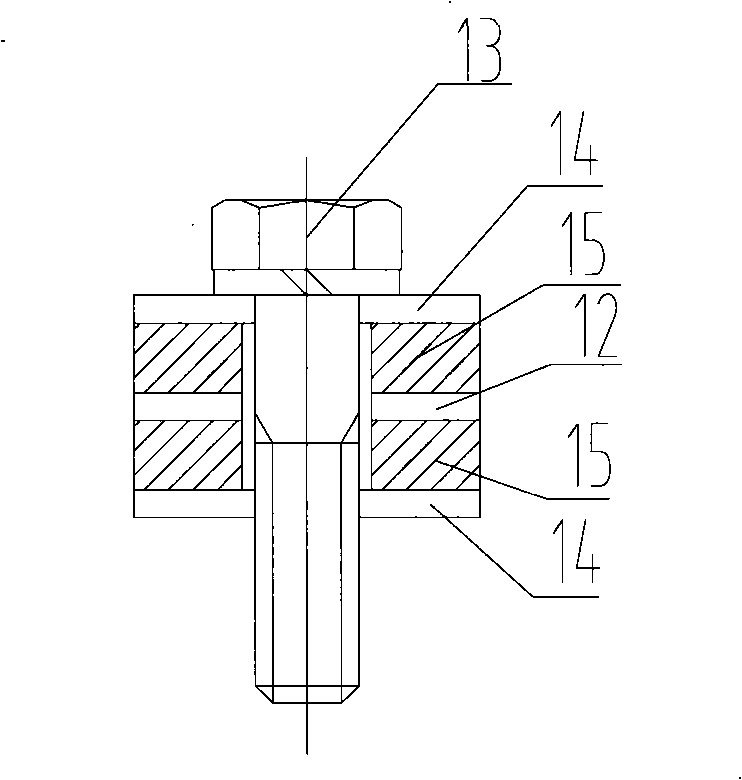

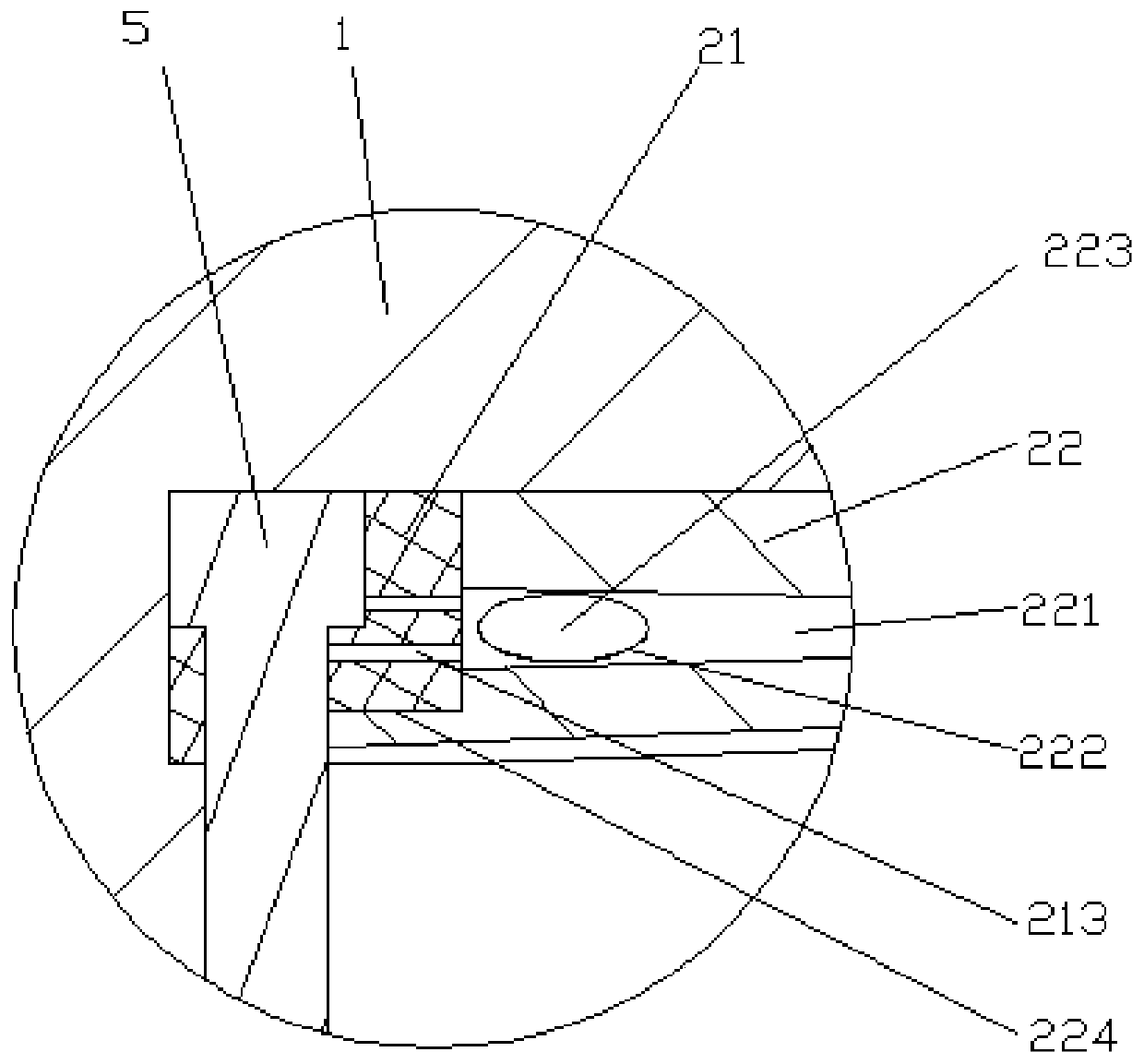

Mixed flow fan

ActiveCN101349277AReduce vibrationReduces the possibility of looseningPump componentsLighting and heating apparatusDrive motorImpeller

The invention provides a mixed flow fan, which comprises a driving motor, an impeller wheel, a wind-sock, a guide vane cylinder and a guide vane, one side of a wind inlet of the wind-sock is equipped with a cover plate, the cover plate covers a part area of the circumference of one side of the wind inlet of the wind-sock to reduce the actual wind entering area of the wind inlet, and the diameter of the impeller wheel still keeps adapted to the original wind inlet. The wind inlet of the wind-sock of the fan is equipped with the cover plate, which reduces the actual wind entering area of the fan, can largely increase wind pressure, and enables radiating wind to have a better radiating effect. The optimized implementation mode of the invention further takes measures to improve the quality of radiating wind flow, enables the fan to reduce vibration, and takes vibration insulation measures. The mixed flow fan is particularly suitable for being used in radiating occasions of locomotive inverters, or can be applied to other similar occasions.

Owner:CHINA RAILWAYS CORPORATION +1

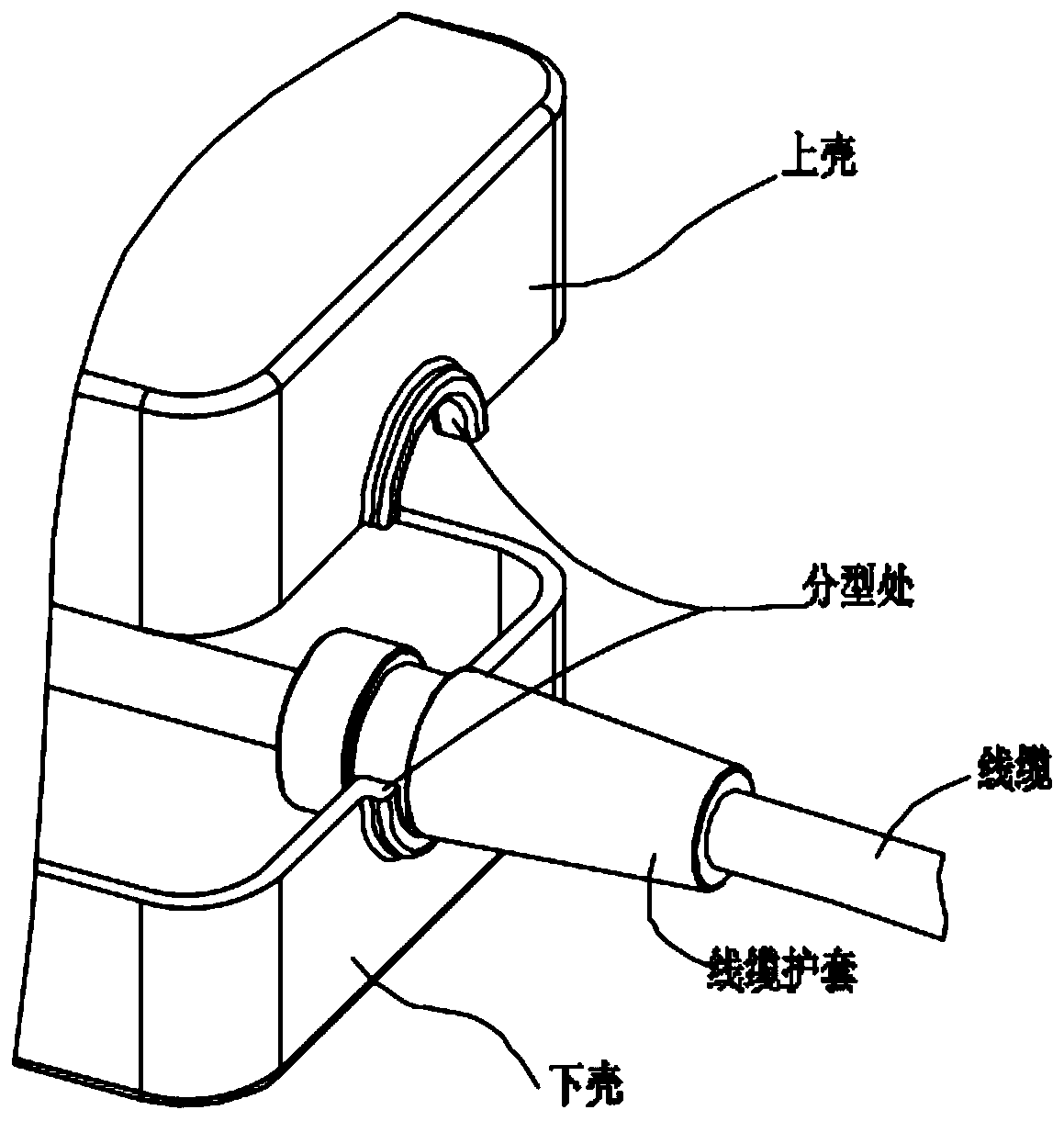

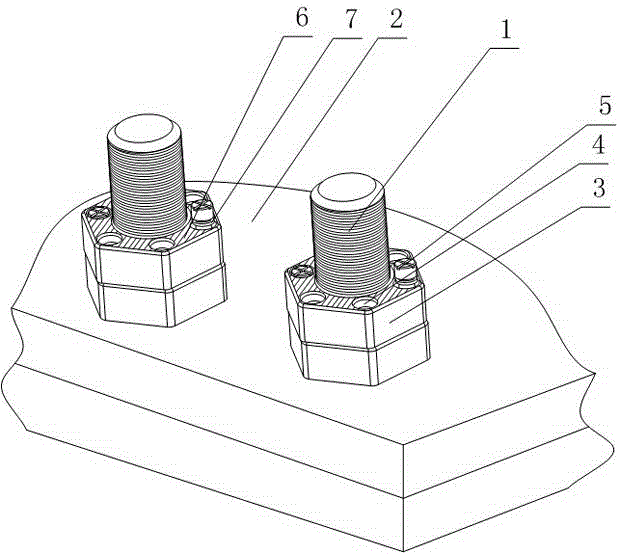

Electrical equipment

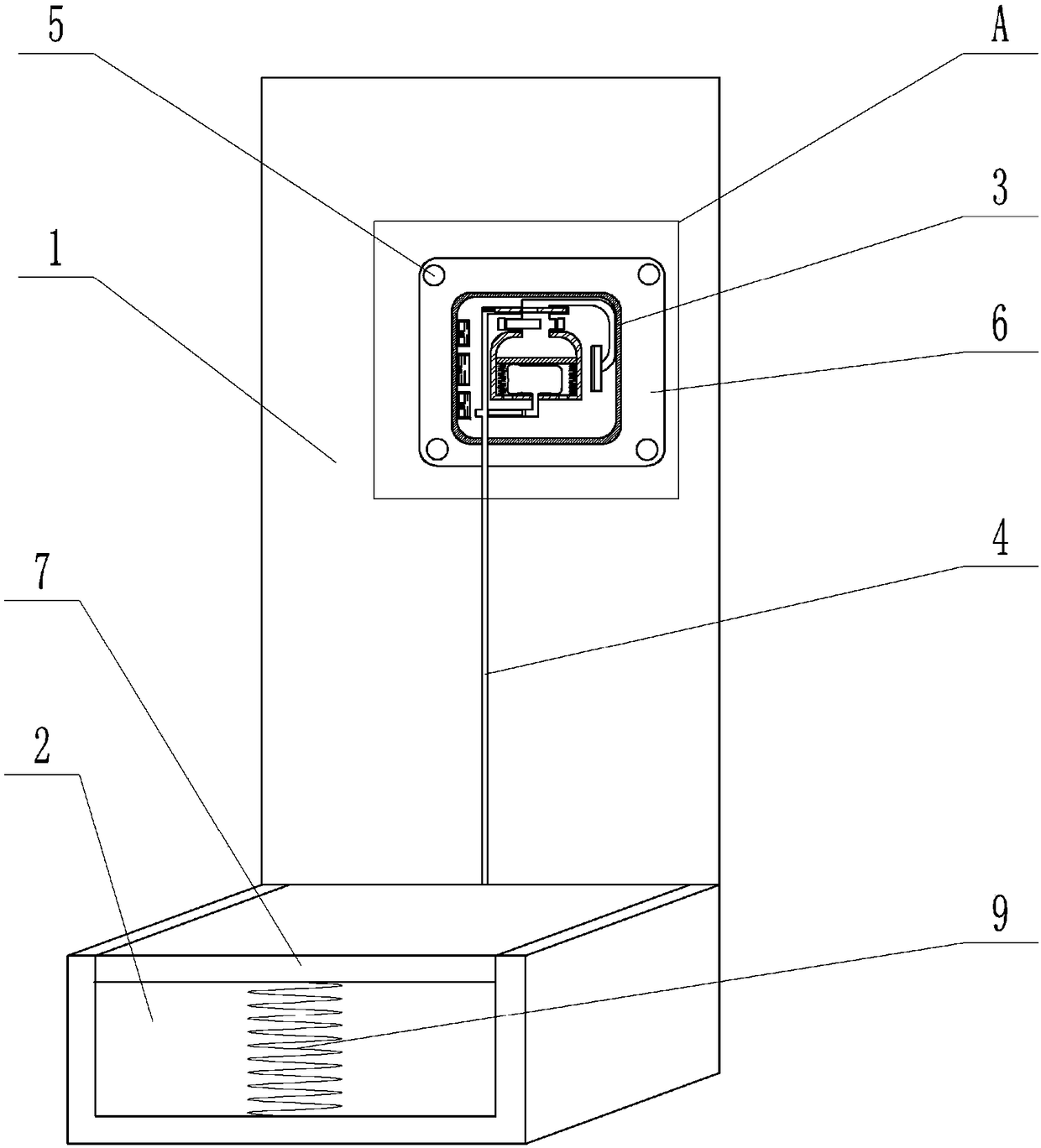

PendingCN110571575ALess chance of slipping and looseningFixed and reliableRelieving strain on wire connectionEngineeringElectrical equipment

The embodiment of the invention provides electrical equipment. The electrical equipment comprises a first shell, a second shell and a cable sheath, wherein the first shell comprises a wire inlet holecomposed of a limiting hole and a rotation stopping hole, and the cable sheath correspondingly comprises a limiting sleeve shoulder and a rotation stopping sleeve shoulder; the second shell comprisesa positioning rib, and the rotation stopping sleeve shoulder further correspondingly comprises a limiting groove. The cable sheath is arranged in the wire inlet hole in a penetrating manner, so that the rotation stopping hole and the rotation stopping sleeve shoulder are in hole-shaft fit, and the cable sheath is prevented from rotating relative to the first shell; and the limiting sleeve shoulderand the limiting hole are in hole-shaft fit, so that the cable sheath is prevented from moving in the direction of penetrating into the cable inlet hole. Therefore, according to the technical schemeprovided by the embodiment of the invention, the cable sheath can be reliably fixed, the possibility that the cable sheath slides and gets loose relative to the electrical equipment is reduced, and the cable of the electrical equipment is effectively protected.

