Corrosion-resistant high-strength hexagonal bolt

A hexagonal bolt, high-strength technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of bolt connection brittle fracture failure, loss of corrosion resistance, structural strength decline, etc., to reduce the possibility of reduction, improve corrosion resistance, The effect of increasing the compression force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

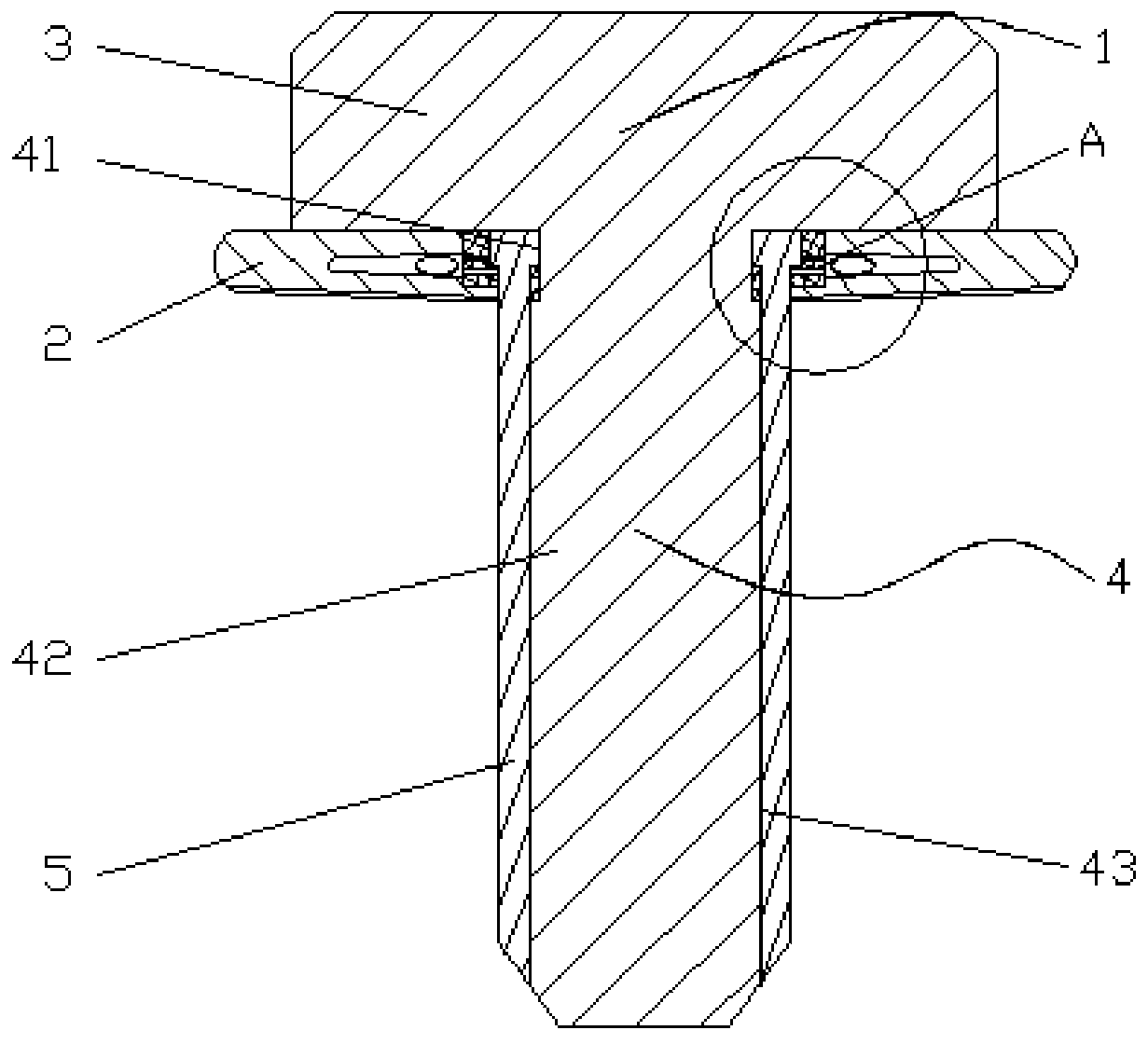

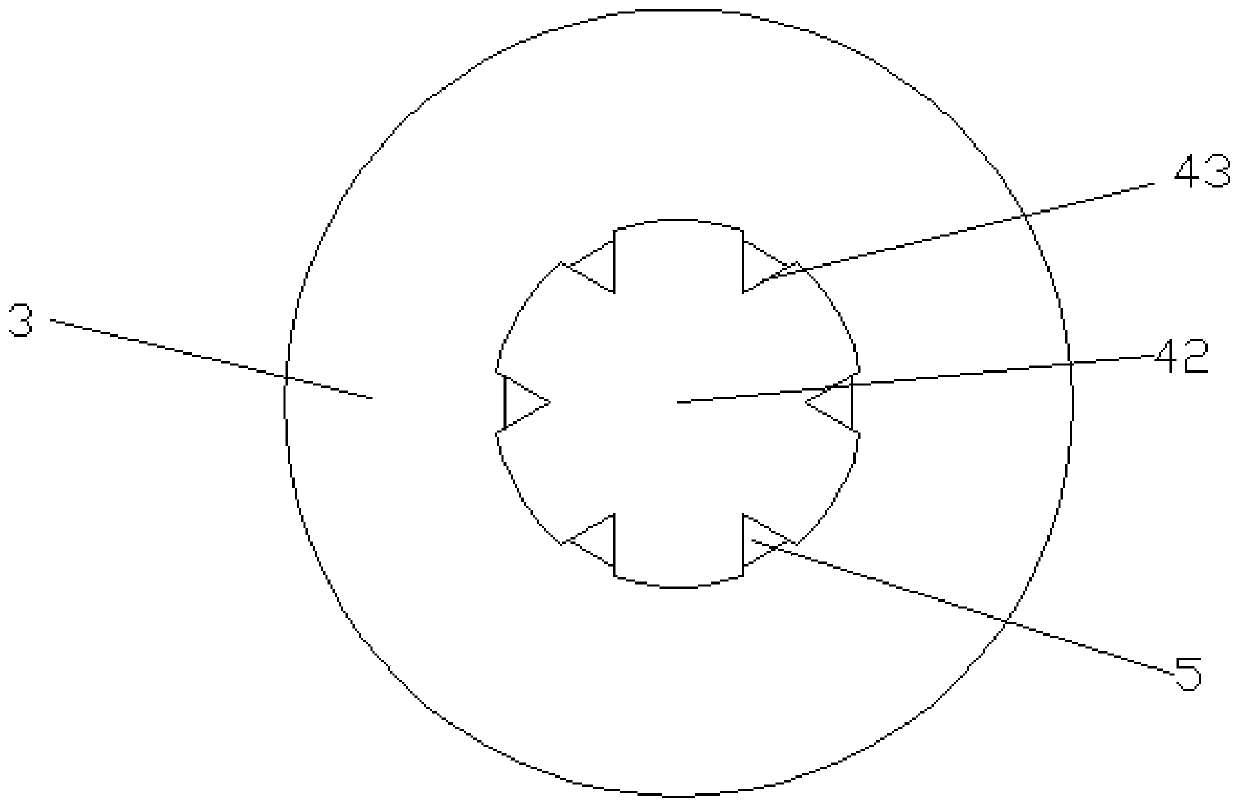

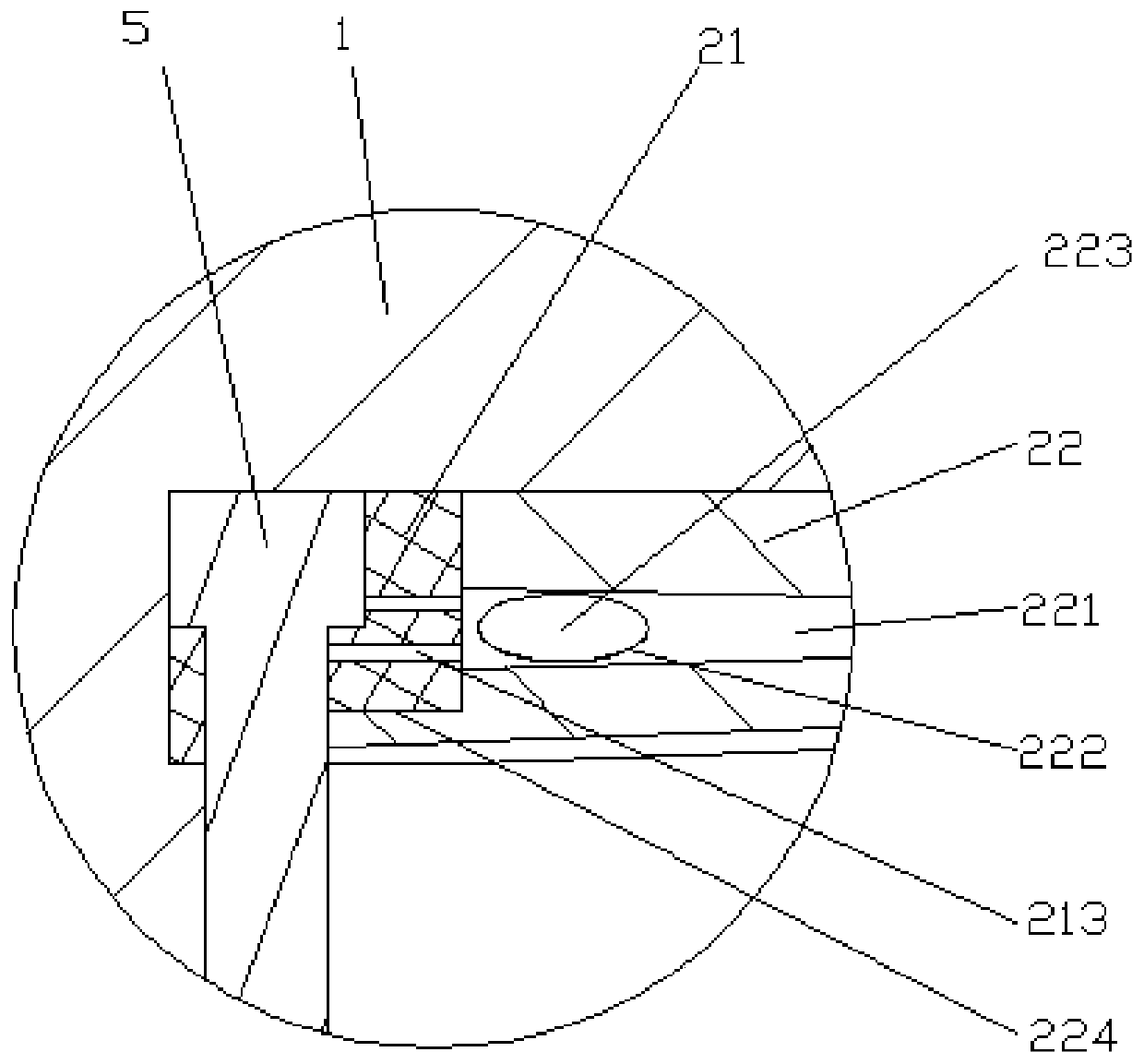

[0020] Referring to the accompanying drawings, a corrosion-resistant high-strength hexagonal bolt of the present invention includes a bolt body 1 and a gasket 2, and the bolt body 1 also includes a screw head 3, a stud 4 and a reinforcing rib 5, and the stud 4 is composed of The shrinkage section 41 close to the bottom of the screw head 3 is composed of a threaded section 42 away from the bottom of the screw head 3. The outer wall of the threaded section 42 is provided with a number of side grooves 43. The gasket 2 also includes an inner elastic washer 21 and The outer anti-loosening washer 22, the inner elastic washer 21 is nested on the shrinkage section 41, the outer anti-loosening washer 22 is connected with the stud 4 through the inner elastic washer 21, the top surface of the inner elastic washer 21 A plurality of first opening grooves 211 are provided, and a through groove 212 is provided at the center of the groove bottom of the first opening groove 211. The reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com