An underwater dedusting and grinding machine

A technology of a leather machine and a rotating motor, which is applied in the field of underwater dust removal and leather grinding machine, can solve the problems of adhesion of dander, difficult to remove, and poor cleaning effect of abrasive debris, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

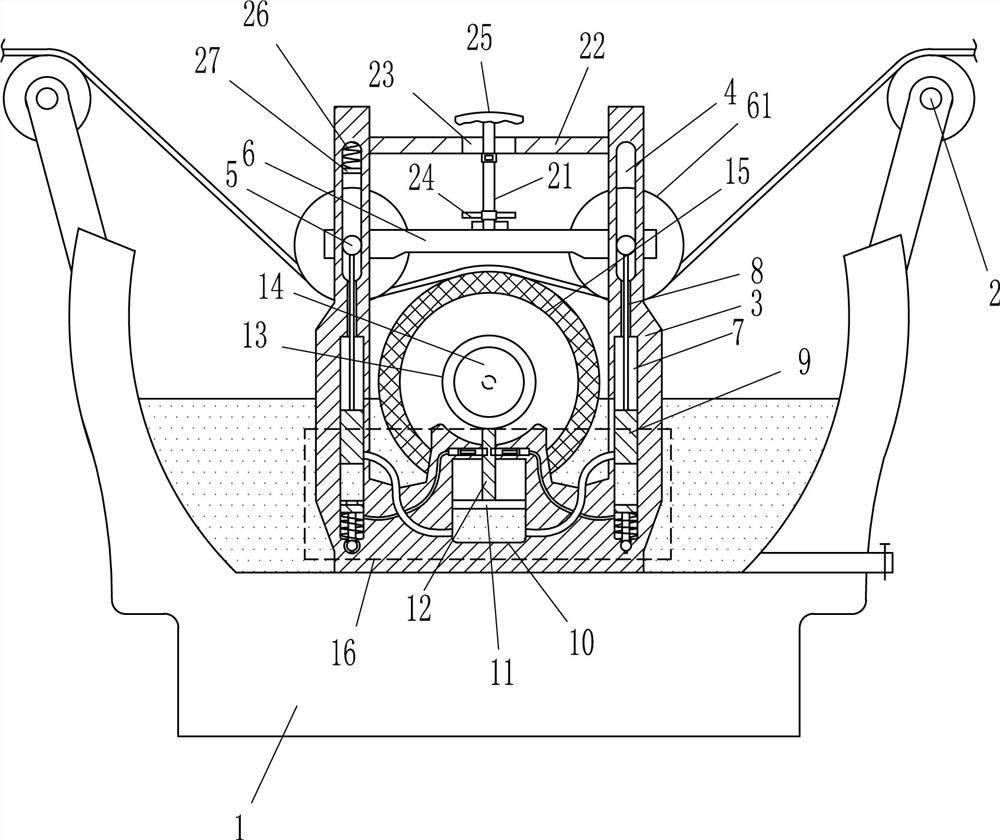

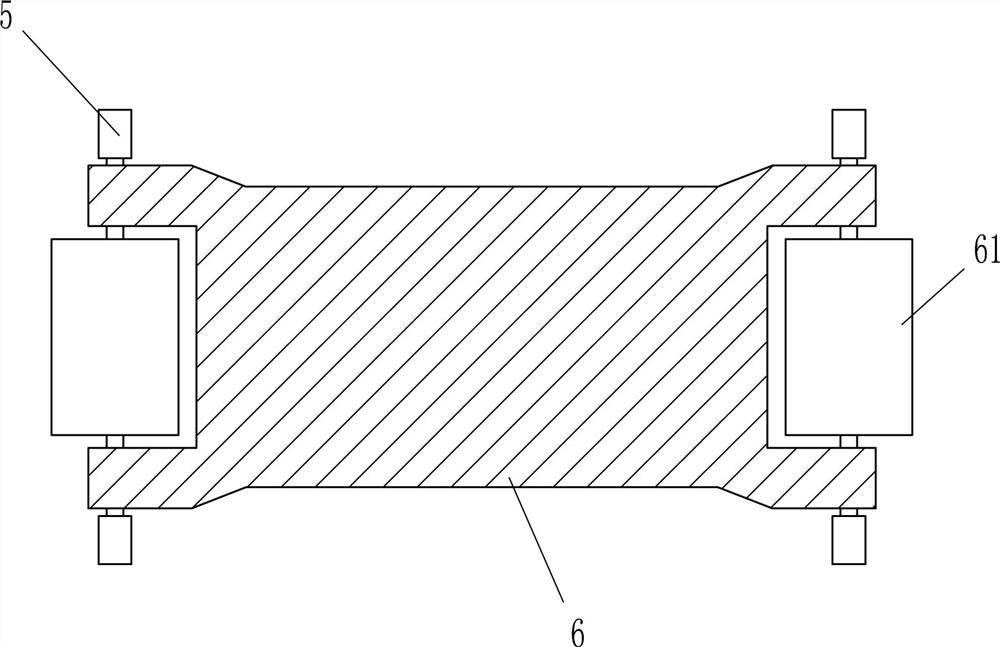

Embodiment 1

[0017] like Figure 1-3 As shown, an underwater dust-removing and leather grinding machine includes a liquid storage table 1, a guide roller 2, a mounting frame 3, a sliding shaft 5, a mounting plate 6, a pressing roller 61, a first cylinder 7, a connecting rod 8, a first A piston 9, a communication pipe 91, a second cylinder 10, a second piston 11, a bracket 12, a mounting seat 13, a rotating motor 14, a leather grinding wheel 15 and a clamping device 16, the liquid storage table 1 is symmetrically provided with left and right The guide roller 2 and the liquid storage table 1 are symmetrically provided with mounting brackets 3 in the front and rear through bolt connection. The mounting brackets 3 are all provided with sliding grooves 4, and sliding shafts 5 are movably arranged in the sliding grooves 4, and between the sliding shafts 5 A mounting plate 6 is provided, a pressure roller 61 is arranged symmetrically on the mounting plate 6, a first cylinder 7 is arranged symmetr...