Owner:HUAWEI TECH CO LTD

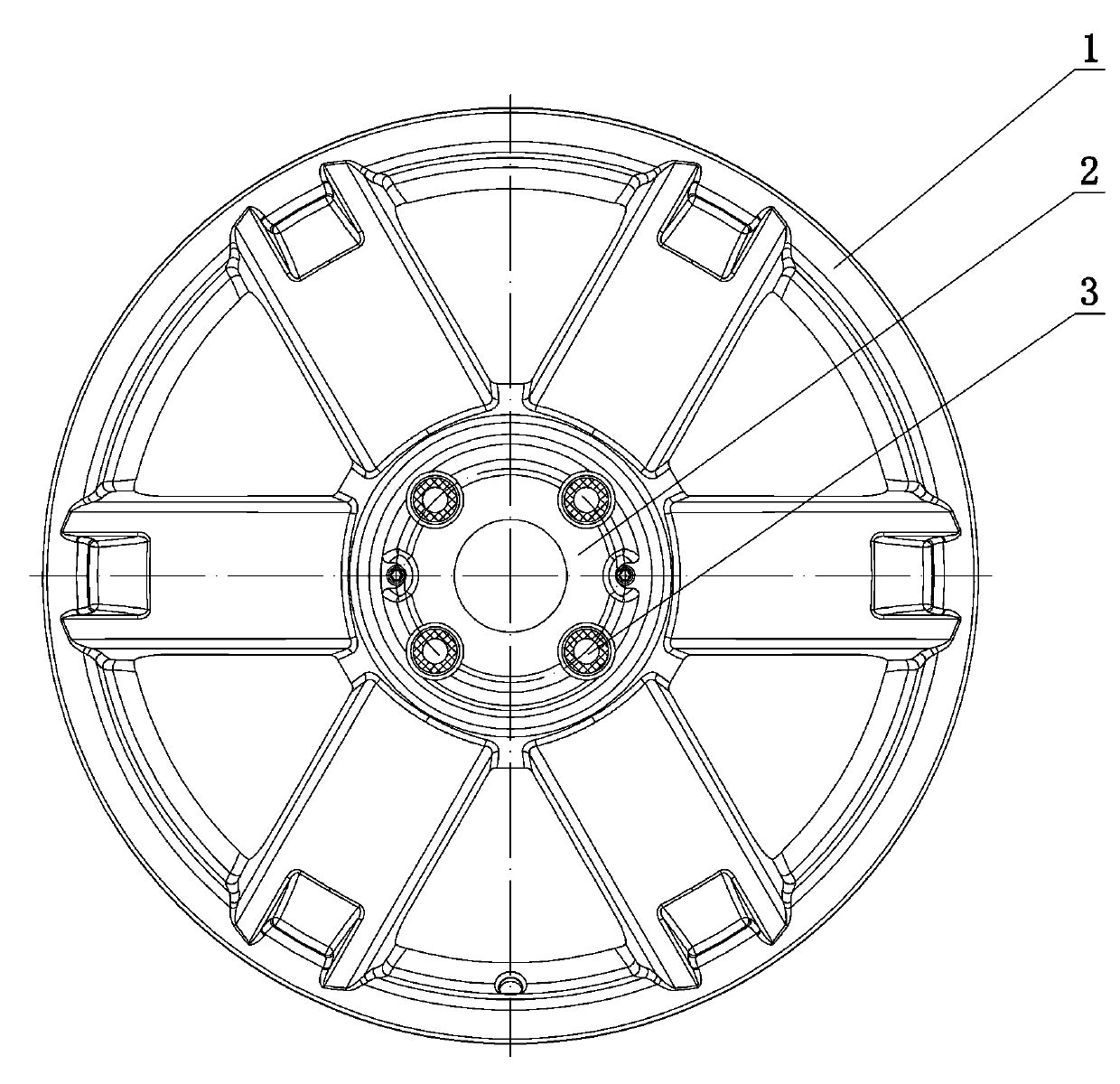

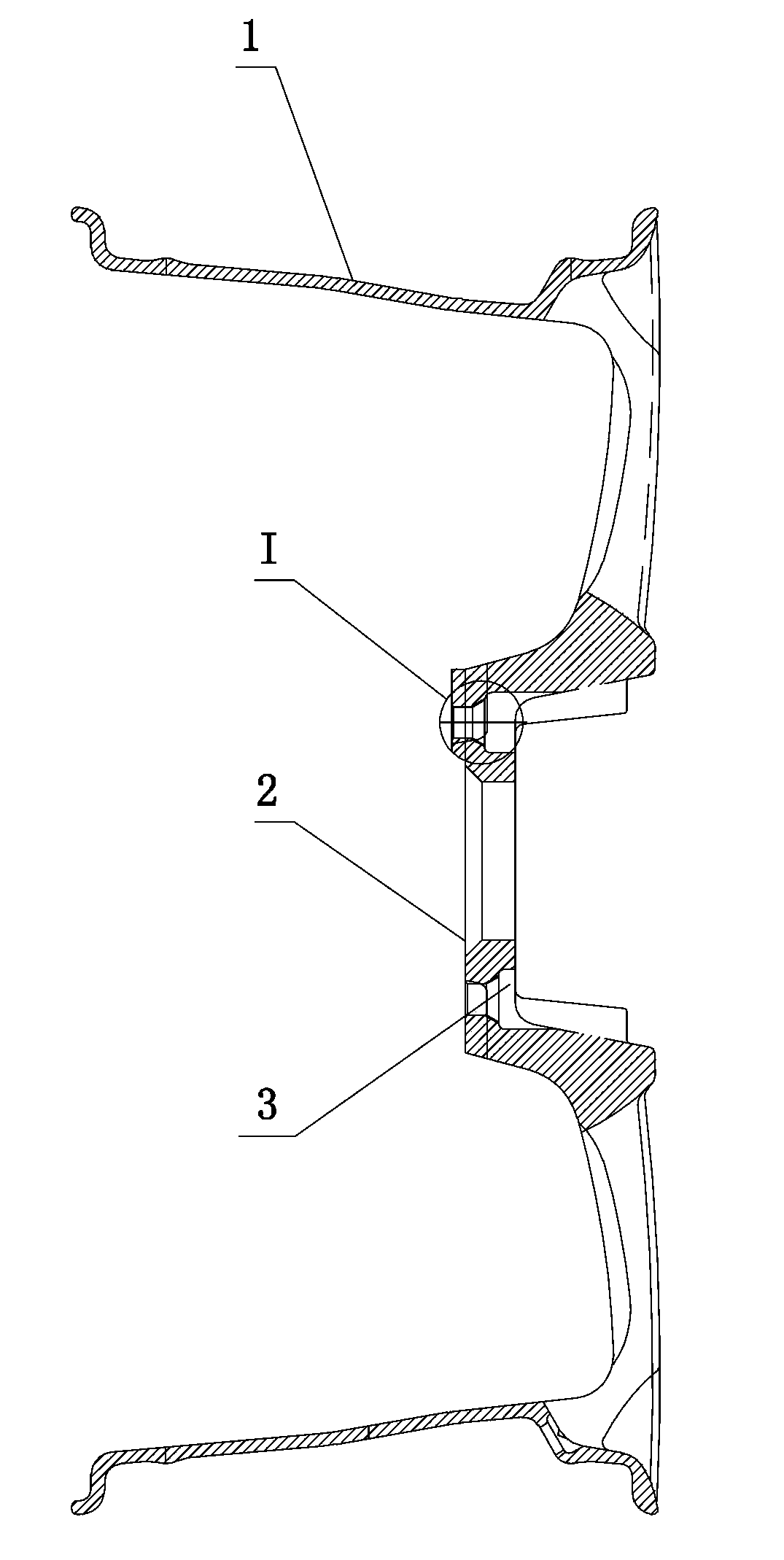

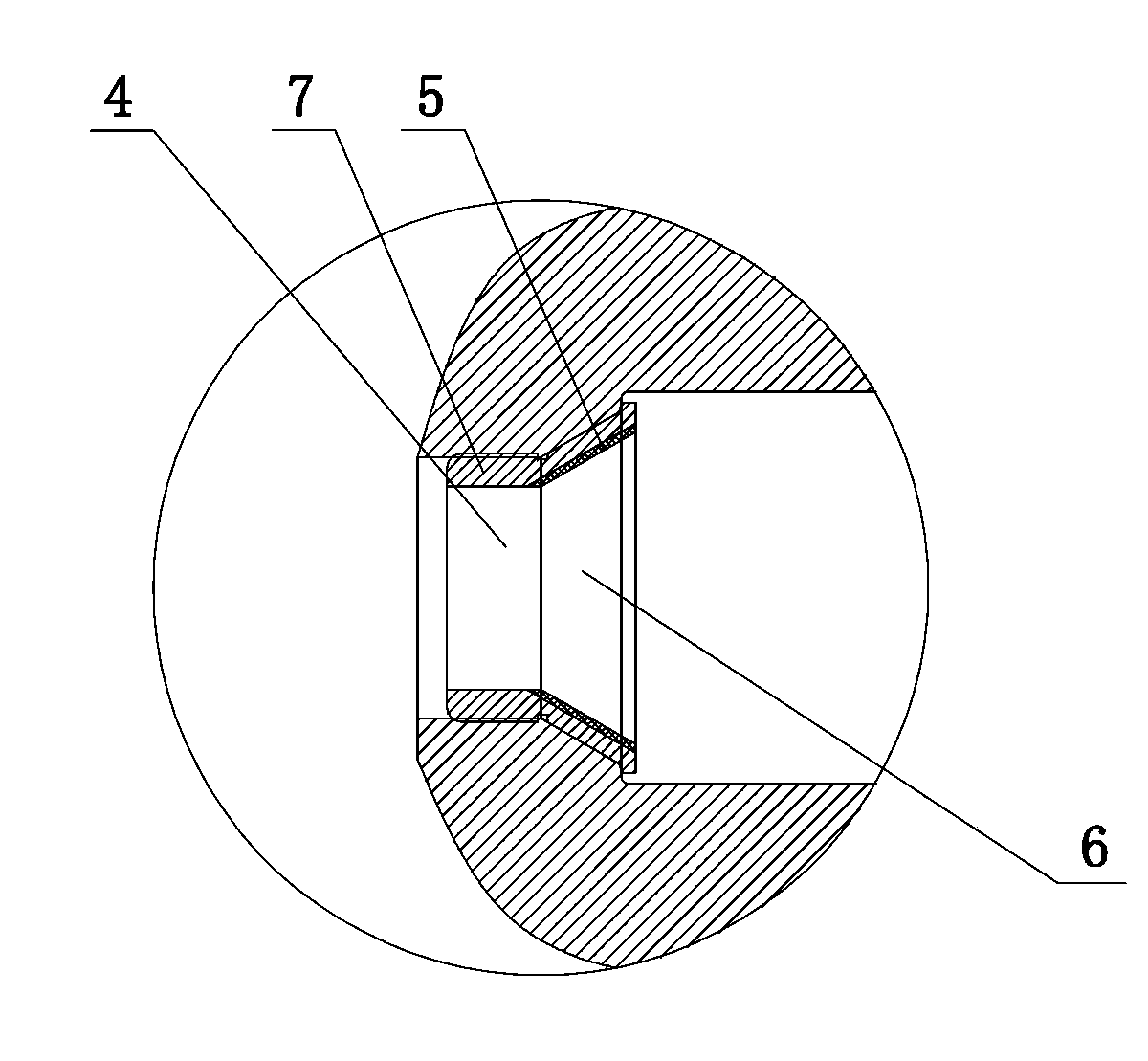

Reinforced aluminum alloy hub with antiskid bolt holes

The invention relates to a technology for improving automobile parts, and discloses a reinforced aluminum alloy hub with antiskid bolt holes. The reinforced aluminum alloy hub is provided with a hub body, wherein at least four mounting holes are formed in a mounting hub of the hub body. The reinforced aluminum alloy hub is characterized in that a steel sleeve is arranged in each mounting hole, wherein a bolt hole is formed in each steel sleeve, and consists of two sections, i.e. a cylindrical hole and a taper hole; antiskid knurls are formed on the surfaces of the taper holes of the bolt holes in a rolling way. According to the reinforced aluminum alloy hub, the problems of potential safety hazards in driving due to the facts of bolt hole damage and loosening probably caused by insufficient strength and poor antiskid performance of the bolt holes in a conventional aluminum alloy hub are solved; the invention is applied to the improvement of various types of aluminum alloy hubs.

Owner:湖北省阳新昂运铝轮有限公司

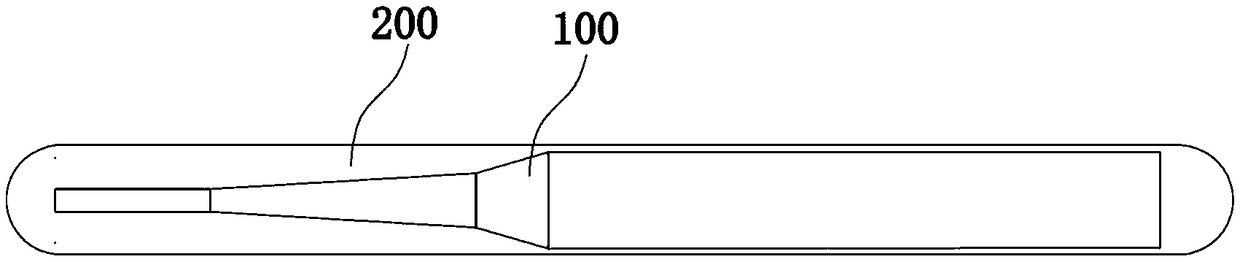

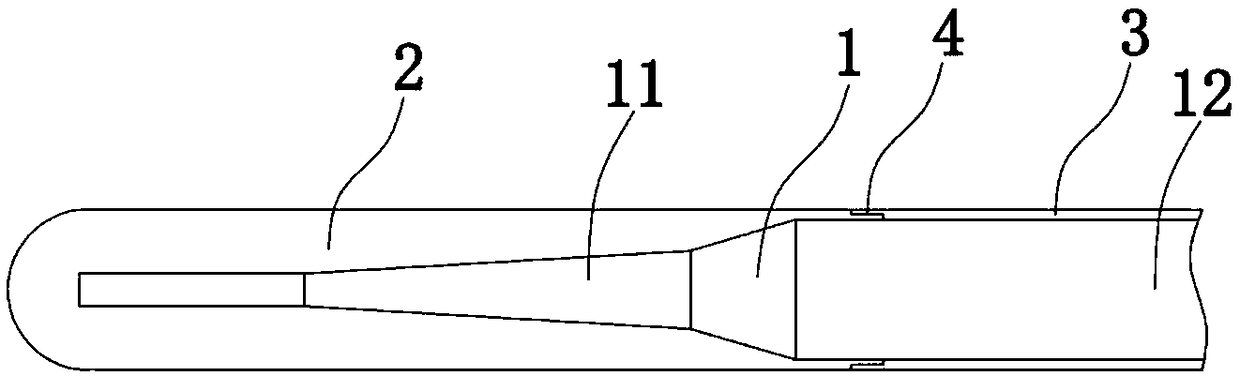

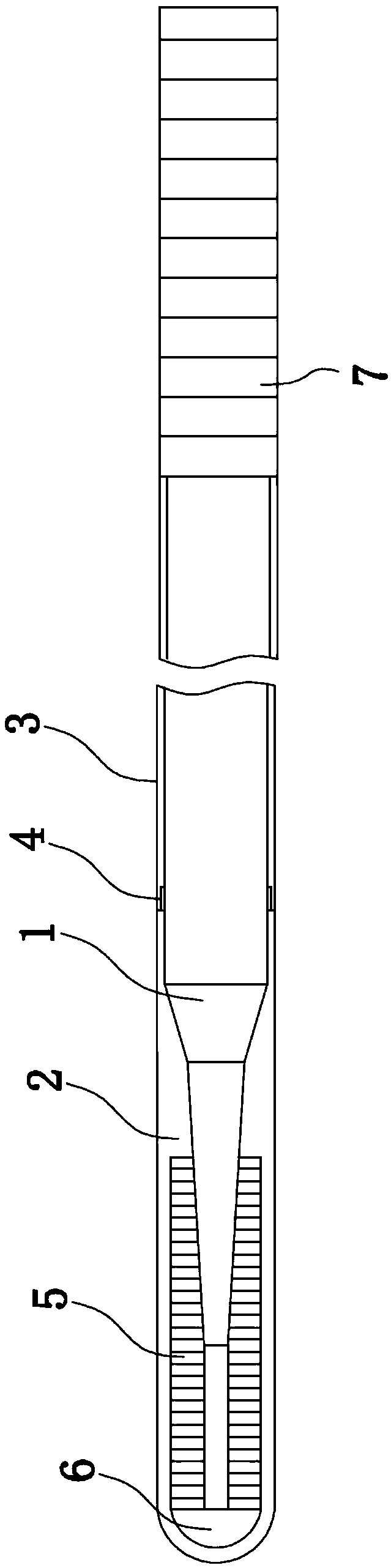

Anti-scratch ultra-slip guide wire, coating method and coating device thereof

The invention provides an anti-scratch ultra-slip guide wire, a coating method and coating device thereof, wherein the anti-scratch super-slip guide wire comprises a core wire, the tapered section ofthe core filament is coated in the polymer, the other areas of the core filament are encased in hydrophilic or hydrophobic super-slip sleeves, the heat shrinkage temperature of the super-slippery sleeves is higher than the melting point of the polymer tubes and they partially coincide with the push rod of the core filament. In the coinciding region, the super-slippery sleeves are coated with the polymer and the thickness of the polymer in the coinciding region is smaller than that in other regions of the polymer. The design of the scheme is exquisite, the arrangement of high molecular polymerpipe and super-slip sleeve, the two pipe are partially overlapped and coated, so that the high molecular polymer pipe can be restricted by the super-slip sleeve, the pulling force of the polyurethanepipe coating can be increase by more than 10N, the possibility of the high molecular polymer pipe loosening can be reduced, and the safety can be improved.

