Nozzle connection structure, arc extinguish chamber using the same and breaker using the same

A connection structure and interrupter technology, applied in the direction of circuits, electrical components, electric switches, etc., can solve problems such as difficulty in ensuring the sealing performance of nozzles and moving contacts, nozzle damage, etc., to avoid assembly internal stress, improve reliability, Effect of Compensating Part Tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

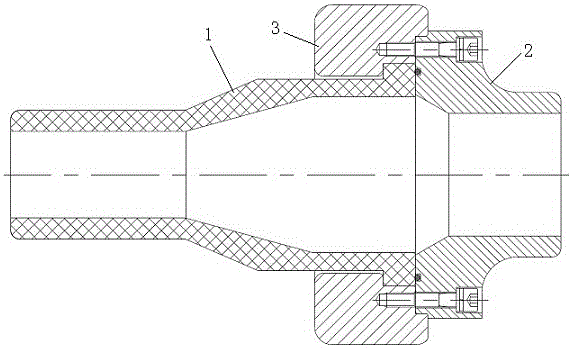

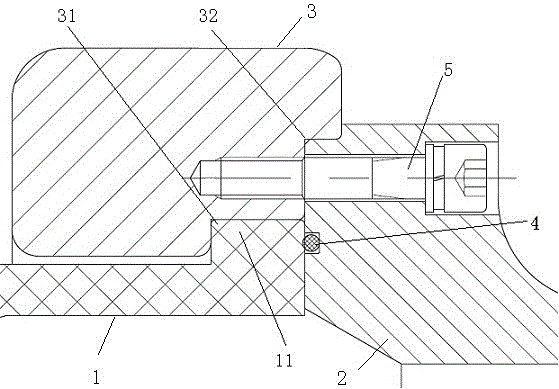

[0021] The specific embodiment of spout connection structure of the present invention, as Figure 1 to Figure 2 As shown, the spout connection structure includes the spout 1 and the movable contact 2 arranged front and back, and the guide ring 3 set on the outside of the spout 1. The guide ring 3 is provided with a stepped hole with a small front and a large rear. There is a convex ring 11 protruding outward, and the convex ring 11 is clamped in the stepped hole by the guide ring 3 and the moving contact 2 . The stepped hole is a three-stage stepped hole, including a small-diameter section, a middle-diameter section 31 and a large-diameter section 32 from front to back. The protruding ring 11 cooperates with the stop of the middle diameter section 31, and the front end surface of the protruding ring 11 stops and cooperates with the step surface between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com