Green building unit type curtain wall heat preservation structure

A green building, unitized technology, applied in building components, building structures, buildings, etc., to reduce the occupied space, reduce the possibility of loosening, and hinder heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

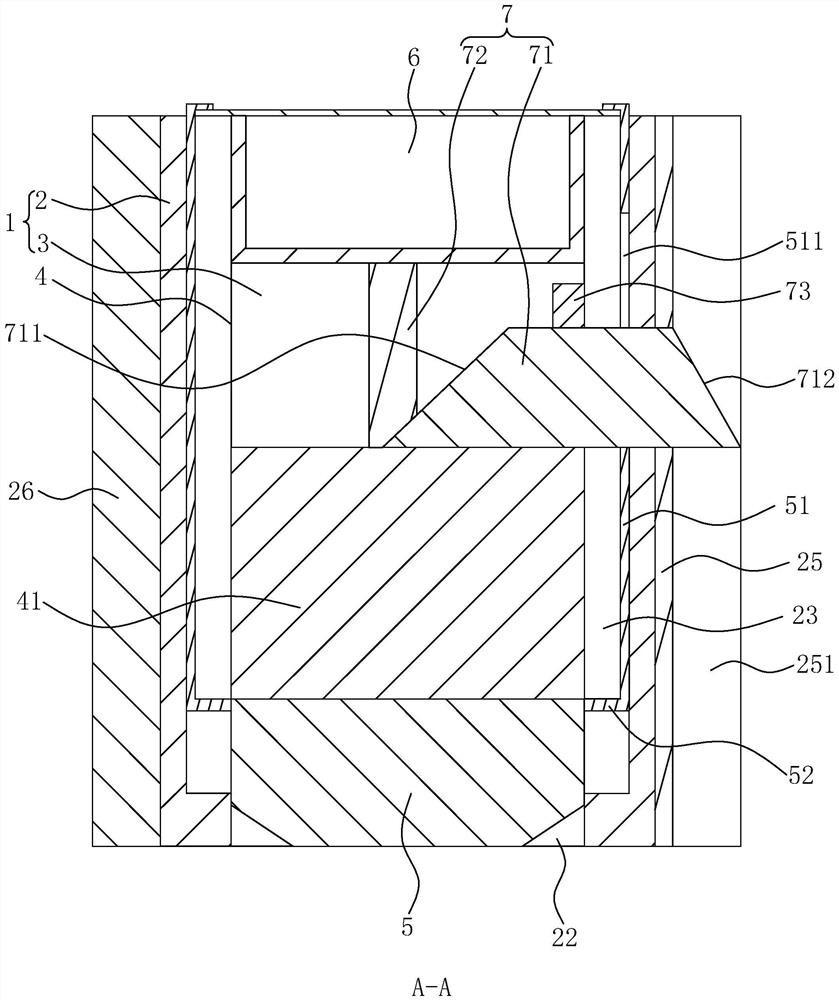

[0036] Before the unit board 1 is installed on the wall, both the plug board 5 and the plug box 6 are shrunk in the positioning frame 2, thereby reducing the occupied space of the unit board 1 and facilitating the storage and transportation of the unit board 1 .

[0037] refer to image 3 , Figure 4 , the two vertical inner walls of the positioning frame 2 are provided with lifting grooves 23 , the lifting grooves 23 penetrate to the top of the positioning frame 2 , and the lifting grooves 23 communicate with the receiving opening 21 . In the lifting groove 23, a lifting rod 51 is vertically slidably arranged, and there is a distance between the lifting rod 51 and the flashboard 5. The bottom end of the lifting rod 51 is fixedly connected with a connecting rod 52, and the connecting rod 52 is fixedly connected to the plugboard 5. The top end of the rod 51 is fixedly connected with a limiting plate 53 .