Owner:SUZHOU HIGHWIRE MEDICAL DEVICES CO LTD

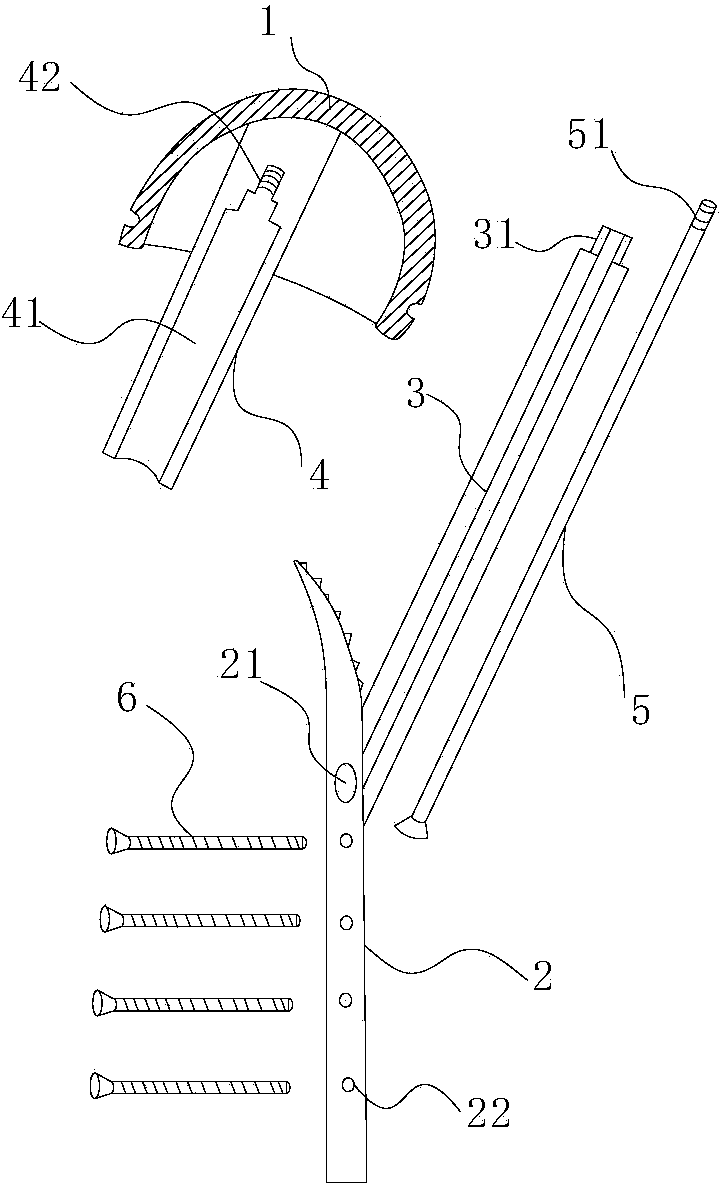

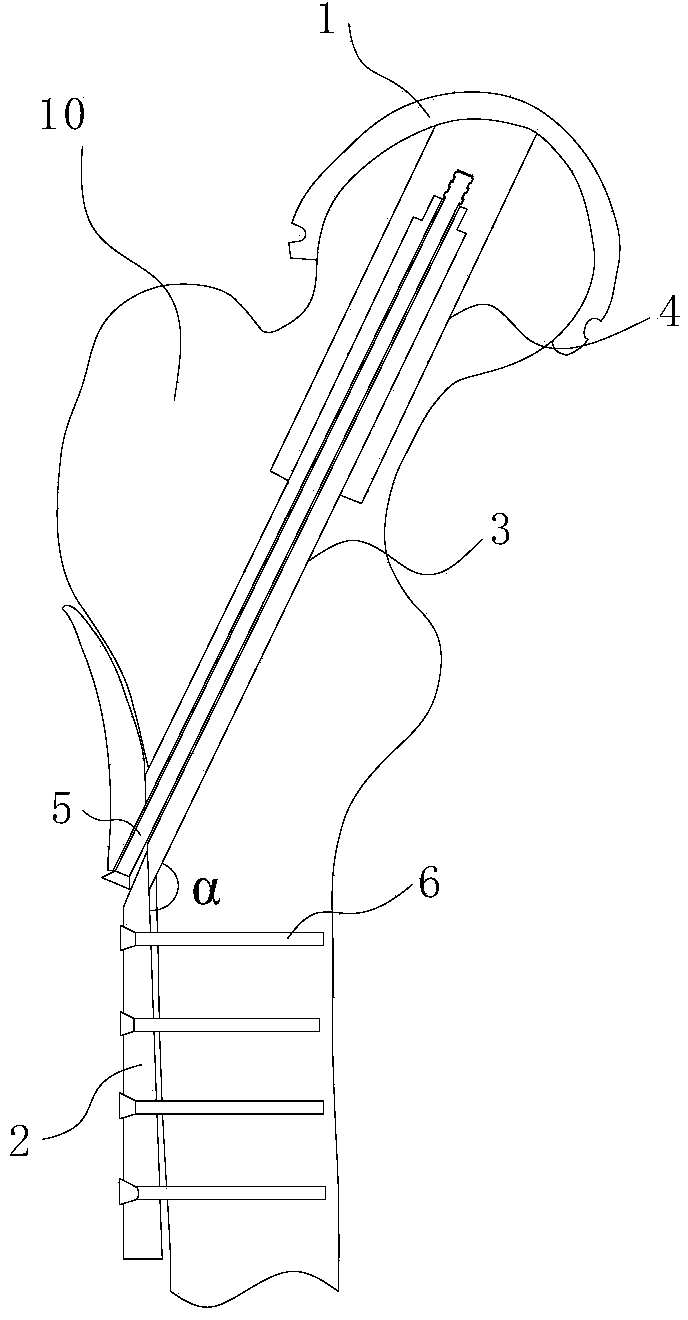

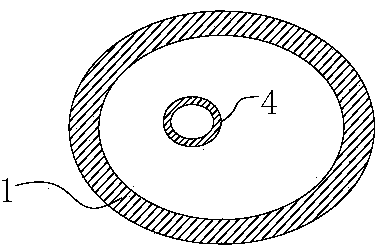

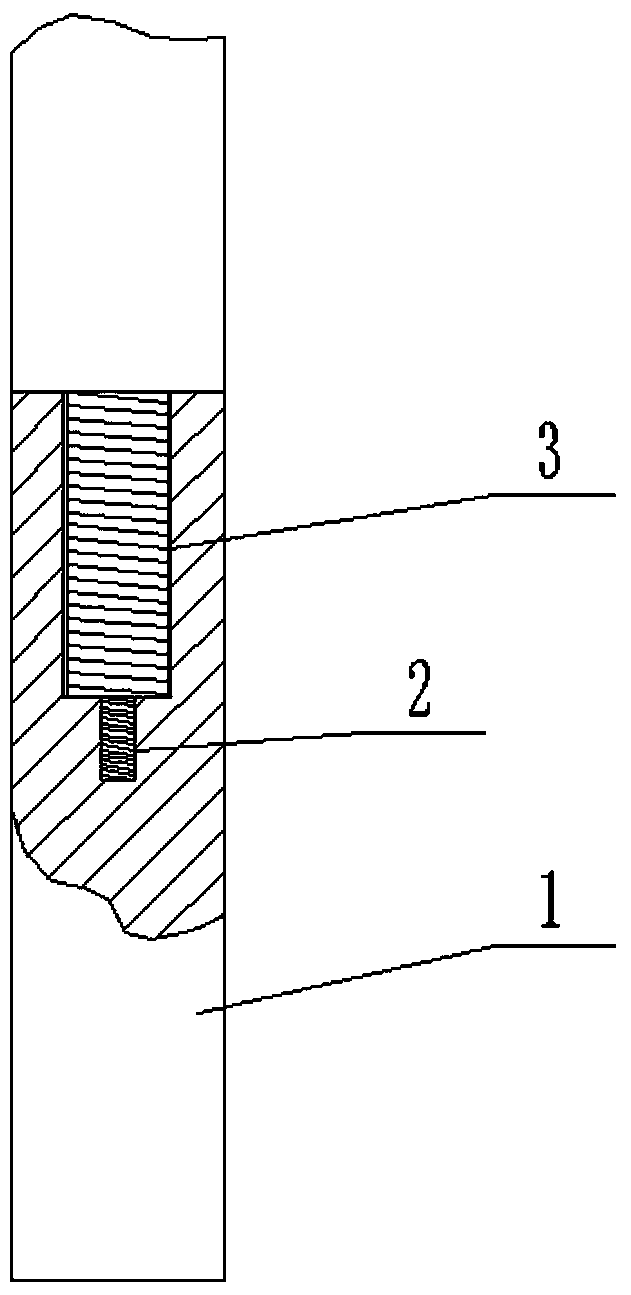

Biotype artificial hip joint surface replacement prostheses

ActiveCN103445886AReduces the possibility of looseningHigh mechanical strengthInternal osteosythesisJoint implantsArtificial hip jointsFemoral bone

The invention discloses a biotype artificial hip joint surface replacement prosthesis comprising a hemispheric prosthesis cap, which is cooperated with the shape of the caput femoris and is disposed on the caput femoris; a carrying steel plate, which is fixedly disposed on one side of the tuberosity of the caput femoris; a carrying column; an inserting column; a main bolt used for fixing the carrying column; and at least one auxiliary bolt. The invention can be used to prevent the loosening of the prosthesis and the fracture of the femoral neck around the prosthesis effectively.

Owner:刘礼初

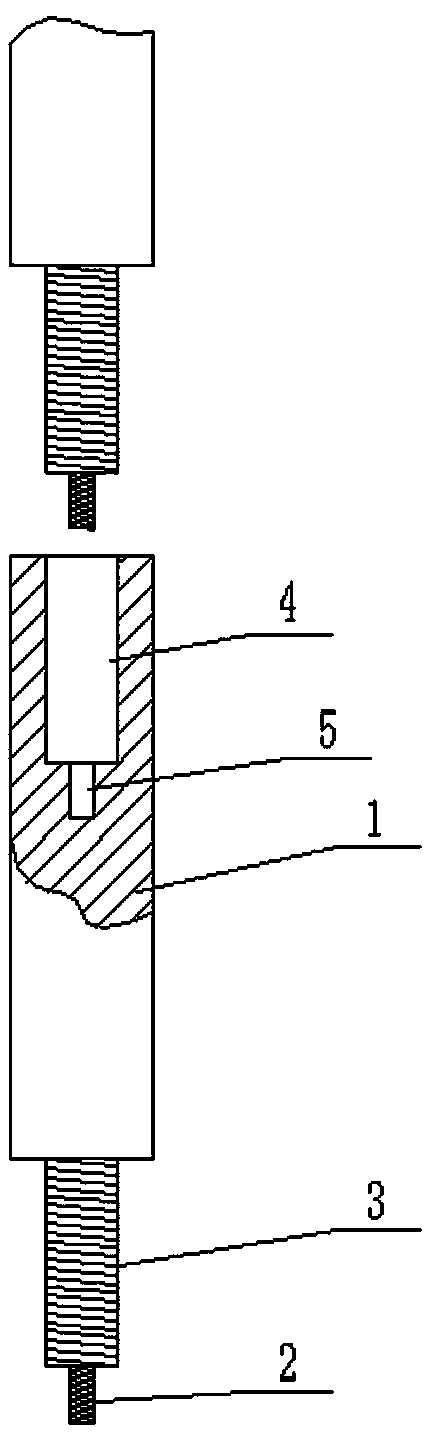

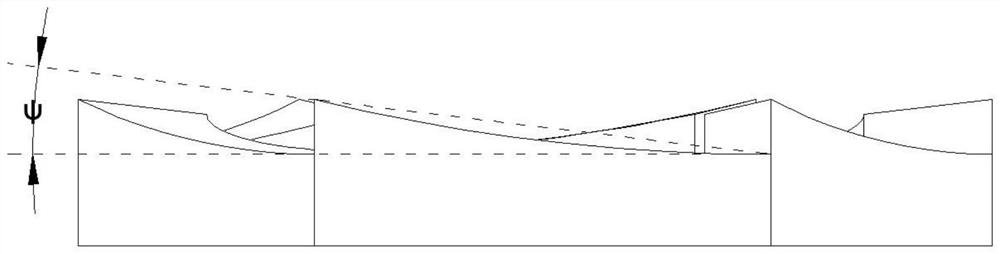

Connecting and fastening type petroleum drill rod

PendingCN108661572AFasten the connectionEasy to fixDrilling rodsDrilling casingsScrew threadPetroleum

The invention relates to a connecting and fastening type petroleum drill rod. The petroleum drill rod comprises a rod body, wherein a first threaded column and a second threaded column are arranged atone end of the rod body, and the first threaded column and the second threaded column are connected into a whole; the first threaded column is coaxial with the second threaded column; and the first threaded column, the second threaded column and the rod body are connected into a whole to form a stepped shaft structure. According to the design, the connecting and fastening type petroleum drill rodhas the beneficial effects that the connection is very stable and the possibility of loosening is very low.

Owner:JIANGSU TUOCHUANG SCI INSTR CO LTD

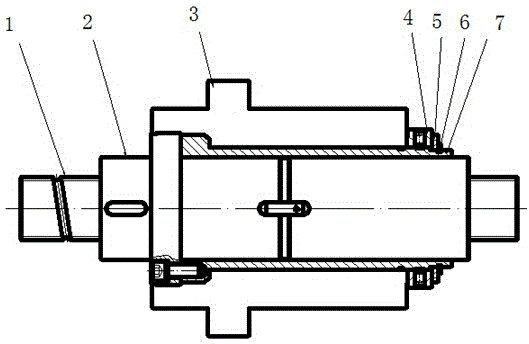

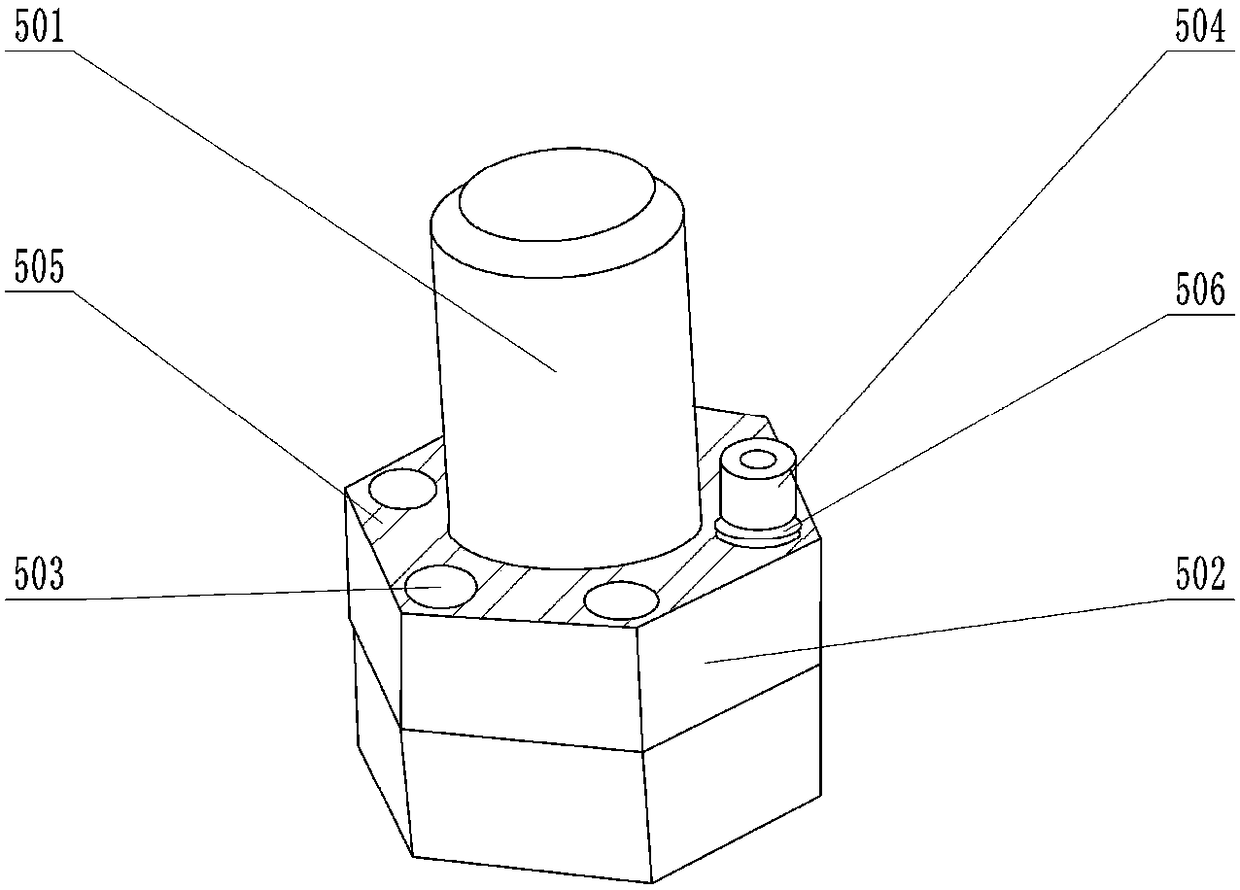

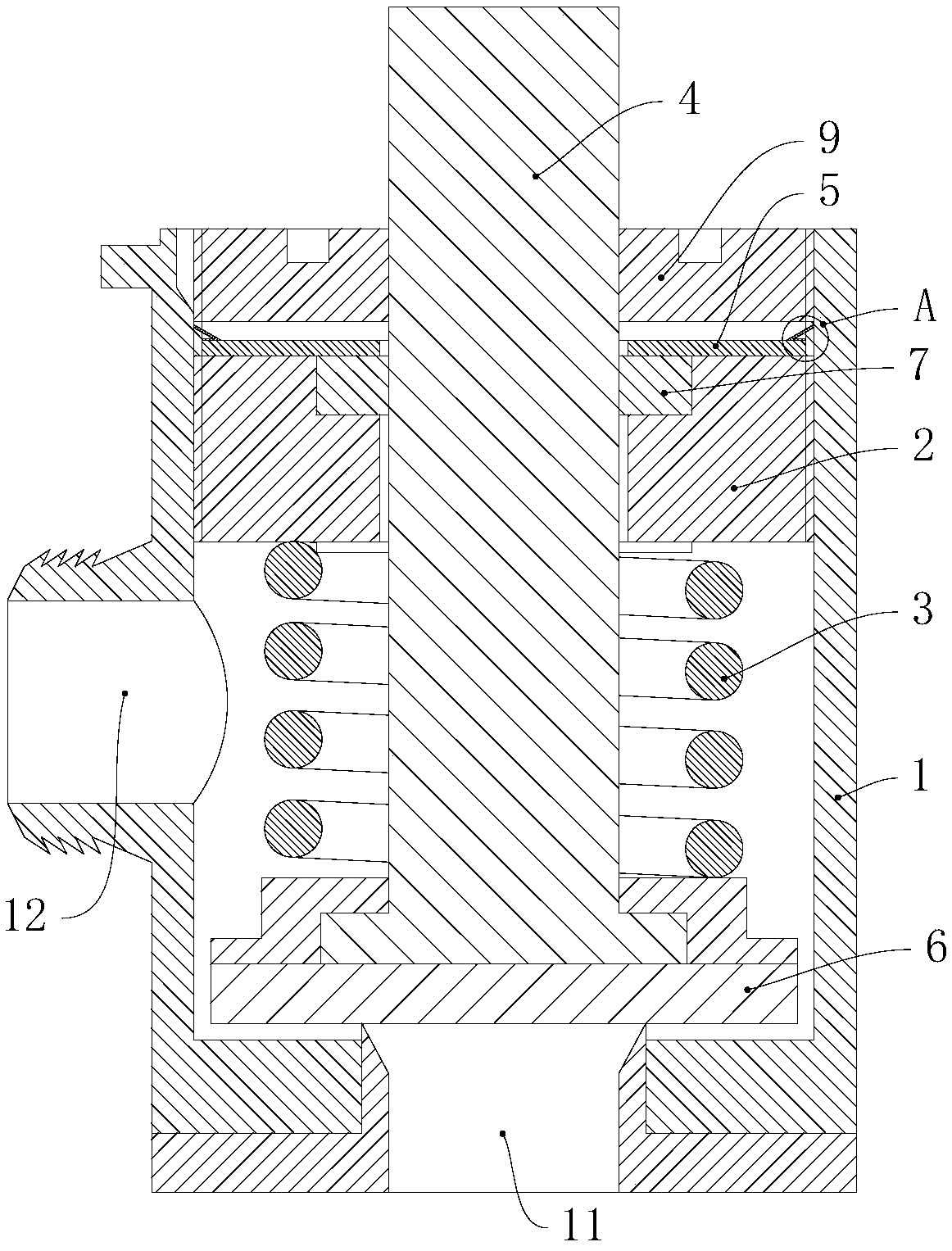

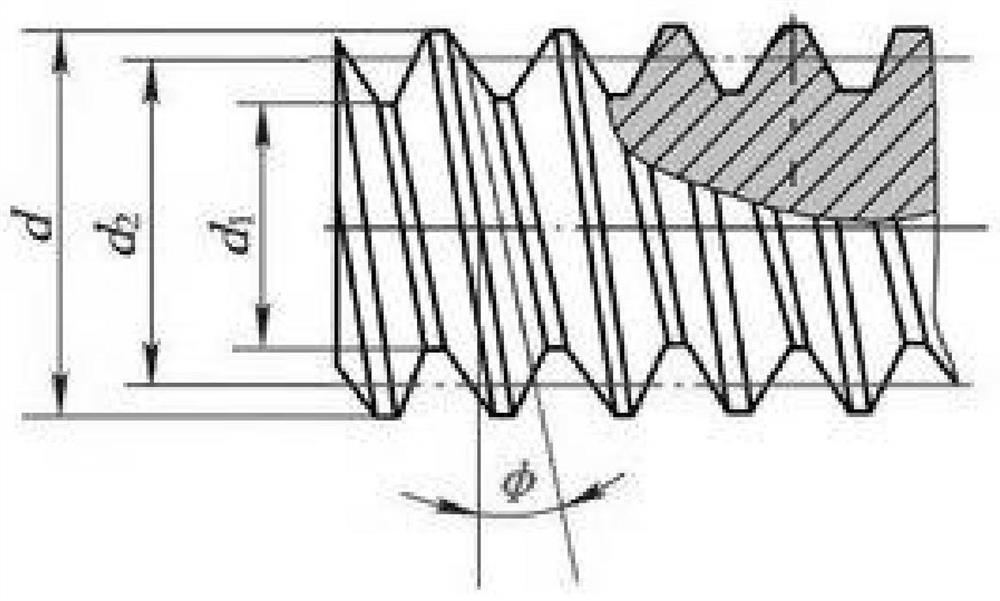

Nut rotation type ball screw pair with anti-loosening device

InactiveCN105065596AReduces the possibility of looseningImprove reliabilityGearingBall screwRolling-element bearing

The invention discloses a nut rotation type ball screw pair with an anti-loosening device. The nut rotation type ball screw pair comprises a ball screw, a ball nut pair, a shell containing a rolling bearing, and a nut sleeve. The ball nut pair and the sleeve nut are arranged on the ball screw in a sleeving manner and connected with the shell. A locking nut is arranged on the outer side of the nut sleeve. One end of the locking nut is connected with the end of the shell. The other end of the locking nut is provided with a stop gasket and an elastic check ring. The possibility that a traditional nut rotation type ball lead screw pair locking device gets loose is reduced to the maximum extent, and the reliability of the nut rotation type ball screw pair is greatly improved.

