Anti-loosening nut and gasket assembly

An anti-loosening and assembly technology, applied in nuts, threaded fasteners, screws, etc., can solve the problem of low pre-tightening force, and achieve the effect of increasing the pre-tightening force, reducing the amplitude, and prolonging the anti-loosening life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

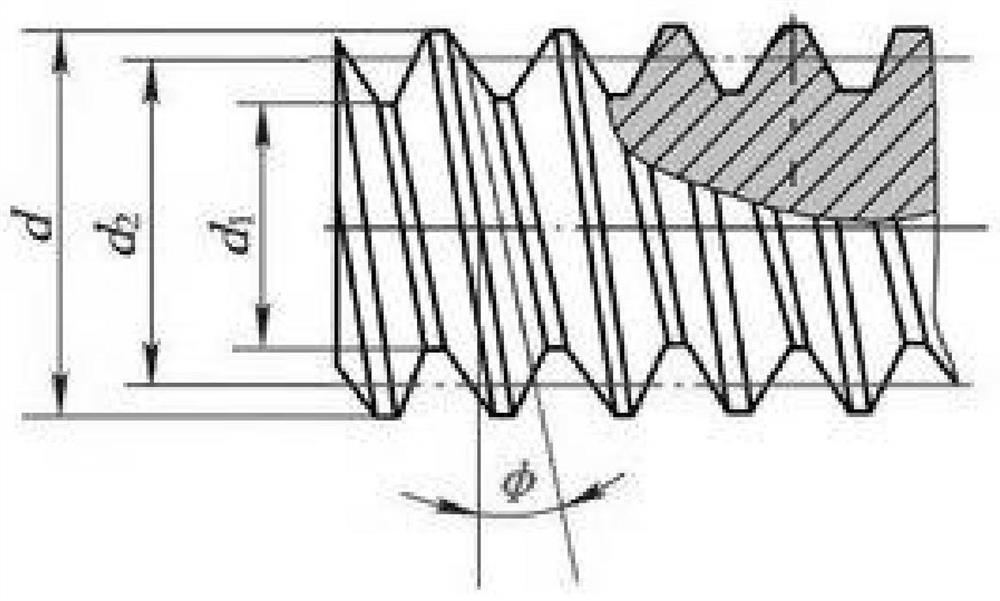

Method used

Image

Examples

Embodiment 1

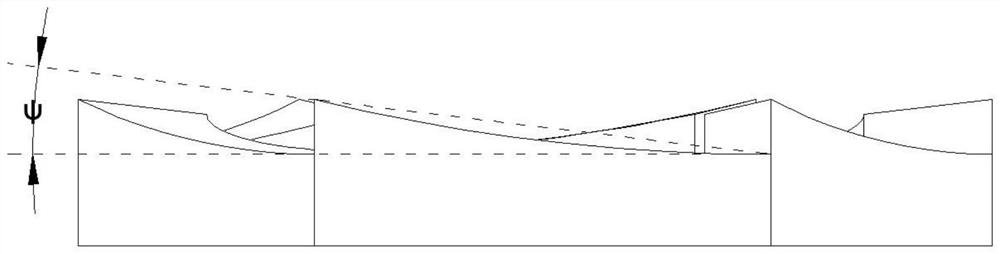

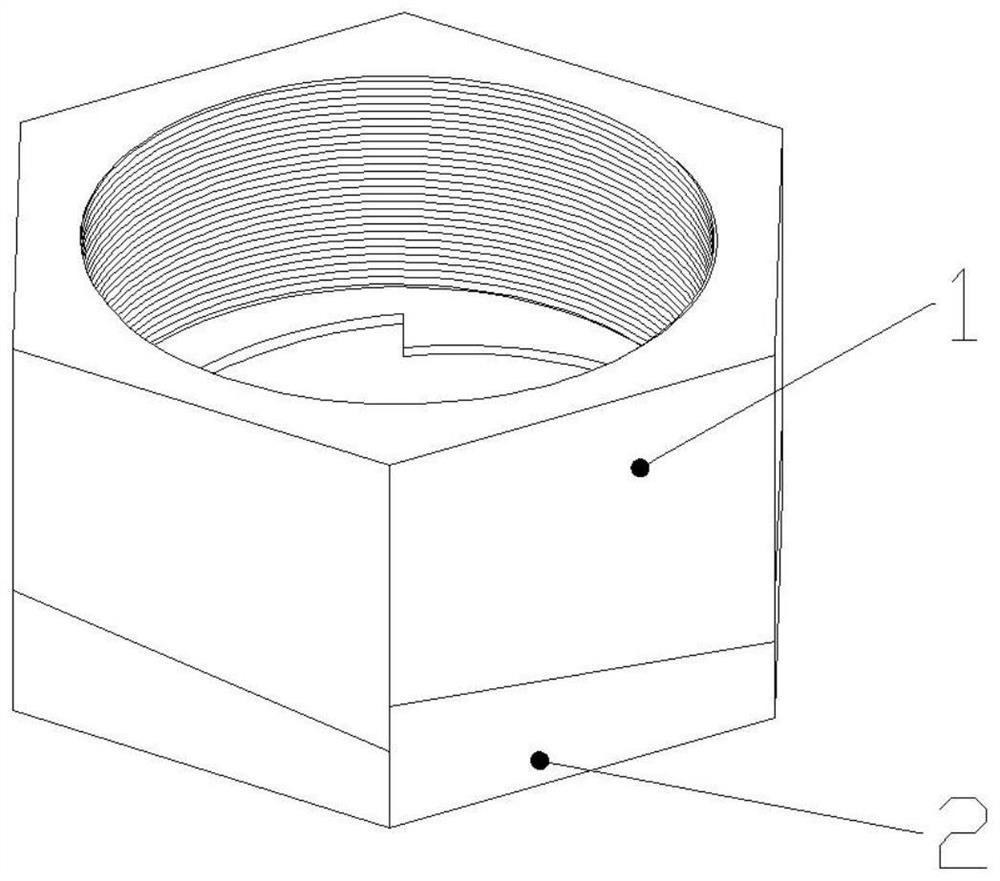

[0039] Please refer to Figure 3-6 , image 3 It is a three-dimensional view of the overall structure of the nut washer assembly in this embodiment, Figure 4 It is a schematic diagram of the relative rotation of the nut washer assembly in this embodiment, Figure 5 It is a perspective view of the nut of the nut washer assembly in this embodiment, Figure 6 is a perspective view of the gasket of the nut washer assembly in this embodiment. An anti-loosening nut washer assembly, including a nut 1 and a washer 2, six wedge-shaped blocks are evenly arranged on the contact surface of the nut 1 and the washer 2, for the convenience of distinction, the wedge-shaped blocks on the nut 1 are called The wedge block A11, the wedge block on the gasket 2 is called the wedge block B21; the lower end surface 111 of the wedge block A of the nut 1, and the upper end surface 211 of the wedge block B of the gasket 2 are arranged oppositely and are all slopes, and the nut 1 and the When the g...

Embodiment 2

[0042] Please refer to Figure 8 , 9 , Figure 8 It is a schematic diagram of the relative rotation of the nut washer assembly in this embodiment, Figure 9 is a perspective view of the gasket of the nut washer assembly in this embodiment. The difference between this embodiment and Embodiment 1 is that in this embodiment, the lower end surface 111 of the wedge-shaped block 11 of the nut 1 and the upper end surface 211 of the wedge-shaped block B21 of the gasket 2 are both curved surfaces; the gasket 2 faces the object to be fastened 4 One side of the surface is provided with anti-skid teeth.

Embodiment 3

[0044] Please refer to Figure 10 , Figure 10 is a perspective view of the gasket of the nut washer assembly in this embodiment. The difference between this embodiment and Embodiment 2 is that the side of the gasket 2 facing the surface of the fastened object 4 is provided with anti-slip teeth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com