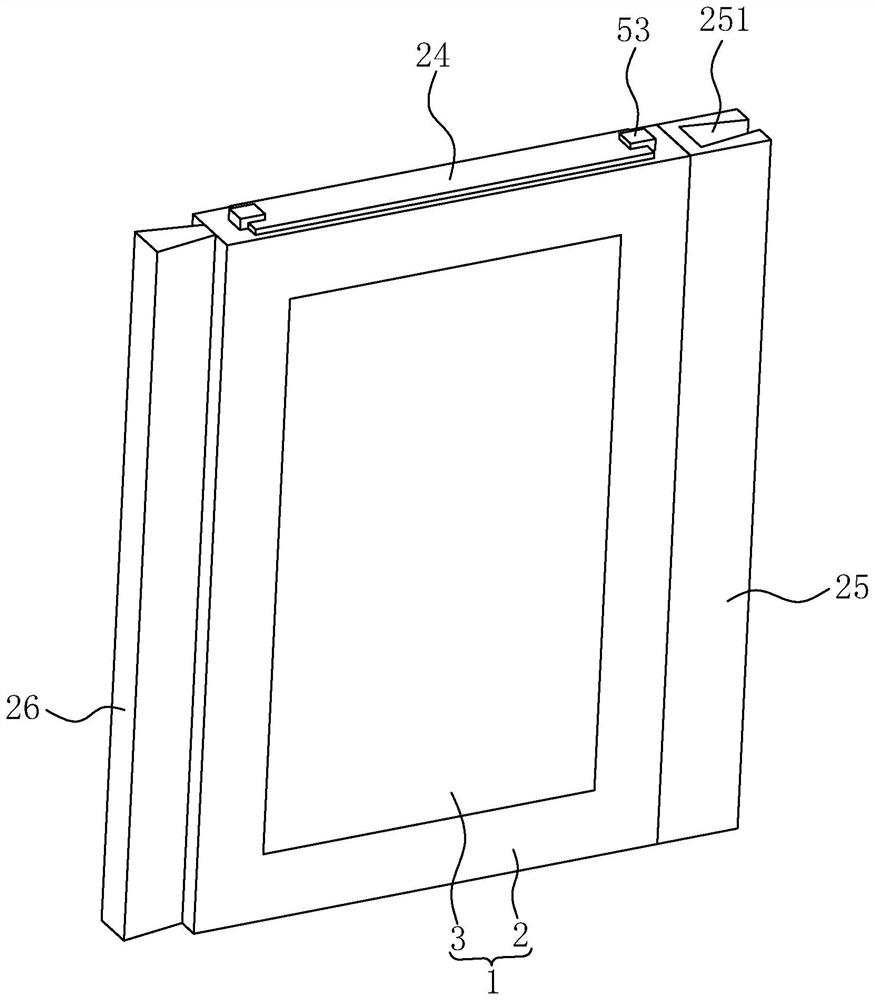

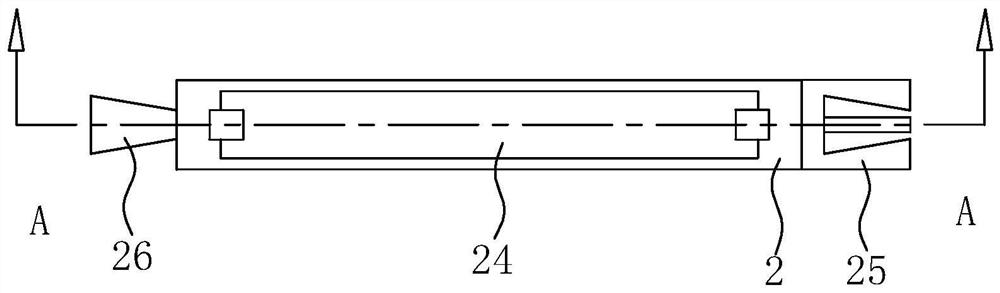

[0038] refer to figure 1 , image 3 , Figure 4 , when transporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com