Owner:NANJING TECHN EQUIP MFG

Corrosion-resistant high-strength hexagonal bolt

PendingCN111503113AImprove structural strengthImprove corrosion resistanceWashersNutsCorrosion resistantEngineering

The invention discloses a corrosion-resistant high-strength hexagonal bolt which comprises a bolt body and a gasket; the bolt body further comprises a screw head, a stud and reinforcement ribs; the stud consists of a contraction section, close to the bottom of the screw head, and a threaded section, away from the bottom of the screw head; a plurality of side edge grooves are formed in the outer side wall of the threaded section; the reinforcing ribs are arranged in the side edge grooves respectively; the gasket further comprises an inner side elastic gasket and an outer side anti-loose gasket;the inner side elastic gasket is nested on the contraction section; and the outer side anti-loose gasket is connected with the stud through the inner side elastic gasket. Compared with the prior art,the corrosion-resistant high-strength hexagonal bolt is of a simple structure, is reasonable in design and is capable of effectively improving the structural strength and the corrosion resistance ofthe bolt and ensuring the stability and the reliability of bolt connection for a long time.

Owner:HAIYAN GUANGDA STANDARD PARTS CO LTD

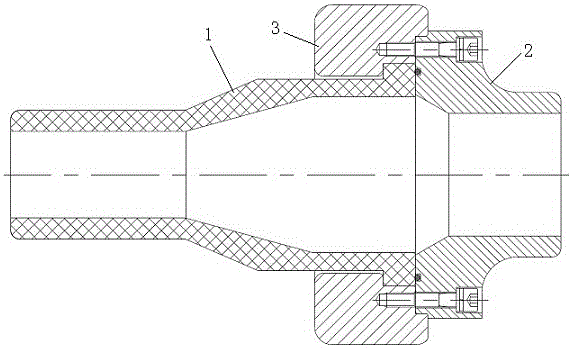

Nozzle connection structure, arc extinguish chamber using the same and breaker using the same

ActiveCN105977073AReduces the possibility of looseningAvoid it happening againElectric switchesForeign matterHigh pressure

The invention relates to the high voltage electrical equipment control field and discloses a nozzle connection structure, an arc extinguish chamber using the same and a breaker using the same. The nozzle connection structure comprises a nozzle and a moving contact which are respectively arranged in front and at the back; the outer side of the nozzle is sleeved by a flow guiding ring which is internally provided with a stepped hole with the front end being small and rear end being big; the rear side of the nozzle is provided with a protruded ring which protrudes outwardly; and the protruded ring is clamped in the stepped hole of the flow guide ring by a flow guide ring and the moving contact. In the nozzle connection structure, the arc extinguish chamber and the breaker, the protruded ring of the nozzle is clamped in the stepped hole of the flow guide ring by the flow guide ring and the moving contact, and a breaker nozzle is fixed on the moving contact by virtue of the flow guiding ring. Compared with the traditional direct bolt joint, the nozzle connection structure has reliable connection, reduces the possibility of looseness of the nozzle and prevents foreign matters produced by nozzle wearing.

Owner:PINGGAO GRP +3

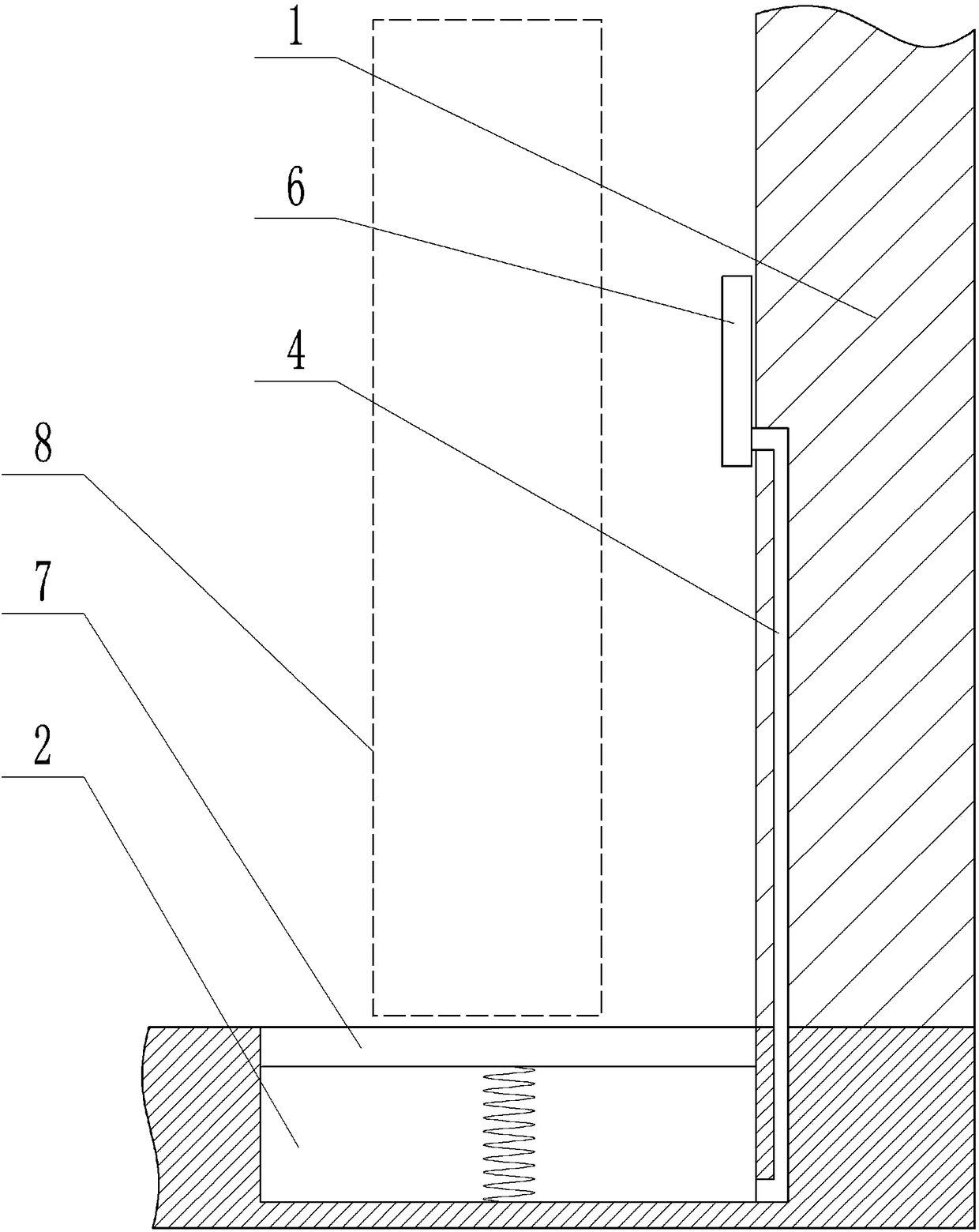

Building anchor rod fixing and mounting machine

The invention relates to a building anchor rod fixing and mounting machine. The machine comprises a position adjusting device, a fixing frame, a connecting port fixing device and an anchor rod fixingdevice. The fixing frame is mounted at the upper end of the position adjusting device. The anchor rod fixing device is mounted at the upper end of the fixing frame. The connecting port fixing device is arranged at the lower end of the fixing frame. By means of the building anchor rod fixing and mounting device, the problems that an existing anchor rod is generally inserted inwards manually, the anchor rod is prone to oscillating and deviating when a person holds the anchor rod by hand to decline, the anchor rod is prone to being inserted obliquely, in addition, due to the large grouting impactduring grouting, the position of a connecting port between the tail end of the anchor rod and a grouting machine connector is prone to loosening, and consequentially, the grouting progress is affected can be solved, and the machine has the advantages that the anchor rod is limited when being clamped, it is guaranteed that the anchor rod can stably decline, in addition, the situation of oblique inserting caused by deviating in the declining process is avoided, the position of the connecting port between the tail end of the anchor rod and the grouting machine connector is further fixed and sealed, and the probability of loosening in the position of the connecting port is reduced.

Owner:ZHONGNING COUNTY XINQIJHANG AGRI DEV CO LTD

Intelligent switch

PendingCN108538666AIncrease contact areaIncrease the bearing areaLavatory sanitoryElectric switchesFastenerEngineering

Owner:重庆博创知识产权运营有限公司

Safety valve, pressure system and water heater

ActiveCN109488795AAvoid damageAvoid premature failureEqualizing valvesSafety valvesPressure systemEngineering

The invention relates to the field of spring loaded valves. A safety valve provided by the invention comprises a valve body and a valve element, the valve element is fixedly arranged in an inner cavity of the valve body, and the inner wall of the valve body and the valve element jointly define a pressure relief passage; and a fastener is further included and is fixedly arranged on the valve body,and the fastener abuts against the end, far away from the pressure relief passage, of the valve element. The fastener abutting against the valve element is additionally arranged so that the valve element can be supported by the fastener when impacted by high-pressure fluid; and the capacity of the valve element to bear fluid impact is improved by abutting supporting of the fastener, the possibility that the valve element looses due to long-term fluid impact is reduced, the possibility of movement of the valve element towards the direction away from the pressure relief passage due to fluid impact is reduced, damage caused by fluid impact to the safety valve is prevented to a greater extent, and the safety valve is prevented from losing efficiency in advance.

Owner:GREE ELECTRIC APPLIANCES INC

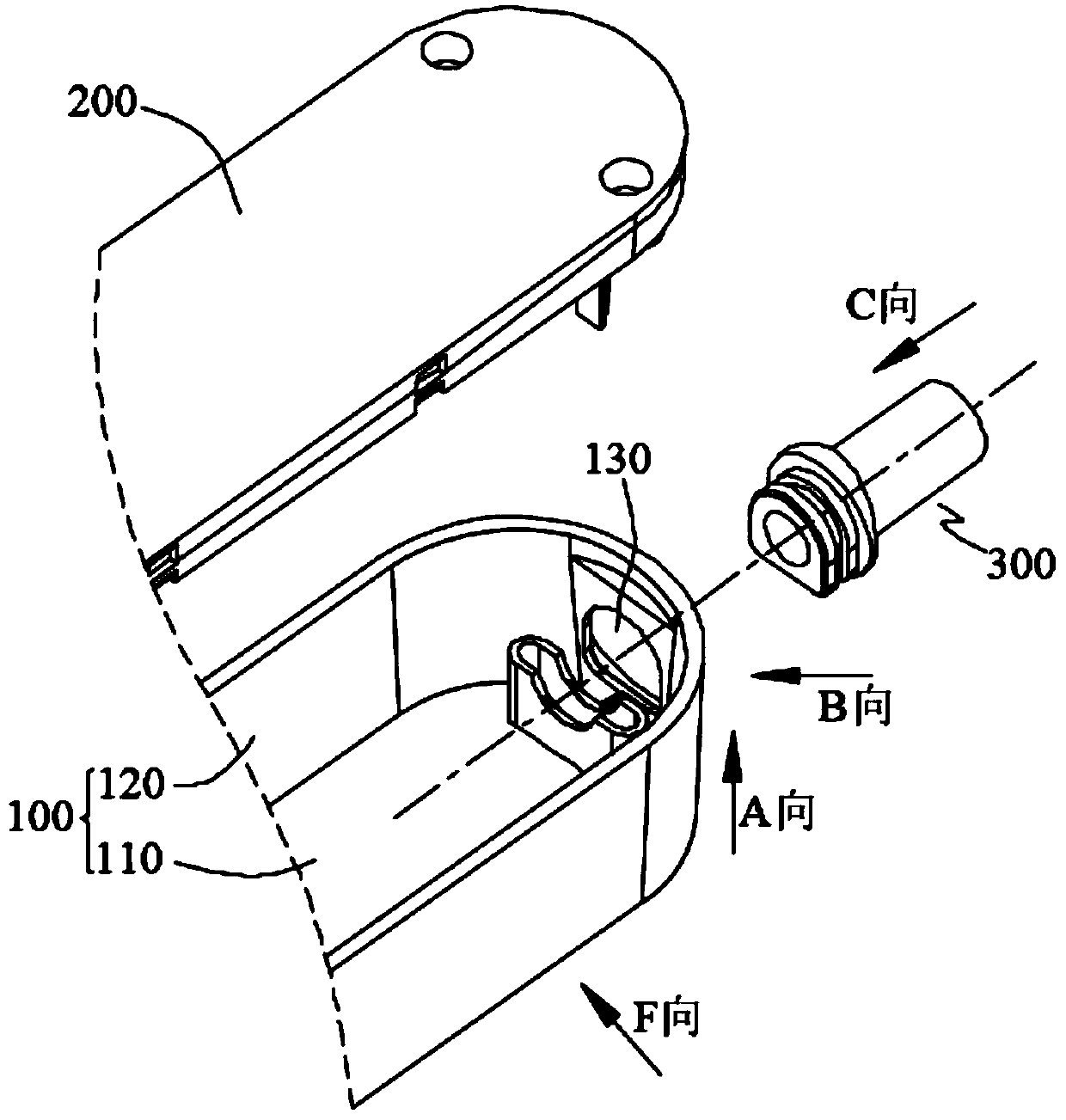

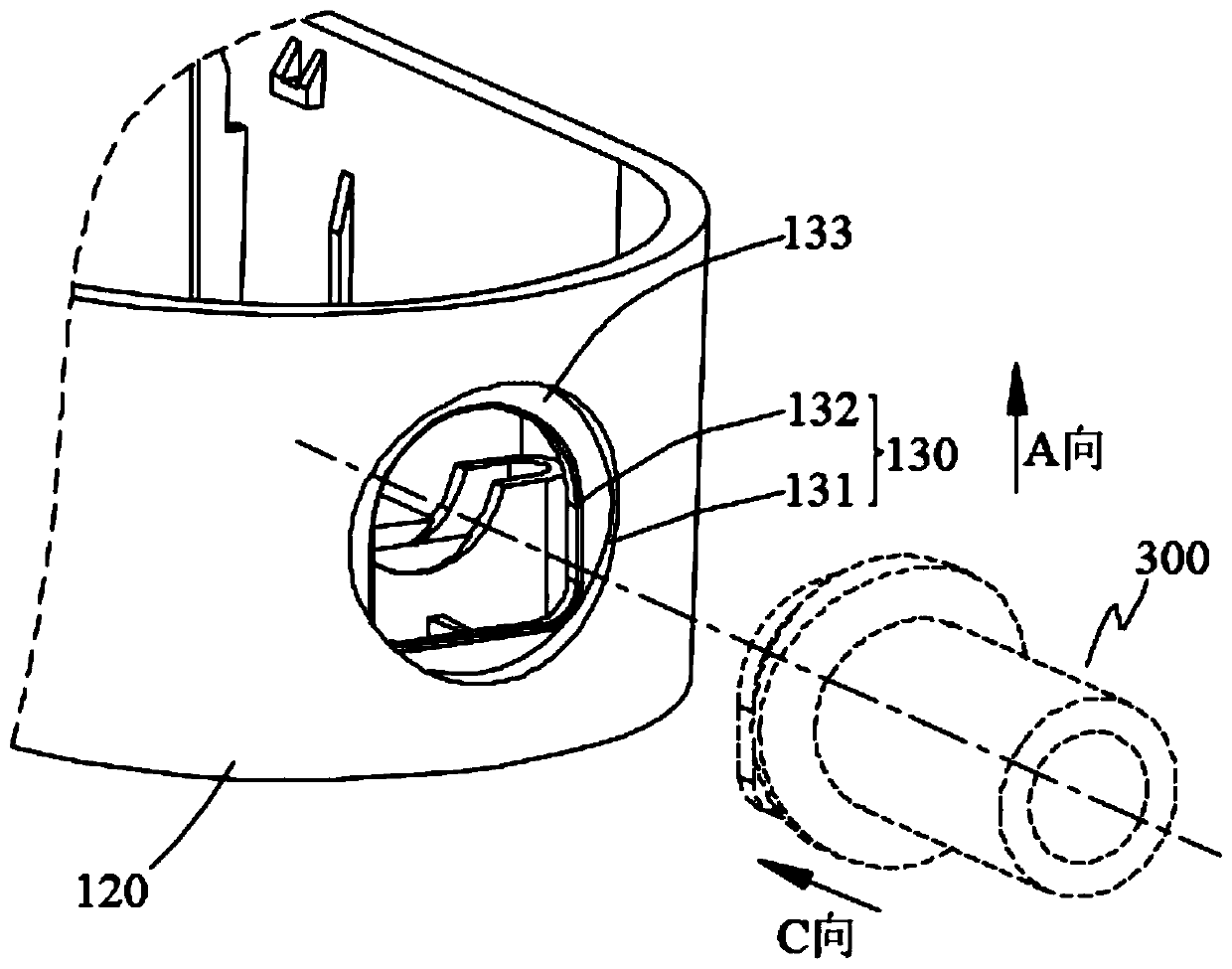

Paddle latch

ActiveUS9624700B2Easy to adjustReduces the possibility of looseningKeyhole guardsConstruction fastening devicesEngineeringMechanical engineering

