Combined type locknut component

A combination technology of anti-loosening nuts, applied in the direction of nuts, threaded fasteners, screws, etc., can solve problems such as connection failure, looseness, and potential safety hazards, and achieve the effects of increasing service life, reducing looseness, and increasing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

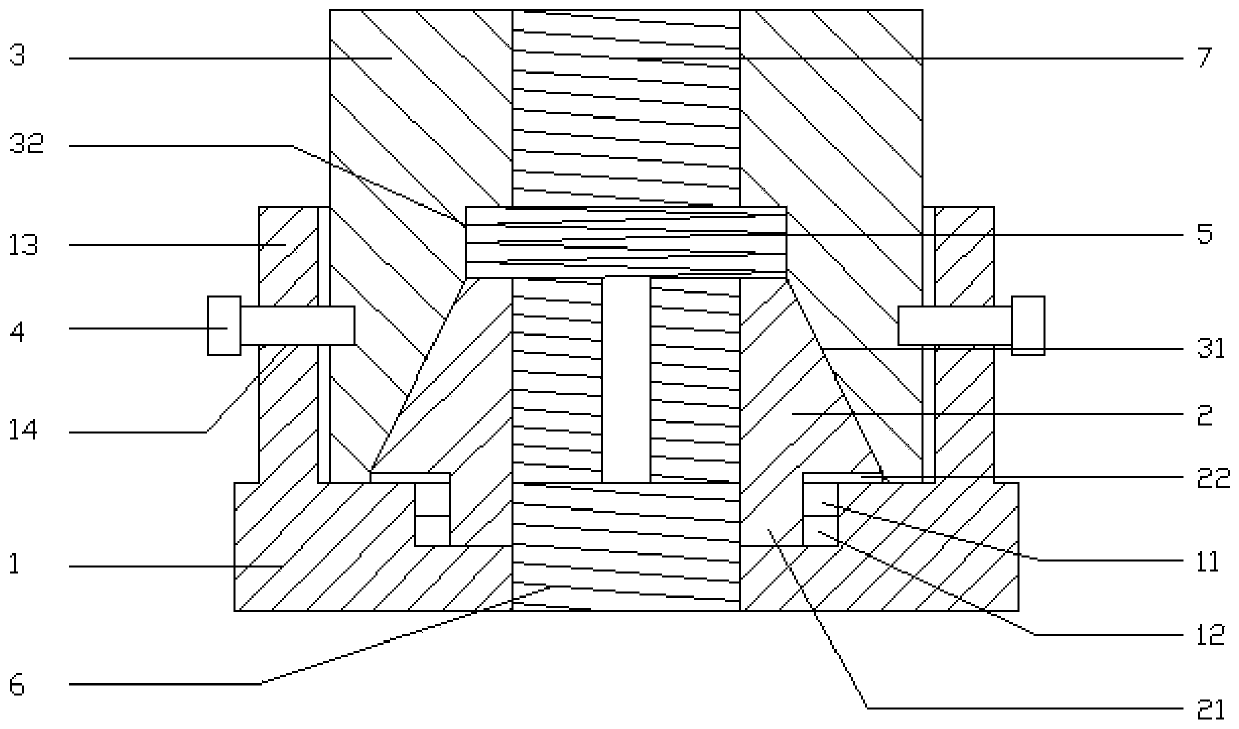

[0014] Referring to the accompanying drawings, a combined anti-loosening nut assembly of the present invention includes a first nut 1, an anti-loosening clip 2, a second nut 3, an auxiliary fastening bolt 4 and a return spring 5, the first nut 1 and the second The center of the two nuts 3 is respectively provided with a first through hole 6 and a second through hole 7, the inside of the first through hole 6 and the second through hole 7 are provided with internal threads, the upper surface of the first nut 1 A group of opening grooves 11 symmetrical to the first through hole 6 are arranged on the top, and a limiting slide groove 12 is arranged below the opening groove 11. The upper half is connected, and the number of the anti-loosening clips 2 is two. The bottom of the anti-loosening clips 2 is provided with a limit protrusion 21, and the limit protrusion 21 is located in the opening groove 11 and the limit chute. 12, the outer side of the anti-loosening clip 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com