Embodiment 2

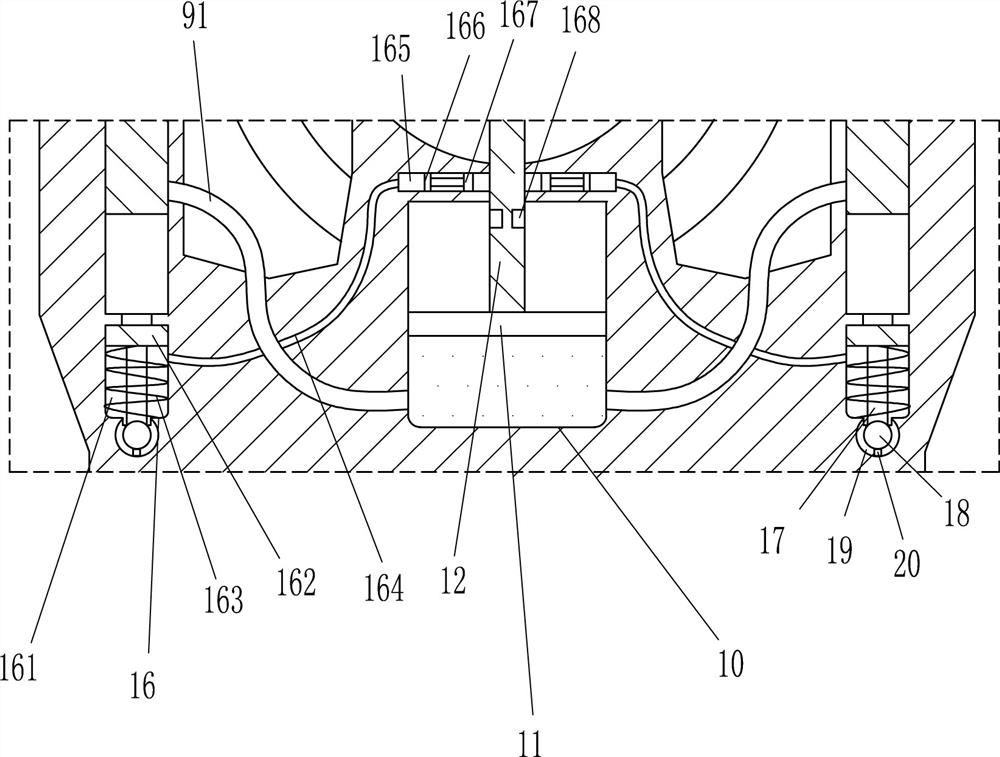

[0021] like figure 1 and image 3 As shown, on the basis of Embodiment 1, it also includes a moving rod 17, a clamping ball 18, an elastic ball groove 19 and a button 20, the bottom of the third piston 162 is provided with a moving rod 17 by means of screw connection, and the bottom of the moving rod 17 is provided with a moving rod 17. The clamping ball 18 is welded, the bottom of the third cylinder 161 is provided with an elastic ball groove 19, the clamping ball 18 is matched with the elastic ball groove 19, and the lower part of the elastic ball groove 19 is provided with a button 20, and the button 20 is connected to the rotating motor 14 through a line.

[0022] When the third piston 162 moves downward, the first elastic member 163 is compressed, the third piston 162 drives the moving rod 17 to drive the clamping ball 18 to move downward, and the clamping ball 18 is clamped into the elastic ball groove 19 to play a fixing role , the clamping ball 18 squeezes the button ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com