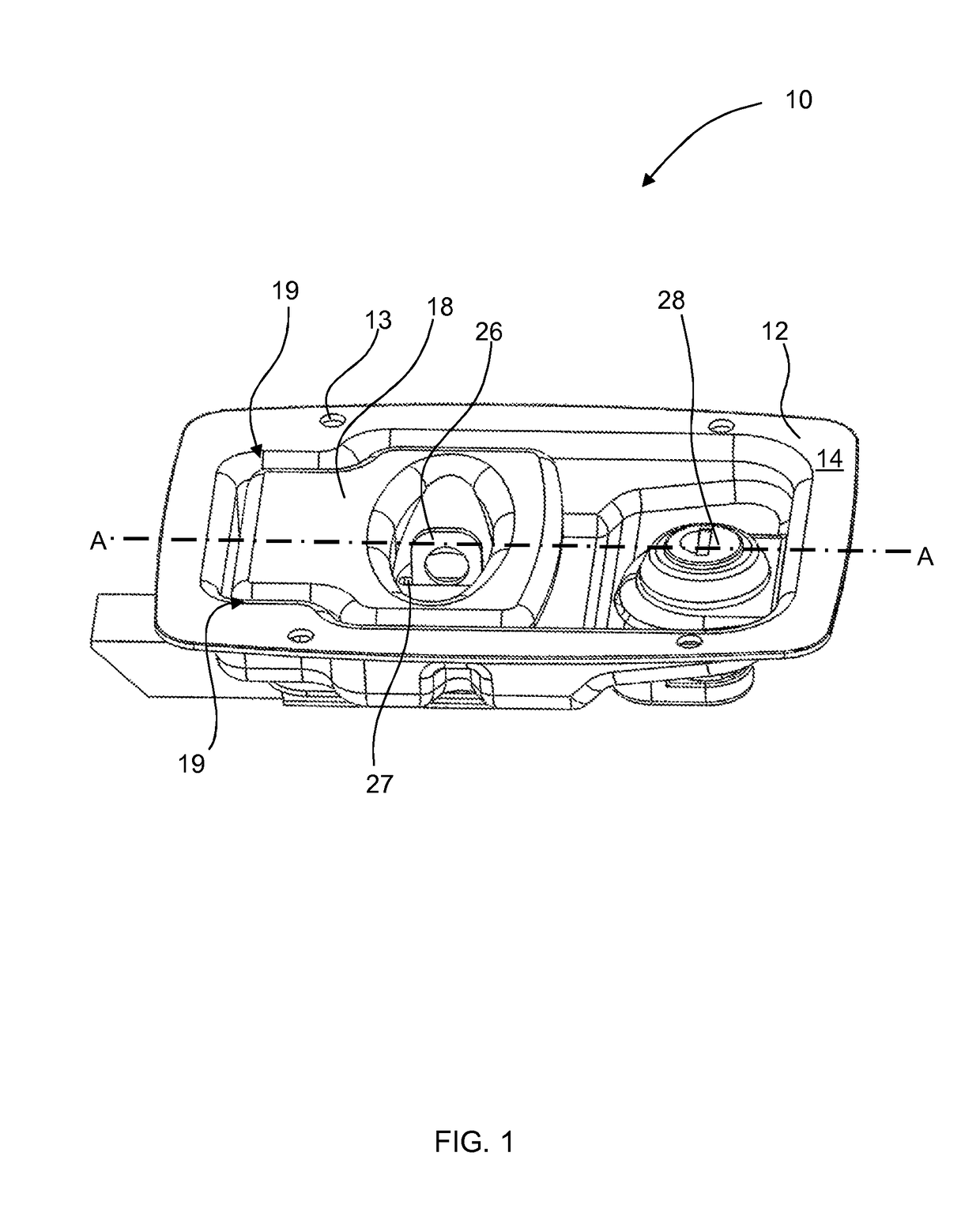

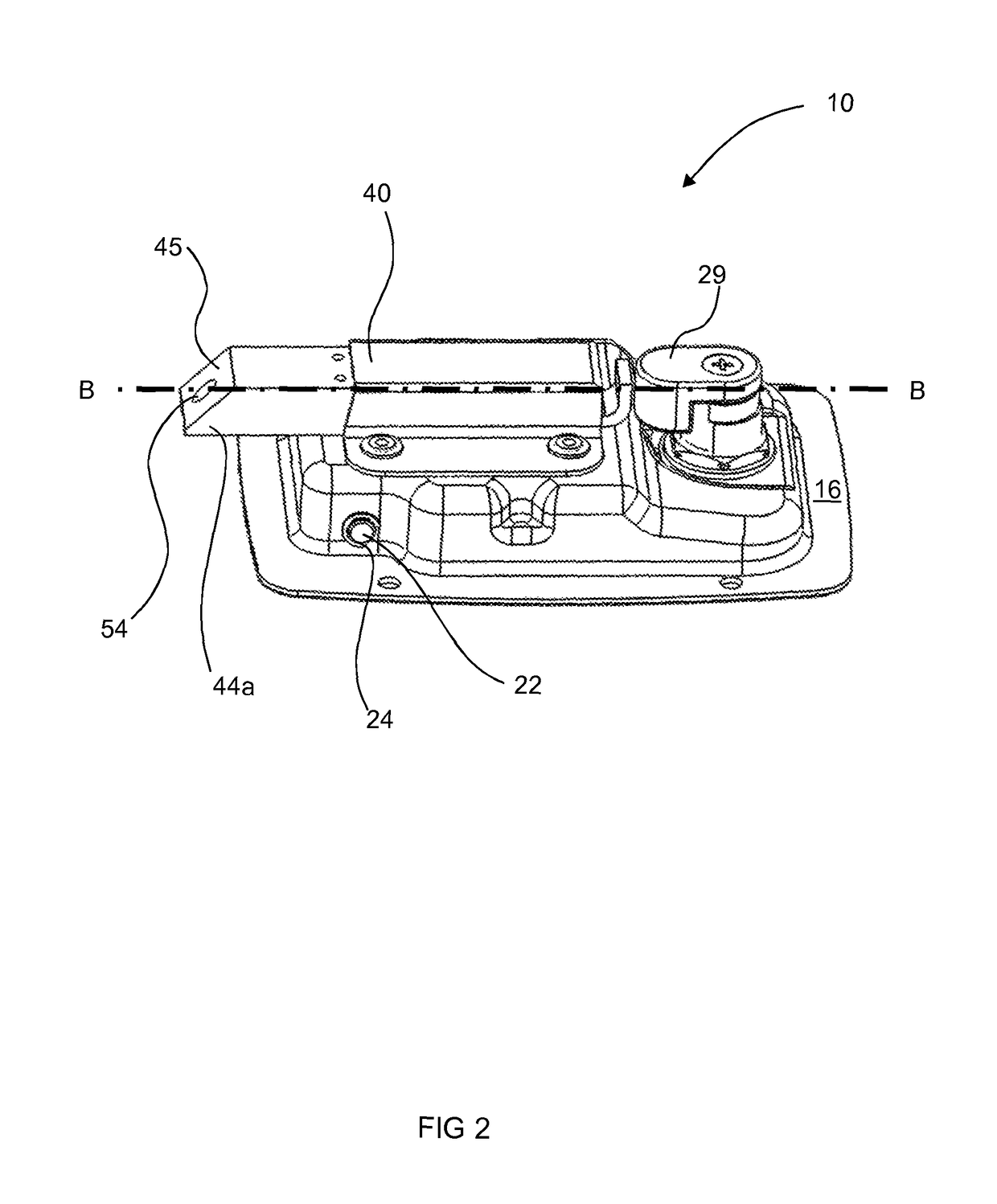

A paddle latch comprising a housing, a latch member and a bolt; wherein the bolt is mounted for sliding axial movement between a first, deployed, position and a second, retracted, position. The latch member is configured to move the bolt between said first and second positions upon actuation by a user. The paddle latch further comprises an adjustment mechanism. The adjustment mechanism is configured to provide selective adjustment of the deployed position of the bolt with respect to the housing.

Owner:WESTON BODY HARDWARE

Anti-port-damage industrial Ethernet switch

ActiveCN110416827AAvoid loose damageFixed neatlyCoupling device detailsNetwork connectorsIndustrial EthernetEngineering

The invention discloses an anti-port-damage industrial Ethernet switch, which includes a body. Multiple network cable ports are installed by inserting in a side of the body. An Ethernet circuit boardis fixedly installed in the body. Each network cable port includes a port base plate welded onto the Ethernet circuit board, the port base plate is covered with a port cover, and a network cable socket mechanism is installed in a sliding manner between the port cover and the port base plate. An anti-pulling bunching mechanism is installed by inserting on one side, equipped with the network cable ports, of the body. Network cable connectors are installed by inserting in the anti-pulling bunching mechanism. The anti-pulling bunching mechanism makes network cables in order and reduces the damagepossibility of the network cable ports caused by the pulling between the network cables. An anti-pulling guard plate fixedly inserts the network cable connectors into the network cable ports to avoidthe damage possibility of the network cable ports caused by the shaking of the network cable connectors. The elastic plugging / pulling of the network cable ports reduces the damage possibility of the network cable ports caused by rigid plugging / pulling.

Owner:北京平和创业科技发展有限公司

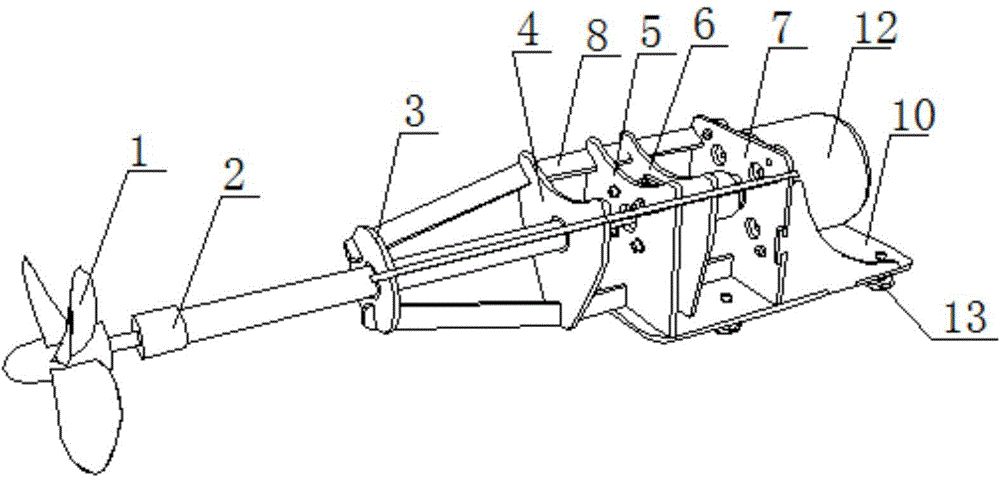

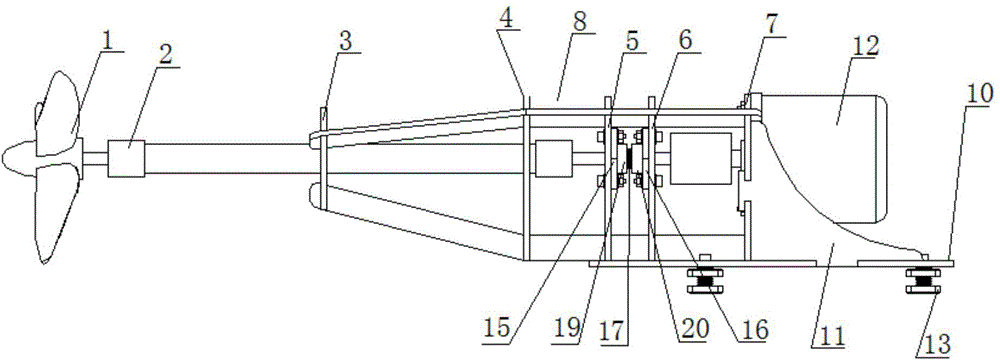

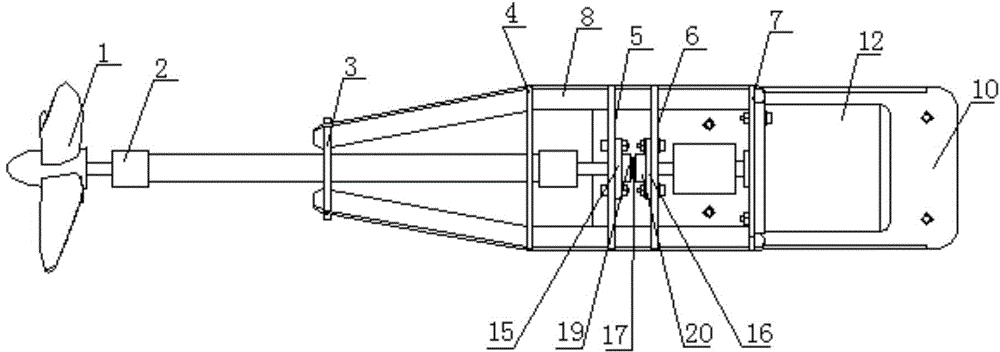

Novel electric propulsion device

ActiveCN104443338ASimple structureReasonable designPropulsion power plantsPropulsive elementsPropellerMotor shaft

The invention discloses a novel electric propulsion device. On the basis of an original simple motor support which is only composed of a motor installation plate and an installation base, a transmission shaft installation plate and a tensioning connecting piece are additionally arranged, and the characteristics that the structure is simple and the design is reasonable are still kept. Thus, when a linkage part (such as a propeller) runs at high speed, the transmission shaft installation plate and the connecting piece will support a transmission shaft and share a part of force, so that the situation that propulsion force generated by the linkage part is completely and directly transmitted to a motor shaft through the transmission shaft is avoided; moreover, the connecting piece can tension the transmission shaft and a motor through the motor installation plate and the transmission shaft; a buffering assembly is additionally arranged, vibration generated by the linkage part and vibration generated by work of the motor itself can both be buffered through the buffering assembly, and the probability that the motor shaft and the transmission shaft become loose is reduced.

