Wind power variable pitch all-in-one machine structure

An integrated machine, wind power technology, applied in the direction of structural connection, manufacturing of motor generators, electrical components, etc., can solve the problems of cumbersome wiring and high cost on site, and achieve the effect of convenient maintenance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

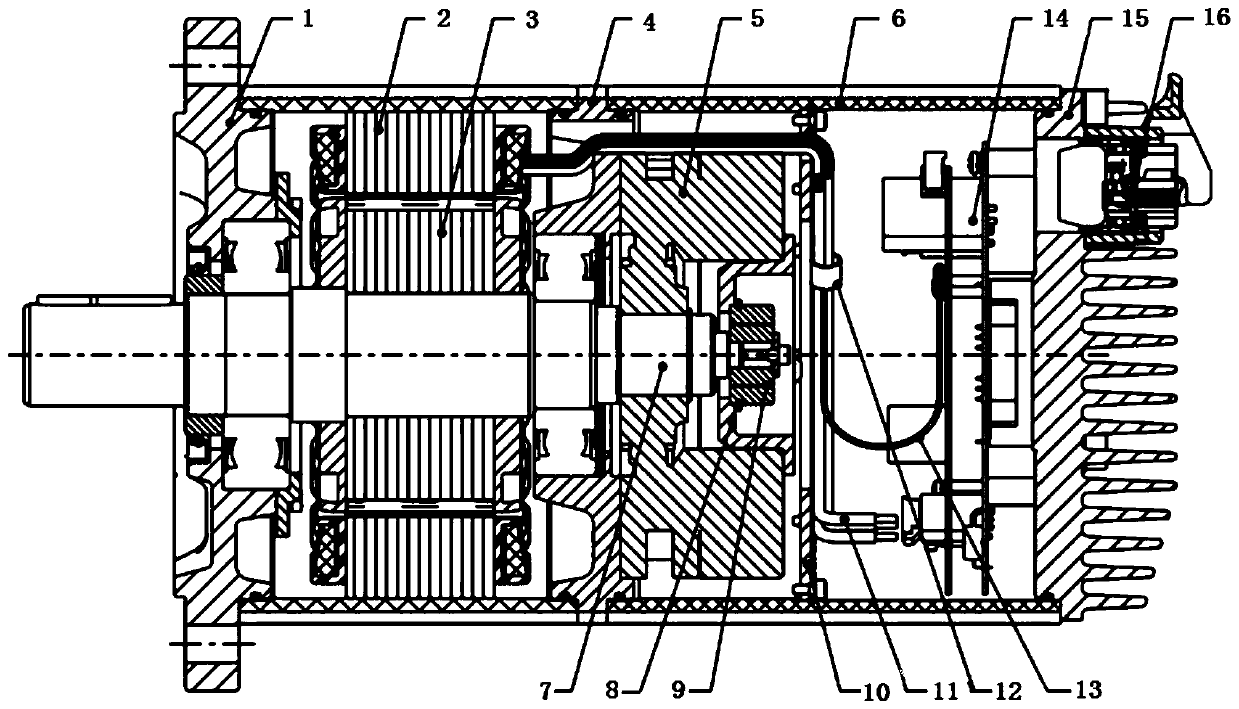

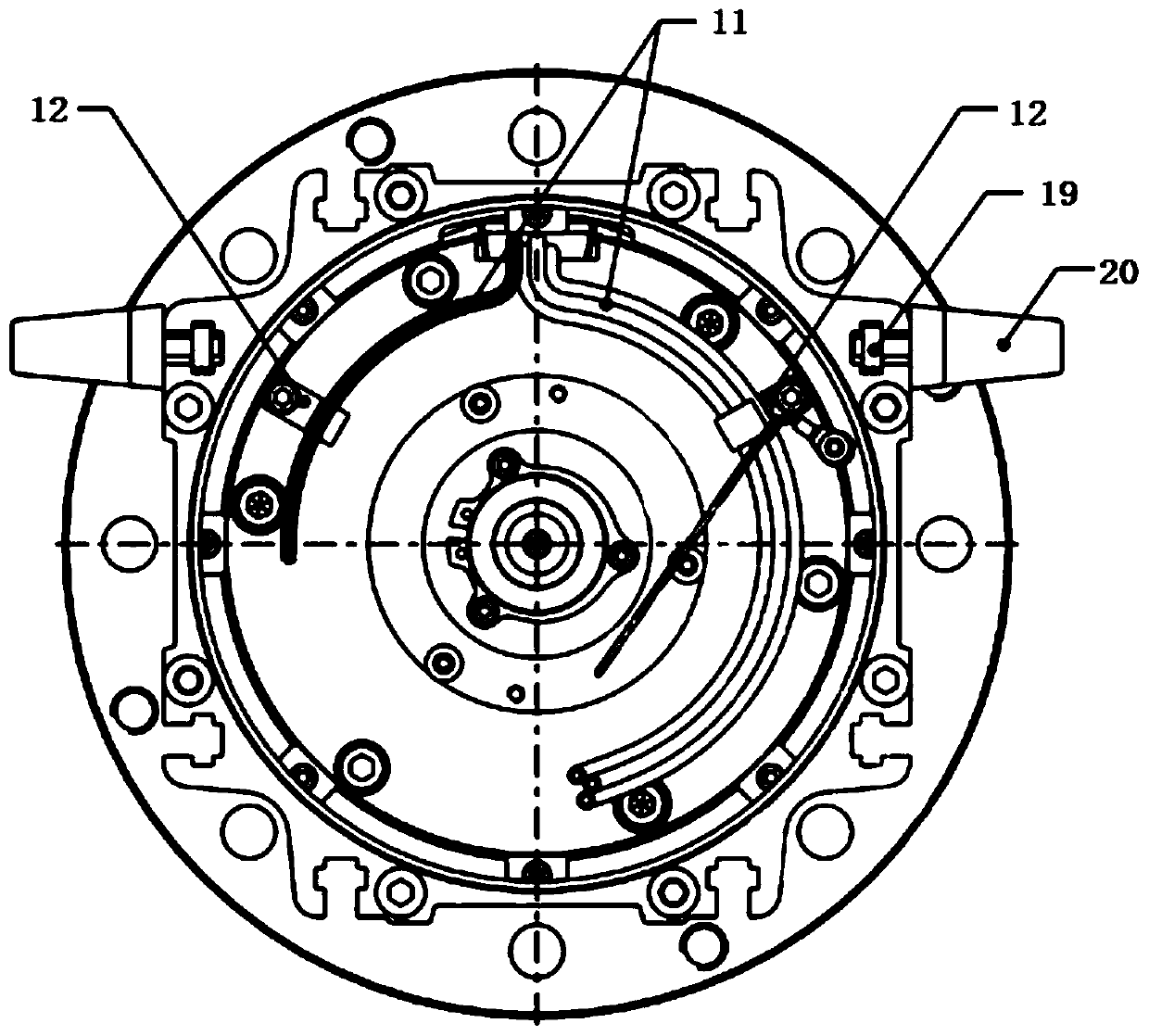

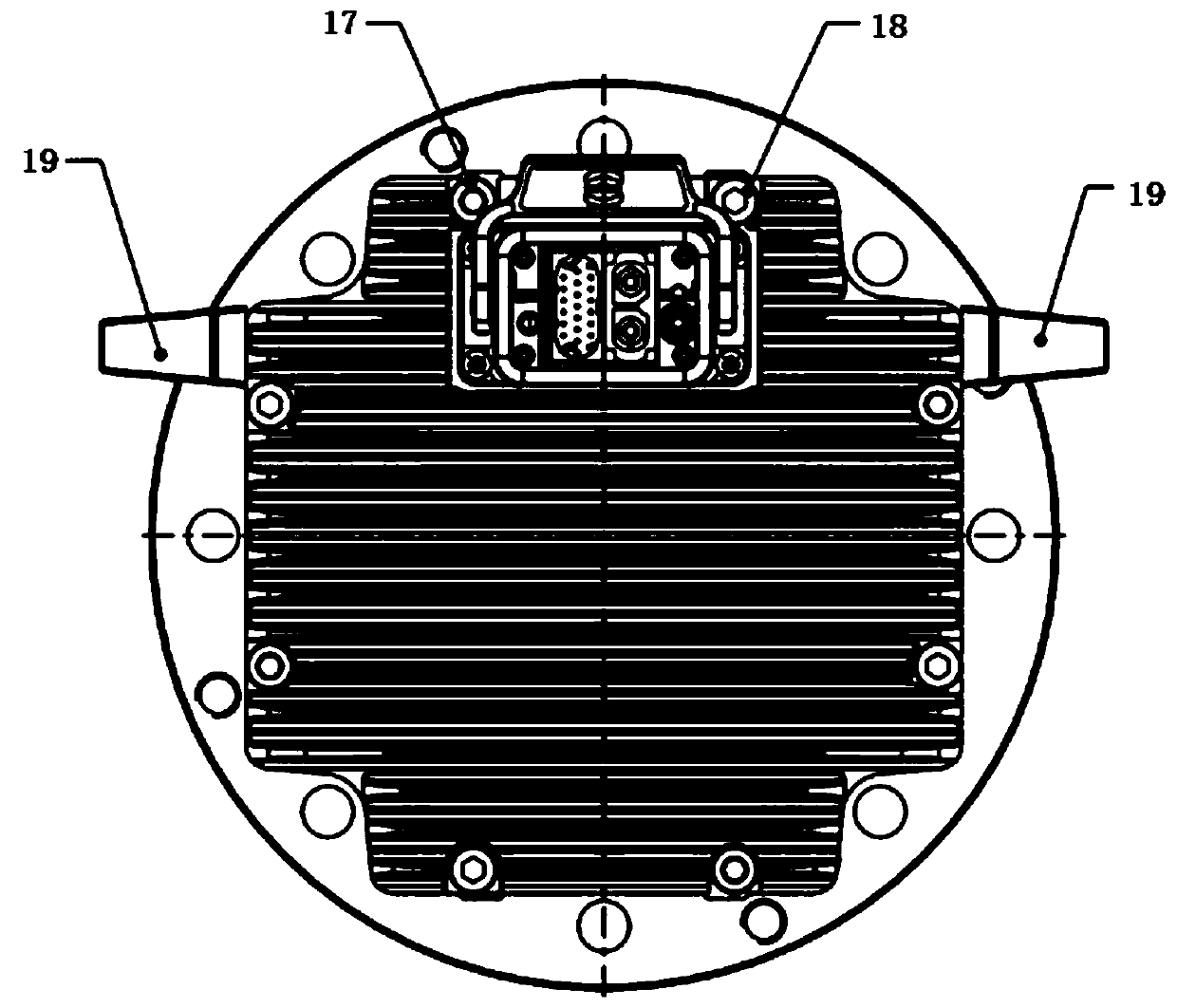

[0028] According to the attached Figure 1-6 The specific implementation manner of this technology is further explained:

[0029] A wind power variable pitch motor and drive integrated machine structure, the structure see Figure 1 to Figure 4 , including front flange 1, stator 2, rotor 3, rear flange 4, brake 5, brake cover 6, shaft 7, encoder adapter 8, encoder 9, support plate 10, motor, brake and encoder leads 11. Cable fixing clamp 12, anti-drop steel rope 13, driver 14, radiator 15, connector 16, long screw rod 17 and anti-loosening screw 18. Among them, the front flange 1, the stator 2, the rotor 3, the rotating shaft 7 and the rear flange 4 form the main part of the motor; the outer ring of the brake 5 is fixed on the rear flange 4 by screws, and the inner ring of the brake 5 is fixed on the rotating shaft 7; The adapter 8 is fixed on the outer ring of the brake 5 by screws; the outer ring of the encoder 9 is fixed on the encoder adapter 8 by screws, and the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com