Nut rotation type ball screw pair with anti-loosening device

A ball screw pair, nut rotation technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of falling off, low reliability, loose locking device, etc., to reduce the possibility of looseness performance, improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

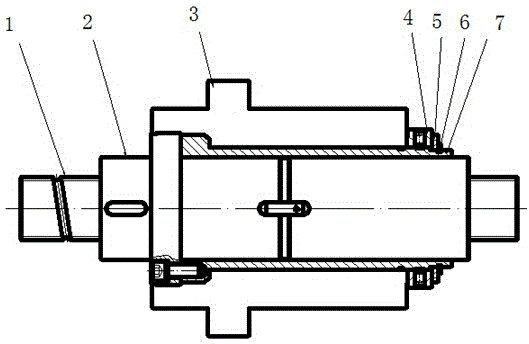

[0011] A nut rotating ball screw pair with an anti-loosening device, comprising a ball screw 1, a ball nut pair 2, a housing 3 containing rolling bearings and a nut sleeve 7, the ball nut pair and the nut sleeve are set on the ball screw and Connect with the shell. A lock nut 4 is arranged outside the nut sleeve, and an inner end of the lock nut is connected to the end of the housing, and a stop washer 5 and a circlip 6 are arranged at the other end of the lock nut. The lock nut, the stop washer and the elastic circlip are all sleeved on the nut sleeve. The elastic circlip is arranged on the outside of the stop washer.

[0012] When working, the ball screw is fixed in place. The power source drives the ball nut pair to rotate and move linearly along the raceway. The nut sleeve is installed on the ball nut pair, and the ball nut pair is regarded as one, and the housing (including the rolling bearing) is installed outside it. The housing is driven by the ball nut pair to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com