Owner:ZHEJIANG OCEAN UNIV

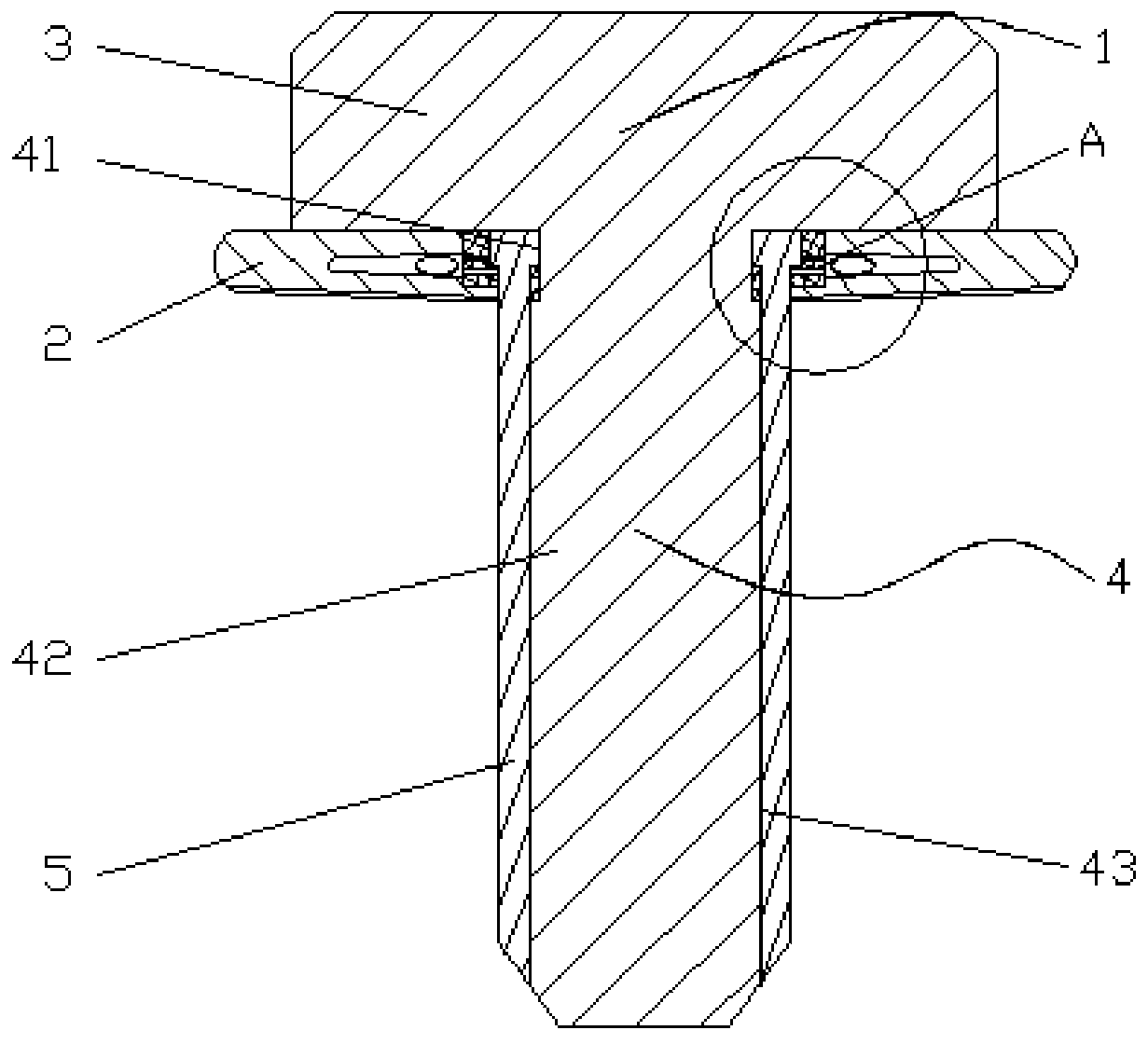

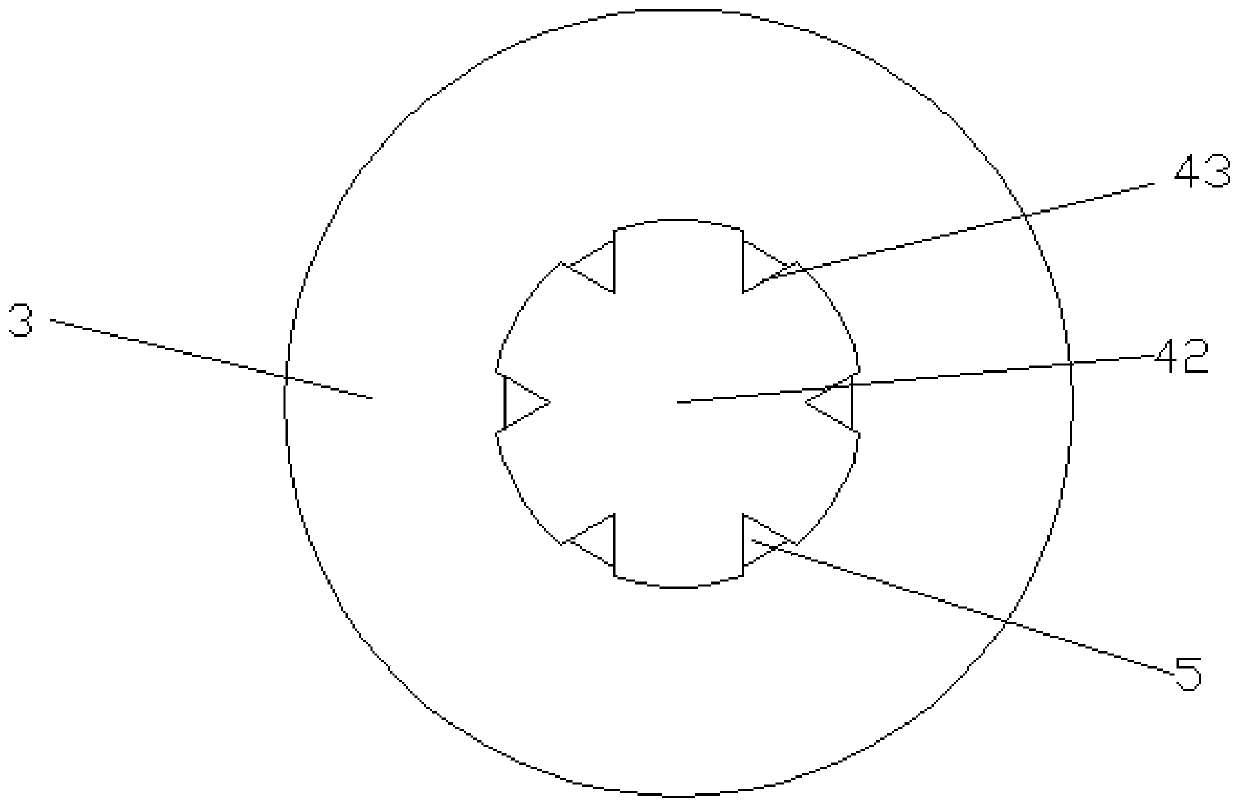

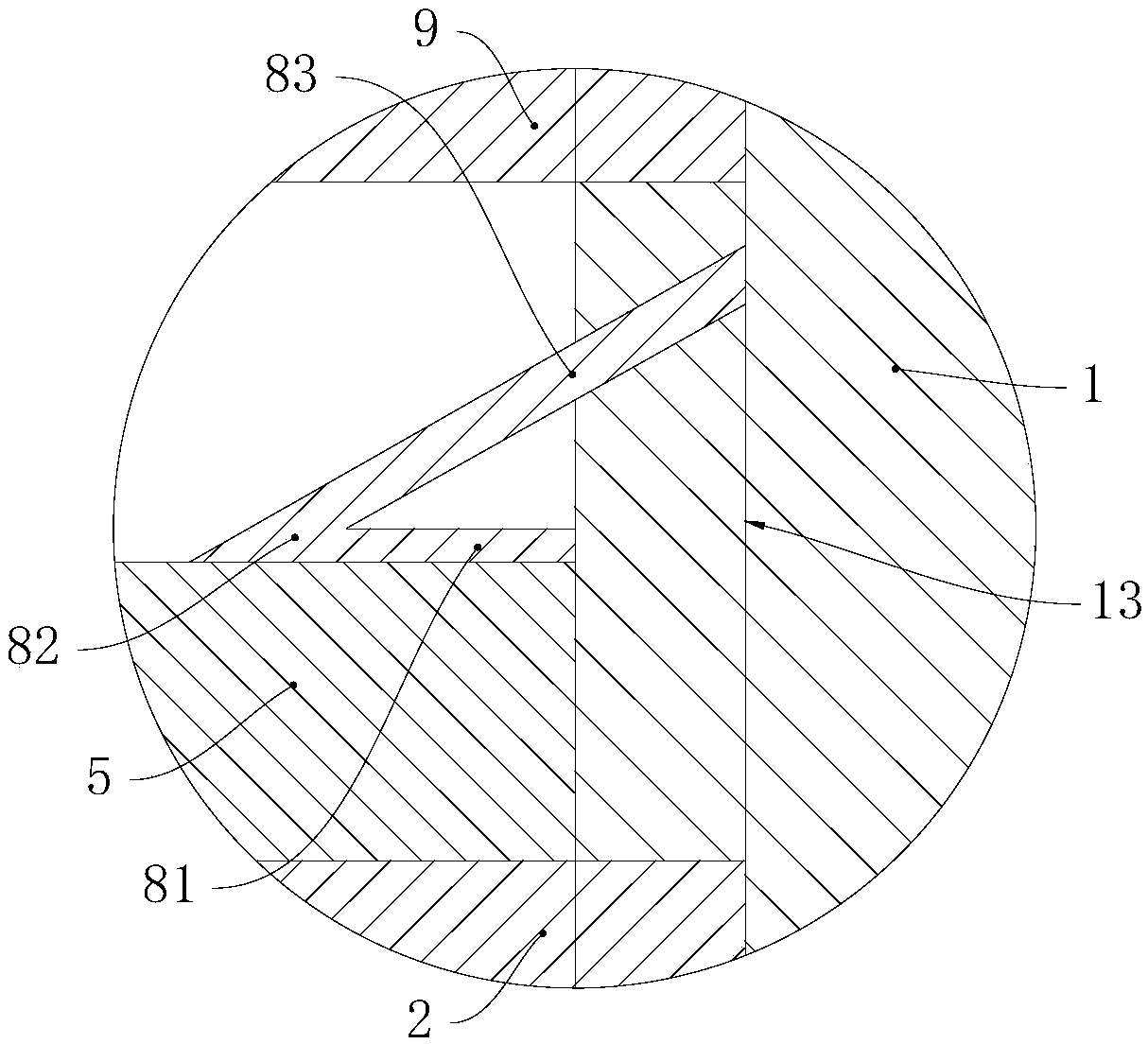

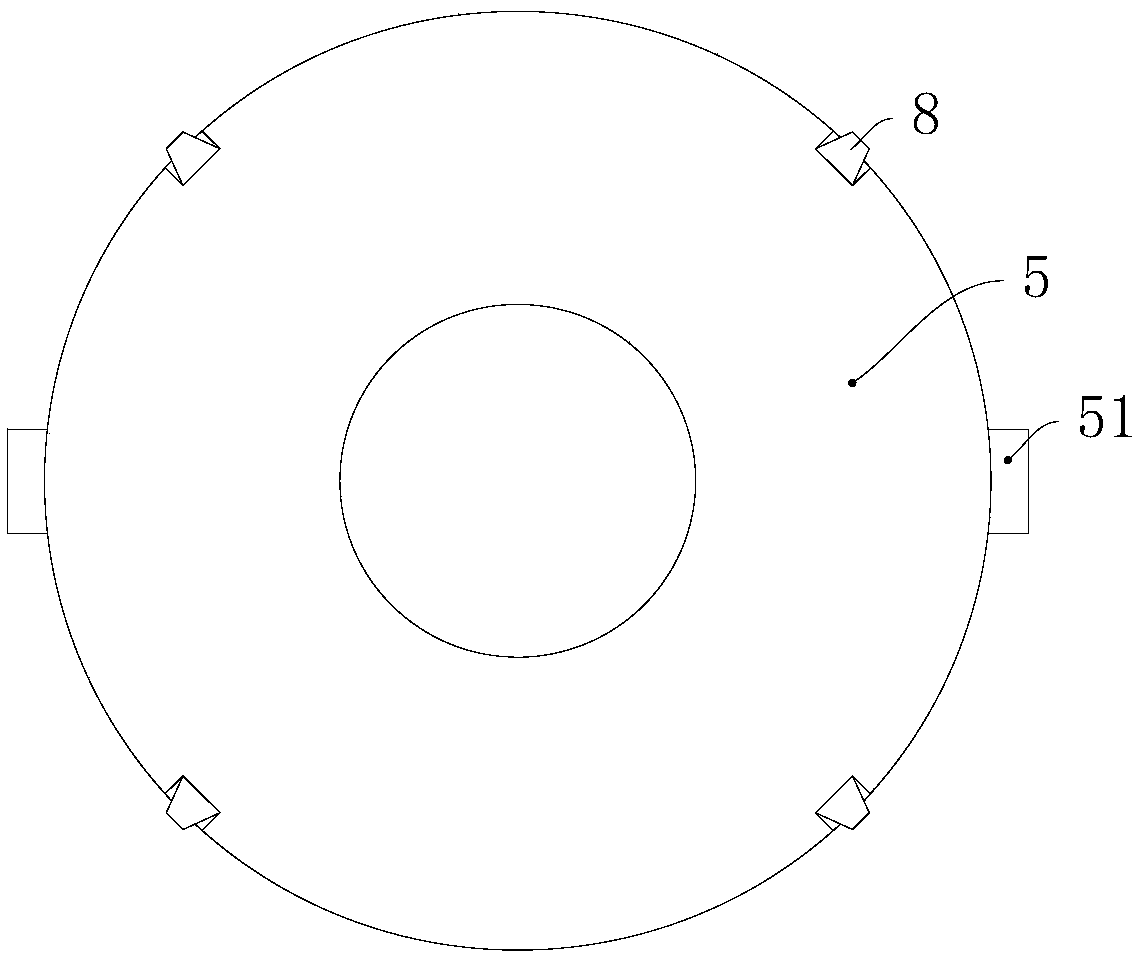

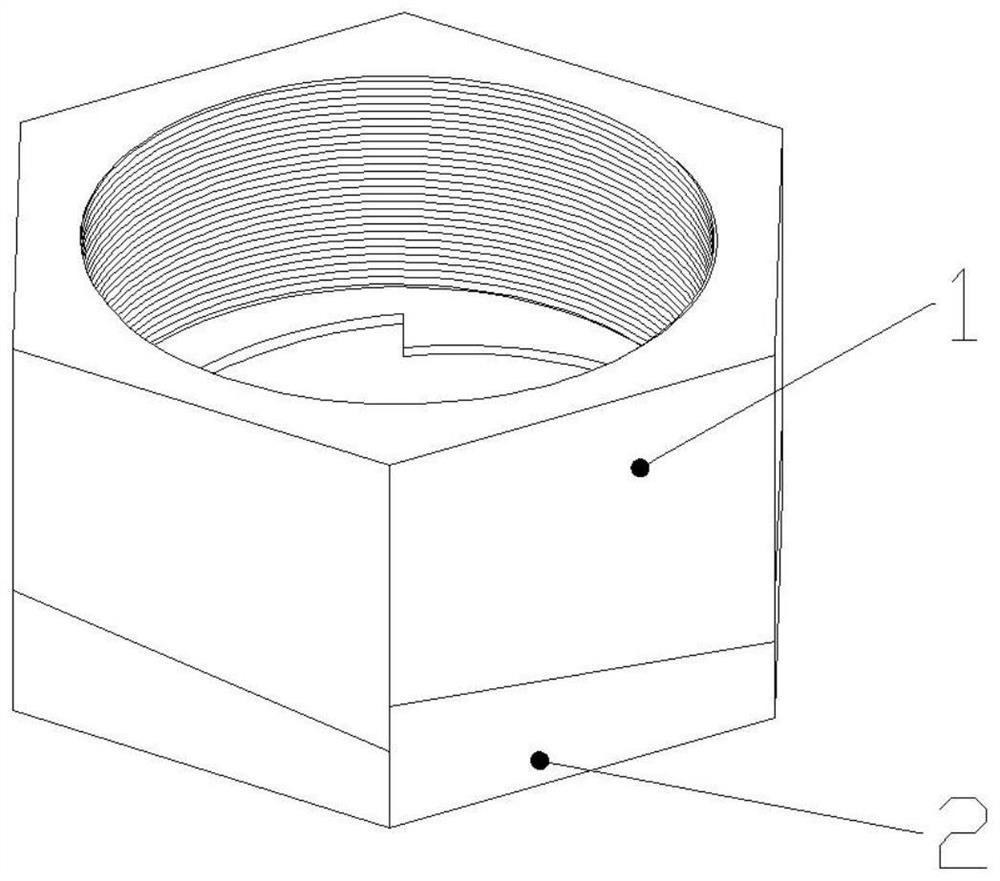

Anti-loosening nut and gasket assembly

ActiveCN114135564ALoose component is smallReduces the possibility of looseningNutsBoltsCounter rotationFastener

The invention discloses an anti-loosening nut and gasket assembly which comprises a nut and a gasket, and wedge blocks are arranged on the contact faces of the nut and the gasket. The lower end face of the wedge-shaped block of the nut and the upper end face of the wedge-shaped block of the gasket are oppositely arranged and are inclined planes, and when the nut and the gasket rotate relatively, the lower end face of the wedge-shaped block of the nut and the upper end face of the wedge-shaped block of the gasket slide relatively and then are in staggered pressing contact, so that the height of a nut and gasket combination is changed; and the heights of at least one part of the wedge blocks on the nut are sequentially reduced, so that the gasket can slide relative to the nut when the gasket reversely rotates around the fastening direction of the nut. When the gasket rotates reversely, the component force for pushing the nut to loosen is small, the loosening possibility of a fastener is reduced, and the anti-loosening service life is longer.

Owner:LHASA YUZHIXIN TECH LTD CO

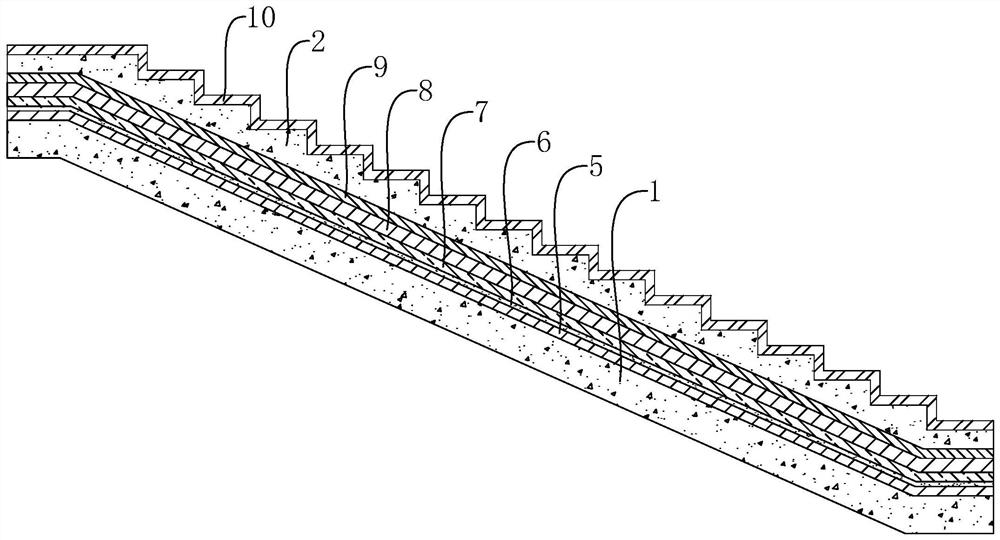

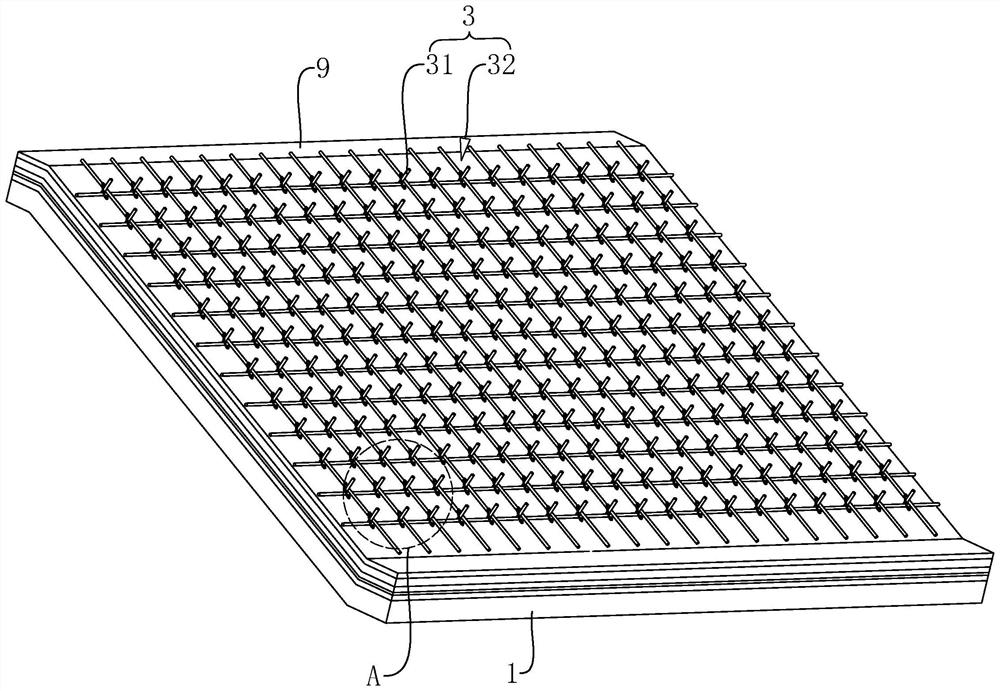

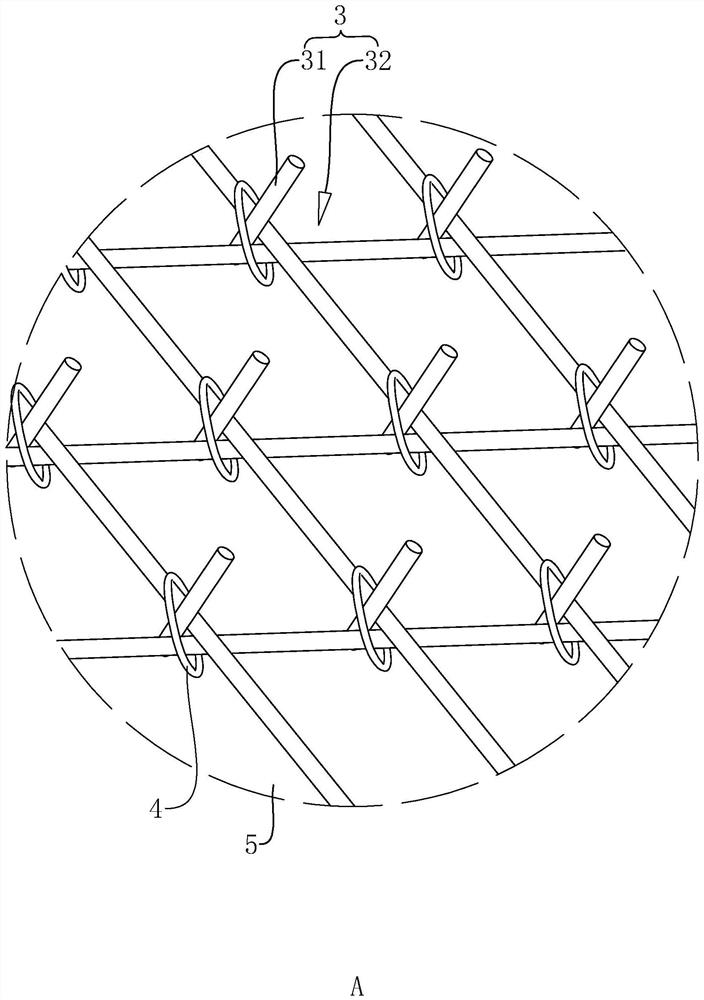

Structure for preventing steps of pitched roof from slipping off and construction method thereof

ActiveCN114016676AImprove connection strengthEasy maintenanceBuilding roofsRoof covering insulationsArchitectural engineeringStructural engineering

Owner:晋陵设计(江苏)有限公司

Anti-pulling type new energy automobile charging port connecting mechanism

InactiveCN112803201ALock firmlyNot easy to looseEngagement/disengagement of coupling partsCharging stationsData verificationElectrically conductive

The invention relates to an anti-pulling type new energy automobile charging port connecting mechanism. The connecting mechanism comprises a socket assembly and a plug assembly. The socket assembly comprises a socket groove frame, a connector, a connecting table, a conductive contact mechanism and an induction input mechanism; and the plug assembly comprises a plug supporting rod, a conductive connection assembly and an induction output mechanism. The charging contact mechanism is locked and closed through the mechanically-driven lock catch mechanism, manual pressing and locking are not needed, and compared with a single-spring-bolt mechanism, the lock catch type locking mechanism is more stable in locking and not prone to loosening; and in addition, a wireless radio frequency system is adopted in the data verification mechanism, and compared with traditional hard wire connection, the data verification mechanism is not prone to being cracked, and safety is higher.

Owner:深圳市逸科网络科技有限公司

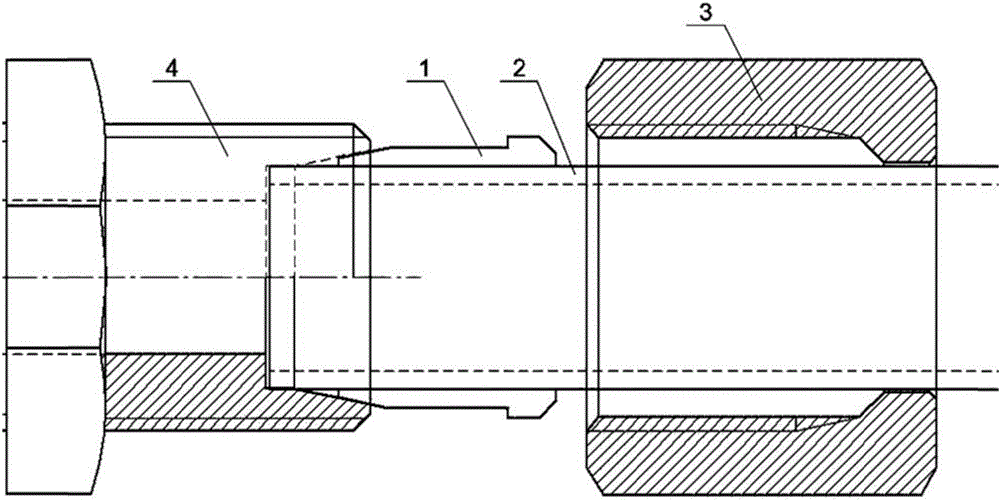

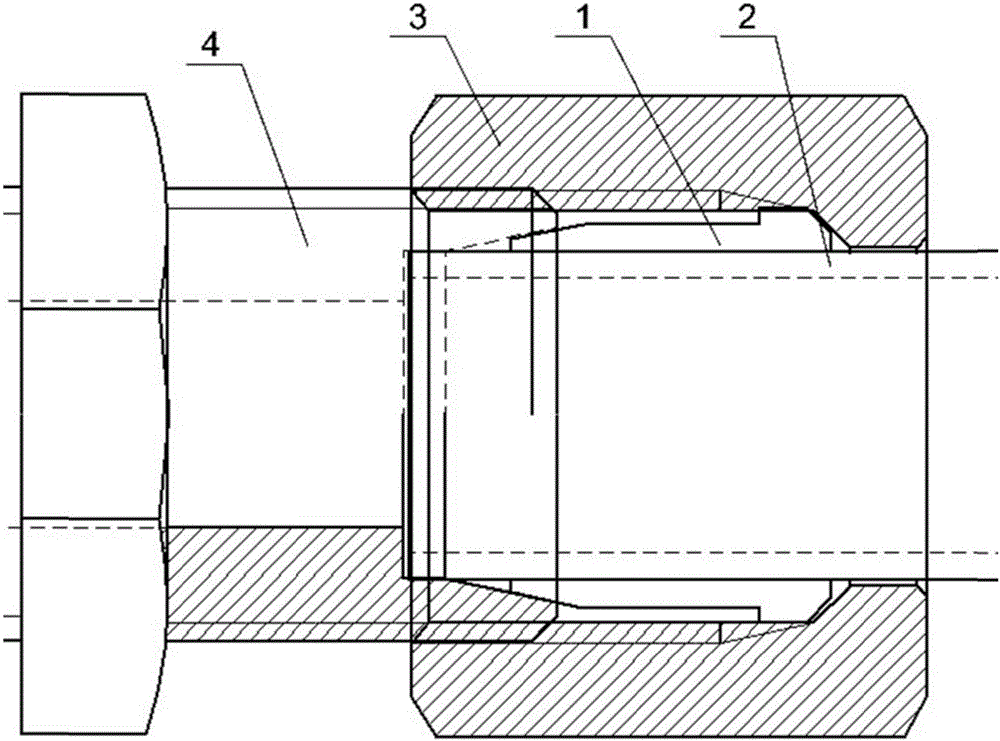

Sealing joint

InactiveCN106481905AImprove sealingFit closelyJoints with sealing surfacesEngineeringInternal cavity

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Green building unit type curtain wall heat preservation structure

The invention relates to the field of building curtain walls, in particular to a green building unit type curtain wall heat preservation structure which comprises a unit plate, an insertion plate and an insertion box are arranged in the unit plate in a sliding mode, and the sliding direction of the insertion plate and the sliding direction of the insertion box are collinear. Frame strips and inserting rods are fixed to the unit plates, the unit plates are located between the frame strips and the inserting rods, and the inserting rods on the unit plates are used for being matched with the frame strips on the adjacent unit plates in an inserted mode. A driving assembly is arranged in each unit plate, and when the inserting rods are inserted into the corresponding frame strips, the driving assemblies in the unit plates connected with the frame strips drive the inserting plates or the inserting boxes to penetrate out of the unit plates. The unit type curtain wall has the effect of improving the heat preservation performance of the unit type curtain wall.

Owner:深圳市华宇泰幕墙工程有限公司

Artificial elbow joint surface replacement prosthesis

ActiveCN105640673APreserve integrityAvoid destructionJoint implantsKnee jointsMedullary cavityHollow cylinder

The invention discloses an artificial elbow joint surface replacement prosthesis. The prosthesis comprises a prosthesis part matched in shape with distal humerus and mounted at the distal humerus, as well as an internal fixed steel plate and an external fixed steel plate which are connected with the prosthesis part and fixed to an inner side column and an outer side column of the humerus respectively, wherein the prosthesis part adopts a hollow cylinder-like structure; the external shape of the prosthesis part is the same as the joint surface shape of the distal humerus; the external contact surface of the prosthesis part is a smooth coating surface and is in contact with the joint surface of proximal ulna; and a first connecting part and a second connecting part are arranged at one end, connected with the prosthesis part, of the inner fixed steel plate and positioned in two perpendicular planes respectively. According to the prosthesis, the bone mass loss caused by operations of wide-range dissection of soft tissues around elbow joint, osteotomy, marrow expansion and the like in a prosthesis replacement process can be avoided, the prosthesis loose of an insertion-type prosthesis can be avoided, and the incidence rate of deep infection caused by intramedullary operation can be reduced.

Owner:WUHAN UNITED IMAGING HEALTHCARE SURGICAL TECH CO LTD

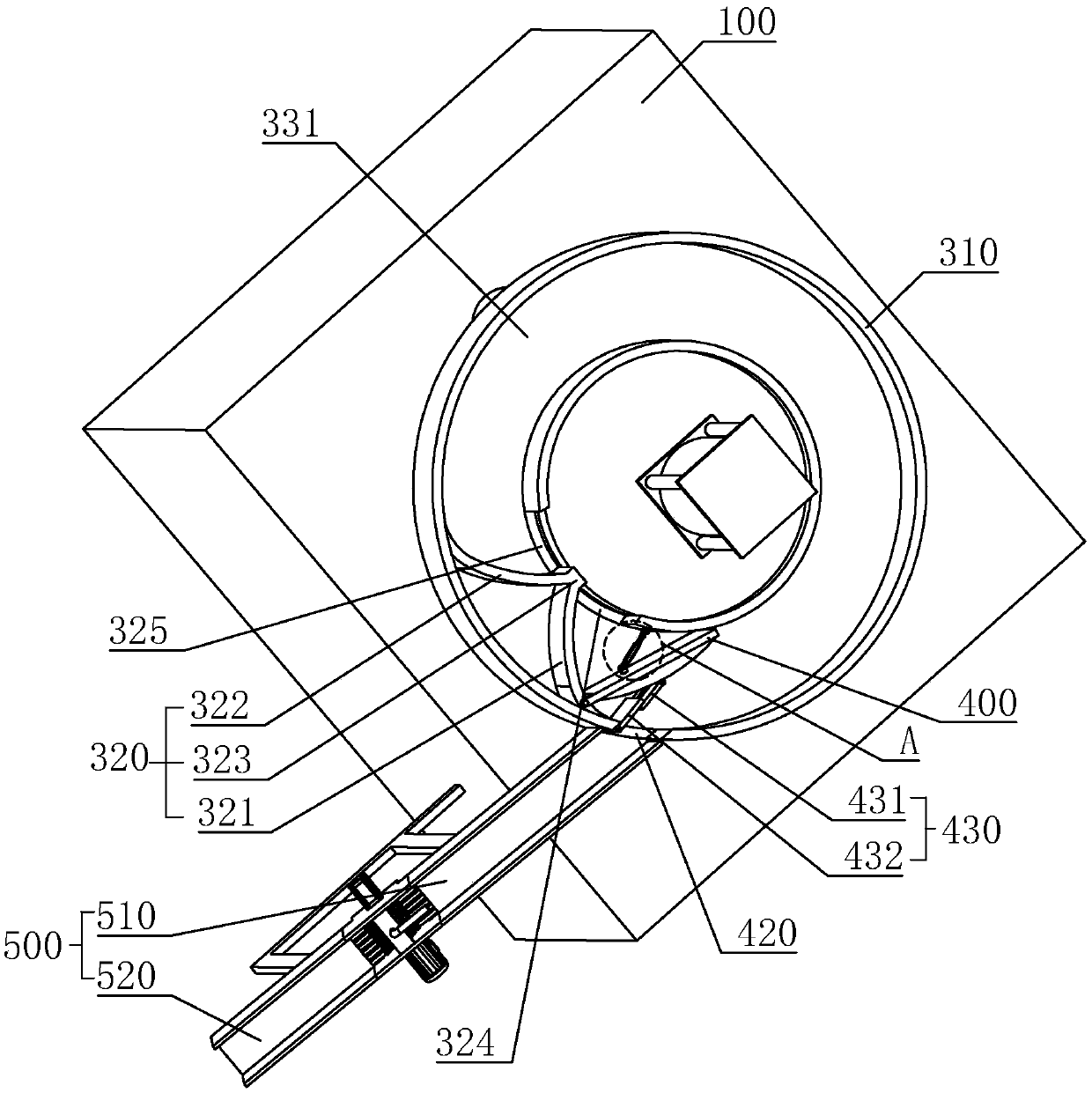

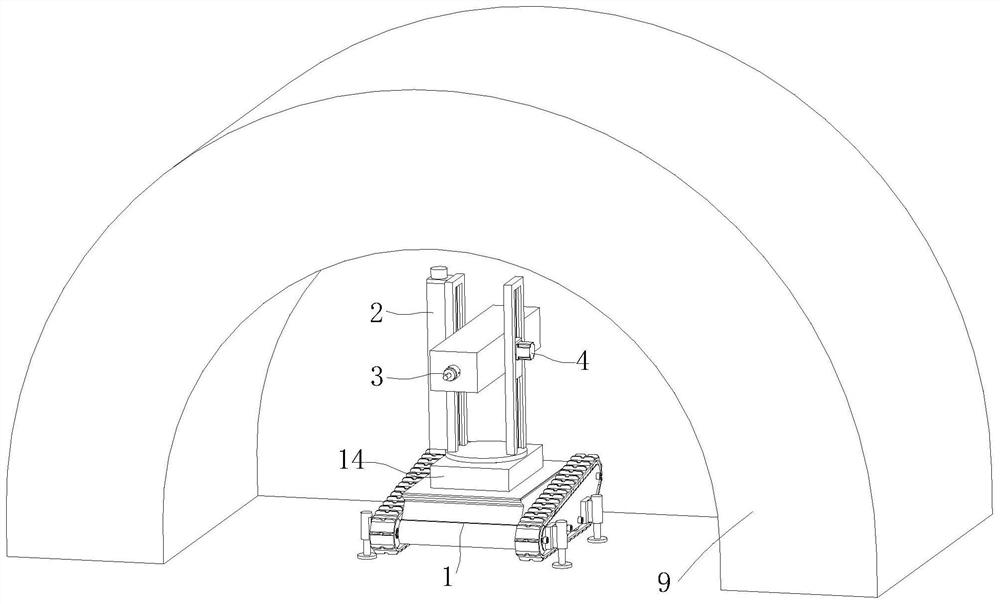

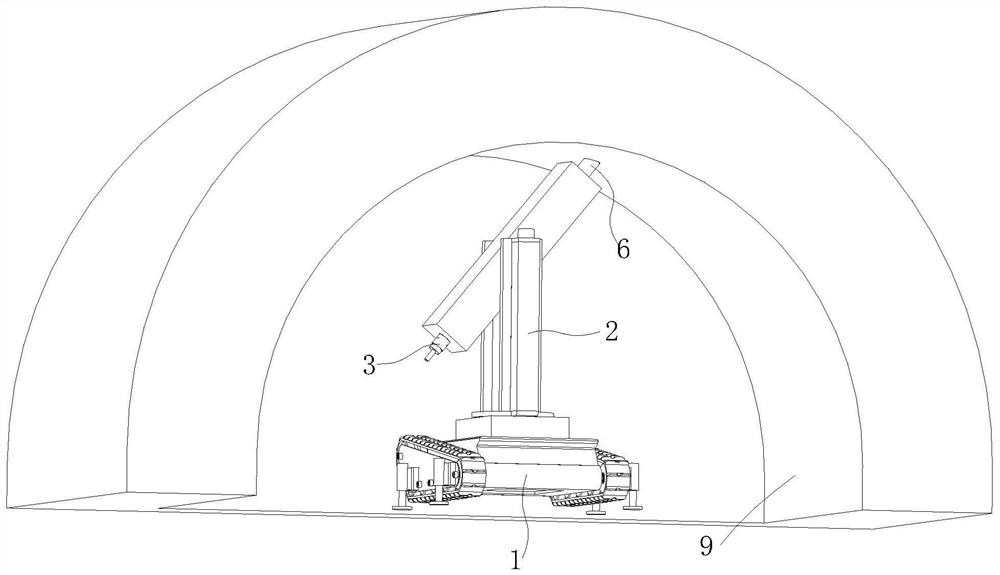

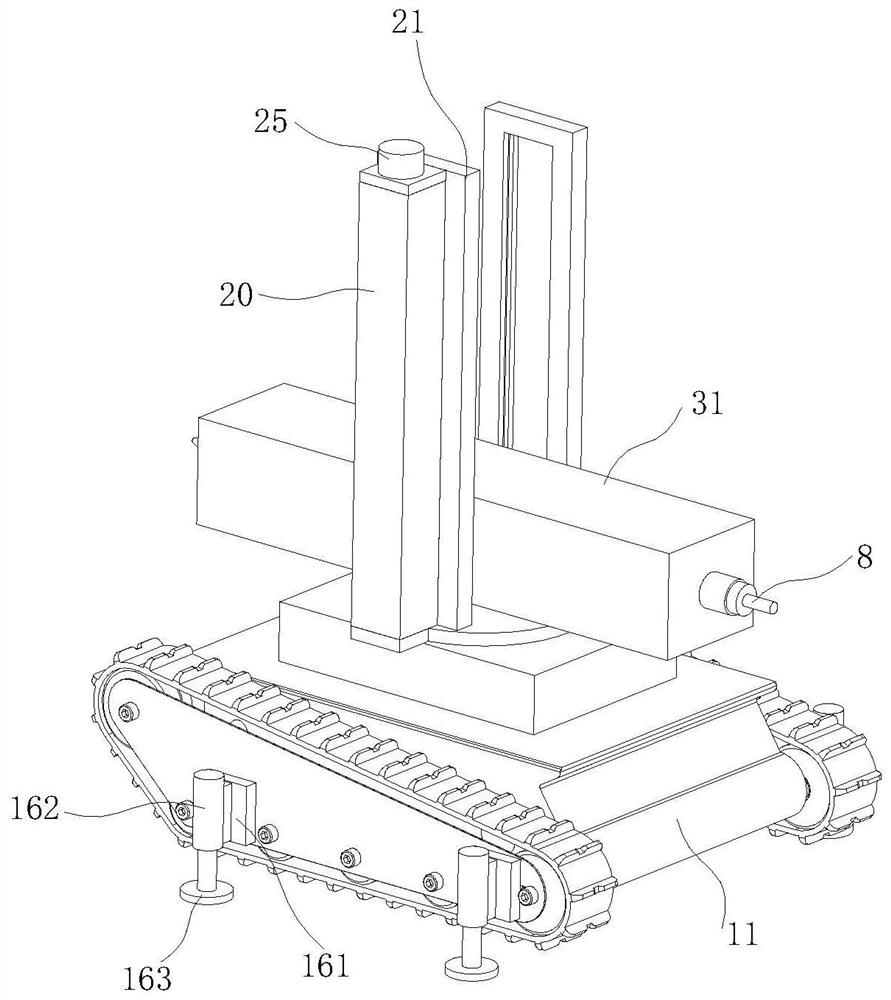

Tunnel water inrush early warning sensor punching device, mounting device and water inrush early warning system

PendingCN112761521ASimple structureEasy to useMining devicesDerricks/mastsEarly warning systemPunching

The invention relates to the technical field of tunnel water inrush early warning, in particular to a tunnel water inrush early warning sensor punching device, a mounting device and a water inrush early warning system. The tunnel water inrush early warning sensor punching device comprises a horizontal angle adjusting mechanism, a height adjusting mechanism and a punching mechanism, wherein the height adjusting mechanism is arranged on the horizontal angle adjusting mechanism and can rotate on the horizontal angle adjusting mechanism, and the punching mechanism is arranged on the height adjusting mechanism and can move up and down along the height adjusting mechanism. According to the tunnel water inrush early warning sensor punching device and the mounting device, the punching mechanism can be freely adjusted in the horizontal direction and the vertical direction, the adjusting precision and efficiency are high, punching and mounting construction can be conveniently conducted on mounting holes with different heights and different angles, the structure is simple, use is convenient, and the punching and mounting efficiency is improved.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Cable connector

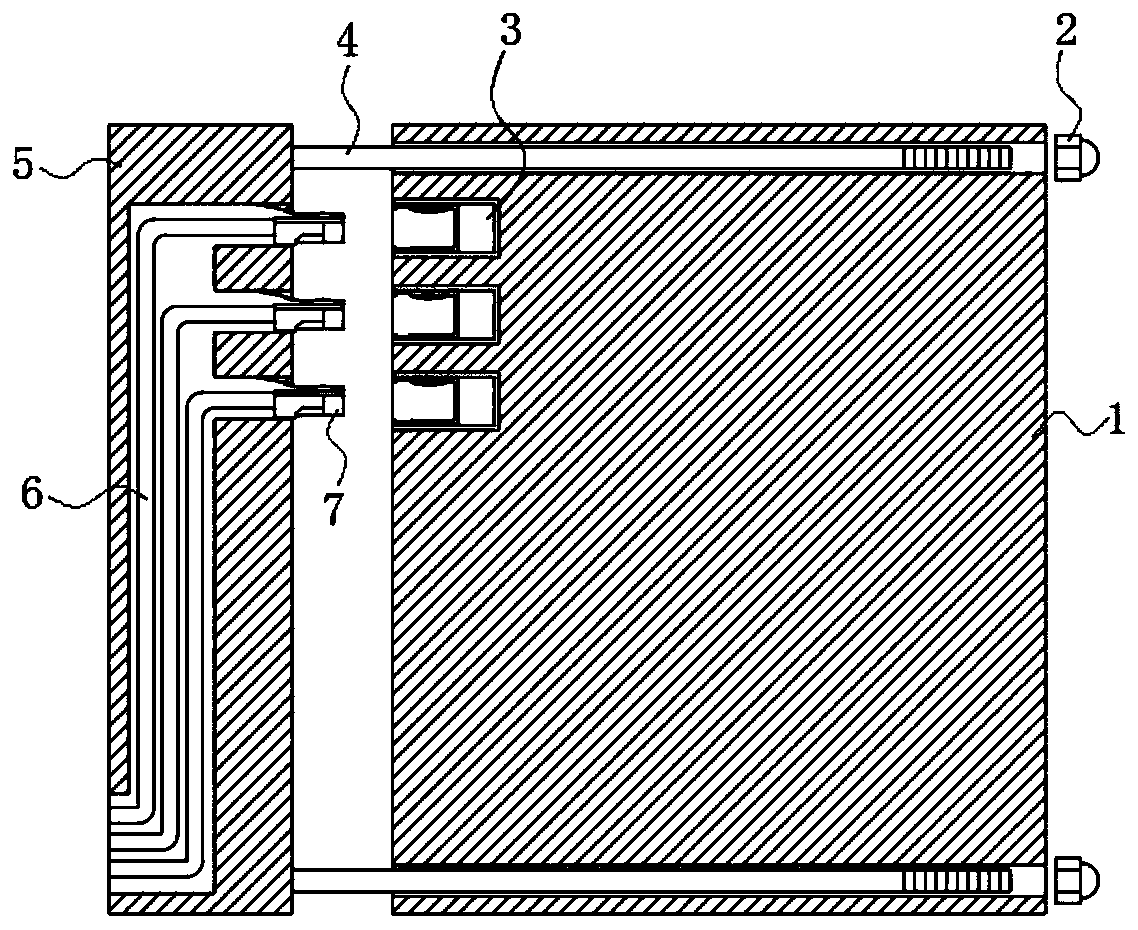

ActiveCN110829051AReduces the possibility of looseningIncrease contact areaElectric connection structural associationsRotational axisScrew thread

The invention relates to a cable connector, and the connector comprises an upper clamping plate and a lower clamping plate; cable holders are arranged on the upper clamping plate and the lower clamping plate, wherein long-strip-shaped cable inlaying grooves are formed in the upper clamping plate and the lower clamping plate respectively. Each cable holder comprises a movable sliding block. Slidinggrooves used for sliding of the movable sliding blocks are formed in the upper clamping plate and the lower clamping plate. A rotating frame is arranged on the inner wall of the openings of the sliding grooves; a plurality of inserting pieces are arranged on the rotating frame in a linear array manner; a rotating shaft is integrally arranged in the middle of the inserting pieces, the rotating shaft is rotationally connected with a rotating hole in the rotating frame, a poking piece is arranged on one side wall of the rotating shaft, a plurality of pushing pieces are fixed to the bottom of themovable sliding block in a linear array mode, the poking piece makes contact with the pushing pieces, and a cable inserting piece is arranged on the side wall of the other side, corresponding to thepoking piece, of the rotating shaft; pushing screws are further arranged at one end of the upper clamping plate and one end of the lower clamping plate and are in threaded connection with the upper clamping plate and the lower clamping plate, and the ends of the pushing screws make contact with the movable sliding blocks.

Owner:SHENZHEN XFANIC TECH CO LTD

Fastening structure suitable for movable floating nuclear power plant platforms

ActiveCN104533924AReduces the possibility of looseningImprove sealingNutsBoltsStructural engineeringNuclear power plant

The invention discloses a fastening structure suitable for movable floating nuclear power plant platforms. The fastening structure comprises bolt column bodies, the platforms connected through the bolt column bodies and two nuts matched with the bolt column bodies; a plurality of small bolt holes are evenly formed in each nut, and the two adjacent nuts are connected in the mode that small bolts are installed in the small bolt holes. According to the actual sea condition characteristics, an existing fastening structure is improved; according to the bolt screwing principle, the multiple small bolt holes are formed in the end face of each nut, the structure mode that the small bolts are arranged is used, and the multiple small bolt holes are formed to reduce the weight of the main nuts; meanwhile, the small bolts are evenly distributed so that fixation between the nuts can be scattered to the end faces of the nuts, the contact area between the two nuts is accordingly increased, the mutual stress area is increased, the possibility of looseness between the nuts is greatly reduced, and the overall sealing performance of the bolts is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

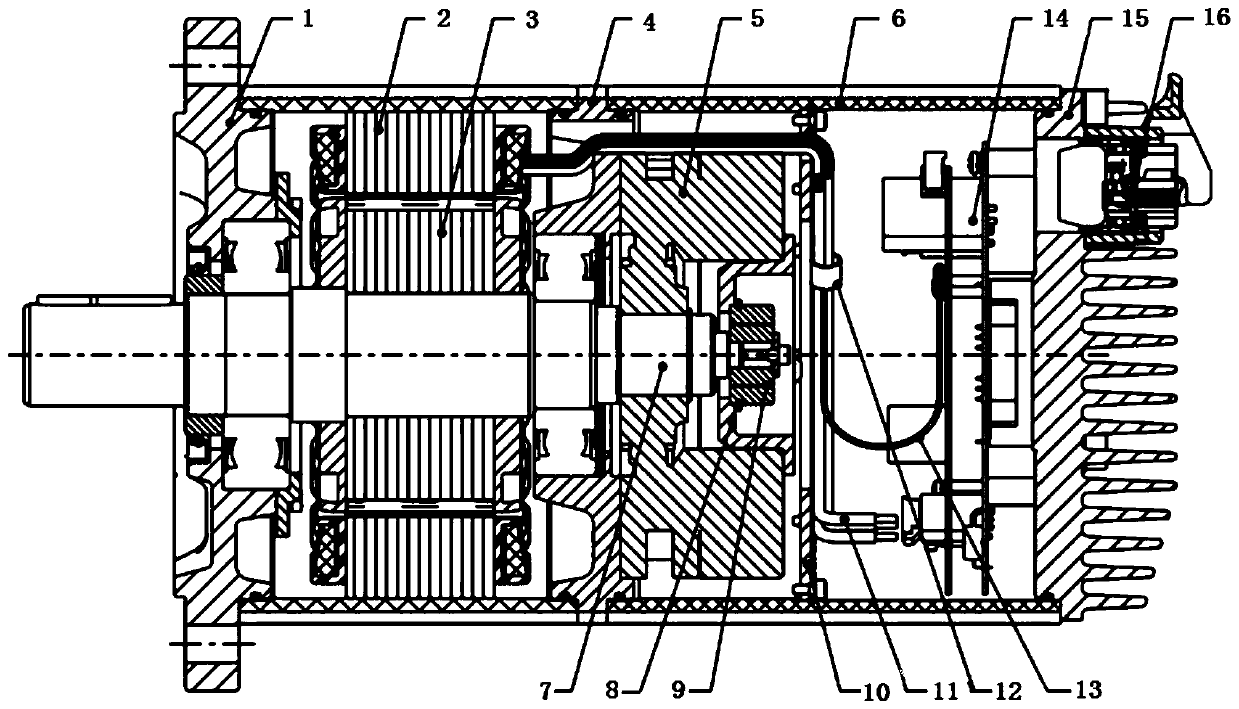

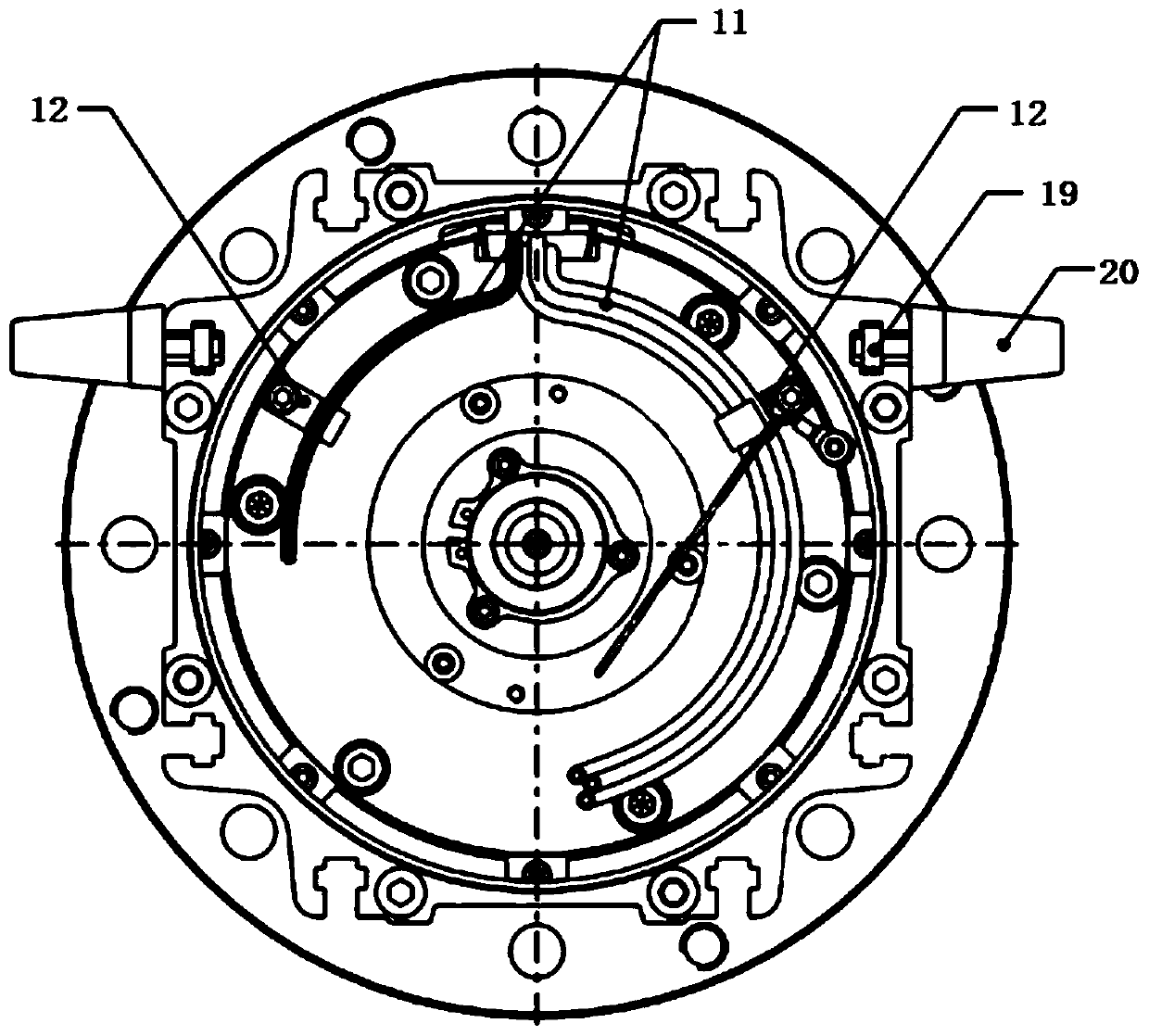

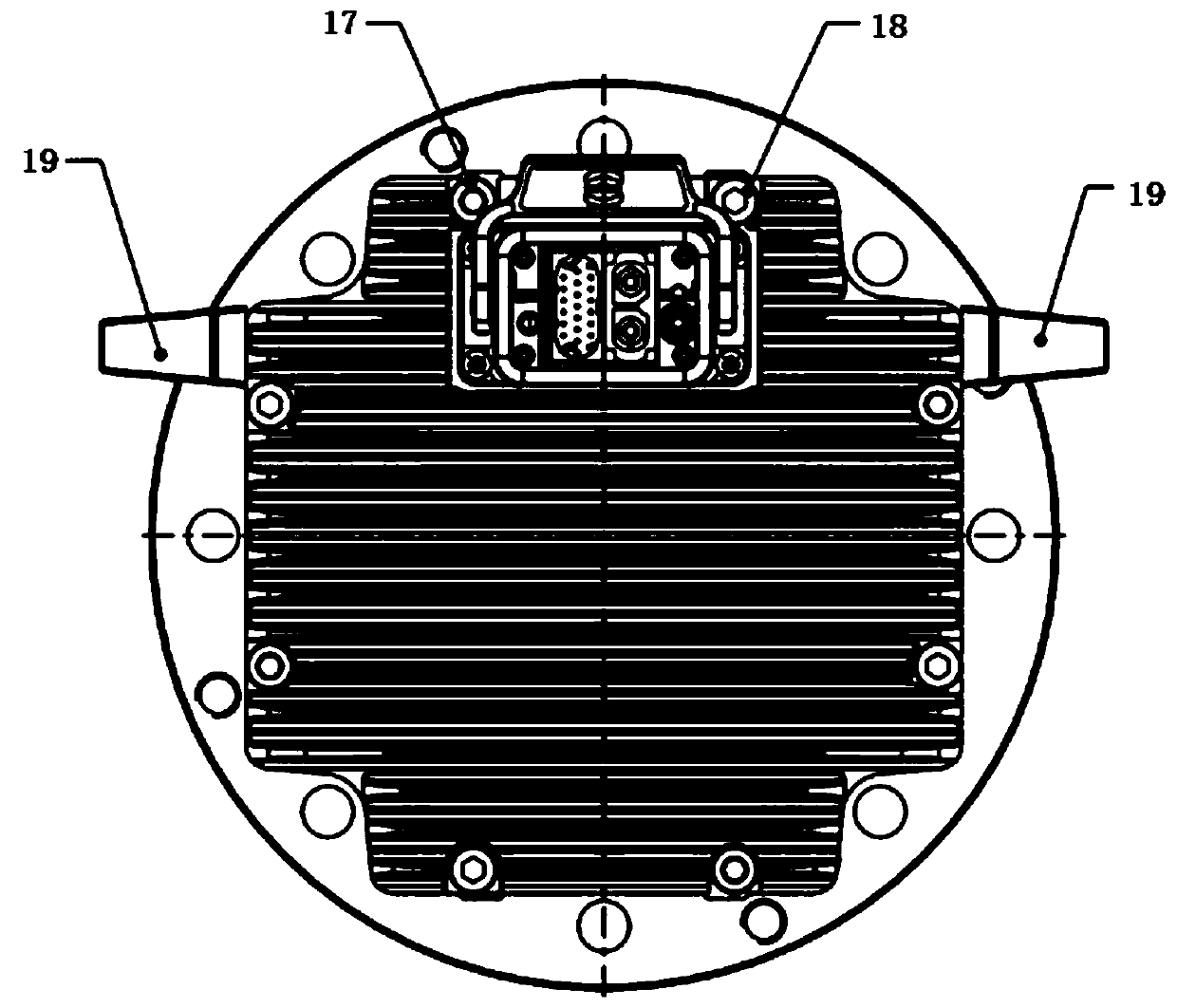

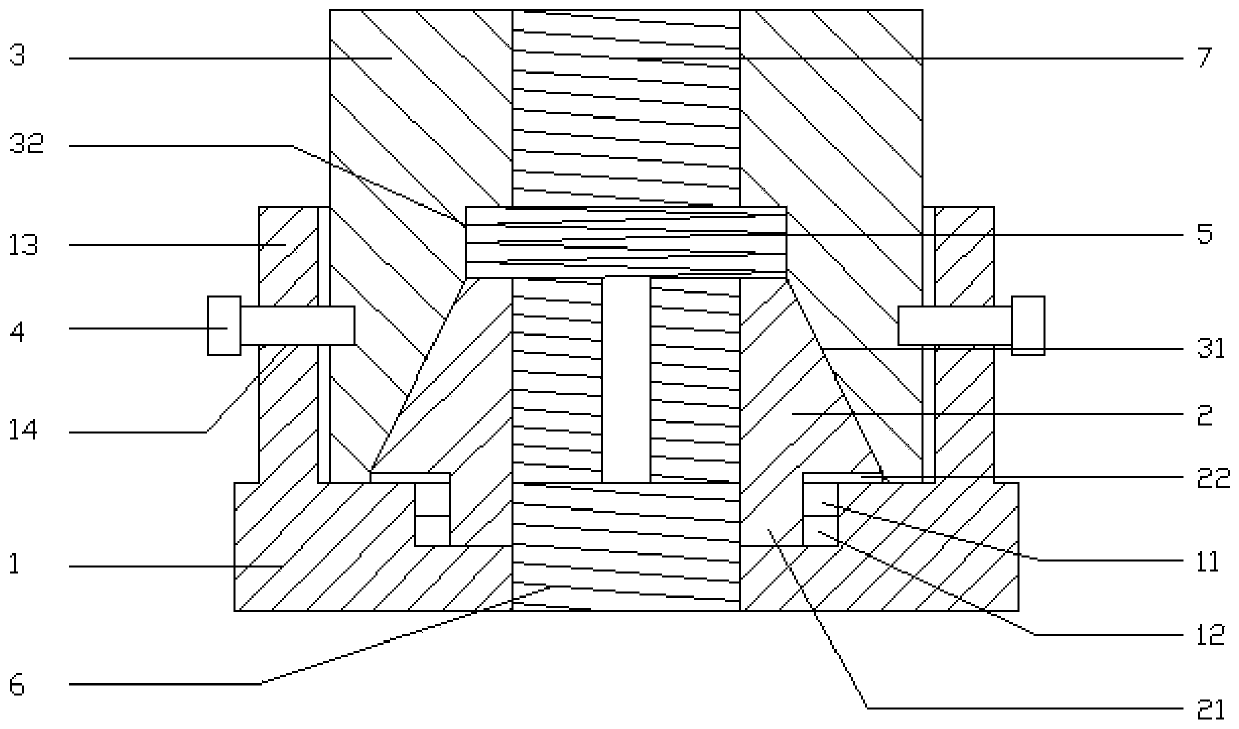

Wind power variable pitch all-in-one machine structure

PendingCN111555542ACompact structureReduce weightManufacturing dynamo-electric machinesMechanical energy handlingBrakeElectric machinery

The invention discloses a wind power variable pitch all-in-one machine structure which comprises a motor body, a brake, a brake cover, an encoder adapter, an encoder, a supporting plate, an outgoing line, an anti-falling steel rope, a driver, a radiator and a connector. The outer ring of the brake is connected to the rear flange of the motor body, and the inner ring of the brake is connected to the rotating shaft of the motor body. The encoder adapter is connected to the outer ring of the brake; the encoder outer ring is connected to the encoder adapter, and the encoder inner ring is connectedto the rotating shaft; the brake cover is connected to the rear flange; the supporting plate is connected to the brake cover; and the driver is connected to the radiator, and the radiator is connected to the brake cover. One end of the anti-falling steel rope is connected to the supporting plate, and the other end is connected to the inner side of the driver. The wind power variable pitch all-in-one machine structure is very compact in structure, and the brake, the encoder and the driver are all installed on the motor body, thereby facilitating the later maintenance. Compared with the prior art, under the condition of the same performance output, the cost is low, and on-site wiring is simple.

Owner:PHASE MOTION CONTROL NINGBO

Combined type locknut component

PendingCN110886762AReduces the possibility of looseningProtect the bottomNutsBoltsEngineeringIndustrial engineering

The invention discloses a combined type locknut component. The combined type locknut component comprises a first nut, an anti-loosing clamping piece, a second nut, an auxiliary fastening bolt and a reset spring; compared with the prior art, the combined type locknut component is simple in structure and reasonable in design, can effectively absorb vibration load, guarantees the stability and reliability of connection of the bolt for a long time, and can also recycle the other components in a way of replacing a damaged component, thus lowering the using cost.

Owner:海盐大宁紧固件股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com